Wood-fired sauna stoves: pros and cons

Wood-fired sauna stoves have both pros and cons. In order to fully appreciate both those and others, you need to understand the types and design of ovens.

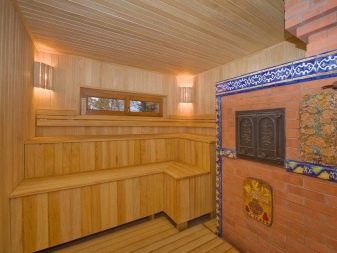

Peculiarities

From the time of Ancient Russia to the Soviet period, wood-fired sauna stoves were made only of bricks. The work of laying out the stoves was difficult and costly, but there were no other alternatives. Now, along with brick structures, metal stoves are used. Today, both options are used with approximately the same frequency, only there is one problem. There are practically no services on the market for high-quality laying out of brick ovens. There are few specialists in this industry.

Another thing is a metal stove. It comes ready-made and can be installed even by a self-taught master without much experience. These stoves are made from various metals and are usually complemented by a water tank that can be placed in different places in relation to the stove body. Metal construction is used not only for baths, but also for steam rooms and Finnish saunas. The only difference is in the type of stove, more precisely, in what type of steam it will supply.

Modern furnace models open up a wide range of possibilities. Now it is possible not only to regulate the temperature of the water in the tank, but also the temperature in the room. You can also buy a stove in a wide price range by contacting a specialized store for help or by choosing a suitable option via the Internet. Each of the options has its own pros and cons.

By purchasing a stove in a store, it is possible to evaluate and touch the product, visually see its dimensions, evaluate the model for possible defects. On the other hand, you have to overpay, since the price of the product includes the cost of renting premises, electricity, employee salaries, etc.

Buying via the Internet is more risky, since there is no way to personally evaluate the goods, but at the same time, you will not have to overpay. The company saves a lot on renting a store and avoiding other expenses. All you need is to rent a warehouse and create a website.

There is an alternative way. You can evaluate the selected model in the store, and then order it via the Internet from a trusted supplier. This way you will save money without giving up the opportunity to assess on the spot whether a given stove is right for you or not.

A feature is the fact that you need to choose the stove installer very carefully. The design is not cheap, and it is important to take a responsible approach to this issue: study the available information about the specialist, see photos of his work, read reviews. Only if you are convinced that the chosen master is a real professional in his field, you can trust him with the installation. After all, an incorrect installation can lead not only to a loss of operational properties, but also to something worse: for example, the fact that carbon dioxide will not come out, and people in the bath will simply burn out.

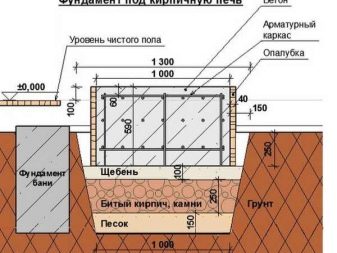

Another important nuance is the large weight of the ovens. As a rule, they weigh from 160 kg, so it will be necessary to additionally strengthen the foundation under the bath. Ideally, if the foundation was carried out carefully and without excessive savings the first time. If the foundation is not strong enough, then the whole structure will sag.As a result, the stove will collapse, regardless of whether it was made of brick or metal.

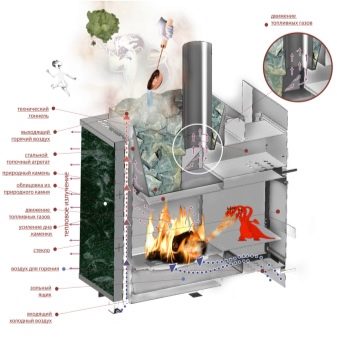

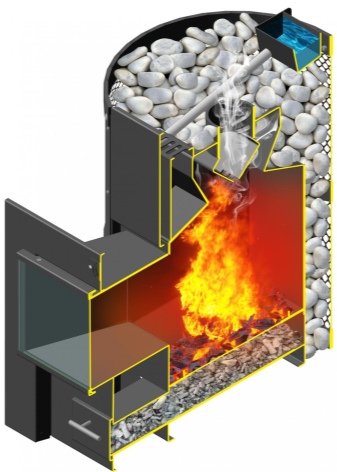

All wood-burning stoves are filled with stones, which, when heated, give the necessary heat.

It is important to strengthen the foundation so that it can support the weight of the entire structure, including the stones.

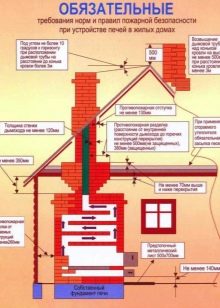

A typical feature is that wood-burning stoves are subject to increased safety requirements, especially if the stove is not equipped with a remote firebox. It is imperative to ensure that oxygen does not burn out and that people are not harmed instead of benefit. In addition, when the stove is located directly inside the steam room, there is always the possibility that the wooden steam room will catch fire.

When choosing a wood-burning stove, many do not realize that they are unwittingly paying attention to a wood-burning boiler. To prevent this from happening, you need to figure out what exactly the differences are.

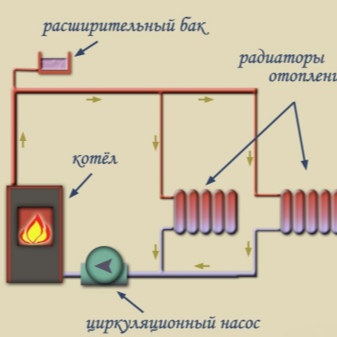

Difference from the boiler

Many people mistakenly confuse a wood-burning boiler and a stove, but this should not be done, since the differences between them are quite significant. Having bought a boiler by mistake, a person may be faced with the fact that the bath will not be heated correctly to the temperature he needs, and all the costs and efforts to correct this will be in vain. The only way out is to dismantle the boiler and install a furnace, which will need to be bought, and this is an additional expense.

The oven is a heat source. She heats everything around. Even when you are near her, you will feel warmth. The stove is capable of heating both the steam room and the dressing room. It effectively generates heat to the outside, rather than trapping it from the inside.

The boiler works a little differently. All the heat is concentrated inside him, so nothing will be felt next to him. The heat is subsequently distributed (usually around the house) through a pipe system. If you put such a boiler in a bath, then there will be no sense in it. You will need to heat the boiler to incredible temperatures in order to have at least a small return. As a result, you will get a small return at a very high cost.

Choosing a truly suitable oven is currently not so difficult. There is a huge assortment of various models on the market, equipped with all sorts of additional functions and parameters. However, it is the diversity that complicates the problem of choice. All other things being equal, it is rather difficult to choose a single option.

Here you need to pay attention to criteria such as appearance, material, type of furnace furnace and others.

Advantages and disadvantages

As mentioned above, you can install the stove either of brick or metal. Both options have their own advantages and disadvantages.

You should start a conversation with brick ovens., since they are the more traditional ones.

The advantages of this type of model include the following aspects.

- The type of heat that such a stove emits. It is soft, not dry and scalding, but as comfortable as possible for a person. The temperature can vary over a wide range.

- Temperature preservation time. Such ovens take a long time to warm up, but also do not cool down for a long time. For example, the standard heating time for a sauna with a wood-burning stove is ten hours, but during the same period the steam room does not cool down.

- The atmosphere being created. In a bathhouse with a brick oven, a favorable microclimate is created that does not negatively affect the well-being of people. These are those cases when the oven is installed correctly.

- Easy operation. It is easy to heat such a stove, as well as to carry out maintenance measures. As a rule, the fuel burns out completely here, so all that remains is to clean out the ash.

- Durability. With proper care, brick stove structures can last forever, so it is important to comply with all requirements during installation, follow all instructions.

Brick models also have disadvantages.

- First of all, we are talking about the heaviness of the structure.A brick wood stove weighs an average of 300 kg. This imposes certain restrictions on where it can be mounted. The base must be strong and stable.

- You will also need to pay attention to strengthening the walls. If the bathhouse is built of wood, the walls around the stove must be additionally protected with metal sheets, since the wood may not withstand the heat and catch fire.

- Even a small brick structure takes up a lot of space, since brick walls are thick when compared to metal ones. It will be problematic to build a truly functional stove in small baths.

- The brick model needs to be restored from time to time: check for cracks, renew the inter-joint mortar, and the like.

- For the construction of wood-burning brick stoves, fireclay refractory bricks are used, and they are quite expensive. So, the construction of a brick stove will cost more than buying a finished metal one.

Metal stoves are more popular. They are distinguished by a number of advantages compared to brick ones.

- Democratic cost. Buying and installing a metal stove is much cheaper than arranging a brick analogue.

- No need to reinforce the floor. The only thing that is necessary is to make sure that the foundation is non-combustible, fireproof. The weight of the loaded stove structure (meaning that firewood is already loaded into it, and the tank, if any, is filled with water) rarely exceeds 200 kg. The floor under the oven weighing less than 200 kg will not necessarily be reinforced, just a solid foundation will be enough. If the weight of the stove is not much higher, then it is best to strengthen the floors with logs and flooring from a thick and durable board (oak is good). However, keep in mind that a wood-burning metal sauna stove for domestic use usually weighs 150-160 kg. More massive options are purchased for professional commercial use.

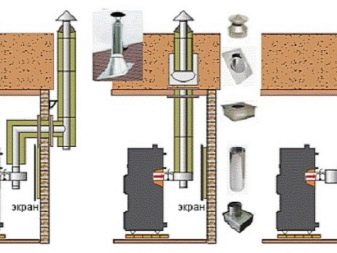

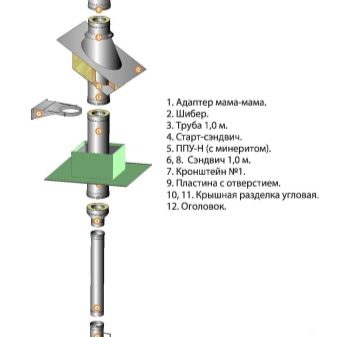

- Elective chimney. There are several options for how to make a chimney for metal stoves. The first option is a classic pipe that brings smoke out through the ceiling. The second is through the wall. The third is a chimney made of sandwich pipes, which is easier than others in construction and, moreover, is several times cheaper.

- Rapid set of temperature. Unlike a brick oven, a metal stove does not need to be heated for 8-10 hours to achieve the required temperature. To obtain a high degree of air heating, it will take no more than an hour.

- Small size. The metal structure is many times smaller than the brick one, so it can be installed even in the most compact bath buildings.

- Ease of installation. Installation and connection of a metal stove will not cause any particular difficulties. Even a beginner can do it

In addition to the above advantages, metal models also have disadvantages.

- It is necessary to pay increased attention to fire safety requirements. The metal body heats up more than the brick body, which increases the risk of fire.

- It is for this reason that it is necessary to shield walls, especially those made of wood. For these purposes, it is best to use sheet refractory material (PVTN), but metal panels are also suitable.

- Particular attention should be paid to the arrangement of the chimney. It must be displayed correctly, and everything must be rechecked several times. Otherwise, the smoke that goes to the bathhouse instead of the street will fill the room and people will burn out.

Views

First of all, all wood-burning stoves are divided into two categories: closed and open. Furnaces from each category differ in a number of characteristics.

The closed-type oven differs in that the stones are covered with a special lid. This favors the fact that the stones do not cool down for a long time, and the temperature lasts longer. The steam that forms here is moist and soft regardless of the temperature.

Despite the fact that something similar has been built in Russian baths for a long time, the closed-type heater is recognized as a novelty.

The open stove does not have a stone door, which is why it has a number of features. So, if it takes a long time to warm up a closed-type model, then an open-type structure heats up very quickly. The temperature in the bath will be an order of magnitude higher (up to 90-100 degrees), while the closed-type stove heats the air only up to 40-60 degrees. The humidity in the room is minimal, so such wood stoves are more relevant for saunas than for baths.

Wood-burning sauna stoves are classified according to the position of the firebox, which can be built-in or remote.

The first option is discouraged, as it is unhealthy, although it helps to save space. In this case, the firebox is located inside the steam room, and firewood, if necessary, is thrown right there. Such an arrangement is dangerous because the oxygen in the room is burned out, and people can feel weak, dizzy and even choked. Please note that a high-quality ventilation system is not a logical solution, but a useless waste of money, since the temperature in the ventilated room will drop, therefore, the stove will have to be heated more, and ventilation will not replenish the burned out oxygen.

The remote firebox is much more functional and more convenient. It is located in the adjacent room and has no effect on the oxygen balance in the steam room. Regardless of the temperature, people will feel equally comfortable in a steam room with such a stove. The only drawback is that a large bath area will be needed: it should consist of at least two rooms (steam rooms and a dressing room, for example).

Furnaces are also subdivided by material. As mentioned above, brick is the classic option, but metal is more modern.

Wood-burning stoves for cast iron baths, which have a number of features, are very popular.

- A cast-iron stove heats up a room many times faster than a brick one.

- The heat generated by warming up such a model is soft and comfortable. In addition, the temperature lasts a long time.

- Cast iron is durable, does not deform under the influence of high temperatures over time, does not corrode. In addition, cast-iron options can be combined, for example, gas-fired and working both on wood and gas.

Steel ovens generally have some disadvantages, including uncomfortable heat, rapid heat loss, and infrared radiation. They are susceptible to deformation when exposed to excessively high temperatures (for example, when chipboard is used to maintain combustion instead of regular firewood).

Among other things, the ovens can be powered by electricity. They are not wood-fired, since they are not supported by fuel. You can often see electric fireplaces that work on a similar principle, however, an electric stove can be used to heat a heated sauna room, which will allow the steam room to stay cool longer.

Particularly noteworthy are the models-steam generators, which fill the air with moist high-temperature steam. Such electric models are often mounted in addition to ordinary wood-burning ones, in order to be able to quickly turn the sauna into a hammam, while choosing mini-samples so as not to clutter up the space.

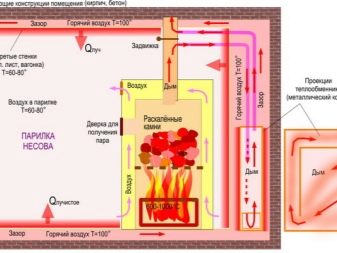

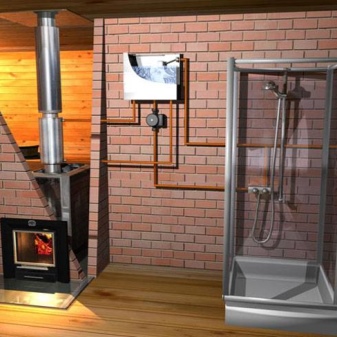

Furnaces with a heat exchanger or with a tank - designs that, among other things, also provide a comfortable temperature in the dressing room or other bath rooms. A special tank is connected to them, the water in which is heated while the stove is heated. Heating radiators can also be connected here.

The model with a heat exchanger can work not only on wood, but also on coal and electricity.

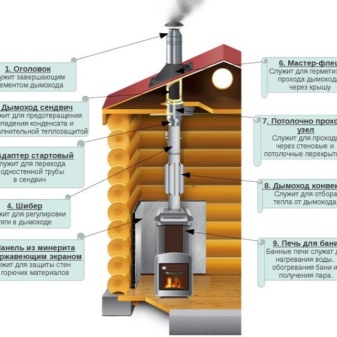

Chimney device

By and large, chimneys are divided into two types: internal and external. It is logical that the internal chimney is for the most part located inside the room, while with an external location, almost the entire chimney is taken out to the facade.In Russian realities, the external chimney is more popular, since it allows you to keep heat in the room for a long time.

The internal chimney is easier to clean than the external one. In addition, it saves heat. The disadvantage is that it is incredibly difficult to design such a structure, even though the internal chimney does not need to be insulated.

The external model is constructed more for aesthetic purposes than for practical purposes. Here you have to think over the fastening on the facade, drill holes from the outside.

Natural cravings are critical. The better it is, the better both the chimney and the stove will function. If you do not take this factor into account, then you can come to the conclusion that combustion will not be supported due to disruption of heat exchange processes in the furnace. In addition, smoke accumulating in the room can lead to poisoning. So that the draft is not too strong or too weak, you need to design the chimney responsibly and carefully.

A chimney for a wood stove made of any material consists of the following elements:

- Pipe. It serves to bring smoke out.

- Connecting elements. They are used if the pipe consists of several parts. They are ordinary or angular.

- Flanges. They are flat parts with bolt holes. They are used for tight and strong connection of pipe parts.

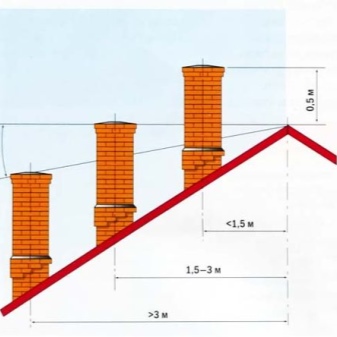

Before proceeding with the arrangement of the chimney system, you need to carry out all the calculations. They must be correct, since any mistakes can lead to the fact that the chimney will not work properly in the future. The calculation for wood-burning stoves has a specific feature.

Here you need to pay attention not only to the height of the pipes, but also to their diameter.

When calculating the height, it is important to remember that there is a natural draft in the chimney. For best results, you do not need to run the pipe too high or too low. In the first case, there is a risk that the thrust will be too great and the fire in the furnace will die out under the pressure of the wind. In the second case, too little traction is guaranteed. Professionals do not recommend making the chimney height above the roof level more than 50 cm.

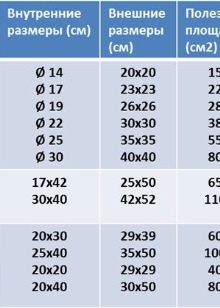

The performance of the entire system depends on the calculation of the diameter. The cross section affects not only the thrust force, but also the temperature in the chimney. The most optimal is a circular or cylindrical section rather than a square one. Remember that the height and diameter of the section are correlated with each other: when one changes, the other also changes. To calculate the diameter depending on the length of the pipe, use special tables, for example, as in the picture below.

The material of the chimney plays an important role. So, the pipe can be iron or brick.

The material is chosen depending on what the wood-burning stove is made of, but this criterion is not always a determinant.

What the chimney is made of affects its functional characteristics.

- If the chimney, like the stove, is made of brick, there is a problem of strengthening the base. It is also necessary to make a fireclay brick pipe due to the high temperatures. The inside of the pipe must not be treated with plaster, as condensation forms here.

- Metal pipes are usually made of stainless steel due to the condensation that forms. Such chimneys consist of modules that are connected to each other using flanges and connecting elements. The metal option is much cheaper and more functional than building a brick structure. In addition, you can additionally insulate the pipe by making it double-walled: inside there is a stainless steel, and the insulation is built into the pipe.

Keep in mind that designing and installing a chimney for a wood-burning stove is an operation that only a professional can do. Only he will be able to calculate and establish everything correctly.The installation of the stove itself is not so difficult, both the operability of the stove itself and the well-being and health of people relaxing in the bath largely depend on the chimney.

Manufacturers and reviews

So, deciding to install a wood-burning stove, first you need to decide which model to give preference to. If the technical characteristics and features were mentioned above, then it is worth learning more about which countries and manufacturers are recognized as the best in this area. A special rating of manufacturers was compiled by users. This includes only manufacturers of metal structures, since brick ovens are built only to order according to an individual plan by single craftsmen. I am glad that the list of leading manufacturers includes not only foreign manufacturers, but also Russian ones.

Company "Litkom" from Russia offers ovens for steam rooms Vesuvius... Today these models are among the most popular due to the optimal price-quality ratio. The manufacturer offers a wide range of products that differ not only in characteristics and material, but also in dimensions. There are both stoves designed for heating small baths and for large steam rooms.

Manufacturer "Hephaestus" from the Republic of Belarus offers excellent quality models, but there is one drawback: the price. The products of this company are by no means cheap, and not everyone is willing to pay that kind of money. Many buyers say that they have largely overpaid for the brand, since the manufacturer is well-known.

"Ermak" - a company from Russia, which is loved by customers due to the democratic prices for its products. Indeed, the cost of stoves here is much lower than that of others, but this does not affect the quality. Users note a long service life, no deformation, rapid heating of the room. The designs themselves are fairly reliable.

"Teplodar" Is another Russian manufacturer offering decent quality models. This brand is often compared to Ermak, since the lineup and prices are almost identical. In many respects, the choice is due to the aesthetic preferences of buyers: some people like the Ermak ovens more in appearance, others like Teplodar.

Termofor Is a Siberian company that produces some of the highest quality stoves. The products are reliable and of high quality, with a high aesthetic appeal.

In 2016, Termofor ovens were recognized as "Product of the Year", which shows the company's products from the best side.

Finnish model brands Harvia are distinguished by excellent thermal performance. Judging by the reviews, the stoves heat up quickly and keep warm for a long time, while they look attractive. The model line includes both small samples and large-sized heavy cast iron furnaces. The stoves are distinguished by their minimalistic design, which appeals to many.

Helo Is also a Finnish brand that offers a wide range of different stoves for home steam rooms and saunas. There are also ovens for professional use. All models are economical, while being able to heat a large bath area. The price for household models is a maximum of 40,000 rubles.

Finnish brand Kastor is distinguished by the specificity of the operation of the furnaces. Heat is emitted not only by stones, but also by the walls of the furnace. Therefore, such models are well suited for installation in the steam room itself, and not in an adjacent room. In the manufacture of products, materials with increased heat-resistant indicators are used.

Feringer Is a Russian manufacturer offering stoves for baths and saunas operating on different energy sources: wood, coal, and electricity. The plant has been operating for over 10 years, and during this time it has won the recognition of buyers. Stoves are available with both dry heat and steam, which are more suitable for baths.

Brand from Sweden Keddy offers quality models that do not look like wood-burning stoves thanks to a special design solution. More such samples resemble fireplaces, which is attractive from an aesthetic point of view. In addition to stoves, the company also supplies chimneys made of cast iron.

Company Hark - from Germany, therefore the German quality of its products is guaranteed. So, the company offers over a thousand different models, so that even the most spoiled buyer can find something suitable. The manufacturer has been operating for more than a century and a half and during this time has become a leader in Europe.

Thorma - a joint project between Germany and Slovakia. The stoves are characterized by a minimalistic design: they are not like typical models, as they are tall and narrow. Among other things, there are also cylindrical models. All products of the company are characterized by high power and fast heating.

How to do it yourself?

In everyday life, homemade stoves are found as often as purchased ones. This is due to the fact that the self-manufacturing option is often cheaper, but this rule does not always work. So, it will be necessary to buy a brick or metal, pay for welding, equip a chimney, strengthen the foundation, make a lot of effort, spend a lot of time. If this prospect does not scare you, you can safely start building with your own hands.

It is worth starting by studying the process of building a brick wood-burning stove.

You will need to purchase the following materials and tools:

- brick red;

- fireclay brick;

- sand and clay of medium fat content for mortar;

- metal corners;

- doors for the firebox and for the blower;

- gate valve;

- if provided, then a tank for heating water;

- trowel;

- mallet;

- building level;

- plumb line;

- rule;

- hammer;

- construction tape.

First, you will need to mix a thick solution of sand and clay. The solution needs to be checked: roll small balls out of it and dry completely. If cracks have gone along them, then the solution will need to be redone. If not, drop the balls onto a hard floor. If they remain intact, then the solution is made correctly.

Be sure to strengthen the foundation. To do this, you need to use a concrete fill. A simple floor on logs will not work, it will not support the weight of the oven and will break or sag.

When strengthening the foundation, it is best to use reinforcement.

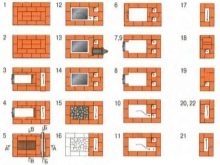

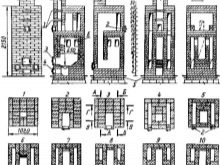

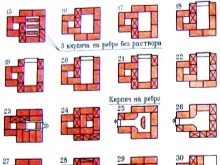

Next, start laying out the oven itself. To do this, you can use special schemes. Here is some of them:

Remember that fireclay bricks are laid only inside the fuel chamber, since only there will be such high temperatures that red bricks, which, by the way, are also fireproof, cannot withstand them.

At the final stage, the chimney is installed and all systems are checked for operability. It is important to check the natural draft of the chimney. Pay attention to the evenness of the masonry: a stove laid out evenly will not only look more aesthetically pleasing, but will also last longer. Finally, weld the door for the combustion chamber. Your oven is ready.

Before proceeding with the construction of a metal furnace, it is necessary to improve the characteristics of the metal. Surely every person has seen red-hot stoves at least once in his life, but few thought that this would affect the functionality of the structure. A number of characteristics are lost, not to mention the appearance. Therefore, it is important to choose the right metal and prepare it properly.

It is necessary to check the metal for warpage. The side and top edges heat up the most, so the sheets from which they will be made must be red-hot and allowed to cool slowly. After carrying out such a procedure, they are deformed, and it will be necessary to trim them with a hammer and cut them to the desired size. Such a simple technique will avoid warping in the future.

So, the sheets should be thick, at least 1.5-2 mm. All parts of the furnace must be cut out of the metal.A preliminary sketch will help to determine their number and size.

Next, carry out welding work. Remember that the regulation of electricity is extremely important: only with the correct amperage will the seam turn out to be uniform, beautiful and durable. Pay attention to how smoothly the parts are welded, otherwise the furnace body will "lead". By and large, you should end up with a solid box.

Now cut a rectangle in one of the sides and knock it out with a hammer. This will be the place where the combustion chamber door is installed. Do not discard the rectangle, it will still come in handy.

Weld the stove in a similar way, and then collect all the elements together. Equip the chimney and remove the pipe from the stove. Check the health and functionality of the structure. Your oven is ready.

Advice

Experts have prepared several recommendations on how to make the manufacture of a wood-burning stove for a bath as economical as possible, and operation - long-term.

Such advice should be heeded.

- If you made a metal stove, then pay attention to the legs. In the classic version, four legs are used, but it is better to give preference to sled legs. They will help reduce the load on the floor, while making them look more interesting.

- To reduce the heating of the walls when refractory materials are not at hand, you can line the furnace structure with red refractory bricks. This will significantly reduce the risk of fire. However, pay attention to the fact that the brick has a high thermal conductivity, otherwise increase the temperature characteristics of the firebox.

- Make production as waste-free as possible: make a door for the combustion chamber from a rectangle cut from the side of the firebox. Firstly, it will fit perfectly in shape and size, and secondly, it will help you save a little.

- If a water tank is provided, then it is best to choose stainless steel for its manufacture. When performing welding work, remember that stainless steel is welded in a special way. Certain skills are required here.

- To increase safety, make a barrier structure around the sauna stove, which is a kind of wooden fence. It will protect you from accidentally getting burned on the stove. This is especially true for baths where children will be.

- If you bought or made a stove, and its power turned out to be insufficient, then there is a way to fix everything. Additional metal sheets can be welded on the sides of the structure. They will enhance the heat given off by the stove.

- If possible, then it is better to equip the door with an air supply regulator. This is done in order to, at will, adjust the rate of fuel burning, accelerate or stop heating of the steam room.

- A brick oven must be erected near the wall of the dressing room, adjacent to the steam room. The distance from the firebox to the wall, taking into account all the walls and details, should be at least 30-40 cm, otherwise the risk of ignition will increase manifold. However, this indicator can be reduced to 15-20 cm if you use special protection (asbestos cardboard, for example).

- Regardless of which stove is installed, a sheet of iron is placed under it, which protects the floor from excessive overheating and fire. The thickness of the sheet must be at least a centimeter, otherwise the protection will be ineffective.

- It is best to expand the lining sheet, bringing it out about 20 cm in front of the oven. This is done in case burning coals fall out of the combustion chamber to protect the floor from burning.

- Ash, oak, birch, linden, alder, aspen, as well as some conifers: pine, spruce, are recognized as the best firewood for melting a bath. Fruit trees are also very popular: pear, apple, cherry, plum. These rocks have good thermal conductivity and a long burning life.Among other things, they have a beneficial effect on the human body.

- Often, to quickly raise the temperature in the steam room and for the appearance of wet steam, many people pour water on the stones in the stove. This must be done carefully, otherwise the oven may fail. It is not recommended to pour out more than 100 ml of water at a time, otherwise a fire may result. Water should be poured not in a purposeful stream, but as if in a fan. Then the steam will be as intense as possible and the temperature will rise quickly. The stones should turn crimson after being saturated with water.

Wood-fired stoves are an excellent purchase that will make your sauna rest pleasant and useful. Take good care of your stove and it will serve you for decades.

For information on how to choose a wood-fired sauna stove, see the next video.

The comment was sent successfully.