Choosing cast iron rings for the furnace

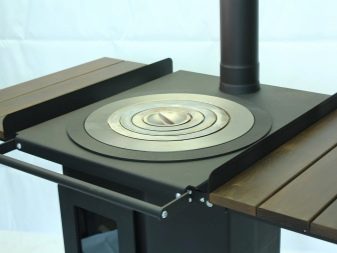

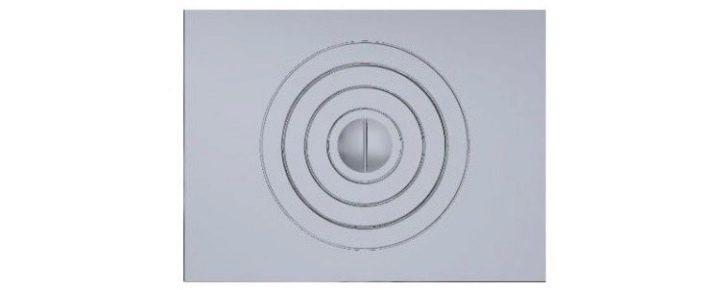

Many people who have stoves in their homes install stoves on them. They are often called cooking floors. They are a structure consisting of several rings. Today we will talk about furnace rings made of cast iron.

Advantages and disadvantages

Cast iron kiln wheels have many advantages.

- Inertial heat transfer. Cast iron surfaces, gradually cooling down, will evenly warm up the entire room.

- Strength and fire resistance. Such structures are practically not exposed to mechanical stress, they can serve as long as possible without deforming or breaking. In addition, they can withstand the highest temperatures.

- Corrosion resistant. It is achieved through a special layer applied to the cast iron.

- Durability. Cast iron products can last over 40 years.

- Environmental friendliness. With proper care, cast iron kitchen products are absolutely safe for humans, they do not emit harmful components.

But such oven circles also have some disadvantages.

- Relatively fragile material. Assembling and transporting cast iron products will require caution.

- Considerable weight. Items made of such material have a large mass, which complicates their installation and transportation.

- Absorbs odors. Most often this happens due to the long-term storage of various food products on cast iron surfaces. In addition, the food itself can darken.

Remember that if you do not follow the simple rules of care, such cooking decks will quickly become covered with rust. After each use, the structure should be washed; almost any detergent can be used for this.

If, nevertheless, a rusty layer appears on the surface, then it will need to be cleaned off with an iron brush.

Popular manufacturers

Now we will take a closer look at some of the manufacturers of such cast iron products for furnaces.

- "Kaiser". This manufacturing company manufactures slabs consisting of several cast iron rings. The assortment includes models with different diameters. The thickness of the circles is at least 10 millimeters. The constructions are installed on the flange. Kaiser produces oven plates weighing 8-10 kilograms.

- Vesuvius... The company manufactures and sells solid and prefabricated slab models. The circles from which the structure is assembled have different diameters. All of them can be used as a full-fledged cooking device for preparing various dishes.

Selection Tips

Before purchasing such circles for furnace equipment, you need to pay special attention to some of the nuances. First, decide what size the products should have. First of all, you need to take into account their diameter.

Most often, in specialized stores, customers can see rings with a diameter of 120, 180, 240, 350 mm. A single cooking deck can be assembled from them. Each circle can fit a cauldron of a certain size.

Assembled on such a structure, you can cook dishes in a pan, in a saucepan and other utensils.

Also before buying should be carefully inspected by yourself materialfrom which the rings are made. It is best to select models with special protective coatings. Some products are made using chrome. Such hobs can last as long as possible.

Nowadays, enamel rings are also produced. They will not rust even after long-term use.Chips and scratches will not form on the surface.

The comment was sent successfully.