Woodbeds: purpose, varieties, production

Firewood must be dry at any time of the year, therefore creating a special place for the safety of fuel is an important task. Woodsheds can be of different sizes and capacities, they are necessary in private households and administrative buildings in the outback. This topic is of particular relevance for Russia, where in most of the country there are long winters with a stable subzero temperature.

What it is?

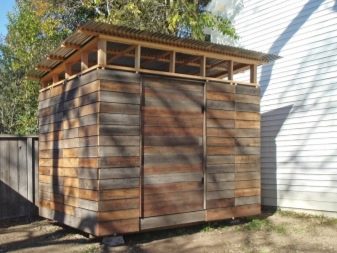

A firewood is a simple structure, but with many nuances that must be taken into account. Woodsheds have existed for thousands of years, exactly since the time when houses appeared that needed to be heated in the cold season. These objects are functional, they often carry an aesthetic load. In our era of the existence of innovative materials, zealous owners manage to make real works of decorative art out of these technically simple structures. Folk craftsmen even manage to make a woodsman not only as a fuel storage, but also as a gazebo, greenhouse, workshop, etc.

The simplest design that can be found in any rural house is a canopy-shaped woodshed. It is not difficult to design such a structure. In any private household, such an object is necessary, it is difficult to live without it, because firewood is always needed dry. Often, woodburners are made in a barn, but ventilation must be present there. If the household is large and a lot of firewood is required, then a spacious structure of a large area should be made for their storage.

Most often, villagers and summer residents use used wooden materials to build an object. Old beams, boards, beams, window frames - all this can be an excellent building material for creating a solid woodshed that will serve for more than a dozen years. First of all, you should choose a suitable site for it. It is recommended to proceed with this from common sense.

When entering a private household, firewood should not be visible, such structures are "pushed aside" to the background. At the same time, the woodshed should be within walking distance from the house.

Construction begins with site preparation, which is cleared and leveled. Then the work is done according to the following algorithm:

- the groundwater level is checked;

- the level of the gravel cushion is determined;

- pits up to 40 cm deep are dug in the corners;

- guides are installed in these holes and poured with concrete;

- the rails are attached using diagonal bars or parallel crossbars.

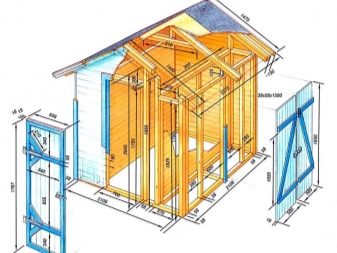

The bars are laid out in the lower part, the strapping is done. It is important to consider that the perpendicular posts must be of different heights. If the roof is pitched, then the angle must be at least 20 degrees. After the racks are installed, the roof can be made. The upper strapping is made using a bar and boards. The rafters are laid, the crate is made.

Dry firewood is a rather heavy material, it is inconvenient to carry them in the cold season, therefore close proximity to home stock of such a valuable product is the right decision. It is also important to provide good access for transport. Firewood will sometimes need to be brought in by car, so it is important that vehicles enter the territory of the household without hindrance. The woodshed should be on a "pillow", that is, on a height of about 15-20 cm.So the firewood in the lower rows will not absorb moisture from the ground, which means it will not rot.

Often, the woodshed becomes an extension to the main structure on the site, that is, it can additionally protect the wall from the cold wind. If you apply imagination and skill, then you can make a wonderful landscape object from it, distinguished by originality and taste.

Before starting work, it is important to make a schematic drawing of the project, draw up a table that will indicate the materials necessary to create a structure.

Varieties and characteristics

Woodsheds can be of different designs:

- open, made of wood in the form of a canopy;

- frame made of bars;

- from old barrels;

- from pallets;

- from timber, metal, boards, plywood or PVC sheets.

The sizes of woodsheds can be very different. If the structure is made in the form of a canopy, then first of all a good foundation should be made so that moisture from the ground is not transferred to the lower rows of firewood.

In some cases, the owners of household plots cast a concrete area or put reinforced concrete slabs. These works are not cheap, but such woodcutters are distinguished by their reliability and good quality. The most common option is to add gravel, this is quite enough if you place a woodpile of firewood on sheets of roofing material. The site is also most often fenced with a curb made of reinforced concrete blocks or beams impregnated with a primer or antiseptic. The beginning of work starts with the elaboration of the plan-scheme of the future object and the calculation of the materials that will be required.

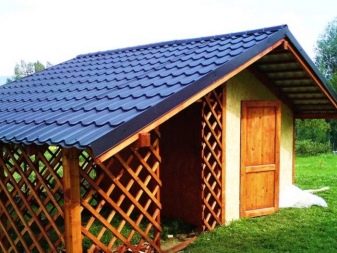

A canopy log usually has three walls and a roof. You can make a woodshed-shed in the form of a gazebo. The design has a claim for originality, it can be decorated by attaching decorative details. The roof is made at an angle of at least 20 degrees so that moisture can flow freely onto the ground. This design will reliably protect the wood. Good airflow ensures that moisture in the form of condensation does not accumulate on the wood. Such an object can be built next to the main house or erected behind the bathhouse.

The advantage of such small wood bills is also the fact that there is no need to cast a strip foundation, it is enough to install two pillars in the corners of the site. The material for such supports can be:

- corners "6";

- wooden logs;

- profile pipes 150 mm;

- timber.

The walls can be made from boards with a thickness of 20 mm. Diagonal and transverse fasteners should be made between the vertical fasteners from the inside. In the cold season, snow will accumulate on the roof, therefore, the load on the roof and vertical supports will increase. It will be imperative to strengthen them with spacers-fasteners. Also, under the roof, a rigid frame should be made from the corners. This element will also provide additional rigidity, mating all the elements into a single support node. Such a structure can be made in a couple of days, and a wood-burning man can serve for more than a dozen years. You only need to periodically carry out a small preventive maintenance.

Polycarbonate is popular among modern materials for building a woodshed. Its sheets are durable, do not corrode, do not deform under temperature and humidity changes, reliably protecting the material from precipitation. Sheathing walls with polycarbonate is not a bad idea. The weight of such a structure will be minimal, the walls will be strong and the fuel will not be swept away by changes in temperature and humidity. For better ventilation, gaps of 2-4 cm are often left between the sheets. Some homeowners decorate such woodsheds with forged fragments. The most important thing in the creation of such structures is the creation of a structure with high-quality natural ventilation.

Professional builders recommend building a woodshed on the north side of the house. The reasons for this are as follows:

- there is no direct sunlight;

- the north side is traditionally cold and the woodshed can be an additional "heat" zone. "

An important point when creating a roof is that it should protrude 25 centimeters, not less, so that moisture, flowing down, does not fall on the wood. The roof is made using the following materials:

- slate;

- roofing material;

- metallic profile;

- polycarbonate.

Also, woodsmen are made on a pile foundation, which is not inferior to the strip foundation in terms of strength factor. Its advantages:

- making a pile foundation is much easier;

- no time for shrinkage is required;

- its cost is four times lower.

Any piles can be bought in a store or made by yourself. Alloyed tubes (of which piles are usually made) are easily screwed into the ground, their service life exceeds 50 years. Between the piles it is necessary to make a "cushion" of gravel, lay the gaps with timber or concrete blocks 20x20 cm, make transverse fastenings, then sheathe the walls with sheets of polycarbonate or flat slate.

Before building the facility, the groundwater level should be examined. If the site is located in a lowland, then the groundwater can rise to the surface itself. In this case, a "pillow" of gravel with a height of 20-25 cm should be made. The tool that will be needed in this case:

- Boer;

- Bulgarian;

- pliers;

- hammer;

- small sledgehammer;

- drill;

- screwdriver.

Many on the roof of the woodshed make various additional structures:

- terrace;

- flower bed;

- a small greenhouse.

When creating a firewood, it is important to correctly arrange the logs, which at the same time can become an element of decor. Forged products made of cast iron go well with wood.

Design features

The design of a woodshed depends a lot on how the woodpile is stacked.

The easiest way to lay firewood is with a round woodpile. In this case, it is desirable that the firewood has a rounded shape. They look colorful, the material dries quickly enough. Around the designated point, small-sized firewood is laid out in diameter, the distance to the center is twice the length of the firewood. That is, if the wood is 30 cm long, then there will be a distance of 60 cm to the center. The laying is done without any special gaps, quite tightly and stretches almost to the ceiling.

As soon as it becomes noticeable that the load has increased, the upper rows are slightly deformed and another row can be laid out in a circle without reporting until the second row is 25 cm.

The second row in the middle is inserted into the gaps. In this case, the wood is installed by the "end-to-end" method. The advantage of this design is that it is stable and can be quite large. At the same time, it looks very aesthetically pleasing. You can make a woodpile in the form of a triangle or quadrangle according to the same scheme, it is also possible to combine these figures.

Often, firewood is carefully plowed along the wall. The height of the woodpile may be small, but due to its compactness and rational arrangement of the material, a lot of them can fit.

The woodshed can be built from used materials, while it will look very beautiful. Sometimes it is not just a shed for storing firewood that is built, but a complex of buildings, for example, a woodshed with a bathhouse or a gazebo with barbecue. If all structures are made of first-class materials, covered with red tiles, then they will look. in a single complex.

How to use?

It should be borne in mind that there are various insects in the wood that feed on them. If the house is made of timber and logs, then close proximity to the prepared firewood is not the best idea. It is correct to make a passage 2-3 meters wide between the house and the firewood. This arrangement will provide insurance that the material of the walls of the house will be protected. A woodshed is a source of increased fire hazard, this is also the reason why an object is often built a few meters from a residential building or a bathhouse.

Some people make woodcutters in the garage, allocating for this a separate room on the side, which may have two entrances: from the side of the garage and from the street.Such a building can be made in half a brick. Due to the presence of two doors, it will be well ventilated.

Before laying the roof, you should lay the surface with roofing felt, then condensation will not accumulate under it, the boards will not rot. The floor does not need to be laid; a fine or medium gravel cushion is sufficient. If you intend to transport firewood on a cart, then this option will not work, since it will be difficult for the wheels to drive over the stones. In this case, you can make a small flooring along the edge of the firewood, especially for transporting firewood.

Some homeowners fill the usable area with concrete or make wood floors using logs. All wooden elements must be lubricated with an antiseptic or fire-fighting primer. Often, woodburners are made with walls made of lattices (they use fittings or bars). There is a rational grain in this - such an object is well blown, the tree will not die.

How to do it yourself?

Building a woodshed with your own hands is not a big deal. It requires a minimum of materials and the ability to own an elementary tool. The step-by-step construction instructions look like this:

- a drawing is created;

- costing is done;

- material is procured;

- walls and canopy are mounted;

- firewood is stacked in a woodpile.

Usually for a private house up to 100 sq. meters, where 4-6 people live, about 2-3 cubic meters of firewood is required for the winter. A small woodshed is required. Often, zealous owners harvest firewood for several years in advance, buying them at wholesale prices. In this case, the storage room for storing firewood is made of a sufficiently large size (16-20 square meters). In height, it makes sense for such an object to be no more than 2.8 meters, since only with such dimensions it will be quite easy to throw firewood upstairs.

During the cold season, the walls are covered with sheets of plywood or metal. In this case, precipitation will not fall on the tree, which will contribute to its safety.

For information on how to build a woodshed with your own hands, see the next video.

The comment was sent successfully.