Brick stove for a bath with a firebox from the dressing room: installation features

It seems that no one will argue that a good bath, in addition to hygienic purposes, is an excellent way to treat and prevent diseases of all kinds. The use of bath procedures largely depends on its most important part - the steam room. And the steam room itself, in turn, is good with a properly folded stove.

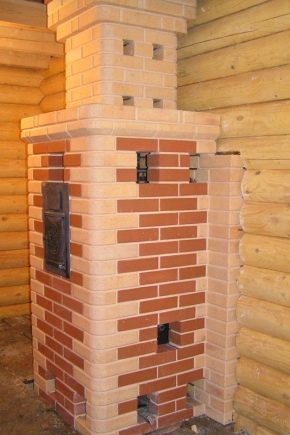

The most popular and easy-to-maintain type of heater is the stove with a firebox.taken out in the dressing room. Today I would like to talk about just such a variant of its location.

With the eternal choice - a stove made of metal or brick, the choice of the absolute majority is a brick stove. Many factors speak in its favor: moderate, non-scalding heating of the air, aesthetics of appearance, humidity and the degree of steam supply, which is easier to regulate.

Features: advantages and disadvantages

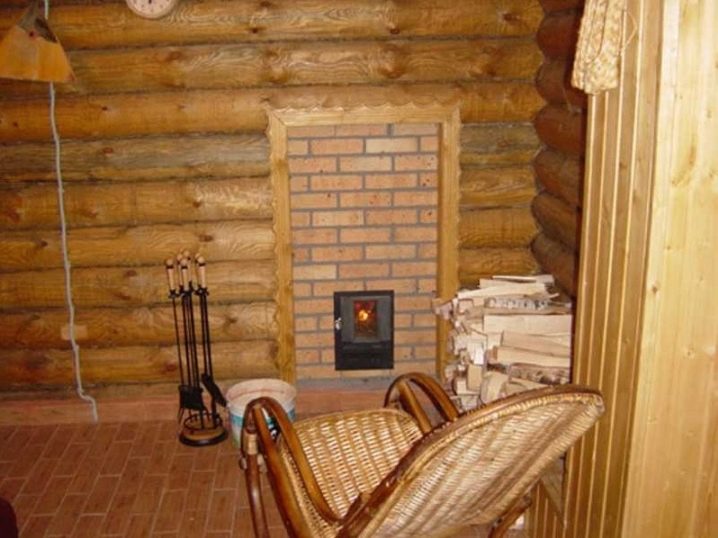

Of course, the installation of a standard heater is simpler than the complex arrangement of such an additional accessory as a firebox placed in the dressing room or in another room. This is more expensive, but we can say with confidence that all this will be covered by the comfort that this option will create when using it. Especially this configuration of the stove will have its say in winter.

Another of the advantages is that you can do without arranging a ventilation system in the steam room due to the fact that there will be no burnout of oxygen in the steam room, since the metal parts of the stove are taken out of it.

For practical reasons, the dimensions of a brick oven primarily depend on the size of the steam room, the number of people, the seasonality of using the bath, and the purpose of using the oven itself.

The conclusion of the firebox of a brick stove to the dressing room is convenient because

- there is always an opportunity to clean the ash, melt the stove;

- firewood is always at hand, they are always well dried;

- the heating mode of the furnace is easier to control;

- the heating of the dressing room is always provided by the heat of the stove;

- carbon monoxide in the event of a loose fit of the firebox door enters the dressing room, and not into the steam room;

- the iron parts of the furnace do not overheat, do not burn out oxygen in the steam room, do not dry the steam.

Disadvantages of the location of the furnace firebox in the dressing room:

- the brick oven heats up for a long time;

- the stove consumes more firewood than a metal stove;

- to throw firewood, you have to run out to the dressing room.

Mounting

Deviation from the rules for installing sauna stoves is the most common cause of fire.

Here are some guidelines to avoid this:

- The stoves should be at least 35-50 cm from the wall if the bath is built of fire hazardous materials.

- The air gap between the metal parts of the stove and any wooden structure should be at least 1 m. If the dimensions of the bath do not allow this, it is necessary to use external protective special screens.

- The firebox door should be at least one and a half meters away from the opposite wall.

- It is strictly forbidden to install the stove directly on a floor consisting of combustible materials: cardboard covered with basalt chips is placed on top of the boards, which, in turn, is covered with sheet metal. The dimensions of the shelter should exceed the dimensions of the projection of the furnace by more than 5-10 cm.

- The floor under the firebox door must be covered with a non-combustible coating, with an area of at least 40-50 cm2.

If the pipe is installed by hand, it is necessary to install a so-called pass-through unit, which will protect the pipe from contact with the roofing.

Brick kiln foundation

Considering that the weight of a standard brick and mortar on it is about 4 kg, for this reason, the furnace requires a very solid foundation. In addition, the high temperature of the furnace is capable of heating any material, even of considerable thickness, it affects the surrounding soil layers for a long time. Therefore, the foundation of the furnace itself should not come into contact with the material of the bath foundation. To avoid the stove settling, it should be thermally insulated with mineral wool.

The foundation must be waterproofed with a material such as roofing material. When sheets of waterproofing are laid, their edges are folded and coated with clay so that the lining is more than one and a half centimeters thick. It is imperative to mount the waterproofing at the level of the beds and floorboards, between the bricks of the stove wall and the boards, be sure to put metal and asbestos sheets on top.

Bath brick oven

The most common design of the bath is a combination of the stove wall and the wall of the dressing room to save materials and better heat transfer. If the bathhouse itself is built of stone or other non-flammable materials, mineral wool or special non-flammable sandwich panels on a silicate or asbestos basis are used to insulate its walls from the stove.

If the walls and ceiling of the bath itself are made of wood, then the fire safety standards for thermal insulation state that it is necessary:

- provide a gap of at least 1.3m between the heating oven and the ceiling or wall;

- the firebox door in the dressing room should be 1.2 m or more from the nearby wooden wall;

- in the case when the firebox passes through a wall made of flammable material into another room, it is necessary to make an insert made of refractory material of at least 500 mm, which has high heat resistance and a length equal to the length of the firebox;

- a fireproof covering is laid on the floor in front of the door (metal is most often used) with an area of 40x80 cm.

A mandatory requirement is fire insulation or cutting of brick surfaces of the walls of the furnace and wooden structural elements. In fact, it is brick and clay, laid in layers with a certain gap, or asbestos sheet. After such work, a ceramic cover is formed, which largely insulates the wooden structures. In addition, they protect against tongues of flame escaping through the cracks resulting from the destruction of masonry in the event of an emergency.

The chimney is insulated with thermal insulation wool in the same way. Additionally, a strapping made of metal sheets is applied.

The outlet of the furnace pipe through the ceiling or wall is the most fire hazardous area. At this point, the ceiling is embroidered and finished with bricks, in the same way as was done with wooden walls.

If the bath is small, and a brick structure of a relatively large size and mass is not required, it is allowed to install a stove with a firebox, placed in a small dressing room, placed on a wooden floor covering. The ordering of such a furnace is very simple - no more than five in a row, and no more than ten rows themselves.

The stove may also be placed not on a concrete foundation, if all fire safety measures are observed. Sometimes it becomes necessary to open the floor and organize additional support or lintels.

In this case, the following restrictions must be observed:

- total mass - no more than semitones;

- 600 kg - for an established floor;

- 700 kg - for freshly laid floor.

If these conditions are met, a brick compensator is laid out for the base of the furnace. The asbestos fiber is added to the masonry mortar, which is applied to the base and side screens.

Types of bricks suitable for work:

- Standard ceramic bricks have dimensions of 25x125x65 mm. It needs additional processing with heat-resistant varnish to increase resistance to critical operating conditions - temperature drops and high humidity.

- It is more reliable to use fireclay refractory bricks, since it is made precisely for such purposes.

It has a straw color and comes in three sizes:

- standard 230x125x65 mm

- narrower 230x114x65 mm;

- narrower and thinner - 230x114x40 mm.

Subtleties of output through the overlap

Compliance with fire safety measures with the correct outlet of the furnace tube through the ceilings and the roof is especially important from the point of view of the possibility of fire. The firebox is insulated from the ceilings as carefully as possible. If the bath is made of stone or consists of non-combustible materials, it is enough to make gaps on each side of the channel. Later they are filled with asbestos or mineral wool cord. A layer of insulation is applied with a thickness of more than 2 cm.

Provided that the bath is made of wood (timber, or logs), the gap must be left much more significant - at least 25-30 cm. Brick in this case plays the role of an insulator. Sometimes in wooden baths, gaps are left along the entire chimney. For this reason, the installation of thermal protection is omitted.

The chimney is installed at the final stage of construction. The pipe is connected using a pipe. When using a metal chimney, it is led through the roof slabs in a sleeve, which is easy to purchase in retail chains of the corresponding profile.

In the case when there is a desire to make a pass-through unit with your own hands, you must follow the following scheme of actions.

- The opening in the ceiling is made so as to leave a gap of more than 30 cm from the pipe to the nearest wooden ceiling structures on each side.

- The steel box is made of sheet metal. The edges can be fixed with any screws. It is inserted so that its lower cut is flush with the ceiling, not lower.

- A cardboard covered with basalt chips is laid between the walls of the box and the overlap material.

- From the bottom, the box is overlapped with a moisture-resistant gypsum board with an opening for the pipe itself.

- Then the chimney is mounted directly. The voids remaining in the box are laid with mineral wool.

- "Flashmaster" is a sleeve made of heat-resistant silicone material that can withstand high temperatures. Alternatively, it is permitted to use a homemade sheet steel box with insulation, similar to the protective chopping box described above.

The height of the chimney section above the roof should not be less than 80 cm.

It is quite difficult for yourself to master all the subtleties of installing a brick oven in a bathhouse, but nothing is impossible if you have drawings and a guide to action at hand.

Helpful hints

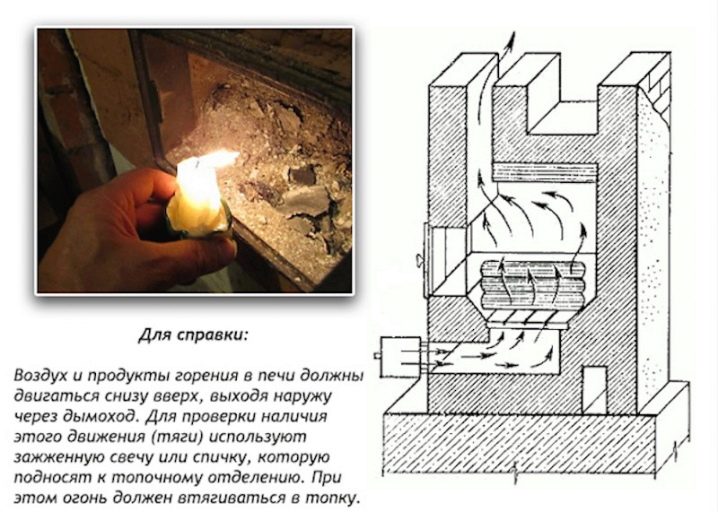

When heating the stove, the smoke must freely go into the chimney, since if carbon monoxide is not removed through the hood, it can seriously harm the human body. If there is a problem, the cause of the poor draft must be found immediately and corrected.

Several ways to determine the absence of stove draft or interruptions with it:

- The easiest way is an ordinary sheet of paper or a lighted match brought to the open door during the heating of the stove. If a leaf or flame of a match deviates inward, then there is a thrust. If there is no deflection or it occurs outward, then the presence of the so-called reverse thrust is possible, which can be very dangerous.

- One of the reasons for the weakening of the draft can be a depressurized chimney, a crack, a break, a pipe shift, and other defects.

- Another danger is an accidental spark caught in such a crack in the chimney on combustible material, which leads to a fire.

- The small size of the blower through which the exhaust is carried out can lead not only to the occurrence of reverse thrust, but also to an insufficient supply of oxygen to the fuel combustion process.

- Chimney blockages can also interfere with the normal draft process. In this case, regular cleaning of the chimney will help to restore normal air movement. It should be noted that the presence of even one elbow in the pipe, where the main amount of soot accumulates as a result of aerodynamic processes, will greatly complicate the process of the "chimney sweep" operation.

- If, for some reason, the stove cannot be heated for a long period of time, an air lock, consisting of dense air layers, may form in the chimney. As a rule, it dissolves immediately after the start of regular heating by itself.

- Insufficient volume of the firebox.

- A wide and long chimney does not work with a small firebox.

Traction recovery actions

After eliminating the above reasons, you can use special devices to regulate traction:

- anemometer - will determine the draft in the chimney;

- draft stabilizer - is an "umbrella" over the upper cut of the chimney pipe, not only increases draft, but also regulates it;

- deflector - is a device that enhances traction;

- a rotary turbine is a type of deflector.

In conclusion, it is safe to say that a brick-built stove will serve reliably, subject to certain rules. It is not worth changing the oven once folded, shifting its individual parts, especially the walls, since the likelihood of cracking and even collapse of the entire structure will sharply increase. If necessary, the oven is completely disassembled and re-laid.

How to install a stove with a remote firebox in a bath, see the next video.

The comment was sent successfully.