The subtleties of choosing a stove for a bath

The “heart” of the bath is undoubtedly the stove. After all, the temperature and the amount of steam in the bath depend on how correctly it functions. Manufacturers today offer many options that run on different types of fuel. Which one should you choose? What should you pay attention to? What criteria are important when organizing a do-it-yourself oven? The answers to all these questions can be found in this article.

Peculiarities

A good sauna stove must meet the following requirements:

- Warm up the room up to 40-50C in the lower part of the room and up to 70-80C - in the upper part. In this case, the temperature transition should be smooth.

- It is enough to quickly heat the stones and keep them high.

- Be safe, that is, the risk of carbon monoxide poisoning, burns and fire must be excluded.

Other features are at the discretion of the owner, because for someone it is important that the stove can not only heat the steam room, but also heat the water. While for other homeowners, the latter function is not essential.

Views

From what material the furnace is made of, its main characteristics depend.

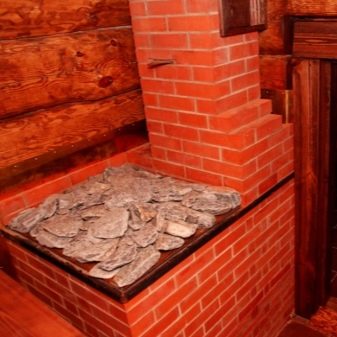

Brick

The brick unit is characterized by high weight (it can reach 1200 kg) and large dimensions. These characteristics directly depend on the thickness with which the brickwork is mounted. The design must have the following mandatory elements: a fire-resistant brick firebox, a grate (grate) made of cast iron (more reliable) or steel, an ash pan (ash is collected here), a coil (serves to heat water), a chimney (modern options have a chimney made of stainless steel or special processing of ceramics) and the foundation (the weight of the entire building rests on it).

For the construction of a stone stove, ordinary and refractory (preferably fireclay, with refractory clay in the composition) brick, sandy-clay mortar are used.

The use of cement mortar is unacceptable. - under the influence of high temperatures, such a furnace will quickly begin to collapse. In this case, the structure is being erected directly in the steam room.

Brick stoves are famous for their ability to warm up to high temperatures and retain heat for a long time - on average, up to 8 hours, although the exact period is individual and is determined by the heating temperature, the size of the structure, and the characteristics of the bath itself.

The advantage is also the high fire safety of the furnace. and the ability to use it to heat large rooms. The steam room creates soft, non-scalding steam.

However, if you decide to choose a brick oven, be prepared for the fact that it will take a long time to warm it up (on average 4-5 hours). In addition, the construction of a brick unit is a laborious and time-consuming, and therefore not cheap project.

Metal

For small buildings, especially if you value high heating rates, metal ovens are the best option. They do not emit carbon monoxide and are durable.

Such devices are compact - they do not take up much space, and they can be welded in any convenient place, and then installed in a bath.

Conventionally, such ovens can be divided into cold and hot. The former are used in those rooms where you need to constantly maintain a given temperature. The latter can usually reach 50-55C, and, if necessary, be regulated.

Hot metal furnaces are used for intermittent heating, and the maximum temperature is 100C. The disadvantage of the system is the inability to regulate the temperature regime, as a result of which there is a risk of overheating.

The ability to quickly heat up is one of the main advantages of this type of unit. The average heating time is an hour and a half. However, it also has a downside - the rapid cooling of the oven. That is why these stoves are not suitable for heating large baths. In addition, during operation of the unit, its body also gets very hot, and therefore there is a risk of burns and a fire. This can be avoided by cladding the walls and floor near the steam generator with thermal insulation material, as well as the use of a protective screen. Finally, to maintain heat, the devices need a regular supply of fuel.

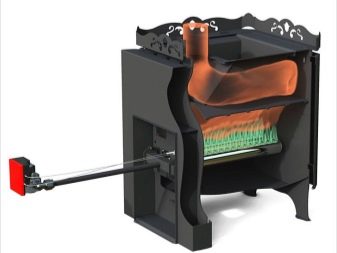

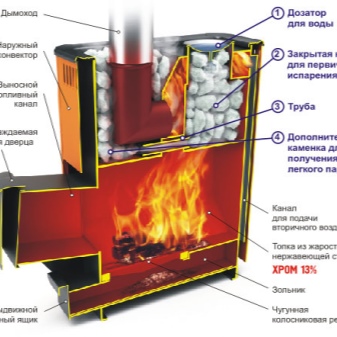

If we talk about the variety of metal furnaces, then it should be said that, depending on the design, they can be of 2 types.

- Closed. It is used for heating small areas and is a vertical "box". It is divided into 3 parts: the lower one is for storing fuel, the middle one is a container for laying out stones (stove), from where steam also comes out, the upper one is a container for water. With the help of a closed-configuration oven, it is possible to recreate the sauna atmosphere characteristic of real Russian steam rooms. The steam is humid against the background of the room temperature. A closed structure requires a lot of fuel and time to heat up, however, such a furnace will also give off heat for a long time.

- Open. An open unit differs from a closed one with an open stove, which is a grate for laying stones. Due to the fact that this element is located directly above the firebox, the steam is obtained dry, and the temperature rises to 100C. Such a stove should be chosen if you prefer dry heat in the bath, like to warm up, and not to steam.

Furnaces can also be divided into those that have a tank for heating water and do not have one. Stoves with a water tank are needed if there is no central water supply with hot water. In this case, the water heated in the tank serves for heating the steam room and for washing. The same water, by the way, is used to add water to stones. If you pour cold water on them, then the combustion temperature decreases, and the stones themselves crack.

Metal stoves with a tank can be of several types.

- With a guide tank. The water tank is usually located just above the firebox, and the heater is next to the last. As a rule, modern manufacturers offer to purchase a water boiler immediately complete with a stove, and its volume is 30-50 m3.

- With an attached or hinged tank. The water container is located on either side of the stove, attaching to it with special hooks or installing on the step. The advantage is the ability to position the tank on either side of the structure, which is convenient in small spaces. The downside is a small heat exchange between the oven and the tank, which means long and uneven heating of the water. Another significant drawback is the quality of the steam. It will not be light, but cluby, too wet. However, such tanks are suitable for a smoke sauna.

- With built-in. In principle, these models are organized in the same way as analogs with an attached tank. The difference between the first is the impossibility of separating the water tank from the stove.

- With remote control. In this case, the tank is taken out to an adjacent room (usually to a washing room, but this is not essential), and heating is carried out by a heat exchanger. Thanks to such devices, it is possible not only to heat the water, but also to heat the room where the tank is installed, and even organize a shower (for example, by lifting the tank to the attic of a bathhouse). True, in the latter case, it is necessary to take care of the powerful insulation of the attic space.

In brick structures, the tank can be located either to the side of the firebox, or above it.

The furnace part can be located both in the steam room itself, and it can be taken out outside of it, for example, into the rest room.In this case, it can be formed by a portal and turn into a kind of fireplace. Heat-resistant glass is used for the fireplace door, so after bath procedures you can enjoy the sight of a blazing flame. Another advantage is that the fireplace stove heats the rooms adjacent to the steam room, primarily the one in which it is located. It is possible to take out the firebox to the next room both in the stone and in the metal part. An important point is to provide reliable thermal insulation of the wall through which the furnace part of the furnace is pulled.

Another type of furnace structure is a structure with a water circuit., the heating of which is realized by connecting to a heating radiator or to a floor heating system. The duration of combustion, as well as the heat transfer rates in such a device, increase significantly, and fuel consumption decreases. In addition, with the help of such a system, it is possible to quickly and evenly warm up all the premises of the bath. It is important to understand that an electric pump is required to circulate the air, therefore, furnaces with a water circuit can only be used if the power grid is running smoothly.

Finally, both brick and metal heaters can be equipped with an additional steam generator. The advantage of this type of device is the ability to quickly warm up the room due to the increased volume of steam, as well as the ability to select a suitable mode of operation of the structure - with the release of dry and wet steam. In other words, the owners of the bathhouse can, at their discretion, create in it the atmosphere of a familiar Russian steam room with wet steam or recreate the spirit of a drier sauna.

Heating types

Depending on what type of fuel is used for the stove, there are several types of them. In addition, there are combined options, for which 2 types of fuel can be used (for example, gas and wood). So, there are the following types of ovens.

Wood burning

Firewood is one of the most ancient sources of energy. Burning out, they will fill the steam room with warmth and a unique aroma. Wood stoves take a long time to warm up, logs must be regularly reported to reach the desired temperature. However, their heat transfer is also high.

Wood stoves are convenient for those regions where there are power outages or gas outages, while firewood is an inexpensive raw material. The disadvantages of the device include the need to control the combustion process in order to avoid a fire, the need to regularly clean the furnace from ash. Finally, the owner will have to take care of the timely preparation of logs and the organization of a place for storing firewood.

Wood-burning structures can differ in the way fuel is loaded. There are designs with internal firewood, that is, directly in the steam room, as well as units with external firewood. In the latter case, the logs are laid in the rooms adjacent to the steam room.

Gas

The main elements of gas stoves are a thermostat and a fuse, the task of which is to control the moment the flame is extinguished, after which the gas supply stops. Unlike wood-burning counterparts, gas appliances do not have a large furnace and ash pan, which means they are mobile. They can even be placed in small steam rooms.

Such devices allow you to warm up the room in a short time. It is important that gas costs are small, as are the cost of the furnace itself and the costs of its installation.

The structure is connected to a common gas pipeline, or the owner can use gas cylinders.

Convenience is the fact that the system implies the ability to adjust the temperature - just set the desired mode. Finally, the unit does not require constant monitoring during operation.

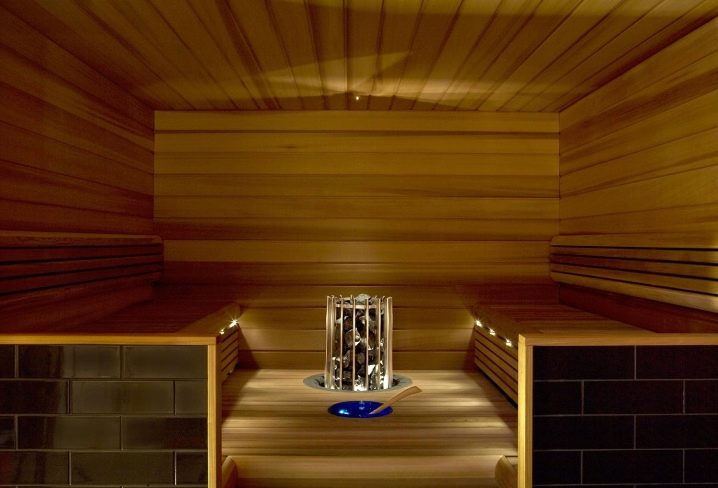

Electrical

The source of energy in such devices is electricity.The devices themselves may differ in size, power, heating time. What unites them is their compactness (they are much smaller than gas and even more wood-burning counterparts), long service life, and high thermal conductivity.

Such structures quickly heat a room (including a large area) to high temperatures, and retain heat for a long time.

They are safe, since the operation of the device is cyclical and automated, they have protection and emergency shutdown systems. In addition, when using them, the installation of a chimney is not required, which becomes the reason for their use in saunas. Finally, due to the absence of ash and smoke, such ovens are easy to maintain.

The functioning of the electrical structure becomes possible thanks to the heater, which can be of 3 types. The heating element or tubular heater is characterized by a high heating temperature, but a short-term service life. Preference should be given to heating elements made of "stainless steel". Belt structures last longer, do not dry the air. Heating is smooth, but high-temperature. The most expensive and efficient are combined heaters that combine the characteristics of the two elements mentioned above. They allow you to quickly heat up the room, while being environmentally friendly and safe.

Electric furnaces are enclosed in a decorative case, which can be metal or lined with natural stone. However, in addition to the aesthetic, the case also has a practical value - it accumulates heat, protects users from UV radiation, and the unit itself - from convection temperature drops, mechanical damage.

Combined

Such models are considered universal and can be fired with both coal (or wood) and gas (liquefied or mainline). This becomes possible due to the presence of additional removable elements in the structure. The gas burner installation here can be replaced by a container where solid fuel is placed.

The main advantage of the device is its versatility and affordability.

Forms

A metal oven can have almost any shape - it can be rectangular, round, cylindrical (both vertical and horizontal), ornamental.

Rectangular designs are the best option, since they provide uniform heating of the bath. This is due to the fact that the heating element transfers heat to the adjacent wall, which helps to reduce the temperature of the wall near the combustion chamber. As a result, the heat flows in the bath are in balance, it warms up evenly.

In addition, it is a robust and reliable design. The corners in such structures are never heated for indicators that are dangerous to humans. Finally, the rectangular oven is ergonomic, it fits well into any room.

As for the structure in the form of a cylinder, there is uneven heating of the structure., which later becomes the cause of its deformation. Strengthening its walls helps to extend the service life of a cylindrical or round structure, however, the absence of corners, even in this version, leads to uneven heating and, ultimately, deformations. Due to their small size and ease of transportation, such ovens are often used to organize a mobile bath.

If the aesthetic appeal of a wood-burning stove is important and its firebox is placed in a room adjacent to the steam room (for example, a rest room), portals are used. Thanks to them, the firebox is stylized as a fireplace, which makes the rest room more comfortable. Moreover, we can talk about a full-fledged portal (then it is possible to achieve a complete resemblance to a fireplace) or only about a metal decorative frame framing the firebox.

The portal can be made of different materials, but they are all united by one characteristic - fire resistance. The most popular framing is made of bricks, tiles (for example, ceramic), stone.Portals can be made by hand or purchased in a store.

As you can see, the shape of the oven is not just an aesthetic characteristic. Fire safety, ergonomics and, most importantly, the performance of the unit depend on it.

Design

The lining of the furnace serves not only to increase the aesthetic appeal, but also to increase the heat exchange rates, and the fire safety of the structure. As a rule, clinker, marble, terracotta tiles or majolica are used for decoration. Such options cannot be called inexpensive, but they are distinguished by an attractive appearance, and their level of heat transfer is maximum.

Application finds natural or artificial stone, among the options - granite and porcelain stoneware, serpentine, marble.

The most affordable finishing option is brick. With this design, the dimensions of the furnace increase significantly, and its weight increases. For interiors of baths, stylized as Russian antiquity, plastered stoves are suitable.

Returning to the brick cladding option, it should be said that silicate is not suitable for these purposes - it does not withstand high temperatures and is unattractive in appearance.

The characteristics of fireclay bricks make it possible to use it in humid rooms with a significant increase in temperature.moreover, it is strong, durable, that is, it is well suited for cladding. The only drawback is the need for additional cladding, if you want not only a warm and powerful, but also a beautiful stove. The optimal material is red brick, ceramic or hollow. It meets the technical requirements of use and allows you to obtain an aesthetically pleasing result.

As for brick cladding, there are 2 possible techniques for its implementation:

- Lattice masonry, that is, the bricks are staggered, and there is a gap between them (suitable for baths of a small area, since it does not take up space).

- A brick screen, which is a monolithic structure (this method is usually used if the metal structure is very hot).

Brick for lining is taken in standard sizes (250x120x65 mm), masonry - 1/2 brick. There is always a small gap between the oven wall and the lining, which is necessary for air circulation.

Among the modern proposals is a steel screen that can be worn on the stove.

However, this option, which increases the thermal efficiency of the structure, cannot be called safe. The case gets hot and can cause burns.

Baths look attractive, the stove in which is divided into 2 rooms, that is, the firebox is taken out of the steam room. It can be arranged in an adjoining common room and designed like a fireplace. Then, after the bath procedures, you can relax, enjoying the view of the blazing fire.

Dimensions (edit)

The size of the stove is directly related to its power, and that, in turn, to the volume of the steam room. The higher the last indicator, the more power of the structure is required for heating. And if more power is required, then the amount of fuel burned increases, and with it the dimensions of the furnace or the number of heating elements. In other words, large baths and stoves are required for large baths and stoves. A small structure, of course, will heat the room, but it will take an unreasonable amount of energy and time.

Based on this, it can be established that when starting to calculate the dimensions of the furnace, you must first calculate the optimal power for heating a particular room. By the way, the "reasonable" time for each type of oven can be called its own interval. For a stone structure, this is at least 4-5 hours, for a metal one, 1-1.5 hours is enough.

At the same time, it is important to understand that in winter the heating time increases, as, indeed, in the absence of thermal insulation in the bath.

The simplest calculation of the dimensions of the furnace structure is the following:

- Divide the volume of the room (that is, its length, width, height, multiplied with each other) by 2. The result is an approximate conditional capacity, sufficient to achieve and maintain high temperatures.

- The result should be multiplied by 2.5-3. This action will reveal the approximate real power of the unit, which heats not only itself, but also stones, a room, adjacent rooms. At the same time, the result obtained is valid for thermally insulated baths.

- If there is no thermal insulation, then there is another mathematical operation - the last result obtained is multiplied by a factor of 1.5.

- If it is necessary to heat not only the steam room, but also the adjacent rooms, then step 3 is skipped, and the result obtained during the multiplication in step 2 is multiplied by a factor of 2.

All of the above actions are aimed at identifying the number of kW required to heat the steam room and adjacent rooms (if necessary) and maintain a given temperature in them.

After the power has become known, we proceed to calculate the dimensions of the furnace:

- The resulting power rating should be divided by 0.5 or 0.6. The result is the optimal volume (in liters) of the wood-burning stove.

- Let's take the square root of the last result to get an idea of the linear dimensions of the firebox.

These actions were performed to calculate the optimal dimensions of the wood-burning stove. However, the relationship between the power and the size of the structure is also valid for metal options. Therefore, before buying, it is recommended to calculate the required power of the unit for heating your own bath (take into account the dimensions of the latter, the level of thermal insulation, the need to heat water, neighboring rooms).

The standard length of metal structures from the manufacturer ranges from 450-650 mm, depth - 450-800 mm, height - 800-1200 mm. There are also mini options, the width of which is less than 450 mm. Accordingly, the rest of the parameters also decrease.

If the oven is laid out with your own hands from bricks, then its standard dimensions are taken into account and the length and width of the structure are calculated. As for the height, to calculate it, the number of rows in the masonry must be multiplied by the height of the brick (65 mm). At the same time, do not forget about the thickness (about 0.5 mm) of the seams.

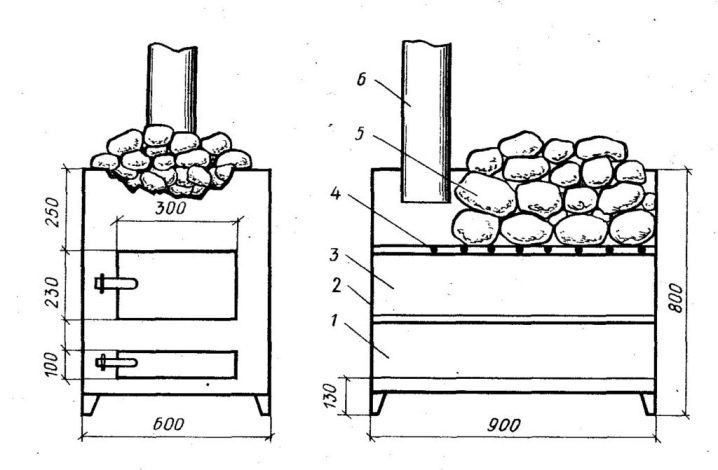

Blueprints

Despite the variety of metal assemblies, homemade stoves do not give up their positions. This is due, firstly, to their low cost, and secondly, to the ability to create a structure that is ideally suited to a particular room.

Self-assembled units usually contain ready-made elements.usually a door and a grill. It is recommended to give preference to metal parts, since cast iron ones require special fastening. In general, the structure should be made of thick layers of metal to eliminate the risk of deformation and damage.

Typical projects of a bath or sauna assume the presence of 2 fireboxes. One is for burning fuel, the second is for collecting ash and creating traction. The chambers are separated by a grill and have separate doors. Experts recommend making the same width and height of the firebox, as a rule, it is 0.5 m each.

Another grate is required if a heater is meant. In this case, it is placed at the top of the stove.

When organizing the heater and water tank, follow the guidelines below:

- Above the firebox there should be a separate chamber separated by a grate. The last one is to have a door. Its purpose is to store stones that maintain a given temperature. Special stones are used, ordinary ones (especially with silicon in the composition) are unsuitable.

- The design is also equipped with a protective window, closing which you can heat water and give steam.

- The upper part of the stove contains a chimney, which performs 2 functions at once - it removes smoke and heats the water.

- A water tank is installed on top, and in order for the water to heat up faster (that is, not only from the chimney), a chimney is put through the middle of the tank.

- The structure needs a cover, which is recommended to be made of wood, which must be protected from fire. Holes are made in the lid for steam to escape.

- A simpler and cheaper option would be to use a thick-walled pipe as the base for the lid.

When organizing a stove, great attention is paid to the chimney. First, it must have a certain height, this is the only way to create traction. Secondly, the places on the roofs where the chimney exits require additional thermal insulation. This is due to the fact that the temperature of the furnace elements is high when heated, which can cause a fire.

The most convenient, of course, is to purchase ready-made kits for arranging such a passage. Among other elements, they have an outer tube with a fungus.

If you have wood walls, you need to take care of a protective screen. The latter is also more profitable and easier to buy ready-made; preference should be given to products with reflective properties.

How to do it?

The simplest and most ancient design of a home-made metal stove is the "potbelly stove". Such an oven can be organized from a barrel by removing the bottom and lid from it and resulting in a cylinder. ½ of its part is filled with bricks placed on the edge, on top of them - a lattice. Stones are laid on the grate, a chimney is mounted. The structure is closed with a lid.

However, despite the simplest manufacture, "stove stoves" are practically not used. This is due to their low thermal efficiency with increased fuel consumption.

For baths of a small area, you can make a small-sized stove made of sheet steel, which is then lined with bricks. The walls of the firebox are laid out in half a brick, and the chimney in ¼ part of it.

Connection diagram

Those for whom operational heating of the steam room to high temperatures, fire safety and a long period of operation are important, choose electric ovens. They have almost no drawbacks, but they need a correct connection.

For ovens with a power of up to 4.5 kW, a single-phase current of 220 W. For larger units, three-phase current is required. If several heating elements are connected in parallel, you need to correctly calculate the cross-section of the electrical wires, since the current increases by 3 times.

For a single-phase connection, use a three-core cable, and for a three-phase connection, use an analogue with 5 conductors. Regardless of the power indicators of the structure, be sure to organize grounding. For safety reasons, use only copper wires, this applies to wiring throughout the room.

The cable leading from the unit to the control panel must have special rubber insulation.

Despite the variety of electric furnaces, they all have a single wiring diagram. The mains voltage is supplied from the controller of the console to the terminals, from the output terminals there are wires to the heating device. In the presence of a steam generator, it has its own wires that extend from the remote control.

One of the key elements of the electrical unit is the control panel. Thanks to the sensors, it is possible to regulate the temperature regime, activate additional functions.

The remote control is usually taken outside the steam room, for example, by installing it on the wall in the dressing room. This is due to the need to protect it from high humidity and heat. The wires from the console must be connected to a separate switch, the power of which corresponds to the power of the electrical equipment. Wall penetrations for pulling wires are pipes made of non-combustible materials. The holes themselves are sealed with cement. It is unacceptable to place wires from the control panel and electric wires in one penetration.

The set of an electric furnace usually contains humidity and temperature sensors. Manufacturers advise to mount them when leaving the steam room above the stove and shelves. For installation, only heat-resistant cables are used, which cannot be extended by connecting to each other.

Preparatory work

Metal and brick ovens require different approaches to the organization of preparatory work. The first does not need a separate foundation. The basis for it is bricks laid in 1-3 rows below the level of the finished floor surface. The next layer is a sheet of refractory material, and on top of it is an iron one. Moreover, the iron sheet should be larger than the furnace area. This will protect the floor from damage from sparks emitted from the oven.

When organizing a remote firebox, thermal insulation of the channel through the wall will be required. For this, the wall adjacent to the steam room is made of brick (refractory). A gap is maintained between the wall and the channel, where heat-insulating material resistant to high temperatures is inserted.

For a brick oven, the organization of a separate foundation is required, which is associated with the large weight of the structure. The foundation is reinforced with a mesh. After preparing the base, you can start laying. If the stove is installed in a wall, then part of the wall is cut out and insulated with non-combustible materials.

Another stage of the preparatory work is the organization of the protective screen to ensure the safety of the walls near the stove. Such thermal insulation in its height should at least correspond to the height of the oven itself. The ideal screen height is to the ceiling. The optimum thickness is ½ brick. In order to save money, a quarter of a brick is sometimes used, however, it is not necessary to guarantee the fire safety of the building in this situation.

A distance of 50-70 cm should be maintained between the stove and the screen with a remote firebox of 5-7 cm.

Subtleties of installation

Only clay-sand mortar is used for laying brick kilns. You can get a strong seam using oily clay and fine river sand. The clay is preliminarily kneaded and soaked in cold water for a day. The ratio of the components of the solution is determined empirically.

An easier way is to buy a ready-made mixture, which you just need to dilute with water. The proportions are indicated by the manufacturer. The stone oven is laid in several stages.

To increase the thermal efficiency of a metal furnace and ensure its safe use, you need to line it with bricks. This is the easiest and most economical way. In addition, special casings can be found on sale today. The latter is marked and matched to the appropriate brand of oven.

If it is necessary to heat not only the steam room, but also adjacent rooms, it is recommended to take the furnace part to the dressing room or the rest room. However, a similar system is available for wood and gas appliances; electric ovens are installed exclusively in the steam room.

For heating other rooms, you can use the underfloor heating system.

The installation of a stove involves the organization of a chimney. Metal pipes are fire hazardous, brick ones are too heavy, and ceramic ones are expensive (besides, their weight is almost equal to the weight of a brick analogue). The best option is to put a sandwich pipe that does not heat up, is lightweight and is affordable. For safety reasons, the pipe should be installed at a considerable height, and also make sure that it rises above the roofs of other buildings. It should have a mesh spark arrester on top.

For information on how to make a do-it-yourself sauna stove, see the next video.

General recommendations

It is necessary to think about the installation of the stove even at the stage of building the bath. In particular, in the area where the furnace is supposed to be installed, it is necessary to lay a shallow foundation. In the future, it will be enough to lay bricks on it in 2 layers, and you can install a furnace structure. Experts recommend making the foundation for the bath and stove different, with an interval of 3-5 mm.This will allow them not to depend on each other when the structures are shrinking.

The minimum distance between the wall and the stove in terms of fire safety is 1 m. The adjacent walls should be additionally protected with a layer of foil with a layer of insulation. A chimney from a sandwich pipe is considered to be fireproof, between the casings of which thermal insulation is also laid.

Manufacturers

When planning to purchase a stove for a bath, it is useful to get acquainted with the most worthy manufacturers of these products.

Gefest

This manufacturer is well known for its household gas stoves. It turns out that its line includes products for baths and saunas. The devices are characterized by good heat dissipation, as well as reliability and a long service life. Negative reviews about the broken units of this company are very rare.

The cast-iron stove "Gefest PB-01" deserves attention here, the power of which is 18 kW, and the efficiency reaches 87%. Such a stove will easily heat a group of rooms.

"Teplodar"

Recently, the company has been actively developing, which is associated not only with an increase in products in the line, but also with a noticeable improvement in quality. The company's catalog contains two dozen basic furnace models and hundreds of their variations. The products are reliable and compact.

Harvia

This Finnish manufacturer is known primarily for sauna equipment, although it also produces suitable devices for traditional Russian steam rooms. Moreover, exotic lovers will find even Asian infrared cabins in the assortment. All production processes are automated, so the equipment works flawlessly and has an affordable price.

On sale there are both the usual floor options and corner models - a great solution for small couples. For the manufacture of the upper part of the heaters, the manufacturer uses steel about 1 cm thick, which guarantees high heat transfer and a long service life of the unit. For the exterior design, fire-resistant paint is used, therefore, even after years of use, the stove retains its visual appeal.

Kastor

Finnish-made stoves have more than half a century of history, are well known in the world market, and today they are gaining more and more popularity in Russia. The first thing that buyers pay attention to is the elegant appearance. Unfortunately, domestic models cannot yet boast the same aesthetic appeal.

However, the "appearance" in the oven is not the main thing, however, it is also difficult to compete with the reliability and thoughtfulness of the models of this brand. Their electric heaters, which have no analogues in the world, are considered especially successful.

Rapid heating of the steam room is achieved not only due to hot stones and heat radiation from the unit, but also due to convection.

Once inside through a special hole in the lower part of the structure, cold air heats up and rises to the ceiling of the bath. In addition, such devices have a special protective plate that prevents carbon monoxide from entering the room.

Finally, the products of this brand can be installed even in small spaces., which is associated not only with the compactness and ergonomics of some models, but also with the presence of a double casing. As a result, the heating of the outer walls is reduced, as is the fire hazard of the structure, so it can be placed closer to the walls of the bath.

"Troika"

The domestic brand "Troika" is one of the best manufacturers of wood-burning stoves for baths, however, their range also includes gas-fired units. Reliability, durability, ergonomics - these are the distinctive features of the products. The heating time of the structure is 1.5 hours. The weight of stones in the ovens can reach 250 kg, which means that the steam will be in the best Russian traditions - light, dry, transparent.

The stoves are made of metal and can be used as standard or bricked. There are also models decorated with soapstone and serpentine.

Finally, this manufacturer is engaged in the manufacture of custom-made furnaces, as well as tests and, if necessary, improvement of the samples obtained.

"Locomotive"

The manufacturer claims that its products combine the best features of stone and metal stoves. Units of this brand are characterized by high speed and quality of heating, no need for regular repairs, durability, and ease of installation.

The name of the product finds echoes in its appearance - the stoves are quite massive, brutal, with pipes in the upper part. They produce large volumes of steam.

In the manufacturer's catalog there are metal-ceramic structures, the furnace part of which is made of metal, and the body is made of stone.

A feature of the designs is a round firebox, which, according to the manufacturer, provides better combustion and a longer service life of the furnace. The brand's collection includes stoves with a different type of steam, that is, you can choose a unit for a bath in white, black, and there are also models equipped with steam cannons.

The volume of the heater is also impressive, in some devices it can reach 500 kg - an excellent solution for lovers of steam and large saunas.

"Geyser"

Another domestic brand, whose products can boast of good heat dissipation, high heating rate and structural reliability. It is worth noting the accuracy and ergonomics of the models.

The structure is based on ligated heat-resistant steel, all welds are double, which ensures a long service life of the furnace, its resistance to temperature extremes.

The heating time is 1-1.5 hours, but the heat in the bath is already 30 minutes after the start of kindling. By the way, thanks to good draft, the stove is heated even with damp wood.

Another distinctive feature of the models is the peculiar design of the cast-iron grate, due to which, if necessary, it can be changed. Models are available with a metal door or heat-resistant glass viewing window.

Reviews

When choosing a stove, it is useful to read reviews and independent customer ratings. For example, the products of the brands Harvia, Helo and Kastor are especially trusted when it comes to electric furnaces. The first manufacturer is the undisputed leader producing products that optimally meet the “price-quality” requirement. If you are looking for a stove with a stylish and unusual design, it is better to immediately familiarize yourself with the Helo offers. Kastor, according to users, is more suitable for small-sized steam rooms, due to the small volume of the heater.

As for wood-burning stoves, the leading positions are occupied by constructions of Finnish and domestic production, especially models with a tank, so beloved in Russia.

If the means and dimensions of the bath allow (load-bearing capacity of the floor), then preference is given to cast-iron stoves. This is due to the high efficiency of the device, long cooling (up to 10 hours), reliability and durability. Buyers note the high performance of the stoves by the Swedish manufacturer Keddy (an expensive option) and the domestic brand Sudarushka (a more affordable option).

Tips & Tricks

One of the main criteria that you should pay attention to when choosing a sauna stove is its power. At the same time, it is better not just to focus on some universal digital indicators. It is important that the power is appropriate for the specific room.

A big mistake would be to purchase a unit with too much power. This mistake is often made by those who strive to quickly heat the bath in a short time. Of course, the room will quickly become warm, but after that the unit will start operating at minimum mode. The result is scalding air in the steam room and cold stones. It is pointless to pour water on them, since the steam in this case will not turn out light and transparent, but thick, like from a kettle.Being in such a room is not just unpleasant, but unsafe.

The other extreme is buying a low-power unit in order to save money. Of course, the device turned on at maximum modes will quickly and efficiently heat the room, but there is no need to talk about a long service life. Like any equipment that works for wear and tear, the stove will quickly fail.

To determine the optimal power of the device, it is necessary to determine the volume of the steam room. The latter is calculated by multiplying the width, length and height of the room.

If the latter contains non-insulated areas (for example, tiling, windows), then you need to calculate their dimensions (multiply the width and height indicators). If there are several such areas, add up the resulting areas of uninsulated areas. The next step is to multiply the resulting value by a factor of 1.2. The resulting result is summed up with the volume of the steam room.

Often the doors to the steam room are double-glazed windows. In this case, add 1.5 to the figure obtained above.

Let's consider this recommendation with a specific example:

- Let's calculate the volume of the steam room, the width of which is 1.5 m, the length is 2 m, and the height is 2.2 m. Multiplying these data, we get a volume of 6.6 cubic meters.

- The steam room has one window, 60x60 cm in size and a tiled area, the size of which is 100x100 cm. Let's calculate their area, and then add up the results - the figure will be 1.36 square meters. m. Now we multiply this figure by 1.2 (constant coefficient), the total is 1.623 m2.

- We add the volume of the steam room and the area of non-insulated sections, that is, 6.6 and 1.62 We get 8.232.

- Suppose there is a glass door leading to our steam room, so we add 1.5 to the last result, 8232. The final figure is 9.732 m3.

It is this indicator that should be guided by when choosing the power of the furnace. Please note that manufacturers usually indicate power characteristics in intervals. For example, 4-9 m3. The unit should be purchased with a small power reserve. That is, for a volume of 9, 732 cubic meters. a device is required not for 4-9 m3, but for 7-12 m3.

There is also a simpler formula for calculating the required power of the stove in relation to the area of the room. It is believed that heating 1 m3 of a room requires 1 kW of power.

If we talk about choosing a metal furnace, then the best option is chrome steel devices. They do not burn out oxygen in the room, the steam remains clean, light. As for the cast iron counterparts, they are durable, but they are afraid of temperature changes and can simply burst.

Before buying a stove, check if it is intended for a sauna or bath. The fact is that sauna products are not suitable for use in a sauna and vice versa. The only exception is the Vetruvia model from the Termofor manufacturer.

When buying heavy metal stoves, especially cast iron ones, make sure that the floor in the steam room is ready for such loads.

Recommendations for the selection of electric furnaces can be summarized as follows:

- Give preference to structures with thick walls.

- When buying a gas oven, specify how much gas it is designed for. The heat transfer rates and the efficiency of the device will depend on this. Each burner has its own threshold for fuel consumption, at which a certain power is generated. If the power received is not sufficient to heat your space, choose a stove with a large burner capacity.

- When choosing any oven, carefully inspect it - all connections must be sealed, the body must not be damaged, no scratches or cracks.

Beautiful examples

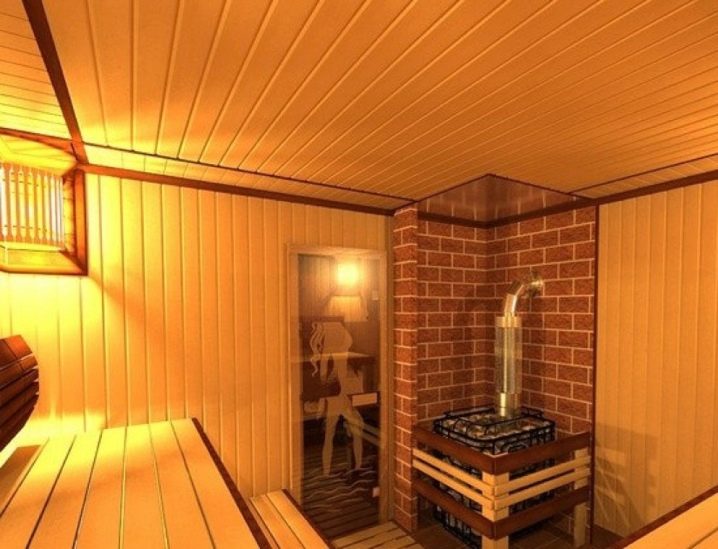

It is not enough to buy a high-quality stove for a sincere sauna rest. Care should be taken to ensure the comfort and aesthetic appeal of the entire room. Of course, a steam room with a stove will become his heart.

Russian interior

Most of our compatriots associate the bathhouse with a national, Russian flavor, and therefore the premises are decorated accordingly. The Russian style looks best in wooden baths made of logs or timber. Like the floor, wooden walls do not require decor.

The stove is large, faced with bricks, tiles, or simply whitewashed. Simple wooden benches and a large welcoming table in the seating area complete the interior. As you know, a Russian person is thrifty, and therefore in the dressing room and the rest room you can often find an old sideboard or armchair, which have already served their time in the living room and now decorate the bathhouse. The details include multi-colored homespun rugs, bunches of fragrant herbs suspended from the ceiling and, of course, a samovar.

Country

Country style also belongs to the rustic, but here you can feel the influence of other countries, primarily France and America. French country is more sophisticated, light. To create it, use wood furniture with carved details, varnished, possibly artificially aged. Natural materials - linen, cotton with elegant floral embroidery. Tableware of bright colors can become a highlight of the interior. On the ceiling, there must be wooden beams, the floor is plank or tiled.

Eastern traditions

An oriental bath is a hammam, therefore, first of all, you should purchase a stove that gives high temperatures and humid steam. However, if you do not like such procedures, you can leave the usual spirit of the steam room, and embody the aesthetics of the East with the help of decoration.

First of all, you need to take care of the walls and floors. It should be a mosaic of bright colors, fantasy patterns, the traditional "oriental cucumber" pattern, and plant elements are welcome.

The scope of imagination can be given when decorating a rest room, turning it into a real hookah. To do this, create a tent made of airy organza, scatter pillows on a small elevation, get bright tea bowls.

Scandinavian style

Scandinavian style is environmental friendliness, simplicity and naturalness of materials. Wall decoration - wood, brick, whitewash. The colors are light, natural. The style does not tolerate something superfluous, complicated, rude.

However, a few bright accents will add originality to the room and complete the interior. These can be, for example, bright lampshades in the recreation room.

As for the steam room, the classic reigns here - wood trim, better in light colors.

Exotic in Japanese

In a traditional Japanese bath, there are no stoves; they are replaced with round barrels of steam. To achieve the style of the Land of the Rising Sun, it is recommended to purchase an electric furnace with a steam generator, which has a barrel shape. As a finish, wood or natural stone is used for it.

When decorating a restroom, give preference to furniture with short legs. - an ottoman and a small table will be enough. Complete the interior with bamboo screens, a miniature bonsai tree, and fans on the walls. Take care of a tea set of the appropriate style.

An updated classic

This option is good for brick or cinder block baths and involves the use of natural finishing materials, the use of calm shades, the presence of arches or small columns. The floor is usually tiled, the furniture is classic, laconic geometric shapes.

Modern

Rarely enough, this style is used to decorate baths, since it is not associated with the usual atmosphere of a steam room. However, the Art Nouveau style looks good when decorating a washing area, a rest room. Its basis is bright colors, modern materials, glass and chrome surfaces. Do not be afraid to experiment with a combination of bright colors, unusual shapes. The presence of multi-level ceilings and several lighting systems is mandatory.

In the rest room, you can put furniture or bean bags of an unusual shape, decorate the walls with printed prints.

Designers recommend refraining from eclecticism in the bath, since it does not differ in impressive dimensions. The combination of several styles will look pretentious, annoying.

When styling, avoid over-decorating the steam room, which is again due to its modest size and very specific purpose. The best design for it would be a combination of 2-3 types of wood or mosaic ceramic elements.

When decorating a bath, strive to ensure that all rooms are stylistically uniform. It is important that the design idea is read in all corners of the bath.

The comment was sent successfully.