We build a bath from a bar

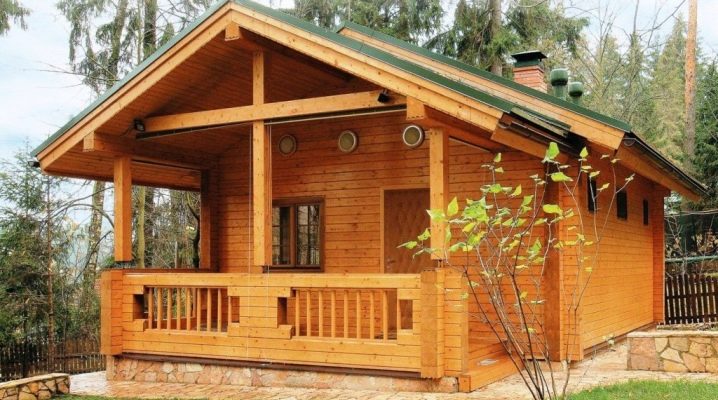

A personal bath, built on a summer cottage or in a private household, for many people today is an indispensable attribute of comfort and a healthy lifestyle. In terms of quality, aesthetics and service life, a bathhouse made of wooden beams almost does not differ from a similar structure made of cylindrical logs, but the process of its construction is much faster, much easier and does not require special professional skills.

Peculiarities

Actually, the baths in the form of a log house are among the primordially Russian buildings, and the tradition of their construction dates back to the times when in Russia all buildings were built for centuries, soundly and without a single nail. It is quite natural that the work on their construction has its pros and cons. So, the construction of the bar itself is notable for its ease and speed, but then requires its long-term drying, which takes about a year.

The implementation of the plan allows you to do without the help of outside labor, but the frame can shrink with minor deformations, however, easily removable.

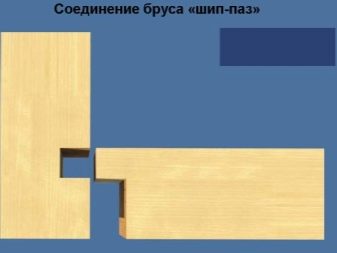

The bar is equipped with a thorn-groove system. This fundamentally connects all parts of the structure, but since we are talking about a tree, the degree of its fire hazard should be taken into account. The material itself is not resistant to the negative effects of microorganisms, wood pests, insects and molds, however, thanks to the sealant, the building as a whole is protected from rain.

For the construction of a log house, a solid foundation is not required, and the entire structure does not need additional finishing. In addition, the timber is at an affordable price.

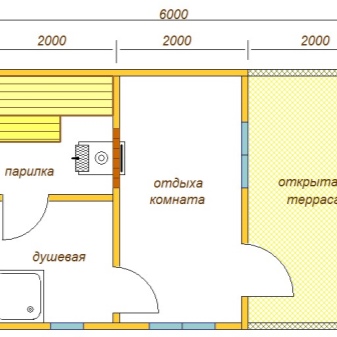

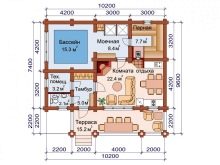

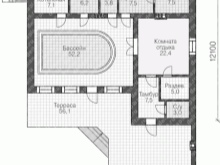

Calculation and layout

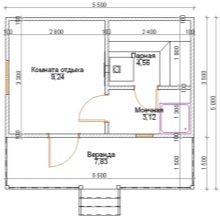

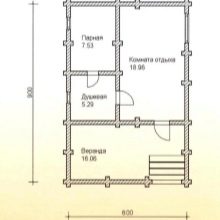

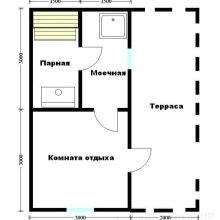

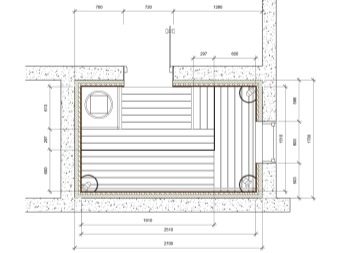

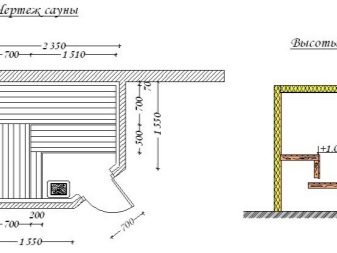

The manufacture of such a bath should begin with its design, which is based on a drawing drawn up based on the structural features of the structure. Here we mean the simplest one-story building or a house equipped with an attic or a veranda, or both. It is also useful to draw up an instruction, taking into account the required material and stages of construction.

The dimensions of the structure are selected based on the need to create comfort for all visitors and the fact that all modern baths can be classified into two types.

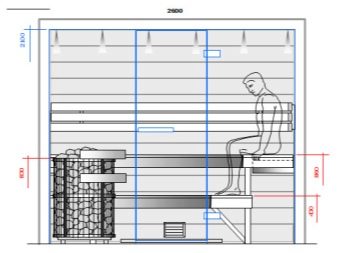

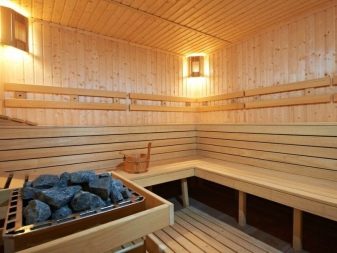

Buildings of the first type refer to dry baths with a temperature of about 60 - 110 degrees Celsius and a humidity of about 5 - 25%, that is, saunas.

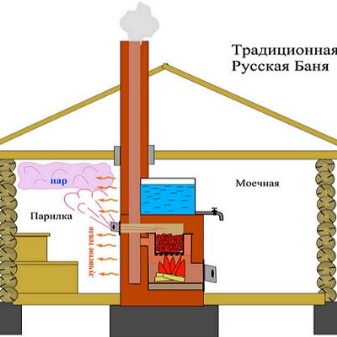

The latter, called Russian baths, are damp steam rooms with a temperature regime of 50-70 degrees Celsius and a higher humidity level, which is 80-100%. This option is a wooden building equipped with a warm dressing room, a washing room and a steam room with a stove and shelves.

The Finnish sauna is a steam room with stones, from which the air in the room is heated and onto which herbal infusions or essential oils are dripped.

As for calculating the required amount of timber, the thickness of each structural element should be taken into account, depending on the planned area of the structure and the amount of material that will have to be rejected. In this case, the amount of timber per cubic meter of volume is taken taking into account the perimeter of the room, which is multiplied by the thickness and height of one timber. This also includes the amount of material for interior finishing work.

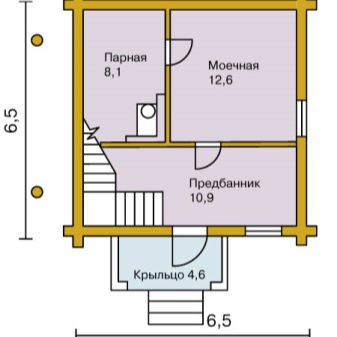

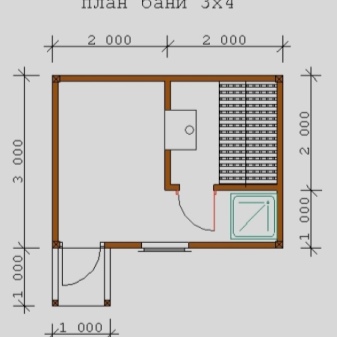

This design includes the number of rooms in the structure and their size, taking into account the fact that approximately 4 m2 of the steam room area should be allocated for one person and with the obligatory calculation of the space for the stove. The foundation of the latter is being built simultaneously with the foundation of the entire structure. Its quality is the main criterion for the durability of any bath. For this, a building foundation scheme is developed at the design stage.

The steam room, dressing room and vestibule are mandatory elements of a Russian bath.

Views

It is quite natural that it is much easier and faster to get a finished project of a bath from a bar, especially since modern manufacturers offer a large number of mobile kits from bath log cabins and other materials for their manufacture, which can be ordered, delivered to the site and mounted on it in the vast majority of large Russian cities.

First, you should decide on the appearance of the future bath and what structural elements are required for it. So, for example, one of the most common types of two-story baths is a building with a veranda and an attic under the roof. The second floor is a summer bedroom where you can spend the night after a bath or give your friends the opportunity to stay there for the night, and the veranda with such a bath will be a wonderful place for evening tea.

If you equip a barbecue in the yard, then an excellent option would be to build a bath with a terrace, which should be wide enough and as open as possible. The brazier itself can also be installed there. A little later, an artificial pond can be built in front of such a bath, which will be a significant advantage in comparison with conventional steam rooms with a pool.

A simple one-story bathhouse with a fairly wide veranda is one of the most common types. such buildings. It is better, of course, to glaze the veranda itself, which will make it possible to turn it into a summer bedroom, equip a kitchen there or install a billiard table there.

For adherents of the traditional Russian steam room, an excellent solution would be to equip it with an equally traditional wide porch, where you can successfully place a table with a samovar and enjoy the views and fragrance of the surrounding nature.

Another curious type of sauna architecture is the house with a steam room, which has a veranda, but under a very wide roof. The advantage of such a structure made of profiled timber is the presence of a covered veranda and an attic with a huge usable area.

In the traditional view, the bathhouse looks like a compact building with small windows., which do not seem to require a large size. Indeed, the windows in such a room are looked at from a utilitarian point of view, assigning them the role of ventilation and natural lighting with minimized heat loss. Nevertheless, bathing procedures can be organically combined with admiring the sunset or the surrounding landscape. For this purpose, there are new creative options for bath houses with panoramic windows.

They not only make it easier to ventilate and dry such a room, but also increase its safety, as they are an additional emergency exit.

These are the main types of log sauna buildings. Having familiarized yourself with them and knowing that, due to the peculiarities of the wood, they are all constructed for shrinkage, one should proceed to a description of the technology for their construction.

Required tools and accessories

To begin the construction of a bath from a bar, you should create the necessary set of tools and accessories for this. Since the building beam is made of wood, standard carpentry tools are required to work with it. Therefore, it will be necessary to prepare axes, carpentry planers, various hammers, hacksaws, electric and chainsaws, pliers and pliers, nail pullers, chisels, chisels and jigsaws.You will also need rulers and tape measures of different lengths, plumb lines, corners and levels.

To protect wood from beetles and microorganisms, it will need to be treated with an antiseptic compound, which will require a brush and a special tray.

Any construction begins with the construction of the foundation. Therefore, there will be a lot of physical work, it will be necessary to dig, transport and drag. Moreover, even if the technique is used, bayonet and shovels, wheelbarrows, manual or electric concrete mixer still cannot be done without bayonet and shovels.

In the absence of an electric concrete mixer, it can be replaced with a trough, cut along a metal barrel or a box welded from sheet steel and a corner.

Since the beam will have to be lifted and advanced to a height, a winch or other lifting mechanism will be required.

Laying insulation will require the use of a construction stapler with staples, a knife, an electric drill, a screwdriver and a grinder with a set of discs, an electric or chainsaw.

How to build with your own hands?

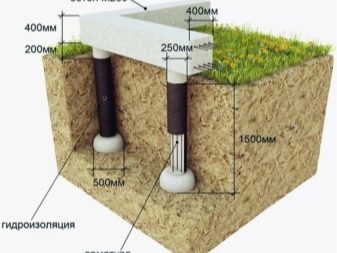

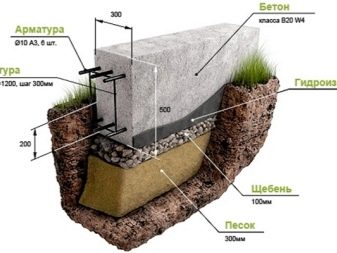

Regardless of whether we are building a bathhouse on our own or using the services of specialists, its construction should begin with laying the foundation. Moreover, if we are talking about a one-story structure, then a columnar foundation will be sufficient for its construction. If the bath has 2 floors, then a more solid strip foundation will be required for it.

The columnar version of the foundation is erected by making brick pillars. They are installed at the corners of the structure, along the inner walls and along the entire length of the perimeter of the future bath. These are 0.5 m high pillars installed at 1.5 m intervals from each other in pits 40 cm deep each. A concrete pad is poured into each such hole before the brick is laid.

For greater strength, the pillars are reinforced.

If we are talking about a strip foundation, then for its manufacture a ditch is torn off, at the bottom of which rubble or sand or gravel is poured in a layer 15 cm thick and formwork from boards is installed. Inside the latter, a reinforcing frame is made and poured with concrete.

Regardless of which of the two types of foundation we are pouring, it is necessary to waterproof it by laying two layers of the appropriate material, which is most often played by roofing material. The horizontal surface of the foundation is filled with molten bitumen, on which roofing material is spread. This procedure is done twice.

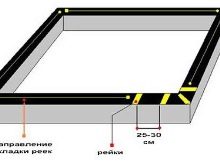

The part of the foundation protruding above the blind area should be at least 15 cm high, and its width should exceed the width of the timber by 10 cm. Thin slats are laid on it along the entire length of the foundation, which are pre-treated with an antiseptic. The height of such slats should not exceed 15 mm, and they fit with an interval of 25-30 cm from each other. This gap is filled with insulation, and they serve to protect the timber from moisture and decay in order to extend the life of the bath.

The first row consists of beams with a section of 20x20 cm. Profiled beams with a section of 15x15 cm are placed in all subsequent rows, provided that all the beams are of the same length. This is due to the fact that the timber of the first row bears the load of the entire structure from the walls and roof of the structure. Such beams must be perfectly flat with a minimum horizontal deviation, which is determined by means of the building level.

Too dense laying of a log house is not required in this case, since later the entire structure will shrink. The lower beam, laid directly on the foundation, does not need to be fastened, since all the overlying rows of the timber structure will press on it, giving it the necessary strength. The first row is then treated with antiseptic or mineral machine oil. Then an insulating layer consisting of moss or tow is laid on the surface of the first crown.

The same procedure is carried out with all subsequent rows of beams.

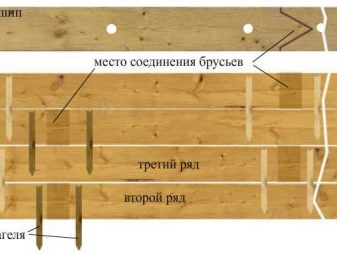

To fasten the stacked crowns, wooden pins or steel pins are used. They are driven into pre-drilled holes, the diameter of which must be equal to the diameter of the fasteners. It is necessary to drill such holes every 1-1.5 m so that the drill drills through the upper beam and captures half the height of the underlying one. Next, the lower bar must be removed, and pins with a length corresponding to the height of the two bars must be driven into the holes, then the insulation layer is laid. After that, the upper bar is installed in its place.

All crowns are installed by this method. Of these, the top two do not need to be touched, because at the last stage of the construction of the bath, ceiling beams will need to be installed and these crowns will need to be temporarily removed for this.

Sheathing

Wood is the optimal material for interior decoration of all bath rooms. For this purpose, lining should be used without defects and of the highest quality and not overdried. She needs to be given the opportunity to adapt to the microclimate of the bath, so that at the end of finishing work, she does not begin to change its structure and swell. Any bath requires high-quality heat and waterproofing. To maximize its service life, it should be insulated and heated wall surfaces protected from fire.

The main room of the sauna building is the steam room. The maximum temperature is maintained in this room, therefore, deciduous lining of birch, linden or aspen is used to decorate its walls. This material is used because it does not release resin when heated strongly. Hardwood dries quickly and does not overheat, so that mold does not accumulate on the surface of the walls.

Ash, which has long been used by Russian craftsmen in the construction of baths, is no less interesting, durable and aesthetic material for such decoration. Ash is very durable and immune to decay processes.

This should also include alder lining of a light, slightly pink hue. This material is also appreciated in Europe for the absence of extraneous odors when heated and for its high strength characteristics.

There it is readily used for interior decoration of saunas.

For washing rooms, rest rooms and dressing rooms, coniferous wood is used. When heated moderately, it emits a pleasant woody smell. They also prefer to make bath furniture from it.

Natural fumes of a natural character from coniferous lining have a healing effect on the state of the human nervous and immune system and the upper respiratory tract. In addition, the spruce board of a beautiful yellowish color has pronounced moisture-repellent properties.

As for the dressing rooms, pine lining is the preferred material to give them the necessary comfort, beauty and hygiene. This highly economical material can be found in several color variations ranging from slightly yellowish to red. It is durable, easy to install, and the resins it releases prevent decay processes. The pine type of lining for finishing the walls of the dressing room can be easily repainted or subjected to other decorative processing methods, although the main preference is given to the natural color of pine.

Other materials that allow you to insulate and decorate the walls of the bath from the inside are gypsum fiber and plasterboard sheets, river pebbles, tile ceramics and even plastic plates. GKL sheets should be green, which is used to paint moisture-resistant drywall.

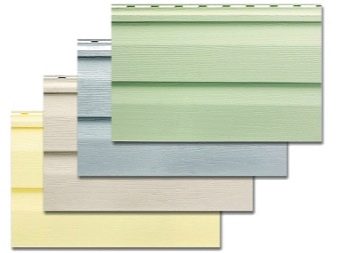

Outdoor decoration

Siding is one of the most famous outdoor finishing materials, but it is more suitable for brick buildings, because it is extremely weakly air-permeable.If for a brick bath this circumstance is not of fundamental importance, then for the wooden walls of a timber bath the lack of the ability to "breathe" under the siding is very significant.

The lining, which was discussed above, allows you to equally successfully clad the bath both inside and outside. If we are talking about external wall insulation, then a crate frame is required, on which steam and heat insulating material will be laid. On top of the latter, a second crate is stuffed, which is the basis for the installation of finishing material, the moisture content of which should be no more than 15%.

Facing with a block house is an ideal opportunity not only to aesthetically decorate the bath from the outside, but also to insulate it without the use of heat-insulating material. The block house is mounted like a lining on the wall or on the crate or directly on the wall. Thermal insulation is not needed in this case.

Another progressive finishing material for a log bath is an imitation of a bar.

It differs from the lining by its greater thickness and cost, while retaining all its qualities. This natural decoration material is used for interior and exterior wall decoration.

The walls of a wooden bath are decorated with facade tiles by attaching the latter to the crate with self-tapping screws. Such tiles are distinguished by their neat aesthetic appearance and considerable durability, protecting the wood from destruction.

In general, the external decoration of the bath is not so obligatory. If a sufficiently high-quality timber went to its construction, then it will be enough to paint the walls or cover them with varnish. Before this, the tree is impregnated with an antiseptic and cracks in the beams are repaired, if any. After the surface treated in this way has dried, a layer of primer is applied to it and staining is performed, which, if necessary, can be done twice.

Materials (edit)

The main materials from which wooden baths are built are profiled and glued and rounded logs. Regarding the latter, it should be said that in popularity this material for the construction of suburban buildings is not inferior to a bar.

The main feature is the processing of each log on a special cylindering machine, as a result of which each log acquires the same diameter for the entire batch along its entire length. At the end of such grinding, mounting grooves are selected in the logs along the trunk and locking joints are made for the corners. The finished rounded log is processed with special compounds to give the necessary resistance to adverse external influences.

The presence of the same profile along the entire length extremely speeds up and facilitates the process of assembling a bath or a house from such a log. Such timber can be solid, glued and profiled.

A solid bar is the result of cutting off the four sides of the edge at the log in woodworking enterprises and giving the product a square or rectangular cross-section. The main advantage of such a bar is its low cost.

Glued laminated timber is made by gluing wood planks, called lamellas, under a press.

If the solid timber has natural natural moisture, then the glued timber is subjected to industrial drying, as a result of which its moisture content is reduced to about 15%. Thanks to this processing, double or triple glued laminated timber at the end of the construction of a bath or a house from it does not shrink and does not crack during operation. For the production of such products, only high-quality wood is used without rot and wormholes.

Profiled timber also has natural moisture, but unlike a log, it is not "led" in the wall of the building, that is, it lies as it was installed. The working surfaces of each individual bar are given a "tongue-groove" or "comb" profile. For its production, round wood is dismissed into a billet in the form of a bar.

The groove-comb system allows you to tightly fix the individual beams together and do without a seal. A bath made from such a bar does not have to be finished and putty. To make the building attractive and look decent, you just need to paint the building. Dry planed timber must be impregnated with antiseptic and fire-resistant compounds to extend its service life.

In addition to the fact that the wall made of profiled timber does not need additional finishing, this material itself is much less susceptible to deformation during the operation of the house. Structures made of profiled timber give much less shrinkage and do not crack in comparison with structures made of logs. The length of the profiled beam can reach 12 meters, which significantly expands the possibilities for the design and construction of objects from it.

Dimensions (edit)

The size of a wooden bath should be calculated based on how many people will take bath procedures in it. Some people prefer to do it alone or take turns to go to the bathhouse when their funds do not allow them to build a large enough structure for a large company. In this case, the total size of such a bath can be about 4x3 or 4x6 meters. Such a small bathhouse can be made as an extension to the house.

In such a situation, there is no need for a dressing room, and the area of each room is reduced to the bare minimum.

If we are talking about a separate sauna building for a small family, then its frame should be about 5x5 or 6x6 meters in size. It is quite natural that for such a separately built bath there is a need for a dressing room. It will serve to protect the interior from frost and wind and a place for drying and storing brooms. It will also be possible to store some of the firewood in it.

To give the structure maximum convenience, it is highly desirable to have all the necessary premises in it, that is, a steam room, a dressing room and a vestibule. The height of the ceiling for all premises of such a bath should be designed depending on the height of the tallest member of the family.

As for large-sized structures designed for visiting large enough groups of people, their size can reach up to 100x100 meters, if funds allow. In such cases, the washing process itself fades into the background, so the area of the steam room and the room should be made larger. The size of the steam room in such a bath, however, should not be too large, since such a bath has to be heated for a long time and it is difficult to maintain a sufficiently high temperature in it for a long time.

Manufacturers and reviews

The success of any company directly depends on the demand and popularity of its products. Many forums discussing the construction of log baths and the acquisition of ready-made structures of this type are replete with positive feedback from the owners on the products of such Russian manufacturers as SC "Dobrynya", "Lesstroy", "Domokomplekt"... Turnkey workmanship, durability and a high level of operational parameters are the dominant criteria for choosing baths from these manufacturers.

Beautiful examples and options

All people are distinguished by the widest range of tastes and preferences, therefore, everyone puts their own meaning into the concept of "beautiful bath". However, there are several factors that directly affect the aesthetics of a given structure. As a basis, you can take a configuration that makes it possible to choose between such options as an angular type of bath building or steam rooms with a gazebo, rectangular configuration, polygons, baths with a bay window, an attic and the like.

Regarding the interior, it should be said that it directly depends on the choice of the owner, who must take into account that the configuration of the bath should be in harmony with the house itself.

At the same time, the planning of the future building should be made in such a way that not only the traditional steam room with a dressing room and a relaxation room would harmoniously fit into it, but also it was possible to build a bathhouse with a bedroom in which you can take a nice nap after relaxing bath procedures.

A bath made of profiled or glued beams is the result of the work of many professionals, after all, the work of not only architects, but also engineers, technologists, designers, and, when building with their own hands, the owners of a private house or a summer cottage, have been invested in its project. In any case, its construction requires the highest quality modern materials and technologies, and each individual case provides its own solution.

For an overview of the technology for building a bath from a profiled bar, see the next video.

The comment was sent successfully.