Kiln clay

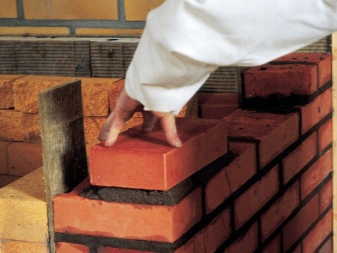

The stages of the construction of the furnace do not tolerate deviations from the accepted norms, and the binding material must comply with them. The strength and durability of the structure depends on the quality of the masonry mortar.

Peculiarities

Clay has been used as a raw material for a kiln since ancient times. To prepare the correct solution, it is necessary to observe the accuracy of the selection and balance of the components.

- Clay. The main part, it is she who gives the solution viscosity, heat resistance, fire resistance. Not all types are suitable for cooking: different breeds contain many impurities that affect the result. Since getting rid of them is not always possible, doing this is very problematic. One of the important parameters in the construction of a stove is its impermeability, that is, tightness. Therefore, the clay must be checked, its qualities are tested: the material has three fat content indicators - normal fat content, medium and high.

- Sand. The second most important ingredient. You can get it yourself, but at the same time you need to remember the requirements: it must be homogeneous and free of impurities, which means it must be cleaned and sieved. Experts prefer river sand, considering it the cleanest.

- Water. You do not need to treat it dismissively - it should not contain foreign inclusions. You can use only well-settled clean liquid, otherwise this will inevitably lead to a decrease in the quality of the batch and the final result when heated to high temperatures. The best option is drinking water.

When preparing for work, it is advisable to have all the components with a good margin. It will be required for mixing samples, replacing the solution, if it turns out to be of poor quality. Quality clay paste is a refractory material that can withstand exposure to open flames. However, it is rather limited in scope. The most suitable for its use are the firebox, chimney and other heat-accumulating structural elements.

The clay is characterized by reliable adhesion and remains effective for many decades even under intense loads up to 1000ºC.

Clay mortar has several advantages.

- Environmental friendliness. In the composition, only natural safe components are used that do not emit substances hazardous to humans and the environment.

- Availability. All components can be found near human habitation, it is easy to get and make a batch with your own hands. In addition, ready-made mixtures are on sale.

- Easy dismantling. If you need to repair the furnace or its section, you will not have to spend significant efforts. The dried mixture separates well from the bricks, leaving them clean and intact.

However, there are conditions that are necessary to obtain a high-quality furnace mixture that can serve for coating a hog. They make it possible to use the resulting heat-resistant mixture. Good clay for stoves and fireplaces is mined at a depth of about 5 meters - it is there that layers of pure material are located, without organic impurities.

Compositions based on it are coated on the outside of heating structures, used for plaster. Clay is indispensable in stoves for summer cottages and houses. Unfortunately, the preparation of a binder that meets all the requirements will take a lot of effort and time.

Quality control methods

Experienced stove-makers never use a solution without checking its quality indicators. It happens this way: the finished clay paste is applied to a trowel and turned over. A good quality solution will not fall off. The degree of fat content is determined in the same way: if the composition is fat, then it adheres well to the construction blade. If the fat content is not enough, and the amount of sand in the paste is exceeded, the solution will fall, separating from the surface of the blade.

Drying method

The technology is simple and not complicated at all. The master kneads 5 test pieces of clay paste, rolls a small ball out of each, and then crumples it into a cake. The easiest way to do this is by placing the bun in the palm of your hand and pressing down with the fingers of the other hand. All koloboks are marked with the percentage of sand.

The resulting cakes are left to dry, this will take 2-3 days. After a period of time, they are examined for cracks and strength - the cake should remain intact when squeezed. Then each piece is thrown onto the floor: a high-quality composition should not crumble.

According to the research results, the optimal ratio of ingredients is determined.

With the help of the veselka

The specialist needs to know the degree of fat content of the clay before he starts preparing the batch. To do this, he uses about 2 kg of material, mixing it with water. The resulting solution is mixed with a wooden paddle, carefully examining it.

- A large layer of adhered clay indicates a high fat content. If necessary, it is lowered by increasing the amount of sand.

- If small pieces of clay remain on the bar, then this is an indicator of the optimality of the composition, which means that it does not need to add sand.

- If the veselka is covered with a clay film, this indicates a lean composition and indicates the need to add more oily clay.

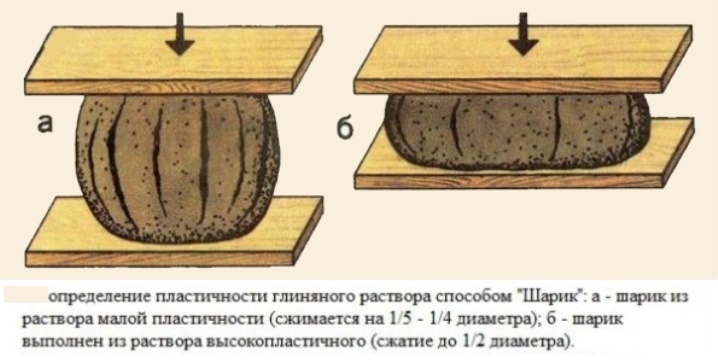

With planks

An absolutely simple way: small balls of about 3 cm in diameter are rolled from the finished clay paste. Each ball is placed between two boards with a smooth surface, gradually and gently squeezing, periodically checking the result. If the ball cracks immediately after squeezing, then this indicates that the mixture is skinny and lacks fat content. When cracking occurs when squeezed in half, this is an indicator of too much fat content. The best option when the ball is flattened, but not destroyed.

other methods

A little more detail on the 5-part method mentioned above. It is necessary to mix 5 parts with a different composition of the clay solution:

- the first one consists of one clay;

- to the second - add 25% of sifted sand;

- in the third part, the sand is already almost half;

- for the fourth, sand takes up more than half of the composition:

- a fifth is 75% sand and 25% clay.

All parts are kneaded separately, bringing to the state of a dense paste. They regulate the quality of the paste with water and sand. Readiness can be determined by touch - if the composition does not remain on the palms, then it is ready. In addition to the above methods, kiln clay is also tested before laying. No matter how the soul resists this, it is better to remake the ready-made solution than to fold a low-quality oven, and then waste energy, time, and money on correcting mistakes.

The composition is checked in the following way: scoop it up with your hand and rub it between your fingers. A slippery and oily paste indicates a good quality of the binder solution.

There is another way, but only a stove-maker with extensive experience can use it - checking the readiness of the composition by ear.

If the solution rustles and lags well behind the shovel, then it is ready.

How to choose?

The quality of the working clay composition is determined by the fat content of the clay and is divided into three types.

- Greasy clay. The most plastic material.However, when dried out, it changes its performance: it begins to crack, decreases significantly in volume, negatively affecting the integrity and tightness of the furnace structures - they are deformed and destroyed.

- Medium fat. The best option, the dream of any stove-maker. When dry, such material does not shrink too much and is not prone to cracking. The composition of a medium-fat base has good indicators in all parameters of adhesion, strength, heat resistance and hygroscopicity.

- Skinny clay. The worst quality is extremely low adhesion rates. It is distinguished by excessive dryness, a strong tendency to cracking, which inevitably leads to deformation of the entire structure.

It is very difficult to find a high-quality base and is a great success of the master stove-maker, which he values, sometimes keeps a secret. As already mentioned, truly pure clay is at a depth of at least 5 meters. It is devoid of extraneous organic impurities, which are rich in the upper layers. The use of clay from the upper layers is a guarantee of a low-quality product.

Several types of clay are used by specialist stove-makers.

- Red clay. It can withstand temperatures up to 1100 ° C, it is used to lay out the furnace body.

- Refractory fireclay. It is needed as a binding solution for laying fireboxes and chimneys - the hottest places.

- Limestone. Its fire resistance is not very good - it can withstand only about 450-500ºC, it is used for the construction of a furnace base and a chimney located above the roof level.

The clay-lime composition is used for plastering. There is also white clay, it is also suitable for heat-resistant mortars, it is used for laying wood-burning stoves with a furnace temperature of no more than 1000 ° C.

As can be seen from the above list, fireclay clay is a versatile material and can be used in the manufacture of furnaces with a wide variety of temperature conditions.

In addition, there are ready-made solutions on sale that greatly facilitate the task for inexperienced stove-makers.

How to prepare clay for kneading?

Each master has his own proven method of mixing a high-quality solution, but now we will talk about the simplest one that a beginner can use in the complex business of building furnaces.

So, how to make clay paste without mistakes? The described method is convenient both for the debutants of the stove business, and for those who build a brick oven for themselves, the only time, and are not going to do this in the future. At the same time, one should not forget that today there are ready-made mixtures in packages on the construction market. The purchase of raw materials in the required quantity and the attached instructions allow you not to think about searching for components in the nearby district. However, for those who have decided to engage in the laying of ovens on a professional basis, this will cost an increase in production costs, and therefore a decrease in income.

Having obtained everything necessary for kneading, delivering it to the destination, the clay is laid out in a prepared container, be it a barrel or a large homemade bathtub. Then it must be soaked with water - the minimum ratio of components is 1: 4, where there is more water than clay. This soaking lasts 1 to 2 days. After the expiration of the period, the composition is mixed until a homogeneous mass (pulp) is obtained. The easiest way to do this is with a construction mixer. The resulting solution is filtered through a special mesh with 3x3 mm cells, sifting out even the slightest impurities and pebbles with this technique.

It is not always possible to get river sand, sometimes it is easier to buy it. In this case, it is necessary to ensure that the material used is not only clean, but also dry. Moisture-infused sand will not allow you to make a high-quality binder solution. Therefore, it must be dried, and then sieved through a fine mesh sieve.

How to prepare the solution correctly?

Getting down to such a crucial part, you need to understand - there are no exact proportions, everything depends on the raw material itself, and its indicators constantly vary depending on the place of production, weather, the season when it was taken from the quarry, and many other factors. This will have to be done independently and on the spot. Besides clay already has sand in its composition, on which its fat content depends: if the percentage is small, then the raw material is fat, if the indicators are high, such raw material is considered lean.

From this follows the difference in proportions - from 1: 2 to 1: 5 by volume.

In order for the mortar for brickwork to have an optimal fat content, it is necessary to find the correct ratio. How to knead the trial composition and determine the desired indicators was described above. Another way of trial mixing, simpler and not too time-consuming:

- a small container is filled with the composition by one third;

- then sand is poured, everything is mixed with the addition of water, if necessary;

- then they check the consistency, picking up a little on the trowel and turning it over, the mass should not fall, but when the blade is turned 90 degrees, the high-quality solution slides off the surface.

When the prepared pasta behaves as described, it means that it is made correctly, and the resulting proportions are used for further work. If the composition falls from an inverted instrument, you need to enrich it with clay and re-check, achieving the ideal ratio of components. The mass adhering to the trowel indicates the need to add sand.

Too oily composition tends to crack, and a skinny one will be fragile.

As for the measure of water, it is also determined empirically. Too thick a mixture will not be able to fill the pores of the brick well, so the seams will be thick but unreliable. The liquid solution simply spreads during the laying process, it is not able to provide normal adhesion, and additional portions will not be able to help. As a result, there will be an overconsumption of raw materials, but the seam will remain fragile. That is why you should always check the quality of the mortar, for example, by running the flat side of the trowel over it.

- If the composition is too thick, the trowel leaves an intermittent trail. You will need to add a little water and stir the solution.

- The trail after the trowel floats too quickly on the sides - an indicator of an excessive amount of water. It is necessary to give the mixture some time to settle, then drain the excess water.

- With a properly prepared solution, the trace remains clear for a long time.

Note!

To prepare a sandy-clay mixture at home, it is best to use “soft” water with a low salt content, otherwise they will appear as white stains on the surface of dried brickwork. If whitewashing is not planned, this will seriously spoil the appearance of the finished structure.

If the builder is confident in himself, he can determine the quality of the mortar using tactile perception. The mixture is rubbed in the hand - if a homogeneous, slightly rough layer has formed on the fingers, the solution is ready. In terms of consistency, the composition should be similar to thick sour cream. If the ratio is chosen correctly, the structure will be reliable and durable. To dilute the composition to putty the surface, you need to add a little more water.

What can be added for durability?

To increase the strength of the solution, many add salt, which increases its reliability. Approximate proportions: add 1.5–2 kg to 1 bucket of finished pasta. The solution with salt will take more time to dry the structure, but after firing it will become more solid and durable.

In addition to salt, lime and cement can be added to the clay solution. Such a solution is suitable for laying the upper part of the chimney and the foundation of the furnace, since cement can withstand temperatures only up to 200-250 degrees.

Instructions for use

The first thing to do to plaster the stove is to clean it of the old mortar, sweep the dust, clean out the dirt.Plastering is started after the oven has warmed up. Algorithm of actions.

- The surface to be treated is abundantly moistened with water.

- Then an initial layer is applied, it is called a spray. To do this, prepare a solution in a more liquid consistency, and throw two layers onto the oven with a brush or broom. The second layer is applied after the first one has already set a little. This is necessary to cover the entire surface without cracks. Before applying the next layers, it is imperative to moisturize the previous one.

- To prevent the surface from cracking, it is necessary to plaster it using a reinforcing mesh, which is fastened with nails.

- After the mesh is fixed, it is covered with a layer of liquid clay paste as a soil, almost talkers.

- After the primer has dried, the base coat is applied with a thickness of 2–5 mm. If there is an urgent need for a thicker coating, then the process is divided into 2 stages - the first layer dries up, then the next one is applied. This is the largest consumption of the mixture when working with the surface.

- And the last, final layer, designed to create a perfectly flat surface, the so-called "cover" with a thickness of 2–5 mm. A more liquid consistency is used, the one that was prepared for spraying.

As it is now clear, the preparation of a clay mixture (solution) is a simple process.

It is much more difficult to lay a stove, where special care and adherence to the necessary rules is required. Any errors in the sequence of work are unacceptable and may result in poor performance of the stove. This is especially important for beginners.

For information on how to make clay mortar for laying a stove, see the next video.

The comment was sent successfully.