How to make a metal sauna stove with your own hands?

Once there was a bathhouse in every courtyard, especially in villages, now it is a rarity. It is rather difficult to find a specialist in laying stoves, and not everyone can afford the payment for his work. But for lovers of a bath there is a way out of this situation - a metal stove.

Features: pros and cons

A true connoisseur of the Russian bath will, of course, prefer a brick stove, it keeps heat for a long time, with its help the air in the bath is created more humid. These characteristics have a beneficial effect on human health, which is undoubtedly the advantage of the Russian bath. To melt such a stove with wood to the desired temperature is a troublesome business and it will take from 3 hours to a day. It requires serious, regular maintenance, it must be cleaned every year, sorted out, oiled at least once every 2-3 years, this also requires a specialist and a lot of money. A substantial supply of firewood is also required.

The metal oven quickly heats up to redness and cools down quickly, emits hard infrared radiation, and dries the air greatly. It is available for purchase at a price of 10,000 to 100,000 rubles. But cheap options are short-lived, and not everyone can afford expensive ones, and it is not a fact that they will satisfy all your requirements. You can make a metal stove for a bath with your own hands, the main thing is to be able to handle a welding machine or have a professional welder as a friend. It is not a problem to purchase material for its manufacture; you can do it even in places where scrap metal is purchased.

Homemade stoves are diverse in their design and depend on the size of the bath, imagination, capabilities, and most importantly, on the preferences of the owner. In a Finnish sauna, the air temperature reaches 85 degrees, and the air humidity is low - from 5 to 15%. In a traditional Russian bath, the air temperature should be 55-65 degrees, and the air humidity should be up to 60%. The design features of these products for the bath will depend on this.

In a Finnish sauna, for optimal heating of the room, a large furnace part is needed, which heats the air around it. It is not necessary to make a stove for such a stove, and if it is made, then it is small and not closed, because you don't need a lot of steam in such a bath.

In a Russian bathhouse, the stove, on the other hand, should produce a kind of fog with a temperature of 150 degrees. This effect can be obtained with the help of stones heated to at least 500 degrees, preferably in a closed large stove arranged on top of the firebox.

What result should be obtained from a metal stove:

- the speed of warming up the steam room;

- keep warm in the stove and the bath for longer - this will help to increase the size of the firebox and (or) create a stove arranged inside or outside the stove;

- saving space in the steam room;

- security.

Types of construction

Due to high temperature loads, the fuel unit itself is made of heat-resistant raw materials with good heat transfer: thick-walled steel, heat-resistant (fireclay) brick, stone.

Homemade iron stoves for a bath can be divided according to their design features.

- The firebox is located vertically or horizontally to the floor;

The stove is two-chamber with vertical loading of firewood, the stove is located in the body of the stove.A stove with three compartments and horizontal loading of firewood, a heater and a water tank are located above the firebox next to:

- metal stoves with a firebox door placed in the dressing room or located in the steam room;

- with a stove located inside or on top of the stove;

- stove with or without a water tank.

A stove with a vertical firebox takes up less space in the steam room, but firewood also burns out faster, since the flame captures the entire volume of the firebox. To maintain a constant air temperature in the steam room, you will have to throw more firewood, which, of course, does not bring comfort at all. In a firebox located horizontally, it will take more time to burn fuel, however, such a stove takes up more space in the steam room, so it is better to take the firebox to the dressing room. Stoves fired from the dressing room take up less space in the steam room, the firebox can be made longer, which will allow the wood to burn longer and the steam room will be cleaner. The stove placed in this way will heat both the steam room and the dressing room, but in order to throw up firewood, you will have to leave the steam room.

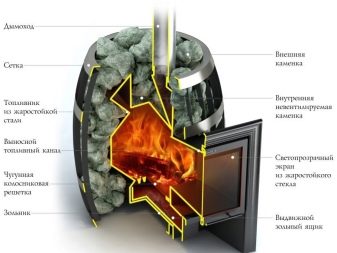

To understand what a stove with an internal or external heater is, you need to understand what a heater is. This is a compartment made of metal or a coarse mesh, into which stones are loaded. Heaters can be either open or closed. The volume of the compartment is determined by the owner himself based on the size of the room, the stove and his desires - the more the volume of stones, the more steam is obtained. It is important that the stove can heat the stones to the desired temperature, for a steam room of 14 sq. m, a stove of 30x40x30 cm is sufficient. To service a closed heater, a hatch must be provided in the upper part of the stone compartment through which you could reach its bottom.

Consider the most affordable options for sauna stoves made of metal:

- with a horizontally located firebox heated in a steam room (made from an old gas cylinder);

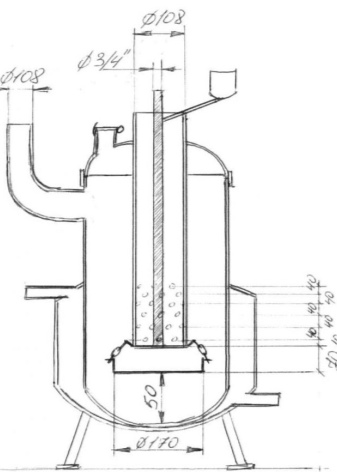

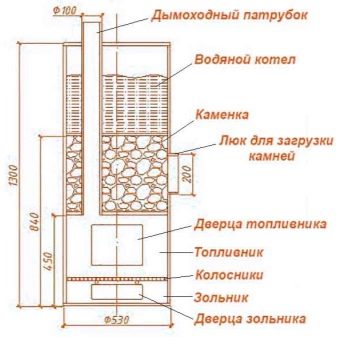

- with a stove and a firebox door located in the dressing room (made of 530 mm pipe);

- with a vertical boiler and three compartments;

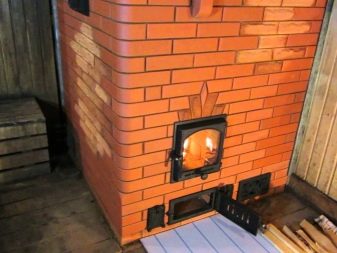

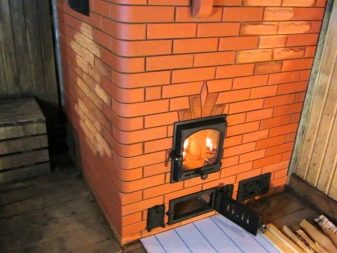

- a stove lined with fireclay bricks inside the firebox or red outside;

- in the form of a boot made of sheet iron with a stove located in the chimney and a stainless steel water tank.

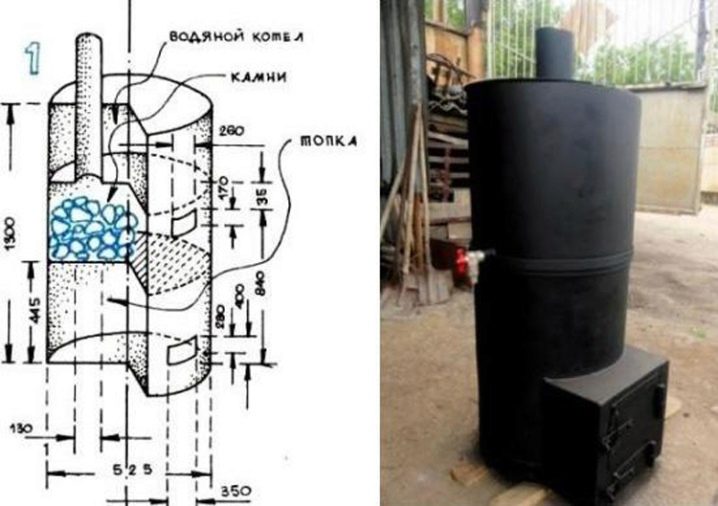

To convert an unnecessary cylinder with a diameter of 500 mm into a small mobile sauna stove with a horizontal furnace, you will need more scrap metal. The device of the second stove differs from the first only in the presence of an uncovered stove and a wood-burning combustion compartment that opens into an adjacent room. The third stove is a boiler, in which there are three compartments: a firebox for firewood, a heater located inside, a stainless steel water heating tank.

Great connoisseurs of the Russian bath understand that it is difficult to heat the stove before creating a light steam, to keep the temperature in the room no more than 70 degrees. To achieve the desired effect, eliminating the temperature overheating of the steam room, you can lining the metal stove with heat-resistant material. The walls in such a stove do not warm up much, the main heat goes to heating the heater filler, but this design carries an increased fire hazard due to the high temperature in the chimney. You can reduce this danger by arranging a heater and / or a water tank around the chimney. It is easier to overlay the oven from the outside, but then the metal walls quickly burn out. This process can be slowed down by using thicker metal or by leaving a gap between the cladding and the metal oven.

The boot-shaped stove also has three sections, but the firebox is horizontal, the heater is located in the chimney itself, which eliminates the temperature loss of the chimney and thereby allows heating up to 24 square meters. In this design, the smoke outlet is delayed by the stove, as if enveloping it, this warms the stones and prevents the heat from escaping immediately. This also reduces the heating time of the room to the maximum temperature, allowing you to keep warm for a long time, and, accordingly, saves firewood.

If the design of the stove in the bath does not provide for a tank with water and it is not possible to supply an electric water heater, make a steel heat exchanger, install it on the chimney, connect with pipes to the water tank, which is located in the place of washing, and the heat energy released by the chimney will be beneficial ...

Heat exchanger made of stainless steel with embedded inserts for connecting hoses or pipes using clamps: The interior of the bath usually consists of wooden elements, and the stove heats up to high temperatures.To ensure the safety of people in the steam room from burns and to prevent a fire, the stove must be covered.

Ways to protect wooden elements and people:

- make brickwork on three sides, separating the stove from the wooden elements;

- sheathe the oven with a thin stainless steel frame with holes that improve air exchange.

Schemes and sizes

Buying ready-made grates and doors will speed up and simplify the process of making a stove, but then the holes in it must correspond to their dimensions. DIY parts will be the size you need. The simplest method of making a stove is to use a canister after the gas.

A drawing of the manufacture of such a furnace from an old cylinder

It is also not difficult to make a stove using a pipe as a body, since the air flow, flowing around the walls of the body, improves heat transfer. The body is practically without seams more reliable, it will serve much longer, and it is more convenient to clean the round firebox. To calculate the length of the remote firebox, you need to know the thickness of the wall adjacent to the pair.

Drawings of a metal stove with a body made of 530 mm pipe, the firebox door is located in an adjacent room:

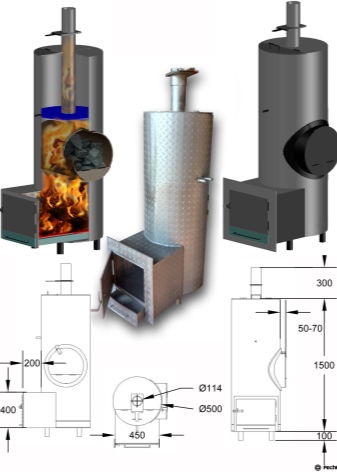

The three-in-one vertical boiler furnace is also manufactured from 530 mm pipe. The difference between this stove and previous options is not only in the location relative to the floor. It contains three sections: a firebox, a heater and a water tank, located vertically, one above the other. The firebox heats the stones, and the water heats up from them. To heat stones and water, the chimney temperature is used, it is located inside the heater and water tank. The volumes of the chambers can be changed at your discretion, but you should understand that with an increase in the size of the firebox, you will need to put firewood less often, since they will burn longer in time. A large heater will take longer to warm up and stay warm for more time.

Dimensional drawing of a vertical oven with three chambers

To the stoves of the first two options, you can install a water tank and a heater from above, only next to, and not above each other. So the number and size of chambers in your stove will depend on how much and at what temperature you like to steam and how much water you need at the required temperature.

The body of a furnace of almost any design and size can be bricked from the outside, but it is easier if it has a simple configuration. The main thing is that it is made of structural or heat-resistant steel of great thickness. The inside of any firebox can be laid out with bricks, only this is much more difficult. Immediately provide for a larger firebox, taking into account the brickwork and exclude an increased fire hazard in the manner described above.

A stove for a bathhouse in the shape of a boot, also, at your discretion, can have the dimensions you need, both the stove itself and its sections. The project of this stove is carried out by welding parts cut from sheet iron (5 to 10 mm thick), a stainless steel water tank and a stove located inside the chimney.

Manufacturing steps

Instructions for making a simple oven from an old cylinder:

- unscrew the valve from the cylinder with a regular key of the required size;

- we fill the cylinder with water to displace the remaining gas and avoid an explosion;

- we cut off the upper part of the cylinder along the seam with a grinder;

- we make holes in the cut off part to install the doors and in the housing for the chimney pipe;

- we weld grates from metal rods, install them on the corners welded in advance in the cylinder;

- weld the previously cut off upper part of the cylinder into place;

- we fix the door hinges and locks to the doors;

- cut the legs to the required size, use a 40 mm pipe for this and attach them to the bottom of the case;

- install the chimney;

- we melt the manufactured furnace to burn out the remnants of the old paint in the open air;

- degrease, cover with heat-resistant enamel, dry;

- we carry out installation of the stove on a permanent place.

The manufacture of a metal stove with a firebox door located in an adjacent room begins with cutting metal elements according to the previously presented drawing:

- cut out a place in the upper part of the pipe for the chimney pipe, weld it;

- weld the legs at the bottom of the pipe;

- insert grate bars made according to the same principle as in a gas cylinder;

- we make the front section according to the dimensions, we weld it to the firebox;

- the opposite end of the pipe is closed by welding with a piece of metal of the required size;

- we make doors, insulate them with basalt wool, weld on and install handles in a specific place for them.

Assembly of a furnace with a vertically positioned "three in one" boiler from a metal 530 mm pipe:

- cut out the bottom, cover, partitions of compartments from metal 5 mm thick;

- preparing the edges of the pipe;

- we weld the grates along the pipe diameter;

- cut out three holes where the hatch for loading stones, doors for the firebox and ash pan will be located;

- we make round holes in the already prepared partitions, we fix it in the pipe to divide the oven into sections;

- to the upper part of the pipe, which will serve as a container for water, we attach one part of the loop by welding, attach the second part to the lid, and fix the tap in the lower part of the container;

- we make canopies for doors, we weld them to the prepared holes;

- we make the doors from semicircular pieces of pipe, cut to size, we attach them to the awnings;

- insert the chimney pipe.

We put a brick on the outside of the metal stove:

- We build a brick screen (sarcophagus) of red ceramic bricks. Do not forget about the air circulation gap between the walls.

- To access the doors, windows are left or it is better to make doors, they will regulate the temperature in the steam room.

- We cover the firebox with fireclay (heat-resistant) bricks on a mortar of fireclay cement, put the brick on the edge. The thickness of the masonry depends on the size of the brick (available with an edge of 3-6 cm).

The finished oven in the form of a "boot" turns out to be heavy, so it is better to weld the main parts separately, and to carry out the installation on site, as a constructor. We will warn you right away that it is difficult to cut parts made of metal of this thickness using a cutter, grinder, and even more so a hacksaw without defects. It is better to contact an organization where there is a guillotine (as a rule, these are metal collection points), this will save you time and nerves, but will increase the cost of the product. The furnace consists of four sections in the form of regular metal boxes. The first section (firebox) is connected to the second (chimney) using a fastening mechanism, the third (heater) will be installed in the second section, and the fourth (water tank), made of stainless steel, is placed in front of the second box.

We start manufacturing:

- marking of workpieces on metal;

- cutting blanks of the required size (four boxes) using a guillotine;

- we fold the walls of the boxes, number them so as not to confuse;

- collect and lightly weld the parts of the section with the bottom wall;

- cut out a hole in one wall with a grinder for free steam out of it;

- another small hole is made above this hole, bolts are attached on all sides near it, we install a door on them and tighten brass nuts (brass does not oxidize);

- pre-wrap the door with asbestos thread for tightness, soot and soot are periodically removed through it;

- at the bottom of the second box, stepping back from the edge of 5-6 cm, from 2 to 4 holes are made, pipes are inserted into them;

- in the first section, from the end, we cut out a place for the fire door and ash pan. From above we make a hole for installing the second section, along its edge to strengthen the hole we weld a corner on one side, from the other three pre-prepared plates about four centimeters wide;

- plates are welded to the inner and outer surfaces with a slight indent from the edge and a slot for installing the second section;

- to strengthen the places prepared for the doors, in the first and third sections, we weld one plate on each side;

- between the firebox and the ash pan we put a grate made of steel bars;

- we weld the grate bars for better combustion of firewood parallel to the blower;

- to strengthen the third box (heater), we weld small metal kerchiefs to it;

- we attach a cover with a pre-cut place for the chimney pipe;

- to the place where the chimney pipe will be installed, we weld the so-called "skirt";

- the heater (third box) is installed in the second section on the tubes previously inserted into it;

- having assembled and once again checked all sections of the stove, we produce the final welding of our structure. It is necessary to weld the seams very efficiently in order to prevent smoke from the bath with carbon monoxide.

Decorative finishing

The stove in the bath is not only a source of heat, steam, increased danger, it can also be a decoration of the room.

If you only care about the safety of the stove, then it is enough to paint it with modern paint to protect the metal from corrosion. The use of heat-resistant enamel based on silicone paints does not differ from ordinary enamels, but protects the metal at temperatures up to +800 degrees. The metal is degreased and then paint is applied. After the first layer has dried, the next layer is applied. It is recommended to cover with paint also those metal elements that will be covered with bricks and insulation.

Furnishing the stove in the bath can perform a purely decorative function in the form of forged ornaments and additional decorative elements of the stove itself. You can use heat-resistant paints of various colors with an antiqued effect. Also, decoration can be used to eliminate the increased danger of a sauna stove.

The stove can be overlaid with red brick masonry (we have already considered this method), but the masonry from the sides can be decorative, in the form of a grid. From the side of the firebox, the stove can cover a screen made of forged elements or just a beautiful mesh fixed in the frame.

It can be closed with a beautiful casing, also covered with heat-resistant paint in the color you like.

A stove lined with a heat-resistant stone will look spectacular, this will not only give a noble look to your product, but also improve the quality of the stove itself.

The decorative finish of your sauna stove depends only on your desire, taste and wallet size.

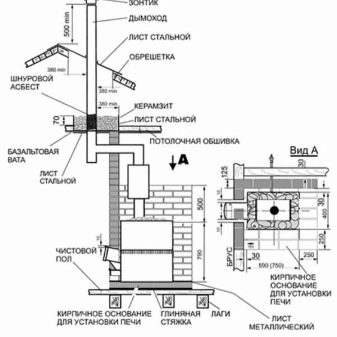

Installation

To install a metal stove in a bath, you need to start by preparing a site for it. Such a stove weighs less than a brick stove, it does not need a foundation, but it has a great fire hazard due to the achievement of high temperatures due to prolonged burning of wood.

The site for installing the oven is prepared at least two times more than the area occupied by the oven itself, and consists of several layers located from bottom to top:

- asbestos coating;

- stainless steel;

- heat-resistant brick six centimeters;

There is another option:

- we dig a shallow pit, in terms of area we adhere to the same proportion;

- fill in sand, crushed stone, tamp;

- fill in with cement mortar, wait for it to harden;

- we spread roofing material as thermal insulation;

- we check the plane with a level, it is better to make a slight slope towards the drain;

- we lay out two rows of red bricks.

To exclude a fire, the stove is placed no closer than one meter from walls and easily flammable objects. The walls around the stove are plastered, bricked, sheathed with sheets of iron or minorite, and the firewood storage area is separated. If the firebox is taken out of the steam room, the opening is also protected from fire by non-combustible materials.

The place for creating a hole for installing a chimney must be provided even when building a bathhouse. The creation of elbows in the chimney will cause soot to deposit in such parts of the chimney, which will impair the draft in the furnace.If it is impossible to exclude such places in the chimney, consider disassembling this area in order to clean it.

The chimney duct should be made of a double wall sandwich filled with basalt wool. As insulation, you can use a square water tank, which is installed in the ceiling.

Having installed the stove in place, we fill the stove with stones of basalt, river or sea pebbles, gabbro-diabase, talcum chlorite, porphyriate, dunite, white quartz, raspberry quartzite. It is better to choose stones of a flat shape and place them on the edge in the heater. Do not use stones with red streaks or blotches (this is iron), it is harmful to health when oxidized.

Helpful hints

If you start to heat the stove in the sauna, and it smokes, a possible reason for this is poor draft. To check it, take a piece of paper, set it on fire and bring it to the firebox. If the flame does not reach the stove, prepare for a repair. It is not difficult to clean the chimney - disassemble it and use a metal brush, scoop and broom to clean it of debris and soot. It is advisable to clean the chimney every year in the summer, so that an unpleasant problem does not catch you at the most unexpected moment - in 30-degree frost or when friends come to take a steam bath. If the chimney pipe is burnt out or rusted, this section, which has become unusable, should be replaced.

Another reason for the poor operation of the stove and chimney (if it smokes) may be the insufficient diameter and height of the chimney pipe. The required pipe diameter is at least 110 mm and the chimney height is three meters.

An iron stove in a bathhouse will last longer without major repairs if you regularly monitor it: clean it from soot, periodically cover it with heat-resistant enamel.

Easy steam for you!

For information on how to make a do-it-yourself metal bath stove, see the next video.

The comment was sent successfully.