Sauna 6 by 3: layout features

In Russia, they have always loved to take a steam bath. Time passes, but tastes do not change. Almost every owner of a summer house or country house dreams of a bathhouse, but not everyone dares to build it. This article will show you how to make your dream come true by making the design and construction process less complicated.

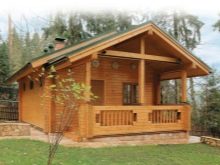

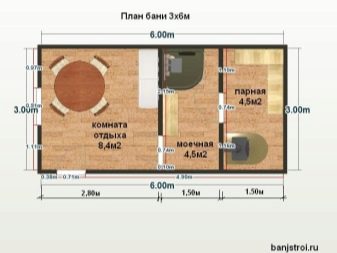

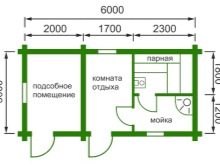

Sauna project 6x3 meters

A bath of this size is 16.8 sq. m. usable area, 21.8 - total area, 23.2 - building area under the foundation. It can accommodate four people at the same time. This can be quite enough for a family or a small group of friends. The bathhouse 3x6 meters consists of a steam room, a shower room, a rest room and a vestibule (dressing room).

The building is divided into three sectors, 2 m each. There is a steam room on the right, a shower room in the center, and a relaxation room on the left. The shower room is divided into two parts, 1/3 of its area is given under the vestibule. At the entrance to the premises, a porch is being erected with a canopy that protects from the sun and precipitation. There are other options: sometimes the bathhouse is 6 by 3 meters, built with a veranda under one roof, or combined with a terrace. In the warm season, a person will be able to leave the steam room to relax in the fresh air.

Often, a bath is made part of a house or a summer kitchen. Such a neighborhood can lead to high humidity in adjacent buildings. To prevent this from happening, you should think carefully about the waterproofing of the room and the ventilation system.

It is necessary to start construction with the registration of technical documentation, drawing up a project with reference to the site plan. The project includes a construction diagram, designation of water supply, sewerage, ventilation and a list of materials.

Building material

You should decide what you will be building a bath from, because it should be comfortable, durable, have a pleasant appearance. Most often they use timber, bricks and various blocks. Each of these materials has advantages and disadvantages.

It can be very cozy in a building made of logs or beams. A pleasant aroma emanates from the walls, they allow air and steam to pass through, retain heat. Heating costs in such cases are low. The disadvantages include the forced care of the building, without which it will lose its attractiveness under the influence of the external environment.

A brick bath will cost more than the timber option, but it will be more durable and can last up to 150 years. Such buildings have good thermal insulation properties, look great and do not need special care. However, brick structures have a higher heat capacity than wood and have lower vapor conductivity. This means that it will take longer to heat up such a bath, and you also need a good ventilation system.

Modern buildings are often erected from expanded clay concrete blocks. It is a very durable, lightweight, non-toxic material. It almost does not absorb moisture, has good thermal insulation. One block weighs up to 8 kg, which makes it possible to build independently.

Foam blocks are a lightweight porous material, it can be formed in large blocks, so objects are built very quickly.

Sometimes cinder blocks are used for construction. They have good thermal insulation, weigh a little, and are easy to work with.

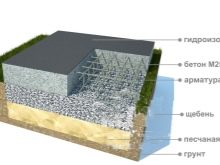

Foundation and walls

If the bathhouse project has already been drawn up, the drawings are approved, and the materials are selected, they begin to build the foundation on the prepared flat area. It is lowered to the level of soil freezing, taking into account the location of groundwater.The foundation is erected from bricks and concrete. It should rise 20 centimeters above the ground so that the wooden walls do not rot. After a few months, when everything dries well, you can start building.

Before erecting walls, it is necessary to lay waterproofing (treat the foundation with mastic or put roofing material). Then, mounting foam is applied to the waterproofing along the contour of future walls and the first row of timber is attached. During this period, you need to be especially careful, because the level of the walls depends on the first crown. The timber is impregnated with an antibacterial mixture even before the construction of the bath. Then the remaining rows of the log house are built, laying each of them with jute insulation.

The final stage of work

At the final stage of construction, the roof is covered, doors and windows are installed. To build a roof, beams are laid along the last timber of the walls. Rafters are attached to them with a distance of one meter. Then a sheathing is installed under the roofing material. The frame is sheathed with metal tiles or profiled sheets. Plywood is laid under the soft tiles.

It should be remembered that a finished structure from a log house shrinks naturally throughout the year, therefore, many construction work is postponed for this period. A bath from a bar has a slight shrinkage, in this case, such a delay is not required for finishing work.

When installing the door frame, it is necessary to use a plumb line to set it as evenly as possible relative to the floor and walls, otherwise the door will not open. Leave 80 mm between the wall and the door to allow the structure to shrink. The door frame will need to be fixed, and the cracks will need to be treated with polyurethane foam.

For a bath 6 by 3 meters, several small windows are provided. After the building has shrunk, the windows and the door frame are insulated.

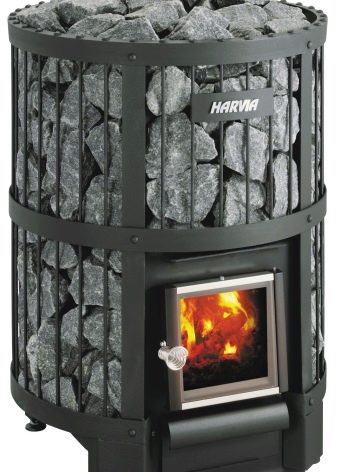

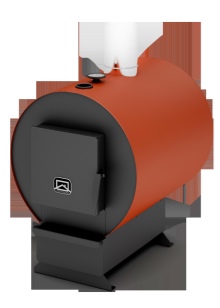

Bake

An ideal sauna stove should be safe and do its job well (heat water, stones and warm air in a steam room). The choice of the oven itself remains with the customer. This can be a heater stove, an electric stove or a gas boiler. Saving on buying a stove can cost you more, because cheap Chinese counterparts quickly fail. Also, do not take coal as fuel, it is better to use firewood.

Bath interior

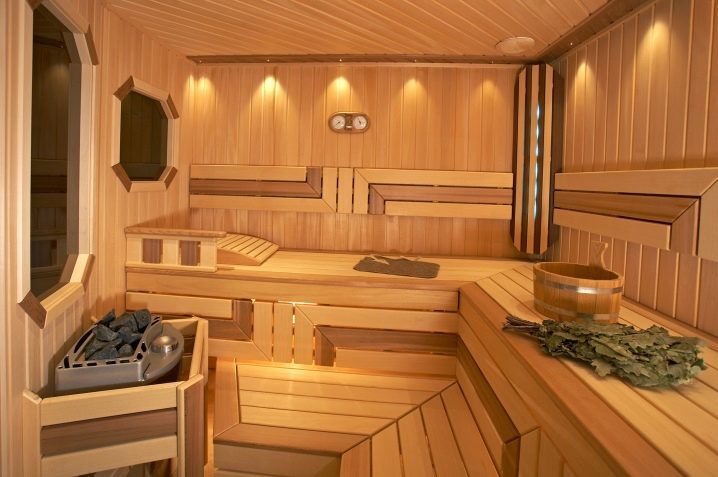

Not only the appearance of the building is important, but also the arrangement of the space inside the premises. Quality materials help create a highly attractive design.

For interior work, tiles, lining made of natural wood, weaving of vine and beech, material imitating timber are used. You can sheathe the floor, walls and ceiling with wood. It will be easy to breathe in such a room and it will be pleasant to be. To work with the lining, a frame is installed and the crate is mounted. It is worth considering that the high temperature heats up the wood, therefore a gap is left between the wall and the cladding, which affects the total area of the room.

The dressing room is a small room in which people change clothes. In this case, it plays the role of a vestibule between the room and the external environment. Here you can place a hanger, narrow bench or stool.

I install a table, chairs, bench and even a TV in the rest room. You will also need a cupboard or dish case.

The main room in the bathhouse is the steam room. It is necessary to ensure good air circulation in it. The materials for this compartment are of high quality and durable. For example, linden has worked well. It smells like honey, is easy to install and does not deform. The wood of pine and other conifers cannot be used in rooms with high temperatures, because they emit a pungent specific odor. They can be left for finishing the vestibule.

A small room should be equipped with sun loungers so that there is enough space for everyone. It is more convenient to make benches, shelves, benches in a rounded shape from especially durable types of wood.Do not use flammable wood and linoleum, which can release toxic substances at high temperatures.

If there is a need to increase the steam room, it is combined with a shower room. Although experts do not recommend combining them, such a project makes it possible for more people to be in the steam room at the same time.

Washing (shower) - a room with a high concentration of moisture. The air circulation should be well established here, moisture-resistant materials, for example, ceramics, should be used. A wet tile floor becomes slippery and should be covered with rubber rugs or wooden ladders. In the washing room, you can install a shower cabin, put a bench or lounger, hang a wooden bucket with cold water. You also need hooks for towels and a shelf for hygiene products.

This is how all the premises of the bath are made out, there is nothing complicated about it. Many owners of private plots cope with this work on their own, because it is especially pleasant to wash and relax in a bathhouse built with their own hands.

For information on how to make a foundation for a bath, see the next video.

The comment was sent successfully.