How to make an overhead door yourself?

Up-and-over doors have become especially popular today. More and more people choose them. They will reliably protect the premises from burglary and will not take up much space.

Design features

Previously, all gates were the same, with large heavy metal doors painted in unpleasant colors. Today they have changed dramatically in terms of design, materials and appearance. To keep your car safe and secure, choose a garage with a reliable swing gate. A distinctive feature from other models is their unusual design. These gates are the most convenient and reliable type of garage construction, which is quite expensive.

When installing a gate of this type, it is necessary to comply with several conditions necessary for further high-quality operation. First of all, this is the size of the opening. The width should not be more than 5 meters, and the height should not be less than 2.85 m. The distance from the wall to the edge of the opening for installing the guides should be at least 120 mm, from the ceiling to the upper edge of the opening 210 mm.

Taking into account the dimensions of the vehicle, the dimensions are adjusted.

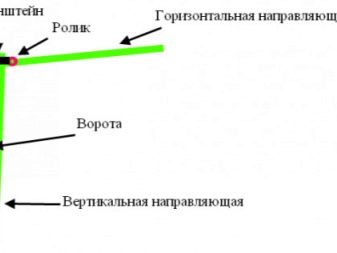

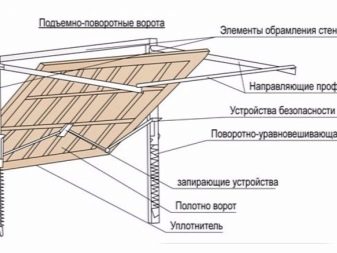

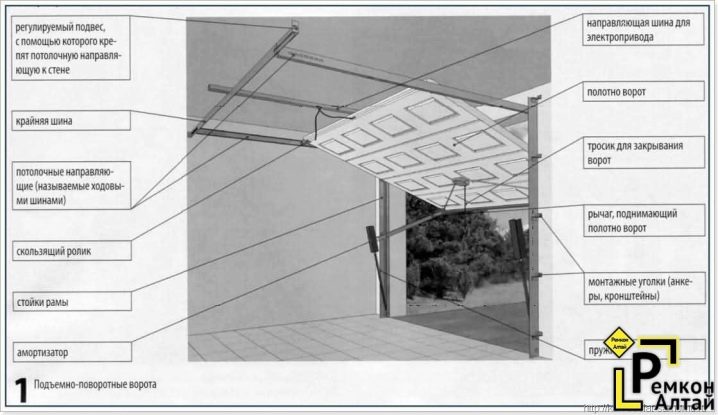

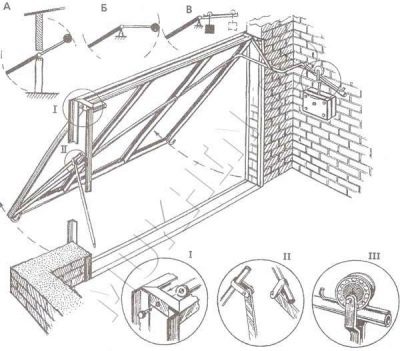

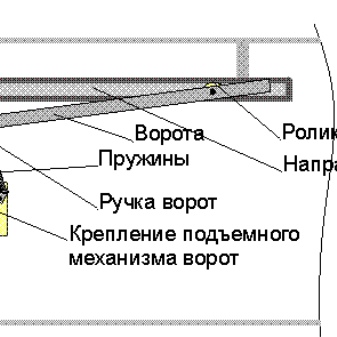

The structure is arranged quite simply. The gate rotates around its own axis, moving from a vertical position to a horizontal one and vice versa. Their constituent element is a frame, which is fixed in the opening of the room or behind it and is the most important element for opening the gate. It is made in most cases from rectangular pipes.

When opening, the roller mechanism and lifting levers are triggered, which move the gate leaf along the guides and fix it under the ceiling of the room. The bottom rises upward, thus creating a visor. When the gate is closed, the expansion springs are immediately stretched, and when they are open, they are in their normal state.

It is known that automatic structures can be made to order. But, despite the difficulties in manufacturing, they can be designed by yourself.

The difficulty in manufacturing depends in most cases on the model you choose, the size and your skills in working with drawings, electric tools and a welding machine.

Performing a product drawing, it is necessary to indicate the main points on it:

- the size of the wall;

- opening parameters;

- the size of the main racks;

- joints of corners;

- length of guides and tires.

If necessary, you can use the ready-made sketches of these models by selecting the required drawing. Before getting started, be sure to read the basic principle of work, as well as the specifics of the installation of this structure.

Views

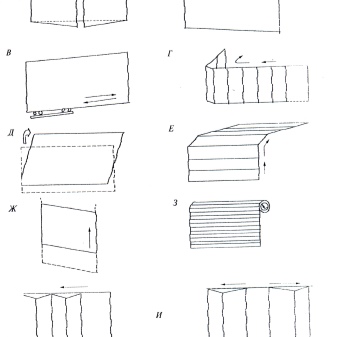

According to government standards and regulations, this design is presented in three forms:

- Lift-section design, consisting not of a solid canvas, but of several sections, which are attached to each other with hinges. There are usually three loops - along the edges and in the middle. On the sides of the gate there are guides with recesses into which the rollers are installed. When opening, the sections move along the grooves in the guides, one after another they rise up. When such gates are opened, the top panel is displaced in relation to the previous one, and an arc is formed. Such gates have good thermal insulation, reduce the distance to the garage, but have a complex and expensive design. They are mainly used in industrial areas.

- Lift-and-turn design the most optimal and convenient to use, despite its cost.When opened, it lies horizontally and protrudes slightly outward. It is easy to use and install. Hacking it is difficult enough.

- Lift-vertical design usually used in industrial premises with high ceiling heights.

How to do it yourself?

If you decide to make an overhead gate yourself, then you need to make measurements and sketch a drawing, prepare the necessary auxiliary means and materials for this, namely:

- return springs;

- brackets;

- counterweights;

- cable;

- roulette;

- level;

- drill;

- components for the manufacture of the sash;

- welding machine;

- corner;

- screwdrivers;

- profile pipe;

- channel;

- guide skids;

- metal for decoration and so on.

Materials required for the manufacture of do-it-yourself up-and-over doors:

- a bar made of wood with a section of 100x100 and 120x80 mm;

- 2 springs with an inner diameter of 30 mm;

- corners 40x40 and 4 mm thick;

- anchor bolts and screws;

- steel rod with a diameter of 8 mm.

Before installing the structure, it is necessary to take into account some of the nuances. Sometimes the installation of the product is impossible, since it is attached only to rectangular openings. The opening height decreases when the door is open. If the sash of the structure is sheathed with a solid sheet, it is dismantled, changing the entire skin as a whole.

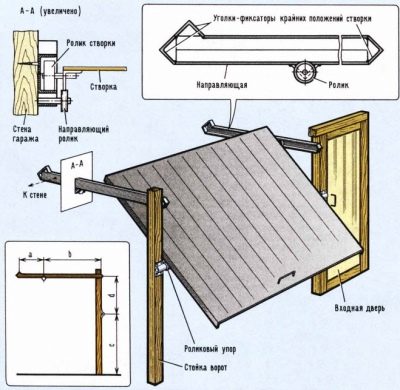

The main components of the structure:

- the frame, which is the main element, all other parts are attached to it;

- swing-type sash, which is mounted in a steel frame;

- spring required for manual closing;

- mechanism for making the sash work.

Mounting

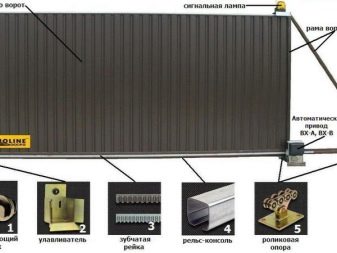

The mechanism that makes the sash work is best made of materials with light weight, which will reduce the load on the product, thereby prolonging its long-term use. Next, a mechanism is selected that is used to open the sash. Articulated lever is the most common because of its simplicity, as well as reliability. You can also choose a counterbalanced mechanism. It is used in the construction of heavy gauge gates.

The following installation steps are:

- Assembling a box of three bars, fastened together with corners or metal plates. The bars are deepened into the floor by at least 2 cm.

- Hinges are installed. An upper bracket is installed at the top under the roof.

- Sashes are made by cutting metal corners to the required length. A frame is made of them with the help of a welding machine, into which the sash elements are mounted and everything is fixed with screws.

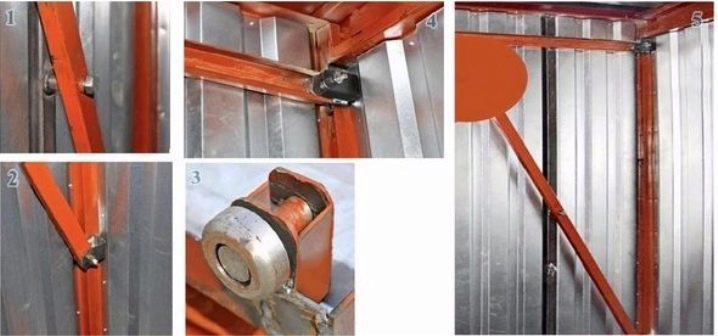

- Installation of rails is a part of the product, inside which hinge rollers are brought. They should move easily and normally.

- To secure the lifting mechanism, the sashes are pre-mounted.

- Fastening the hinge mechanism to the sash. For this, hinges are made. The levers should move freely and parallel to each other.

- Connection of counterweights and springs mounted on a guide bracket. The springs must be fastened to the left and right of the sash in parallel.

- Pads are installed on the ends of the product.

- Plaster the joints.

- The castle is being assembled. You can also control the gate opening process using the remote control.

As a surface finish, you can use plastic or metal sheets.

When installing the product, you must:

- measure and make a frame;

- measure the diagonal of the entire opening;

- the elements of the frame of the canvas must be grabbed with a welding machine so that the sash passes easily, and the gaps are minimal;

- weld the jumpers and all the frames with the apparatus;

- put jumpers;

- clean the seams from welding;

- weld on a metal sheet on one side;

- walk with a primer, degrease, apply paint to the sash surface;

- adjust springs and lifters;

- install fittings;

- attach the handles from below on both sides;

- place the latches on the inside of the product;

- the gate is ready.

Advantages

Homemade lift-and-turn models have some advantages over other types of gates. Among the main ones:

- one-piece durable canvas creates reliable protection against burglary and theft;

- have anti-corrosion properties and resistance to other environmental factors;

- due to their design, they do not take up much space when open;

- do not require finishing with various facing materials;

- there is a possibility of decorating with any inserts;

- open manually and using the remote control;

- the ability to install single and double gates;

- conveniently open, going up, and do not take up much space;

- have good sound insulation;

- do not fail in frost and high humidity.

Reinforced up-and-over doors are the most reliable and look like a shield. The original modern look, made from a variety of materials, comes in a variety of colors. The design is very reliable and can only be demolished with special equipment.

The work must be taken with full responsibility. When making a gate with your own hands, you need to clearly follow the instructions, carefully calculate and use ready-made schemes. Even a small mistake can lead to a problem in the operation of the mechanism.

See below for a clear instruction on the manufacture of up-and-over doors.

The comment was sent successfully.