Features of bolts for swing gates

Double-leaf gates are indispensable for garages or as part of the fence of private houses - with them no thieves and burglars are afraid. In each case, an important element is the locking of the doors - for this, special bolts, latches or latches are used. For different situations, there are different door locking mechanisms that allow you to firmly close the gate. In this article, we will take a closer look at the types of bolts, and also describe step-by-step instructions for creating a bolt with your own hands.

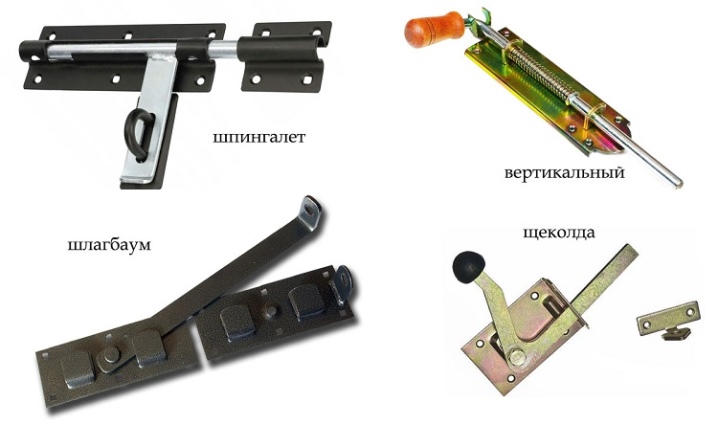

Species overview

Manufacturers create a wide range of locking systems - it is easy to find various metal and wooden model options in hardware stores. In factories, using professional equipment, locks of various types are made.

The electromagnetic variety is the most demanded protective mechanism in our time, it functions thanks to an electric magnet and a metal plate. When electricity is supplied to the mechanism, the magnet holds the metal plate firmly fixed to the second gate leaf. It is impossible to open such a lock with brute physical force, because the power of the electromagnet attracts the plate with a force equal to 500-600 kg - the structure opens only after using a special key that stops the supply of current.

By installing such a mechanism on a swing gate, you will reliably and permanently protect your property from the penetration of unauthorized persons.

The electromagnetic system has a serious drawback - when the power is cut off, the magnet stops working and the lock opens. So that this fact does not become an unpleasant surprise for you, it would be wise to immediately install a block that ensures an uninterrupted supply of electricity.

The electromagnetic protection system is installed without the use of a welding machine. The body of the movement is strong enough to protect the structural parts from mechanical damage, because it is made of high-strength metal alloy. The installation of an electromagnetic lock is not the easiest thing, so it is better not to try to install it yourself.

The electromechanical lock differs in the principle of operation - it fixes the gate with a bolt and a bolt. The mechanism is unlocked using a special control panel, and in the event of a power outage, the leaves remain bolted - this is an additional level of protection. In the absence of voltage, the bolt can be easily opened with a key.

When choosing an electromechanical lock, it is necessary to take into account several factors, the most important of which are the installation location and the weight of the gate. If you plan to lock the gate on the street - you need to choose a model with a stainless steel body - this will significantly increase the service life of the structure in comparison with a regular metal lock.

Also, the choice of the protection system depends on the mass of the leaves - the overhang of the crossbars of the structure is 2 cm, so the model is not suitable for gates with a large weight. An electromechanical lock is always accompanied by an instruction, which indicates the maximum weight of the doors that the crossbars can support. But not all situations require a complex electric lock - the design of the bolt in some cases can be quite simple. There are locking systems that many craftsmen can easily make without special equipment. Most often these are elementary wooden bolts, but also metal latches.

A timber locking mechanism is used to fix wooden gates. Metal structures are more versatile - they are attached to different types of surfaces, such as metal, profile, wood, as well as combined materials. A metal latch for swing gates is created using various technologies, for example, forging is used to create a decorative latch. For the manufacture of forged valves, special equipment and certain skills are required, therefore this method is more often used in production.

For independent creation of the mechanism, simpler equipment is used, such as a grinder, a drill and a welding machine.... Simple locking systems are divided into two main types: rotary and sliding. Let's take a closer look at each type of construction.

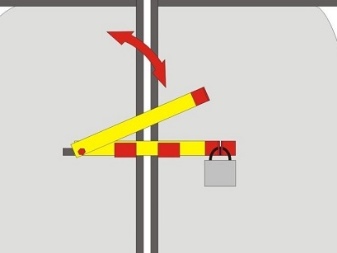

Swivel

Structures of this type are called "barriers" or "turntables". The swivel mechanism is easy to do-it-yourself, efficient and durable. Such devices are usually made from a bar. The disadvantage of the product is considered not too attractive appearance, in addition, in some situations it becomes difficult to open and close the constipation. However, there are some special designs in which a massive and rough "barrier" is seen as part of the style, and not as a flaw.

There is another type of rotary latch - a latch, which is very easy to install and convenient to use mechanism. The only condition for fastening such a structure is reliable fixation of one of the sides of the gate, for which a lower vertical lock is installed on one leaf.

Due to the design features, the latch is usually mounted on wickets or doors.

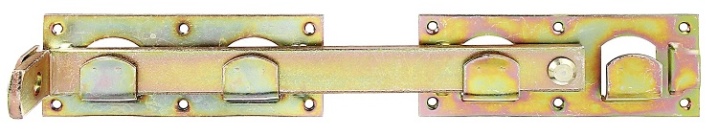

Sliding

Sliding-type mechanisms are divided into two types: horizontal and vertical. The horizontal slide system is a bolt or simple strip design. Installation of such a valve is carried out on a revolving mechanism or frame. The horizontal lock is similar to a latch - for its convenient use it is necessary to install an additional vertical lock.

Vertical type gate valves are most often attached to the bottom of both leaves - this mechanism allows the gate to be fixed in any of two states. In the event that it is necessary to close the garage, you can install sliding vertical locks at the bottom of the sash or at the top. The only condition for such a lock is an unbending frame, because if the canvas bends, you will have to install latches at the top and bottom of each sash.

Selection Tips

The most important criterion for choosing a locking mechanism is the material of the product. For wooden doors, it is best to use a "barrier" or "spinner", because bulky and complex locks on a wooden door are completely inappropriate. If the product is made of corrugated board, it is better to opt for simple latches or sliding locks, because they are quite simple to mount to the frame of the structure.

In the event that you need a reliable garage mechanism, install an electromagnetic lock, but do not forget that it does not work during a power outage. If it is not possible to install an uninterruptible power supply system, it is better to give preference to an electromechanical locking system.

If you have a question about how best to proceed - make the valve yourself or buy it in a store, you need to think over the purpose of the installation. In the case when constipation performs not only a protective function, but also should become a decorative element, it would be wise to purchase finished products in the store.

Install self-made sliding systems when the provided assortment of factory locks does not allow you to choose the ideal option.

How to do it yourself?

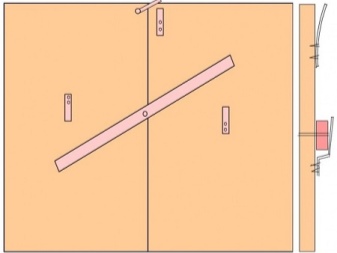

The easiest way is to make a "spinner", which summer residents often use to lock utility rooms with swing doors.Another reason to make the bolt with your own hands is that the "turntable" is not mass-produced. The technology for creating such a bolt is extremely simple, you just need to follow the step-by-step instructions.

- Use a timber or metal strip of a certain size. The optimum bolt length is 2/3 of the sash width. Such a beam will capture at least a third of each half of the gate - this will ensure a reliable fixation. A bar made of a bar is made thicker than 5 mm in diameter in order to withstand the weight of the gate.

- In one sash, you need to drill a hole for fasteners in size M-10 or M-12. Place the through hole at the edge of the gate - approximately 6-10 cm from the edge. It is also necessary to choose the right fastener - with a wide head, and the length should be enough to fasten the gate leaf, a bar, two washers and two nuts together.

- When the bolt is inserted and secured with the first nut, the head must be hidden or its edges must be ground off so that the hardware cannot be unscrewed from the outside.

- In the middle of the bolt, it is necessary to make a through hole and put a bar on the bolt, and then fix the structure with a second nut.

- On both halves of the gate, timber clamps are installed - on one sash, the L-shaped channel must be turned down, and on the other - up.

Such a device is practical and reliable, and the simplicity in its manufacture makes the design in demand among lovers of creating everything with their own hands. Let's consider the "barrier" next. Such a system is also created from a bar or a metal channel. For self-production of the "barrier", follow the instructions.

- In a bar or strip, make a hole for hardware of the size M-10 or M-12. The place of the thread is not in the middle, as is the case with the "turntable" - step back 6-8 cm from one of the edges of the bolt. Be sure to calculate the required length of the bolt, taking into account the thickness of the gate, the beam itself, two washers and two nuts.

- The next step is to outline the location of the hole of the required diameter. In contrast to the previous case, in the “barrier” system the bolt will carry the physical load. In order for the structure to have reliable fastening, it is necessary to install a bolt with a wide head.

- To avoid the penetration of unauthorized persons into your territory, you need to hide the hat or grind off its edges - so it will be impossible to unscrew it from the outside.

- Screw three hooks to the flaps: the first is next to the bolt near the edge of the flap, the second is opposite the first, but near the edge of the other flap, the third is near the far end of the bolt on the second flap.

For added protection, padlock loops can be made in the third latch.

There is another primitive bolt that can be easily made by yourself - a sliding bolt. Previously, such a mechanism was made of wood, but nowadays it is increasingly made from steel strips. All you need to create a sliding bolt is a home toolbox and basic locksmith skills.

- The main element of the locking system is a 40x5 cm steel strip.

- The principle of operation is based on the fact that the steel strip moves in the grooves-guides. These slots must be welded to the plate. A bolt is attached to the grooves by cooking or self-tapping screws.

- When you have finished assembling on one half of the gate, you need to attach another groove on the second, into which the steel strip will enter. This is how the swing gates will be securely fixed.

The sliding bolt can be supplemented with padlock hinges to maximize structural reliability. Next, consider a method for self-assembly of a vertical valve. The bolt in this design is a metal rod bent in the shape of the letter G. Its length is about 70 cm, and its thickness is 12-14 mm. Let's take a closer look at the method of creating a vertical constipation with your own hands.

- First, take fragments of pipes, into which a metal rod will freely enter in diameter.Then weld these pieces to both gate leaves at the bottom, closer to the edge.

- Two more parts of the pipe must be placed in the garage floor or path - metal rods will be inserted into them, ensuring the fixation of the swing leaves.

- To prevent the rods from falling to the ground when you open the gate, you need to weld additional grooves to the shutters - you will insert the curved end of the reinforcement into them.

All of the listed types of locking mechanisms are designed for light gates - they will not withstand too much load. In order to firmly press the shutters, it is necessary to mount several valves, and also supplement them with vertical locks.

There is another option - to make a "sea container", which is characterized by increased complexity of assembly, but also enhanced reliability. The “Sea Container” is appreciated for its ease of use, as there is no need to bend over and pull the bolt to open the lock. Making such a lock yourself is quite simple:

- on one of the flaps, weld three ring retainers in different places, equipped with a special protrusion with a diameter of 15-16 mm for a smooth tube: the first ring must be located 20 cm from the top, the second - in the middle of the end, the third - retreating 20 cm from the bottom;

- attach hooks on both sides of the tube;

- then it is necessary to weld a couple of hooks to the frame;

- check the fixation of the lock - when you turn the tube, the hooks must firmly fix the clamping gate leaf;

- For convenience, a piece of pipe about 30 cm long can be welded to the hooked tube, creating a handle.

"Sea container" is relevant in garages, trucks and trucks, because it tightly and tightly closes the doors.

The comment was sent successfully.