Up-and-over doors: design features

Gates equipped with a lifting swing opening mechanism are quite popular among consumers of various categories. Moreover, the cost of the design in question is quite high. Relevant is the topic of the construction of this structure with his own hand. For this, it is desirable to have some understanding of the welding process and understand in general what the structure under consideration is.

Advantages and disadvantages

It is worth spending time to study the device of such a gate: it is one of the convenient, reliable and safe mechanisms, the process of its installation is responsible. The mechanism under consideration has a number of obvious advantages in comparison with other designs, which are the features of swing-over doors. Other garage doors do not provide the same level of protection, reliability and safety as in this type guaranteed by the strength of the one-piece web.

It is this characteristic that will become a reliable obstacle in the way of burglars and persons seeking to penetrate into not their territory.

A positive feature is the low susceptibility to corrosive processes, as well as a certain resistance to external influences. The last characteristic of the gate is acquired subject to the production technology and material requirements. One of the pluses is space saving: such a gate, when opening and being open, does not need additional free space.

On the positive side - great look that you can create yourself... To do this, you need to correctly select the facing material and decorative elements. They can be decorative inserts or panels. A plus will be the possibility of additional insulation with the help of special panels (for example, from expanded polystyrene). A pleasant bonus is the dual nature of the opening mechanism (automatically and manually).

Both single and double garages can be equipped with such gates.

The disadvantages include characteristics that affect the features of the mechanism itself. A negative moment during the installation and operation of the overhead door is restriction on the shape of the opening: it must be rectangular. An open gate slightly reduces the distance from the floor to the top. There is also a drawback associated with the integrity of the canvas, which excludes the possibility of separately repairing some areas.

If damage appears on any part of the structure, the gate will have to be completely changed.

The spring mechanism creates some problems: the spring can only support a certain weight. When decorating and insulating the gate, you will have to try and keep within the established framework, and this creates some difficulties and requires additional time for calculations. If the gate becomes much heavier after warming and finishing, you will have to use counterweights. The frame may not be installed tightly to the canvas, because of which there will be gaps between them.

You will have to get rid of the cracks with a rubber seal. This option would be unacceptable in a heated garage.

Mechanism action

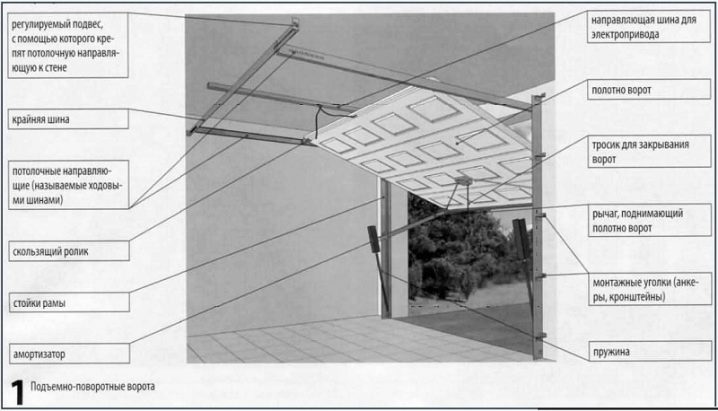

When choosing an overhead door design, you need to understand how such a design works. It doesn't matter if you buy a ready-made structure or are going to build it yourself. The device of such a gate is simple.The gate is a frame, a canvas, as well as guides along which the horizontal and vertical planes are changed.

The main part of the mechanism consists of a steel frame, as it is the driving part during the movement of the mechanism. It is installed one of the first in the garage opening or behind it. A frame is made of rectangular pipes. When the gate starts to open, the action of the roller mechanism and the lifting arms starts at the same time. With the help of the latter, the sashes begin to move in accordance with the location of the guides. After that, the gate is fixed near the ceiling. In this case, the lower section of the gate becomes instead of a visor.

When the gate is closed, the expansion springs are stretched, when open, the springs are released. There are two types of mechanisms, depending on the way the gate is opened. The first consists of hinges and levers, and is the most popular due to its simplicity and reliability. Such a mechanism ensures that the canvas moves freely and does not block when it is not needed. This mechanism requires the implementation of several mandatory requirements.

In particular, the springs must be carefully adjusted, well tensioned. The requirement applies to the guides: they must be located exactly in their place. Counterweights of this type of mechanism are a cable attached to the lower frame corner, which is passed through the middle of the block, and a counterweight is attached to the opposite end of the cable. Such counterweights can only be installed on doors with a sufficiently large mass.

The control can be carried out manually and on the basis of automation.

Instruments

If the installation of the gate with a chain is planned to be carried out independently, it is important to have tools at hand, without which you cannot do without during such work. The set includes:

- level;

- welding machine;

- spanners;

- Bulgarian;

- hammer;

- drill;

- pencils;

- drill;

- screwdrivers.

How to do it?

The manufacturing process of the type of gate under consideration consists of several parts. Each part corresponds to the manufacture of a specific element of the given mechanism. The parts of the process will be:

- frame welding;

- creation of a frame and shutters to it;

- installation of the door leaf;

- installation of a lock and locking mechanism.

Let's take a closer look at each part of the process.

Making the frame

The first stage of the process is the creation of the frame (the main component of the entire mechanism). To make a frame, you must have in your arsenal a steel corner 6.5 cm in size, a metal strip, the thickness of which should be 0.4 cm and a width of 1.3 cm, reinforcement (for secure fixation of the frame). You will need a grinder, tape measure, welding machine and square. To create a frame, we cut the required number of corners (instead of them, you can use a metal profile).

Such corners require 8 pieces. different lengths. The length of four should be the same length as the width of the opening. The length of the remaining four should be equal to the height.

After cutting, the resulting corners are welded to create a frame, while a butt or overlapping connection method is used. Outside, the frame must be carefully processed to ensure the tightness of the connection between the sashes and the frame, which will ensure that there are no gaps and greater reliability of the structure. If a gate reinforcement element is used, it should be fixed in the middle of the gate. The doors are manufactured from 2 mm thick metal sheet. When the fabric is welded to the base, adherence to a special technology is of great importance. In this case, from below and from above the canvas should recede over the edge by about 2 cm, although its width should be less by about 1 cm.

The core and each of the corners must be welded. Then you can weld on the sheet.After completing the installation of the door, the residues of welding should be cut off (residues of welding can lead to the fact that the garage door will deform over time). To keep the gate wings securely, you can reinforce the hinges (weld the lower part to the frame, and connect the rest to the gate). It is also possible to strengthen the hinges by means of an additional reinforcing metal layer, which must be correctly bent, then welded to the upper part of the hinges and to the sashes.

How to manage?

When installing such gates, they use remote, mechanical or manual control methods. Manual control assumes that the owner, using his own power, moves the gate leaf with a leash or by hand. If mechanics are used for driving, an electric motor is assumed. Such control involves pressing a button to start the implementation of the mechanism. In this case, the button can be located in the garage itself and outside.

Controlling a garage door leaf based on a remote mechanism is considered one of the best and most convenient options. However, the remote control is an expensive pleasure that not everyone can afford. If a remote control is used, the owner of such a mechanism gains certain advantages in the form of the ability to control the gate leaf from the house or the passenger compartment. The remote control is based on a microcomputer and a receiver that receives signals. The operation of the remote control method is based on a sensor that detects whether the garage door is closed or open.

Knowledge of the features and principle of operation of possible options for controlling the garage door leaves will allow you to determine which mechanism will be more acceptable for specific conditions and meeting the owner's requirements. Such knowledge will allow you to easily cope independently with the entire process of installing doors with the selected control system. At first glance, the described process seems complicated, although its implementation does not require much effort and cost.

Before you start installing the gate, you should carefully study their device, drive and take into account all the nuances, including reading the instructions. It is not recommended to save on fittings: an abundance of high-quality metal material will only strengthen and protect the structure as a whole. Although the gate itself is quite heavy, it can become loose over time. Therefore, their condition should be constantly monitored and, if necessary, adjusted.

You can find out how to make a do-it-yourself up-and-over gate in the next video.

The comment was sent successfully.