Garage doors: the subtleties of making your own hands

Most of the men are crazy about their car and are ready to spend a lot of time in the garage. But in order to build a major garage and finish it the way you want, you need to invest a lot of money. Fortunately, you can master the intricacies of making some elements of the building yourself, for example, a garage door.

All the nuances associated with the manufacture, installation and maintenance of them will be discussed in our article.

Views

There are the following garage door options:

- swing;

- sliding;

- lift-and-turn (folding);

- lifting and sectional (folding);

- recoil;

- roller shutters (roller shutters or shutters).

Now we will consider in detail the design features of each type, the schemes of their functioning, advantages and disadvantages. We will also tell you about what material to choose in order to make garage doors yourself (wood, galvanized iron or corrugated board), how to strengthen the doors and how to paint them.

Design features

To make reliable and high-quality gates with your own hands, you need to take into account the basic nuances of the structure of each of their types.

Swinging

Swing garage doors are the most common option, known since ancient times for their reliability and convenience.

The design principle is extremely simple - swing gates consist of two leaves, which are based on a metal frame. They can be wooden, iron, made of corrugated board. Closed with external and internal locks and bolts. For added comfort, a wicket can be cut in one of the doors.

The main advantages: cost-effectiveness, ease of manufacture, a high degree of safety. Disadvantages: Requires free space in front of the garage for full opening.

Sliding

If a drive is connected to the swing gates, then they can be automated and turned into sliding ones.

Lift-and-turn (folding)

A modern, neat and compact version, more suitable for insulated garages located on the territory of protected cooperatives. The basis of the structure is a door made of galvanized steel or aluminum, which rises up and is fixed parallel to the floor using a hinge-lever drive, special guides and a retainer.

Main advantages: space saving, ease of use. Disadvantages: high cost, low level of protection, manufacturing complexity.

Lifting-sectional (folding)

A very convenient type of doors that provides high tightness and does not take up much space. The schematic diagram is based on the refraction of a metal sash, consisting of horizontal sections, during the opening process and placing it under the ceiling.

The functioning of the mechanism is carried out due to the hinge hinges connecting the segments and rollers moving along the guide strips. Folding gates are distinguished by good sound insulation, since each section of them is reinforced with a seal.

Main advantages: versatility. Disadvantages: high price, low burglar resistance.

Recoil

A relatively inexpensive, effective and easy-to-use option. The design works on the principle of a wardrobe and consists of one metal door moving along the garage wall using a system of guides and rollers. Sliding gates can be installed both outside and inside the garage.

Main advantages: budget, strength, durability. Disadvantages: the need for a wide facade in the garage.

Roll (roller shutter)

A rare type of lightweight gate. Roller shutters are best used in guarded cooperatives. By their mechanism of action, they resemble roller shutters and consist of aluminum plates that are assembled into a special block fixed at the top.

Main advantages: space saving, easy operation. Disadvantages: fragility and unreliability.

Having studied the design features of various types, we can conclude that the easiest way to make and mount swing garage doors. Their production does not require the construction of complex drawings, professional skills and the use of specialized tools.

And how to do it yourself with your own hands, read below.

Manufacturing

The smooth installation and easy operation of the doors directly depend on strict adherence to the manufacturing technology. We present to your attention a universal step-by-step guide for the production of swing gates for the garage.

Purchase of the necessary materials and tools

For work we need:

- roulette;

- square;

- level (you can use both construction and hydraulic);

- Bulgarian;

- welding machine.

In the process of work will be used:

- corners for assembling the mounting frame (it is better to give preference to corners made of steel 65x65 or 40x40 mm);

- sash sheathing (most often wood, corrugated board or solid metal sheet are used);

- a set of external and internal locks (latches or bolts at your discretion);

- profile (for example, 60x30 mm in size);

- hinged iron hinges for fastening doors.

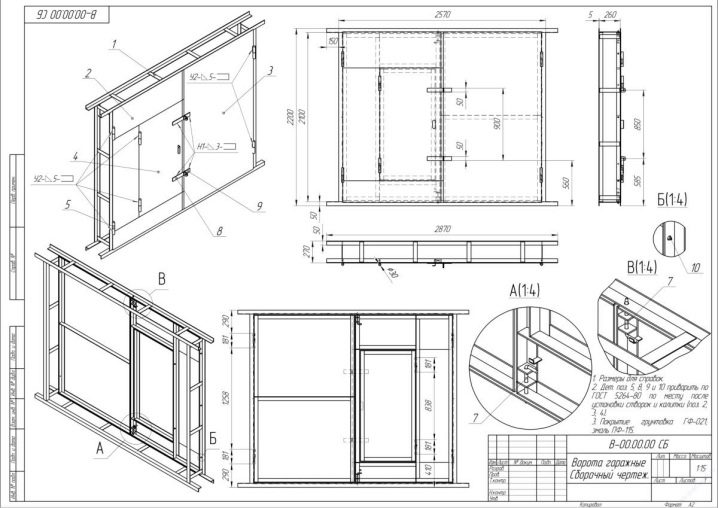

Measuring the opening and creating a drawing

To make a reliable and neat gate without cracks and all kinds of irregularities, you need to carefully approach the measurement of the opening and the subsequent transfer of the data obtained to the drawing.

Algorithm for measuring the garage opening:

- We measure the width. Typically, this figure varies from 3 to 5 meters, depending on the size of the vehicle. Ideally, the distance from the machine to the frame frame should not be less than 30 cm on both sides.

- We measure the height. This size is also removed taking into account the parameters of the car.

We transfer the obtained figures to paper and indicate the materials. The drawing can be arbitrary, the main thing is its accuracy.

Mounting frame

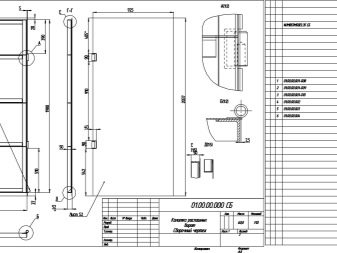

Swing gates consist of 3 basic elements: a frame frame (lathing), doors (sashes) and hinges.

The first step is to prepare the parts and weld the crate, following the technological order:

- We take the prepared corner and cut it into several equal parts. The first half should be proportional to the width of the garage door, the second should correspond to their height.

- We spread the resulting segments on a flat surface at right angles, carefully checking the degrees with a square tape measure.

- Now we need to weld the crate from the finished parts.

Casement frame

Work at this stage should be carried out with special attention, because the tightness of the gate and the convenience of their operation depend on this.

Making a door frame includes the following points:

- We take a cut of the profile pipe and divide it into 4 pieces with a length that differs from the height of the lathing by 20 mm, and by 4 more, the size of which is calculated by the formula: lathing width / 2 - 35 mm. All these calculations are done in order to ensure the ease of entry of future doors into the opening.

- We lay out the parts on a smooth straight surface at angles of 90 degrees, checking them with a square.

- We weld the segments together and get the finished frame.

Sheathing

Sheathing is also one of the most important stages of work, since the appearance and functionality of the structure depend on the literacy and accuracy of its implementation. How to properly sheathe the doors?

We present to your attention a detailed guide:

- We take the material purchased in advance. For example, a solid sheet of iron.

- We cut it to size. Moreover, the sheathing of the left sash should overlap the right one by 2 cm.

- We weld the canvases to the frame, first in the center and along the edges to fix them, and then around the entire perimeter.

Installation of hinges

Before starting work, we purchased hinged iron hinges for fastening the doors. Now is the time to install them.

This can be done very easily:

- First you need to weld the lower hinge element to the frame frame, and the upper one to the outer side of the sash.

- We reinforce the connection by applying a bent metal strip to the top of the hinge and weld the reinforcement insert to the inside.

Constipation and stopper

The choice and correct installation of a reliable lock guarantees the safety of your car. Therefore, it is necessary to approach this stage with all responsibility.

Garages are usually closed from the outside with a mortise or padlock, and from the inside with a pin stopper.

Installing a mortise lock is not difficult, but we will take a closer look at how to mount the stopper:

- First, we drive a piece of pipe into the ground - the movable part of the stopper will enter into it.

- We use a reinforcing pin as a moving part. It must be passed through the loop of the gate leaf.

- In order for the structure to function successfully, it is necessary to constantly monitor the cleanliness of the pipe.

Painting

Before the final installation of the garage door, the sashes must be painted in order to protect the metal from corrosion and improve the overall aesthetic qualities. After preliminary priming, frost-resistant paint for metal or enamel is applied to the door in 2-3 layers.

Warming

At the end of the gate manufacturing process, it is necessary to carry out their internal insulation, otherwise at least 50 percent of the heat will go out of the room. And, you see, warm garages are much more comfortable. For insulation, foam, expanded polystyrene or glass wool is usually used. The heat-insulating material is attached to the inside of the sashes and closed from above with clapboard or wooden strips.

So, we examined in detail the main stages of self-production of swing garage doors. It remains to understand the issues of their installation: how to raise the frame, hang the doors, fix the structure and install the drive for its automation.

Mounting

After you have completed the manufacture of all elements of the gate structure, you can proceed with their installation.

The editing algorithm is also quite simple:

- First you need to install the frame frames. They are attached to the slopes of the garage opening using long metal pins (15-20 cm).

- We cut off the excess pins protruding from the outside, grind and mask with paint so that in the future they do not interfere with closing the doors.

- Now you need to connect the inner and outer battens by means of iron jumper plates.

- It remains to hang the sashes on the hinges and evaluate the finished work.

For greater ease of use, swing gates can be equipped with a special drive powered by electricity - this will make them automatic. The scheme of operation of such a device is based on the use of guides from the profile, which are set in motion by an electric motor.

Folding and rising roller gates can also be mounted independently if there are ready-made opening-closing mechanisms (sashes, sliding parts, slats, rollers and latches) that are sold in hardware stores. All you need to do is make the frame and assemble the structure, in accordance with the attached instructions, and also seal it.

You don't even need a frame to install a sliding gate. All that is needed is to make it out of a profiled sheet and seal the large sash. If desired, you can cut a wicket in it. Installation is reduced to the location of the hardware parts according to the instructions.

Professional advice

To make everything work out as best as possible, let's take into account the opinion of professionals:

- Do not limit yourself to reading a couple of articles with a guide to making your own garage door. Now on the Internet there are a lot of detailed video tutorials and reviews on this topic.

- When choosing materials for work, give preference to lighter and more modern ones. Then the further operation of the finished structure will not be difficult and will not require effort.

- To create a competent and readable drawing, you can use simple specialized programs such as: KOMPAS-3D, AutoCAD, NanoCAD, FreeCAD, etc.

- When welding parts of the frame frame, remember that for greater strength it is better to connect the edges of the overlapped corners.

- For the comfortable operation of the garage door structure, smooth opening and closing of doors and the smooth functioning of locks and locks, it is important to remember to lubricate them and monitor the cleanliness of the systems.

- In order to improve the thermal insulation qualities, you can first cover the seal with polyethylene, and only then cover it with clapboard.

- Garage doors don't have to be standard and trivial. There are a lot of stylish and original solutions for their creation and decoration. It all depends only on your imagination and budget.

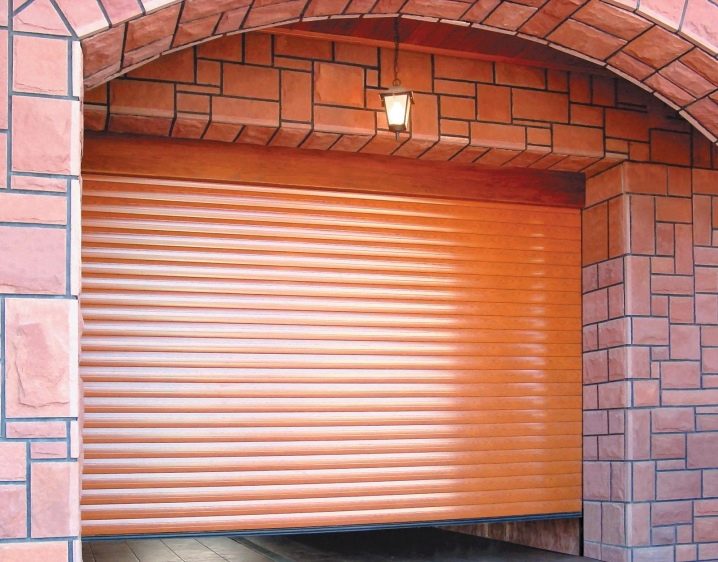

In conclusion, we suggest that you look at several photos of ready-made garage doors of different types.

Beautiful examples

Such familiar swing garage doors can also surprise us with their variety of designs from classic to modern.

There is room for creativity everywhere. Even in the garage! Especially if this garage is decorated with such bright gates.

High-quality and laconic sectional doors are a sign of good taste of their owner.

Connoisseurs of European style will surely like stylish and light roller shutters.

The compact and easy-to-use sliding gates also look very impressive.

How to make a gate with your own hands, see the next video.

The comment was sent successfully.