How to choose a garage door?

None of the strongest and warmest garage can fulfill its function without a reliable gate. In addition to purely utilitarian tasks, they also have a design role. You need to carefully understand all these intricacies so as not to purchase a low-quality product.

Peculiarities

Unlike many other types of doors, garage doors must have a canopy. With the onset of cold weather, the insulation of a house for a car is extremely important, it will reduce the heating fee and radically reduce heat loss. For those who fix cars on their own, this is even more important, since hypothermia can be very dangerous, especially in the garage, when there are no other people nearby, nor the ability to quickly get into a warm room. In addition, with the help of fabric curtains, the penetration of dust from the outside is stopped, and the delimitation of the space inside is provided.

The curtain should not be attached to the opening itself, but at a certain distance from it, moreover, with a cloth overlap the gate with a fair amount to exclude blowing. In areas with a particularly harsh climate, it is recommended to use curtains, which were additionally insulated during manufacture. The designs of the curtains are very different - there is a solid coating, tape systems, samples curling into a roll. The fabric can be pulled out from the side or down from the top.

The tarpaulin canopies are quite dense, they are woven from thick yarn and impregnated with fire-resistant compounds, hydrophobic agents. This material is not prone to decay, it serves for a very long time, but it is very heavy. Polyvinyl chloride will not stiffen even in very cold weather, will not catch fire, perfectly resists the ingress of water and wears out slowly. It is worth considering the option using fabric. "Oxford", favorably distinguished by a unique weaving and high user characteristics.

Large garage doors are not very practical, and not only because they cannot be covered with curtains of normal size. The size of the products is selected individually for your needs and the transport that will be stored inside.

Think about usability, about how important anti-vandal properties and other design parameters are for you.

Views

Wrought iron garage doors are considered not only reliable, but also aesthetically pleasing; moreover, they can be made by yourself. Working with metal is, of course, difficult, but the result will fully justify all your efforts. The strength of the forged block depends on the grade of metal used. Forging allows you to give a variety of configurations and geometric shapes. Regardless, forged fences are heavier than conventional solutions. The gates are divided into sliding and swinging forms. Opening them requires either considerable effort or a very powerful motor, especially when choosing a recoil scheme.

The use of conventional corrugated board is no worse in practice than the use of forged metal. Such material weighs less than usual, is tougher (with the same size and weight), and is outwardly attractive. Unlike wrought-iron gates, products from corrugated board can also be lifting, they are resistant to attempts to break in by any means and are relatively inexpensive.

The swing type implies placing the doors made of corrugated board in a double frame, for the manufacture of which a corner of 7.5 x 7.5 cm is used. The connection of the sashes to the frame is achieved by means of hinges. If necessary, you can always cut a gate into the sash.

Sliding and sliding gates in garages are not very common, because their practical application is difficult. Free space is a mandatory requirement (1.5 times more than the canvas itself). Finding the necessary space for him in a densely built cooperative is extremely difficult. Yes, even in a private, detached garage, adjacent to a residential building and having a common wall with it, this often causes difficulties.

It is not at all necessary to assemble metal sliding gates on your own or go to workshops; there are many cheap kits on the market that are ready to use. The canvas rolls parallel to the wall on a special carriage, most often on several. So that it does not "jump out", special catching parts are used to fix the sash when it is locked.

The standard delivery set includes a frame and a console, rollers, catchers, fasteners. Bases are supplied for carriages, also the set usually includes ledge strips, profile sheets, automatic control systems.

The types of overhead gates are sectional and up-and-over. But folding is safer and can be opened in a relatively small space. If four sashes are used, it is possible to superimpose the central elements on the side ones, attach to them with the help of clamps and a general rotation of 180 degrees. Then in the middle part there will be more space for the car to move.

The swivel-lifting version is one continuous canvas, when opened it scrolls and disguises itself under the very ceiling. Several horizontally directed sections were used, and their movement along the guides is limited by the limits of the opening. Above the door, these guides are bent to a certain radius and help the door profile to take a position parallel to the ceiling. The indisputable advantage of this design is considered radical space saving; the turning gates slightly go beyond the contours of the opening, when they are raised or lowered. It is better not to approach the opening by car at these moments.

The lift-and-turn scheme is devoid of guides and rollers, all work is done by levers and hinges. The balancing of the lifting structure is achieved by springs stretching along the edges from it. Since such a canvas is one-piece, it will be much harder to crack it than a swing-and-lift one.

You can not create any doors at all, without them swing gates work perfectly. They do not have a "blind" zone, when entering and exiting everything is clearly visible, which reduces the risk of crashing the car on the gate. The space available for turning, changing the trajectory also increases. The downside is increased requirements for space under the ceiling - if there is not enough space, you will not be able to use the swing gate.

Hinges are often taken with a bearing. Experts recommend that you always find out the category of their strength and be prepared for the fact that it will not be possible to attach these loops without welding. Never buy accessories for which there are no accompanying documents - almost always it is either a marriage, or a fake, or an element that is already extremely worn out.

As for the materials, iron (or rather, steel) corners of 6.5 cm are most often used for the manufacture of frames, pipes are used to obtain a profile. The rubber seal is designed to contain not so much the cold as the wind.

Options equipped with a wicket are always preferable: they will allow you to go in and out without opening large leaves.Swing doors made of wood with a metal shell should not be chosen; a more modern option is an all-metal structure. But in sectional products, the use of expensive types of wood, on the contrary, indicates that they belong to the elite category.

Rolling shutters, the width of which does not exceed 3000 mm, can be folded manually, while larger ones necessarily require the use of electric traction and built-in control systems. Any rolling shutter is not recommended where there is no additional high-end signaling or round-the-clock physical security is not organized, since their protective properties do not meet modern requirements.

Lifting and turning devices are more reliable, but their significant drawback is inability to conserve heat in the garage... If such gates are trimmed with wood or corrugated board, processing is required to neutralize the effects of bad weather and dampness. Always inquire about warranty periods, type of seal and operating period, safety certificates for finished products.

Standard sizes

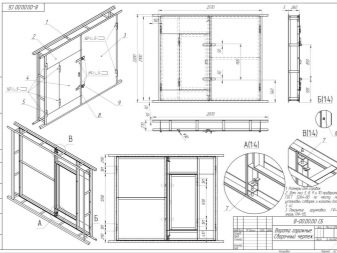

But no matter what type of gate is chosen, no matter what fittings it is equipped with, it is imperative to prepare a project. Let it be the simplest freehand drawing, but you will be completely protected from problems later. Eliminate the situation when a lot of wasted effort will turn into failure just because the canvas does not fit into the opening, for example.

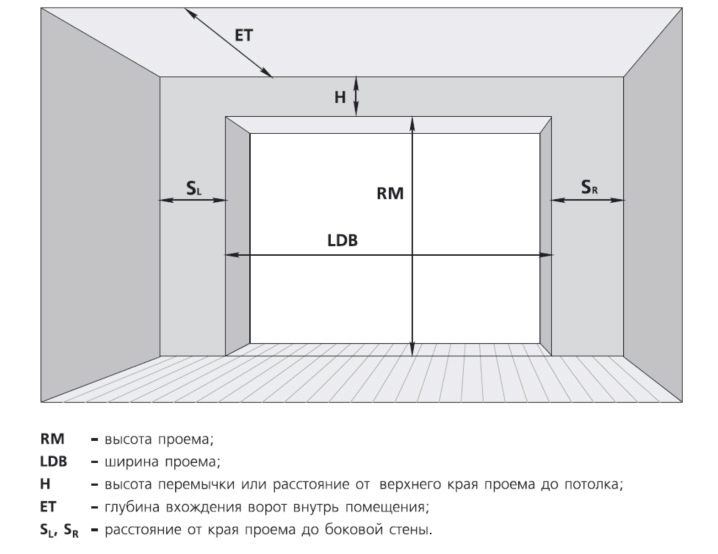

The width of the garage door is determined in such a way, so that at the entrance exactly in the middle from the left and right sides of the car to the frame there is at least 0.3 m. It is advisable to measure this distance, taking into account not the case, but the rear-view mirrors and other elements that go beyond the dimensions. If there is an opportunity to exceed the minimum distance, you should definitely use it, because this will only be a plus for your safety.

The standard provides, however, that for a private garage, even in ideal conditions, it is not worth making the gate wider than 5 m.After all, even with such a value, the weight of the structure turns out to be a very significant load on the fasteners and walls.

In most cases, they are limited to a width of 250 - 300 cm, and always the gap from the edge of the frame to the wall running at a right angle to it is at least 0.8 m.The height is also determined by the dimensions of the car: passenger cars, with rare exceptions, freely pass through an opening with a height of 200 - 220 cm. But the owners of the most powerful SUVs and minibuses should be guided by the dimension of 250 cm.

Assembly and installation

The easiest for self-assembly are swing gates, which you can make without assistance. It is enough to purchase all the necessary set of materials. Collecting up-and-over doors, even for people with solid engineering training and knowledge in the field, is not an easy task.

Almost always they just buy a finished product and install it, as the instructions from the manufacturer say. And the lifting-sectional type completely excludes independent execution: it will take a lot of money, time and effort, the result is almost always deplorable.

Folding structures, or otherwise - "accordion", are just a chain of sections delimited by the seal. Most often, the sections are attached at the top or on the sides using at least three blocks. It is permissible to connect them at a right angle or at an angle of 180 degrees. It is very important to calculate in advance, exactly how many sections you need, because otherwise you will have to redo everything.

Welded frames must be made solid, and therefore the gaps between the corners must be closed with a 5 x 0.6 cm strip, which is oriented horizontally. There should be about a meter between such stripes. 5 x 5 cm corners can serve as a substitute for steel strips, but this will require deepening their horizontal wings into the walls.You will need to form grooves of the appropriate depth, and always in the aisles.

Russian conditions make it possible to use effectively only warm garage doors, because even official standards stipulate that it should not be colder than +5 degrees inside. Otherwise, it will take too long to get the machine ready for use each time. The main insulation materials are mineral wool, extruded polystyrene foam, polyurethane foam. All others do not cope well with the specific operating conditions in garages. They help to make the structure not only energy efficient, but also beautiful finishing materials - OSB board and other options.

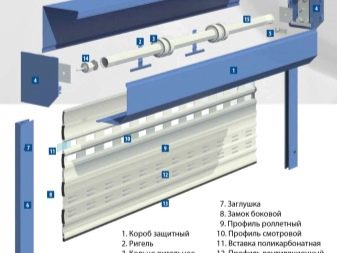

The process of preparing the openings necessarily includes the removal of all cladding and decorative elements, the complete alignment of any face, which is checked by the building level. When you put the guides, do not forget to pick up the level again after each installation step and check the main parameters. Only under this condition is it possible to provide a decent level of thermal insulation, to restrain the penetration of sounds from the outside. Installation of metal rails is carried out on the sides to fix the canvas.

The next stage is the fitting and installation of the box containing the roller for winding the web. They constantly make sure that the shaft runs strictly horizontally, and that the wires and drive parts are brought out, where they can be connected. The end grips are brought to the floor and fixed there in a position determined by design features. But first you need to make sure that the grippers coincided with the border of the web lowered to the limit. Once this has been done, the drive can be mounted as well.

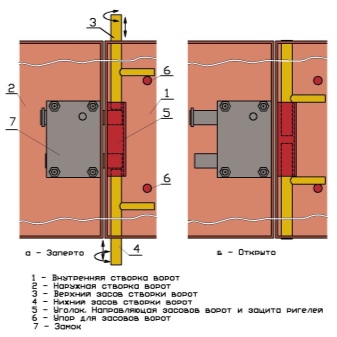

The durability of self-made doors is at a decent level, but, like all others, they require the use of a lock. Most often, one of the doors is closed with locks from the inside, and these locks themselves are introduced into the floor and into the roof; holes of 50 mm are drilled for such elements, always deaf. The second sash will be locked with a padlock.

Depending on the idea, the tongue either clings to the fixed canvas, or goes deep into the hole prepared for it in the thickness of the frame. It is advisable to install a padlock outside, the ears for which are welded to the shutters. If you want to equip roller shutter doors with a lock or use more complex and reliable protection schemes, be sure to consult with experts.

Selection rules

But no matter how carefully the installation takes place, it will not achieve success if you approach the choice of components superficially. The size of the corner for a frame less than 6.5 cm is not very practical. Both corners of 5 cm in size and steel profiles of a rectangular configuration (which are additionally sheathed with iron sheets of 0.2-0.3 cm) can be used on the sash. Hinges for external doors of the reinforced type must be used. Using the diagram, it will be easy to calculate how many components you need to work.

Internal clips should be used in factory, and even more so in homemade garage doors. The more massive the locking structure, the thicker the reinforcement should be; accordingly, the required hole diameter is selected.

Their depth is in any case approximately 20 cm. Hooks are invariably more reliable than simple fittings.

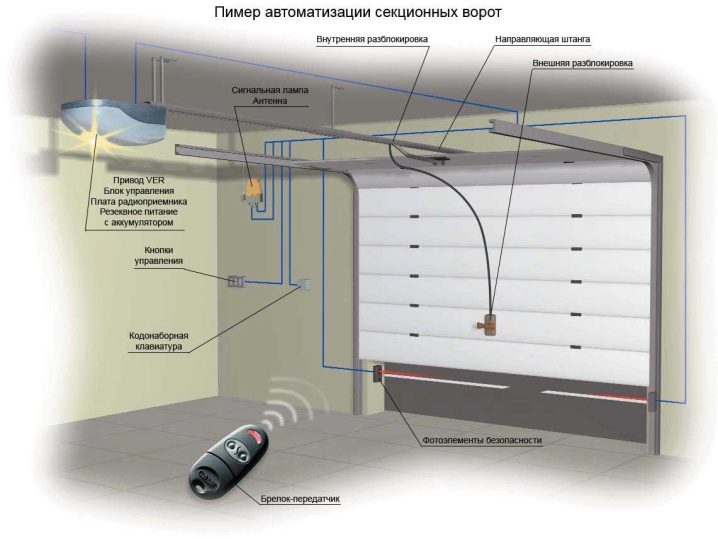

Automatic control

It is advisable to equip sectional and divided gates with automatic controls. Often it is done through a remote control (like the one that gives commands to the TV), but professionals recommend choosing universal control. The fact is that even the most advanced electronics sometimes breaks down. And if the whole system is coordinated only by it and there is no way to fix the gate manually - in the event of a breakdown, it will not be possible to close or open them to the end.

Always ask whether the doors are supplied with sensors that recognize the approach of people, the occurrence of obstacles for closing.Such devices are relatively inexpensive, especially when you take into account the risk of injury or damage to the blade itself, guides and mechanism eliminated by them.

Hacking protection secrets

The best doors and locks are not an absolute guarantee that a burglar won't get into your garage; if a "professional" or even a whole criminal group is acting, there will almost certainly be an attempt to cut the hinges and remove the sash. Protection against this is as follows: from the inside of the frame, just where the hinges are located, a piece of the corner is welded.

The calculation is simple: when the sash is closed, the corner of 10 - 20 mm enters the wall (into the groove in the brick allocated for it) and clings to the frame. Even when the criminals cut off the hinges, the sash will still remain stable on the frame.

An alternative is to use a spider-style lock. The pins of such a constipation are introduced not only into the walls, but also into the floor and even into the ceiling. In this case, it is recommended to put a stopper that does not allow opening the "spider" otherwise than with the original key. Using more complex methods or combining them is not recommended, so reliability is not always at its best, and excessive foresight often leaves no choice but to destroy the walls when the key is lost.

Look carefully so that the pins do not damage the seal and do not worsen the protective properties of thermal insulation, waterproofing.

DIY making

The first step in the work is to complete the frame. It is recommended to start doing it when the front wall is being erected. Only 0.5 m of masonry has been prepared (even less is possible), as the construction is suspended, and only after the installation of the gate can it be resumed. We take the angle grinder and cut the corner into 4 fragments, the length of which will be equal to the width of the opening.

Moreover, the same number of segments should be obtained, the length of which is equal to the height of the alignment. You can cut the metal in even portions, or leave a stock of 0.1 m. Subsequently, this reserve will definitely come in handy.

One side of the corner, located inside the opening, is cut out according to its size, and those shares that will be on the street and inside the wall are left exactly 50 mm in length. However, you can also cut them off, this makes the subsequent welding easier.

The resulting segments must be laid out on a flat surface and check their geometry with a building level. All angles, which must be straight, are measured no less carefully. Next, you need to weld the corners and get a frame, and there are two techniques: in one edge of the corner it moves onto the other corner and attaches, in the second edge it is cut off. A cut allows both elements to be positioned in the same plane, but this leads to a loss of strength.

If the corner to be welded "leads", the self-made gate can still be done as it should - you just need to weld the lever from the scraps in the required position and correct the geometry. Do not forget that the slightest welding defects must be removed from the outside of the frame.otherwise the flap will not fit snugly enough. The frame in which the sashes are placed should be made slightly smaller than the gate frame, the goal is the same - free and tight pressing of the parts of the structure.

For this part, you can use both steel corners and rectangular profiles, the differences will only affect the convenience of work and the degree of permissible load on the frame.

We prepare 4 segments, the length of which should be 1 - 1.5 cm inferior to the height of the gate frame; in a double-leaf system, 8 such segments are required, the other four in length is 50% of the width of the frame minus 3 - 3.5 cm. It is recommended to lay out these blanks inside the finished door frame, this will help to detect defects. A prerequisite is maintaining right angles. An increase in the rigidity of the structure is achieved by welding an additional horizontal segment (spacers that prevent distortion of the geometry of the system). The best place for the amplifier is in the middle of the frame.

It is advisable to take steel sheets at least 0.2 cm in thickness on the sash. A pair of canvases is cut out of them, each 30 - 40 mm higher than the opening, the width of one is 10 - 20 mm less than that of the frame, and the other has just as much more of it. Both at the top and at the bottom of the canvas should be removed from the frame contour by 10 - 20 mm, on an arbitrarily chosen sash, which will open the second, the canvas is separated from the edge of 1 cm of free space.

Since sheet metals almost always "play" when welding, work begins from the corners, even when dealing with a wicket or other minor part.

Then the center of the sheet is boiled, and only then, with a step of 100 - 150 mm, the sheet is completely welded; this stage of work ends by cutting the welds at the corners, thereby reducing the risk of deformation.

Next comes the turn of the accessories, and first of all, reinforced hinges are brewed. Their bottom is attached to the frame, and the top is held on the swing-open sash. To make the fastening as reliable as possible, sometimes 0.5 - 0.7 cm sheet metal is boiled over the hinges (in the form of curved strips), and a reinforcing insert is attached inside the loop itself. Place the structure on a flat surface and lay the sash inside the frame; then consider if there are any errors, interlocking parts for each other when moving. If everything is done correctly and no errors were found, you can mount the gate.

The tarpaulin (curtain) is hung last, after installation. But it is advisable to try it on the ground in order to identify possible deviations and immediately make adjustments. Otherwise, the alteration will turn out to be more complicated and time-consuming, and material costs will increase.

Having mounted the gate, they return to work with the wall, and bricks should occupy the entire gap from the outer to the inner frame. Along the entire length of the masonry, the frame should be firmly walled up in it, therefore, reinforcement rods of at least 0.2 - 0.3 m in length are boiled to the entire height, the other end of them is inserted into the seam of the brick wall. Once we have reached the top of the frame, place the overlapping beam. Depending on the bearing capacity of the lower structures and the foundation of the garage, it can be made of metal or concrete. The final stage is checking the correct operation of the gate: everything should open and lock perfectly, if necessary, clinging metal parts are additionally corrected.

Roller blinds can only be used in a special type of gate, the so-called roller shutter. In conventional designs with sashes, they are not needed at all. If a garage with a non-standard configuration or the opening differs from the usual shape, you will need to order the structure individually. Most often, they try to transform the opening by adjusting it to the roller shutter gates. This method turns out to be cheaper, faster, and more economical than drawing up a special project.

Manufacturers and reviews

Regardless of your skills in working with metal, engineering talent and diligence, a thorough study of specialized literature, factory products will still be more perfect than homemade gates. It is impossible to single-handedly outpace the development of entire companies over many decades. But even among manufacturers, you should choose with extreme caution, trusting only brands with an impeccable reputation. The risk is too great to skimp on this.

Germany is represented on the Russian market primarily by a corporation Hormann. She sells products officially, directly on her behalf; any consumer can contact a registered office and receive a quality product.

Lovers of Belarusian products are advised to pay attention to the brand Alutech ("Trend" and "Classic" series). All its products are equipped with drives of German or Italian production and they are willingly purchased by residents of a number of countries, even European ones.

Russian concern DoorHan purchases components in China and Italy, he values his name and cooperates only with impeccable suppliers who know how to make quality parts.

If a gate with an automatic drive is chosen, it is best to have it made at Nice, Came, Faac or ANMotors. This "brilliant four" makes impeccably reliable engine systems.

Products and services Hermann highly appreciated by consumers for its self-installation capability and ease of use.

Successful examples and options

Garage doors can be done with a minimum of exterior decoration. Geometrically simple construction, smooth metal, solid gray color - nothing superfluous, everything is strictly functional. And by no means faded, because such a solution goes well with brick walls of any thickness.

And here they decided to make a combination of similar colors on the outside: pink brick is diluted with a thick red square of moderate saturation. The glossy surface looks very attractive and evokes only positive emotions.

In this example, attention is drawn to the surface texture, its evenness and neat horizontal stripes of gray. But this is not the limit of decoration skills - take a look at the gate covered with rectangles. Their designers undoubtedly preferred to choose the most natural effect. An exquisite yellowish tint is harmoniously combined with white racks and completely coincides with the color of the walls and roof.

The authors of this project tried to demonstrate the contrast of black and white colors. And they fully managed to realize their plan - stylistic unity is emphasized by the same type of construction material.

Wood imitation can be like this: dark rectangles with a diagonal course of fibers are favorably set off with light stripes around the perimeter. Dark fixing elements seamlessly flow into the even darker building frame. And at the very edge, pinkish vertical elements are slightly visible.

It is not necessary to make just such a gate at home. The most important thing - they are able to look very good and original.

If you follow all the rules for selection and installation, which were discussed in the article, there will be no problems with the gate in the coming decades.

For information on how to choose a garage door, see the next video.

The comment was sent successfully.