How to insulate a bath from the inside?

The most important issue in the design of a bath is insulation and the ways in which you can do it as efficiently as possible.

Peculiarities

Most of the time, the bath was used only as a special room for hygiene procedures. Retaining heat in wooden buildings during the winter season was quite difficult. In Russia, with its harsh climatic conditions, the bathhouse served purely for washing. However, the ancient Greeks spent their time in their baths discussing issues of politics and art, war and peace. Turning to modern times, we can conclude that our attitude to baths has taken over the features of ancient times. It is banal to maintain hygiene with a shower, and the bath is predetermined by a recreational role. With modern technology and materials, it is easy to set a comfortable temperature any day, despite the cold weather.

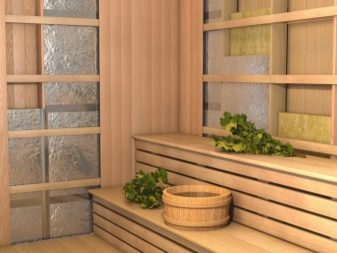

The most important function of the bath is the steam room. The temperature in it is traditionally defined at 90 ° C and 130 ° C.

Materials (edit)

Taking into account several important characteristics will help a successful choice of insulation. A high-quality material must have a vapor barrier, otherwise the penetration of moisture will worsen its condition and stop retaining heat.

The raw materials that make up its basis must meet environmental standards, otherwise the high temperature will provoke the release of toxins that pollute the environment and harm human health. The heat in the room will be retained for a longer time with a low degree of thermal conductivity of the insulation. The material must meet fire safety standards - its flammability must be minimized by correctly correlating the type of insulation coating and the temperature in the bath room.

The low hygroscopicity of the insulating agent will protect the surface of the bath from moisture penetration from the inside of the room. The warranty period is higher for insulation with high water-repellency. The insulating material must be able to maintain its shape for a long time and not shrink, as a result of which the heat in the bath will remain for a long period.

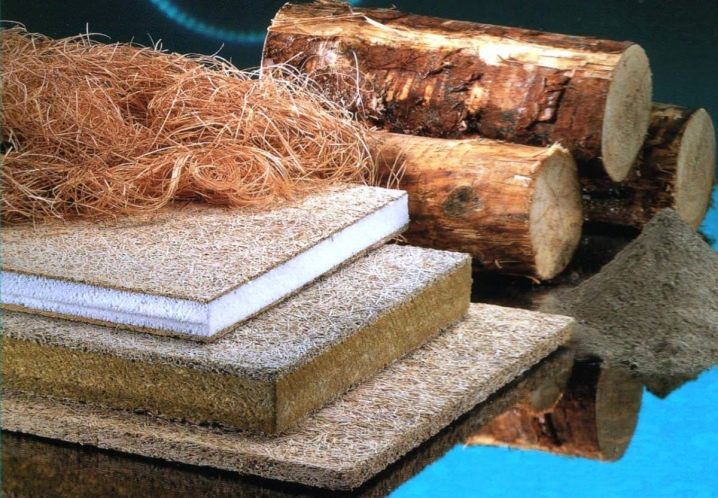

The range of insulation materials is presented in three groups. Organic heat insulators have long been used to retain heat in a bath. They are made from natural, environmentally friendly raw materials. A common option among them is tow with or without resin impregnation, sawdust, layers of moss, reeds, dense felt or jute fibers. Natural ingredients are absolutely safe for human health, but they have many negative qualities. The vegetable base of the insulation contributes to its easy flammability, therefore, the level of fire safety of the building is reduced.

The dry structure of a substance is susceptible to moisture, which it absorbs from the air. The presence of water in the insulating layer contributes to its cooling under the influence of the outside temperature, as a result of which the bath cools down faster. The creation of a heat-insulating layer from organic raw materials is a time-consuming process, the implementation of which requires experience in this field from the master.

Organic materials are attractive to small rodentswho perceive it as food. Plant mass is a favorable environment for the development of microorganisms, the growth of mold and fungus.

The second option is semi-organic thermal insulation materials, the manufacture of which is carried out by analogy with the previous type, but with the addition of glue. The interaction of natural plant components with an adhesive base gives the insulating layer strength and hardness.

The insulating structure has a tiled look. Reed, peat and chipboard plates keep the high temperature inside the bathhouse for a long time. Exposure to steam adversely affects the bonding agent, thinning it, therefore, the use of semi-organic substances is unacceptable in rooms with a high degree of air humidity. It is not recommended to install tile insulation in a steam room where the moisture content in the air is maximum. This material is more suitable for warming dressing room rooms.

The third type of insulation is synthetics. The variety of synthetic materials falls into two categories. Polymer insulation includes polystyrene foam, expanded polystyrene and polyurethane foam. Their use is limited - the coating must not be allowed to be in a high temperature area. Strong heating of the polymer causes an internal chemical reaction, resulting in the formation of styrene, the vapors of which are harmful to human health. Also, high temperatures can cause a fire of synthetic insulation, so its use will be appropriate in a cool rest room.

Penoizol insulation, the only synthetic-based insulation material, is approved for use in steam rooms. A layer of thin aluminum foil is placed on top of the polymer, which prevents heating to a dangerous level. Mineral insulation is allowed for use in any part of the bath. They are represented by two subspecies - basalt wool and glass wool. They are highly resistant to fire and high temperatures.

You can choose a structure from a cinder block, expanded clay concrete blocks, aerated block, gas silicate bricks. You can insulate the old building with penoplex or foam glass. For a cinder block or block system, chopped sawdust is most often chosen.

Insulation scheme

The highest temperature in the bath is maintained in the steam room or in the sauna, while the dressing room is located on the border with the street, so it is constantly subject to slight cooling. Rest rooms are less dependent on the type of heat-insulating material, their air is specially warmed up weakly.

The process of laying the insulation is formed depending on the material of the structure of the bath. Recently built, due to the low thermal conductivity of wood, it does not need careful insulation. After 2-3 years, the wooden blockhouse shrinks and crevices appear between the logs or beams. To insulate it, it is recommended to make caulking between the crowns using natural material in order to preserve the microclimate inside the building.

A wooden structure made of logs or beams takes time to dry. After drying, gaps form between the parts, through which cold air flows into the interior. Jute fiber is used to fill narrow cavities between wooden elements, as it compresses well. Laying insulation directly during construction will facilitate the work. The final study of small areas is carried out after the completion of construction with the help of a mallet and caulk. The laying of insulating material in a brick bath is necessarily carried out during the construction process, since the brick quickly gives off heat.

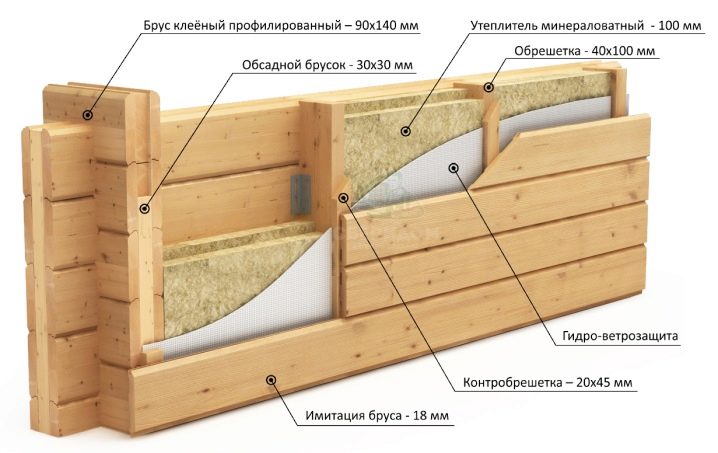

The traditional thermal insulation scheme is a ventilated hinged facade. A layer of insulation is placed on the outside of the walls, after which it is sheathed with siding or clapboard. A space filled with air is formed between the layer of insulating material and the outer coating.The presence of an air gap serves to retain heat, prevents the formation of condensate vapors, the reproduction of putrefactive bacteria and the development of dampness. An alternative way to insulate the steam room is to install a wooden structure around it. The heat-insulating properties of wood replace the heat-insulating material. To do this, you will need a beam, lathing, stone wool, foil insulation and lining.

The surface of the timber is upholstered with lathing, then stone wool. A foil-clad insulation is applied to the layer of mineral material, after which there is a finishing clapboard lining. A panel-type bathhouse implies lightweight heaters - reed slabs, mineral wool and expanded polystyrene. Before laying a heat-insulating coating, panel walls must undergo treatment with milk of lime to eliminate the impact of negative factors. After drying, the lime structure will provide the building with fire resistance and resistance to decay processes. When a bath is located in a cold climate area, it is recommended to insulate its walls with fibrolite or reed slabs. In mild climatic zones, it is preferable to use gypsum or sawdust material.

Calculations

Before the start of the insulation, the working area is limited. Areas not intended for this are covered with roll paper to avoid contamination. For insulation of the ceiling and walls, you will need a 5 x 5 mm bar-rail. To fix the future layer of insulation, a crate is needed. For a brick bath, it is preferable to choose a drywall profile. The fixing of the suspensions occurs on average after 0.7 m, the distance between the profiles should be slightly less than the height of the insulation.

It is recommended to use bars in a wooden bath. Thermal insulation with bulk materials is accompanied by the observance of the distance between the bars of 45-60 cm. The fastening of the lathing parts is carried out using dowels, self-tapping screws in the case of a wooden surface, or anchors for a stone base. Depending on the building material, the length of the fastening hardware is selected. For wood - 2-2.5 cm, for denser structures - starting from 4 cm. The length is associated with the peculiarities of the use of fasteners.

During the installation of the battens, fasteners are selected with a length that ensures a strong fixation of the timber or drywall. The size of the cross-section of the bar is determined taking into account the thickness of the insulating layer to be laid. When insulating with organic or semi-organic material, it is imperative to use a hydro-vapor barrier film to ensure a long service life. Foil, electrical tape, self-tapping screws - auxiliary means during work. Foil tape is required to insulate the surface. 1-2 spools are enough for the entire volume of the treated area. It glues the joints of the tile insulation to create a one-piece sealed plane. Of the tools in the process of warming, you will need a knife, a level, a screwdriver and a plumb line.

Depending on the surface and its location, the amount of required insulation is calculated. When calculating the mass, it is necessary to take into account the rough costs and possible errors, which also consume material. For example, a sawdust-based mixture will require: 10 parts of sawdust, 0.5 parts of cement, 1 part of lime and 2 parts of water. Another recipe for making almost the same mass includes 8 parts of sawdust, 1 part of gypsum and the same amount of water. The composition of such a mixture includes 5 parts of sawdust and clay.

Mounting

The step-by-step instructions for warming a bathhouse consist of several stages. To begin with, it is worth creating thermal insulation for the openings. Leaky doors and windows allow a significant amount of heat to pass through and are an entry point for cold air from outside. Therefore, it is recommended to make the door to the steam room small, with the necessary minimum suitable parameters.To establish an obstacle to the path of air with a low temperature, the threshold should traditionally be located 25 cm above the floor level.

A door made of wood will have the lowest thermal conductivity. The constituent boards without chips and knots should be as even and tightly adjacent to each other as possible. If desired, the doors can be insulated, like the walls, during the assembly process. After the natural shrinkage of the wooden product, the resulting cracks must be repaired with jute or tow, and the door will again store heat with high quality. The lighting in the bathhouse is mostly carried out artificially, so the windows are made of small dimensions. The exception is the rest room, where the window can be of any area, however, in order to avoid hypothermia, it is advised to make it also small.

The glass used in the frames must be double. The air gap between the double glazing creates an accumulation of air that traps the heat inside the sauna room. The glass is installed using a sealant to seal openings between the frame, which can allow cold air to pass through. The remaining gaps between the window opening and the frame must be filled with mineral insulation, for example, mineral wool, on top of which a layer of waterproofing film is applied.

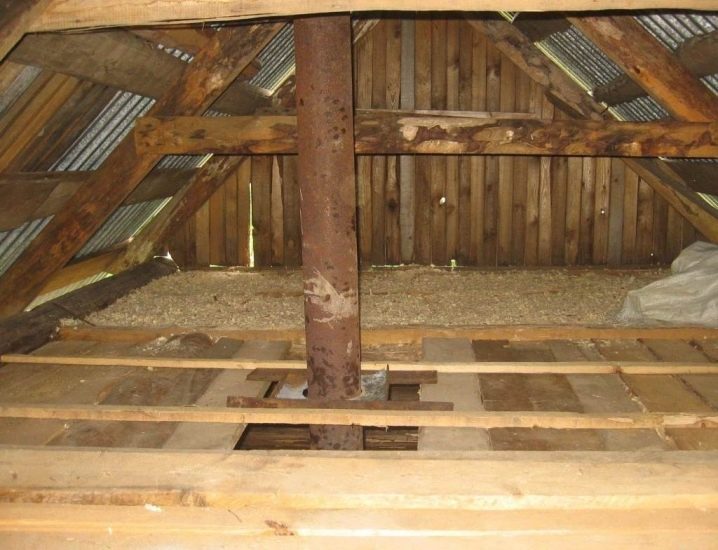

Thermal insulation of the ceiling surface includes roof insulation work, since its large surface in the absence of an insulating layer will allow large volumes of cold air to pass through. The heat of air rises up during cooling, and the fragile roof will contribute to the rapid cooling of the bath. With a high-quality insulation roof covering, the processing of the ceiling can be neglected. Insulation is possible on condition that the bathhouse is located separately from other buildings and has a pitched roof.

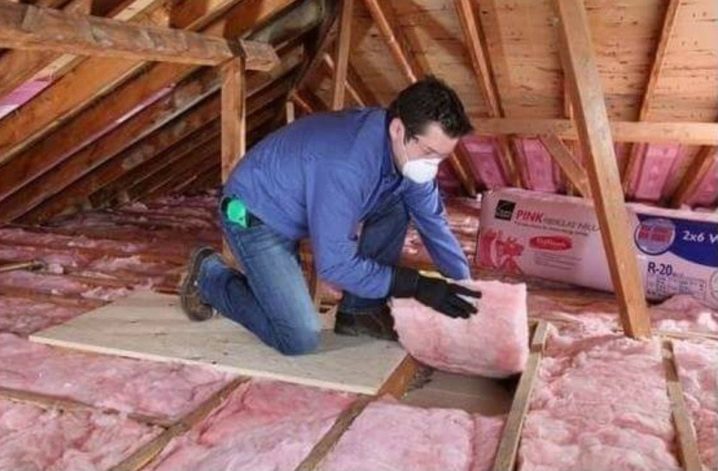

Insulation is carried out using any thermal insulation coating laid on the attic floor. The process of installing synthetic insulation on the roof is similar to the technology of wall surface insulation. When using organic insulation, the frame is initially prepared. When a dry sawdust mixture is poured, it must be dried, cleaned of tar and impregnated with an antiseptic. For insulation, a layer of sawdust is covered on top with a layer of membrane or sprinkled with ash.

Ceiling insulation is done with basalt wool. It is laid on the surface of the walls with a pre-fixed frame. The thermal insulation layer must exceed the thickness of a similar coating on the walls, since warm air rising upward, the temperature of which exceeds the rest of the temperature indicators, comes into contact with the ceiling surface. The insulating coating must be installed with slight gaps on the walls. In the future, it can be used to insulate walls by gluing the joints with foil tape.

The walls inside the bath are covered with an insulating compound after preliminary surface preparation. It needs to be given smoothness, therefore, cracks and cracks are putty between the brick walls. Wooden walls are treated to eliminate the appearance of mold and mildew. First, bars or plasterboard profiles are attached to the wall surface. Insulation is laid in the resulting space. On top of it, a hydro-vapor barrier coating is applied and a wooden crate is installed.

Before installing it, it is necessary to measure the width of the insulation material. The resulting dimensions may not be valid due to possible deformation during movement. Therefore, the lathing is fixed at a distance less than the resulting one so that the material is placed between the wall and the lathing with little effort.The heat insulator must be positioned between them as tightly as possible in order to avoid the formation of gaps, allowing the penetration of cold air and the occurrence of condensation drops. The height of the lathing should correspond to the thickness of the thermal insulation layer. The last stage is finishing.

Bars are attached to the wall surface with their own hands, a heat-insulating component is placed between them. Then, the insulating material is placed in the same place. With a well-defined distance, the heat insulator is held on the wall surface without the use of additional fasteners. In the places of connection, the foil-clad heat insulator is sealed for tightness with adhesive tape with aluminum. Similarly, the places of contact of the insulating material with the crate are glued with a grip of at least 5 cm of insulation and a bar.

Sealing joints must be given special attention.to eliminate the possibility of liquid penetration into the insulation layer. In addition to laying a heat-insulating layer, moisture protection is installed for it. In the rooms of the steam room and the washing room, the method of foil vapor barrier is used, which at the same time will reflect heat. Subsequently, the bath will warm up with less time and fuel costs. To insulate the rest room and dressing room, the temperature of which is lower than in the steam room, you can use other heat-insulating materials. Their laying is carried out with the overlap of one slab by the other by 5 cm and with their subsequent fastening with brackets using a stapler.

The joints and staples for high-quality heat preservation are covered with a layer of foil tape. Do not leave a gap between the layers of vapor barrier material and insulation. A lathing of wooden planks with a thickness of 20 mm is attached to the fixed bars for subsequent covering with clapboard.

Bath floors are of two types - wood or concrete. The technical side of laying a heat-insulating coating does not depend on the material of the floor, except that the concrete structure requires a slightly larger layer of insulation. The classic version of the raw material for creating an insulating layer in the floor is expanded clay. The thickness of the layer of the backfilled material must be accurately correlated with the thickness of the room wall. On average, the size of the expanded clay layer is 2 times the thickness of the walls. The degree of insulation can be increased by reasonably increasing the backfill layer.

Immediately before the procedure for falling asleep, it is necessary to mark the base. It is carried out by delimiting the covered area into sections, the width of which is 1 m or another convenient size. The field with ready-made markings is covered with a vapor barrier film. When pulling, its edges along the wall should be located above the floor level. Laying the film is not necessary if roofing material is already on the surface of the base. To facilitate the work, the guides should be installed and their fasteners. They are located with support on the applied markings and are attached with nails or screws.

Along the border of the level, the placement of beacons is necessary - auxiliary parts, which will orient when filling expanded clay. The height of the installation of the guides is calculated depending on the required thickness of the insulation. Expanded clay must be poured onto the surface and leveled with a wooden lath of the appropriate length.

Advice

When insulating a wooden bath, the best option is a heater made of consumable material - sawdust. To ensure their vapor barrier, a simplified method can be used - the amount of wood insulation required for one cell between the bars is poured into a plastic bag. The properties of polyethylene prevent moisture penetration into the sawdust mass.

The procedure for warming involves starting work from the ceiling surfaceso as not to accidentally damage the walls and floor when processing it.In the area of the chimney outlet, the temperature is high, therefore, for safety reasons, a mineral insulation is used - basalt wool. It is distinguished by its refractoriness and fire resistance. The passage of the pipe through the ceiling must be covered with a protective metal cover.

You can see tips for building a bath from aerated concrete blocks in this video.

The comment was sent successfully.