Arbolite bath: pros and cons, basic principles of construction

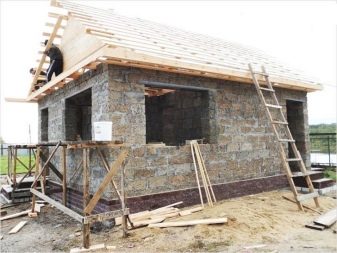

The construction of a bath is one of the must-haves at any summer cottage and just in a country house. However, instead of traditional solutions, you can use a more modern approach - to build a bathhouse from wood concrete. In practice, this material turns out to be no worse than brick, wood or aerated concrete blocks.

Advantages and disadvantages

An important positive quality of a wood concrete bath is a decent thermal insulation. Therefore, inside it is easier to warm up the air to the required temperature. The same air filled the gaps of the chips that make up the material. This is why excellent heat retention is ensured. Others an important property of wood concrete is its incombustibility.

A bathhouse built from this material has approximately the same resistance to moisture as a bathhouse built from concrete blocks. High biological resistance (zero susceptibility to decay and mold nesting) allows to extend the service life. Optimum structural strength is maintained even at high humidity.

Another characteristic advantage of wood concrete is its affordable price, due to which construction costs are minimized.

The lightness of this material, in comparison with the blocks of monolithic concrete and aerated concrete, makes it possible to use a lightweight foundation. And this further reduces construction costs and shortens the work time. There is no need to use heavy equipment and attract a large number of experienced specialists. To process wood concrete, there is no need to use a complex or highly specialized tool. The laying of blocks is no different from the formation of a brick wall. Arbolite elements are used to build structures on the 1st and 2nd floors quite calmly.

But even all of the above points do not allow this material to be considered an ideal solution in all cases. First of all, difficulties can arise when obtaining a working mixture. In artisanal conditions, it is very difficult to make both blocks and the composition that connects them. More precisely, something can be done, but compliance with the standard is not guaranteed. The production of work requires the use of special substances and a strict sequence of technological manipulations.

In addition, arbolite is very easy to let steam through. The substance can absorb water, and therefore vapor barrier of walls in all rooms is imperative.

It won't work just to leave and leave the bathhouse to dry. In order for it to last longer, it is necessary to heat the stove with a half-load of firewood before the end of the water procedures (ideally, there should be even more of them).

Both when buying a factory wood concrete, and when hiring professionals for its manufacture, it is necessary to ensure that it contains aluminum sulfate. If this component is used, the risk of material swelling is reduced. Swelling material, absorbing a lot of moisture, can easily crack in the cold.

In addition, the finishing of such a surface is very difficult. Arbolite, even of the highest quality, has a very poor geometry, which is compensated only by the use of a cement-sand mixture. You will have to make sure that the snow is removed from the base so that no water gets on it.

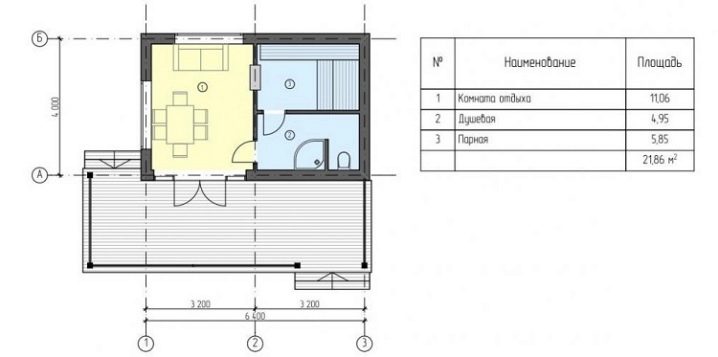

How to choose a bath project?

If it is firmly decided to use wood concrete, it is time to decide on the size.Quite often, a bathhouse in a suburban area is built with a second residential floor, and in this case, the search for a suitable project has its own characteristic features. The total size of the building is chosen according to how many people will use it at the same time. For the constant, systematic use of a bath of this kind, it is required to build an almost full-fledged suburban dwelling. Even in this case it is recommended to choose such projects that allow on the ground floor, in addition to the steam room, to place a leisure room, a gym and some other utility rooms.

Since even when using light wood concrete, the total mass of a two-story bath is quite large, it is irrational to put it on a lightweight columnar base.

Experts recommend installing an unbreakable reinforced concrete tape. It must necessarily go under the soil freezing line.

As for heating, heating with a double-circuit gas boiler is probably the best choice. At the same time, on the ground floor, for the sake of observing traditions and the necessary color, an ordinary stove is mounted a stove.

If it is not possible to connect to the main gas pipeline, it is advisable to heat the bath with a solid fuel boiler. In the absence of a central water supply system or insufficient power, its water supply must be provided by a pump from a well or a well.

In places with a harsh climate, it is useful to place such water sources inside the bath itself. For obvious reasons, it is worth placing a staircase inside, leading to the second floor. Since everything you need to place in a limited area is difficult, sometimes you have to turn to professionals to draw up an individual project.

Basic construction principles

Foundation

When building a wood concrete bath with your own hands, sometimes the base is made of an insulated slab equipped with stiffeners. The recommended thickness of such a slab is 3 cm. It is imperative to provide for insulation of the blind area. To prevent the foundation from getting wet, all liquid is drained from it through the drainage pipe. Both the features of the blind area and the use of a drainage system are taken into account when digging a pit.

When a slab is mounted, one should not forget about passing communications through it in places strictly defined by the project. Vibrators are often used to give concrete the necessary qualities.

Walls

In the usual step-by-step instructions for the construction of wood concrete baths, the fact that they are being built in the spring is often ignored. More precisely, the professionals who compose such instructions forget this fact, which is most obvious to them. If necessary, the blocks can be cut into desired parts using a circular saw. It is complemented with a 33 cm disc. The openings must be strengthened.

Installation of windows and doors

For the bath, it is recommended to choose wooden windows and doors. The thickness of the structure must be such that the dew point is inside the glass unit. If the required thickness exceeds 22 cm, you have to either strengthen the thermal protection, or use triple glazing. Self-tapping screws and anchors into wood concrete walls are almost always screwed manually... Only in some cases are tools used.

Be sure to evaluate what the dimensions of the opening are, how it is located. If necessary, if the level shows the presence of excess, they are cut off, and the surface will have to be sanded. That the part of the block where the chips are exposed, not covered with a cement layer, must be impregnated with a protective mixture... Natural oils are the best option for processing.

Do the same when installing doors.

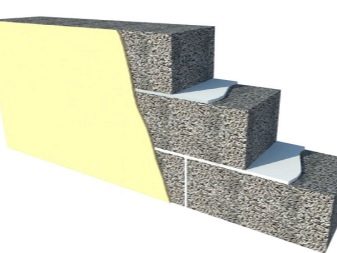

Plastering the walls outside

In some cases, only the seams can be finished with plaster, and the rest of the surface can be left without finishing. In wet rooms, the entire volume is plastered. In dry rooms, all surfaces, except for the seams, are upholstered with clapboard... If, nevertheless, plaster is applied, careful preparation is not needed - adhesion to the surface is provided initially.But in order to extend the life of the structure, it is useful to use steel wire mesh.

It is important from the very beginning to choose a specific option: either limiting it to rough plaster, or adding it with a layer of final finishing. Most often, a cement-sand mass 2 cm thick is used. The decorative qualities of such a coating are small, but it turns out very cheaply. If you use a slightly more expensive lime plaster, you can improve the vapor permeability of the structure.

Making the ceiling

First of all, they equip the overlap. The material must be treated with fire retardants. Mounting plates made of selected metal are used for fastening the beams.

Further:

- hemmed with boards;

- make insulation with expanded clay or other material (most often with basalt wool);

- form a vapor barrier;

- make hydraulic protection;

- put a flooring of boards.

Interior decoration

The material with which the walls of the arbolite bath are finished inside must be:

- strictly hygienic;

- perfectly tolerates heated air, contact with water;

- non-toxic;

- resistant to mechanical damage.

No insulation required. The vapor barrier is only installed in the steam room. For its manufacture, foil-clad material is used. A crate with a gap for ventilation is placed above it. Already a lining is attached to this crate.

Reviews

The attractiveness of a wood concrete bath for owners is associated not only with its cheapness and resistance to fire. Amateur builders indicate that the work is done as quickly as possible. The styling method is quite simple. Thanks to the use of foil insulation and lining, you can provide heating up to 100 degrees in 90 minutes.

It is worth noting that with poor-quality waterproofing, walls can quickly collapse.

For the pros and cons of wood concrete, see the next video.

The comment was sent successfully.