How to make a bath tub with your own hands?

Many owners of suburban areas in the construction of houses provide in their planning for the presence of a good steam room equipped with a bath tub. But if such an idea appeared after the construction and nothing in the project cannot be changed, then you can install a font on the street, where firewood will be used to heat the water. Such swimming in the fresh air will allow not only to overcome depression, improve mood, but also strengthen the body.

Preparation

Anyone can make a bath tub with their own hands, although it is not as simple as it might seem at first glance. First of all, it is worth calculating everything well in order to avoid semi-handicraft production. It is also important to choose the appropriate place for installing the font and determine the shape and size of its structure. The choice of material for the body of the vat, which must be covered with a protective layer, also plays a huge role. At the preparatory stage, they also think over a scheme for draining water, conducting a water supply system and interior arrangement with footrests and seats.

Tools and materials

Before you start making a bath tub at home, you need to worry about the availability of appropriate equipment, in particular, this applies to electric welding. In addition, you will need a "grinder" with a cutting wheel for metal and a jigsaw, which can be used to cut curved parts. As for the choice of material for the case, it is difficult to make it. So, A cast-iron vat heats up several times longer than a steel one, but it has a convenient rounded shape without corners and a smooth surface.

The disadvantages of cast iron include the fact that it quickly rusts and decays over time, so a vat of this material should be installed only on a podium lined with brick or rubble (this will significantly complicate its maintenance).

So that the bath vat will reliably serve for a long time, experts recommend choosing a stainless steel sheet in the form of sheet steel for its body. This material is durable and resistant to temperature extremes. The only thing is that only a professional welder can assemble a stainless steel vat. If there is no experience in such work, then it is better to choose ordinary steel, which even a novice master can weld.

Drawings and dimensions

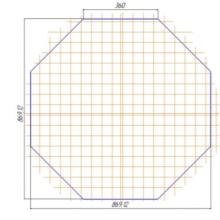

After everything has been decided with the material of manufacture and the place for installing the bath tub, the next item in the preparatory stage of construction work is the creation of drawings, according to which the bath will be made in the future. First you need to sketch out sketches and choose a more suitable shape for the future design. Most often, huge containers are made of metal sheet in the form of hexagons or octahedrons, that is, the font is not round.

Thanks to this form, the pattern of cutting metal blanks and the process of their welding is greatly simplified.

As for the sizes, it is advisable to choose more of them, since miniature designs will be inconvenient to use. Experts recommend choosing standard sizes, in which the diameter is from 220 to 260 cm, the depth is from 60 to 80 cm. In addition, when choosing the size, you should take into account the capacity of the font (how many people can swim in it).

The final stage of the preparatory work is the creation of drawings, which should carry complete information about the size and shape of the future vat.According to the drawn up drawings, the material consumption is calculated and its purchase is carried out.

Manufacturing process

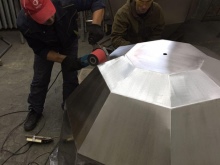

Anyone can make a wood-fired sauna vat with their own hands, the only thing is that this process is complicated, and for its implementation you will need to stock up not only with the necessary tools, materials, but also patience. Before welding a bathing container from sheet material, you need to build a model of its body from fiberboard or cardboard sheets, using previously prepared diagrams and drawings. The model is reduced in size several times.

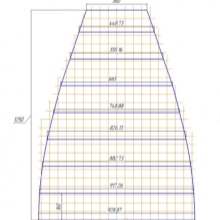

First, the bottom of the vat is cut out in the form of a polyhedron, then the square side walls. Next, the desired angle of inclination is selected separately for each wall and the model is assembled - if the layout is done correctly, then you get a single structure without gaps and you can proceed to the next steps.

- Cutting and assembly. All dimensions and diagrams from the drawings are transferred to metal sheets, while it is important not to forget to leave a small allowance on the cut line. Cutting is best done with a grinder, while small curved elements can be quickly cut out with a jigsaw. This is a very demanding job that requires accuracy and does not allow any deviations from the markings. So that in the future when assembling the structure there are no problems, it is recommended, after cutting, to carefully check the dimensions at all points and be sure to compare them with the distances on the cardboard layout.

Before welding, a special support from rolled steel should be assembled. A hex or octagon is welded first, its inner perimeter must necessarily match in size and shape with the contour edges. After the polygon has been welded, it is placed on a flat solid surface and the side wall blanks are installed in pairs on it. Each pair of opposite walls is welded to the prepared bottom. As a result, a bathing tank is obtained, turned upside down, after which it is unwrapped. The work is completed by boiling the seams and installing the support frame.

- Structural stability check... Before sheathing the vat with a board, the assembled structure should be checked for heat resistance and tightness. You can pour water into the container using the laid water pipe from the bath through a hose. In order to then remove the water from the vat, it is necessary to pre-weld an elbow from a metal pipe in the bottom part. The hot tub must be installed on the site in such a way that its protruding parts do not interfere and are not traumatic.

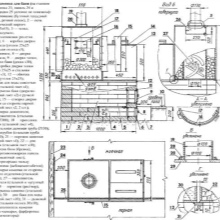

The test of a bath tub is carried out as follows: a metal ballast and a wooden lattice are placed on its bottom, the weight of which should not exceed 180 kg. Then the container is filled completely with water and left in this state to stand for several hours. If during this time the vat has not leaked or cracked, then you can make a fire. Sometimes such vats are installed with a small oven, which simplifies their maintenance.

With strong heating, the welded structure may crack at the seams for the first time, but this is not considered a defect, the main thing is that no delamination of the seams occurs on the body.

- Processing and decoration. After the vat has passed the test for strength and tightness, you can safely proceed to its refinement. If stainless steel was chosen for the manufacture of the case, then it is enough just to walk on it by polishing. A vat made of ordinary steel is blued or phosphated. You can simply apply a protective film - for this, the metal is covered with a mixture of vegetable and machine oil, after which it is fired. As for the inside of the container, it is advisable to cover it with a silicone film or polish it - this treatment will protect the metal from rust.

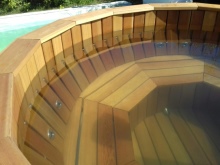

Everything ends with the installation of seats inside the vat and the sealing of the upper edges.It also does not hurt to place a protective railing next to the structure. They can be made of wood, preferring linden or oak. The seats are polished, and the material from which they are made must be impregnated with a moisture-resistant varnish.

- Installation... Before installing the vat on the site, carefully level the area and sprinkle it with an even layer of gravel. It is best to place the hot tub under a canopy, which would be protected from water flowing down from the roof and wind. Since the manufactured vat is heavy and large, it can be unstable. Therefore, it is recommended to additionally install it on a metal cruciform structure.

Recommendations

Despite the fact that making a bath tub with your own hands is considered a difficult task, anyone can handle it. For this, it is important to have some experience with metal and be patient. Novice craftsmen, when making such a font, should also take into account the following recommendations of specialists.

- At the preparatory stage, before installing the vat, it is necessary to take into account all the nuances. A person in such a font should feel cozy and comfortable. If the vat is planned to be located in an open area in order to fully enjoy the solitude with nature, then you should worry about being protected from prying eyes. In addition, the approach to the vat should be comfortable.

- The sizes and shapes of the font are selected individually, but it is important not to forget that all cut metal parts will have to be welded. Therefore, it is advisable for craftsmen who do not have experience in working with a welding machine to select simpler designs. Then they can be refined with a brick or wooden base.

- At the end of all welding work, the seams must be knocked off from slag., then they are processed with a grinder until the maximum surface quality is obtained.

- The vats can be installed both in the bathhouse and in the open area. In the second option, it is necessary to lay a pile foundation using screw piles in the form of a metal rod with a spiral at the end. This will make the installation stable and will not move.

The following video shows how to make a bath tub with your own hands.

The comment was sent successfully.