Sandwich panel garages: advantages and disadvantages

The once-current prefabricated metal garage is now a relic of the past. Today, progressive technologies for the construction of garage structures and innovative building materials make it possible to build a strong, durable, aesthetic and affordable autobox that meets modern quality and safety requirements. One of these materials is polyurethane foam sandwich panels, which are ready to build in combination with high performance properties, which explains the sustained interest of participants in the commercial and individual construction market in them.

Among the existing design options, a garage made of this multi-layer modern material, assembled according to a modular principle, is considered a much more profitable solution than a traditional block or brick building. It is relatively easy to install, there is no need for additional insulation or finishing inside and out. In our article, we will find out the positive and negative aspects of a sandwich garage box, dwell on the necessary technological operations for its assembly and share useful advice from experienced craftsmen.

Peculiarities

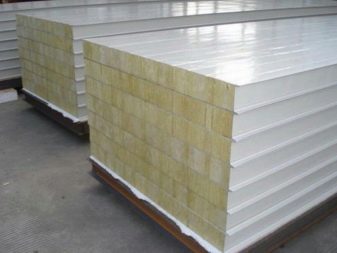

Sandwich panels owe their original name to a peculiar three-layer structure that evokes associations with the American multilayer sandwich variety - a sandwich.

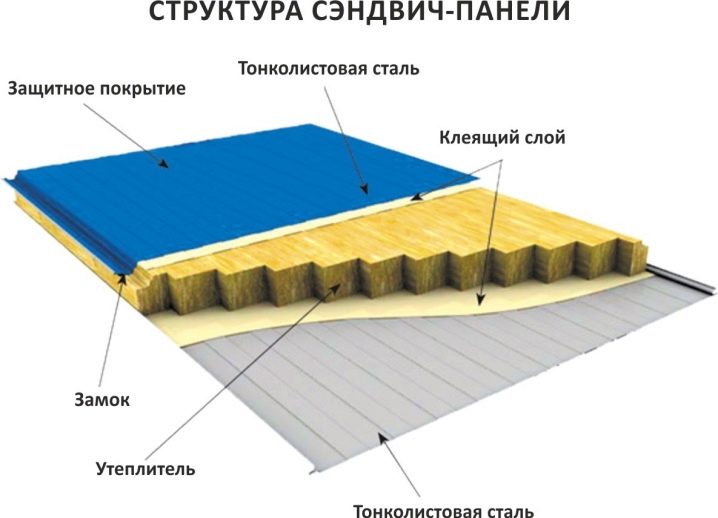

The most common constructive solution for a modular building material is presented:

- Two painted or galvanized steel profiled sheets that provide reinforcing and protective functions.

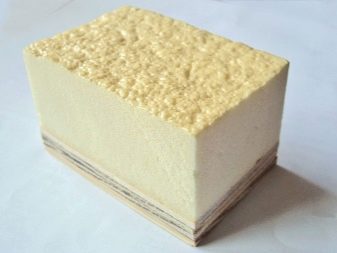

- The core is a heat-insulating layer of mineral wool, fiberglass, polyurethane foam, self-extinguishing expanded polystyrene foam containing fire retardants or polyisocyanurate foam.

In some cases, the outer skin is separated from the heat-insulating layer with a special film, which is characterized by a membrane structure and one-sided internal permeability. It protects the insulation from external factors and prevents the accumulation of condensation in the spring and summer season.

For the production of sandwich panels, the listed layers are glued to each other on high-precision press equipment under normal or high temperature conditions. The result is a superior tool with a wide range of applications in construction and decoration.

Heaters

Any prefabricated garages made of sandwich panels are objects of increased fire hazard. For this reason, when buying them, it is so important to be interested in what kind of insulation is used in them. Mineral wool is considered the best type of insulation. It is durable, fire-resistant and environmentally friendly, since even under high temperature conditions it excludes the release of toxins that are harmful to the environment and hazardous to human health.

The service life of polyurethane and polystyrene foam is shorter than that of mineral wool. Their compliance with fire safety rules is due to the use of raw materials in the production with the addition of flame retardant impregnations, which contribute to the self-extinguishing of the insulating material. But polymer insulation has excellent, almost 100% waterproofness. Whereas hygroscopic mineral wool has to be well protected from moisture.Be aware that polymers release toxins when they burn.

As for polyisocyanurate foam, this innovative heat insulator has all the advantages of basalt fiber (mineral wool) and polymer fillers, but it does not have their disadvantages. You will have to pay 1.5 times more for the purchase of such panels.

Outer cladding

The coverage of "sandwiches" is completely different.

The cladding is made of the following materials:

- Decorative flame retardant paper-laminated constructional plastic "Manminita".

- Flame retardant fibreboard.

- Thin-sheet galvanized steel sheets with a finishing protective polymer coating. \

- Galvanized steel strips.

- Aluminum sheets.

- Moisture resistant plywood.

- Alloyed sheets.

Steel or aluminum panels, the metal walls of which are galvanized or treated with protective polymers: polyester, plastisol, polydifluorionate, pural (Pural), are in stable high demand. Due to such coatings, the panels are not afraid of mechanical damage, corrosion, aggressive chemicals or rolling of sheet material.

Sandwiches lined with oriented strand board (OSP) are used for frame construction. It must be borne in mind that the garage of them will need siding or finishing with some kind of lining.

Application area

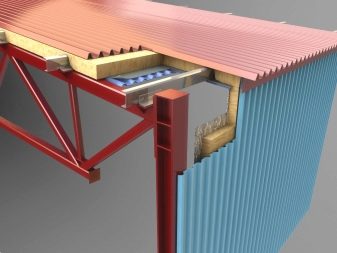

In accordance with the purpose of the sandwich panels are:

- Roofing, from which insulated roofs are assembled. Their outer side is made of a relief profile, which makes it possible to organize a drain. For connection, lock fasteners are used.

- Wall - they form walls in the supporting frame. Fixation of adjacent slabs to each other is carried out by means of a tongue-and-groove connection, which makes it possible to quickly assemble the "box".

Those who have the time and the necessary construction skills are quite able to cope with the self-construction of an autobox from sandwich panels. Everyone else should consider purchasing a ready-made garage construction kit for turnkey assembly from a reliable manufacturer.

Design

The use of a ready-made set of insulated panels, metal frames, fasteners and additional elements for the construction of a prefabricated prefabricated garage-designer is the simplest and most profitable solution. Indeed, when assembling, you only need to be guided by the diagram and follow the manufacturer's recommendations, and not waste time designing a box, buying metal, cutting and adjusting elements.

All kinds of modular garages are on the market today, differing in configuration, the number of parking spaces, the size of the building itself and the entrance, the type of roof - one- or two-slope. The standard design can be supplemented with a reinforced base, insulated gates, doors, double-glazed windows.

Despite the fact that a collapsible autobox is not a capital structure, it has the functional characteristics of a conventional vehicle storage structure. The mobile structure has all the necessary communications and systems, thanks to which the vehicle can be fully serviced. The main advantage of a prefabricated box lined with sandwiches is the possibility of reusable assembly, disassembly and transportation, which does not affect its working qualities and appearance.

Advantages and disadvantages

Any modern building material has both strengths and weaknesses. Sandwich panels are no exception.

Advantages:

- The high speed of construction, which helps to reduce its time by 10 times or more - this is clearly demonstrated by the pre-fabricated modular autoboxes.

- Possibility of all-weather installation of polyurethane foam sandwiches, excluding moisture accumulation and resistant to negative temperatures.

- Trouble-free transportation and reduced costs of transportation of building materials, since the panels are distinguished not only by their strength, but also by their relatively low weight.

- Reduced base load by 100 times or more. For this reason, there is no need to examine the soil before construction and you can save on the construction of a capital supporting structure.

- Eliminate the need for additional finishing, since the boards are a factory product, completely ready to use. Facade sandwiches boast a perfect surface that simply does not need both interior and exterior finishes.

- Hygiene: resistance to damage by fungus or mold, due to which they are used for the construction of objects of the food industry and public catering.

- Low moisture absorption rates, even in conditions of leakage at the joints of the panels with each other, they will not exceed 3%.

Separately, it must be said about the excellent thermal insulation properties of this material. The core of basalt wool, taking into account the sandwich thickness of 15 cm, provides the same thermal insulation as an ordinary brick wall 90 cm thick, which makes it possible to reduce the cost of heating the building during its operational use.

In reviews, users of prefabricated garage boxes often note that storing a car in a warm and, importantly, dry garage, where the minimum humidity is maintained thanks to a well-thought-out ventilation system, prolongs the service life of parts and assemblies. And it is much more comfortable to maintain or repair the "iron horse" in a warm box than in a cold room.

The disadvantages include:

- Short service life - about 45-50 years. Although, according to the assurances of manufacturers, galvanized steel used as a shell of sandwich panels has high physical and technical properties. Plus, the protection of the shell itself is provided by a primer in conjunction with an anti-corrosion and polymer coating. Whether it is worth relying on this is up to you.

- The impossibility of installing oversized hinged shelves or other heavy furniture structures on the walls.

- The need to control the condition of the locking parts of the sandwiches during installation at low temperatures.

- Lack of "vandal resistance", as in reinforced concrete structures or brick buildings, therefore there is a risk of breaking or surface mechanical damage - chips, scratches.

- The use of basalt fiber panels necessarily requires good ventilation. Unlike homogeneous materials, mineral wool sandwiches have the worst thermal insulation ability.

- The likelihood of a draft due to cracks in the areas of joining of adjacent panels in the event of a violation of the assembly scheme and freezing of the joints of the structure in frosty weather.

- Quite a high cost of construction, but since buying the same concrete, brick or high-quality lumber is more expensive than sandwiches, this is all relative.

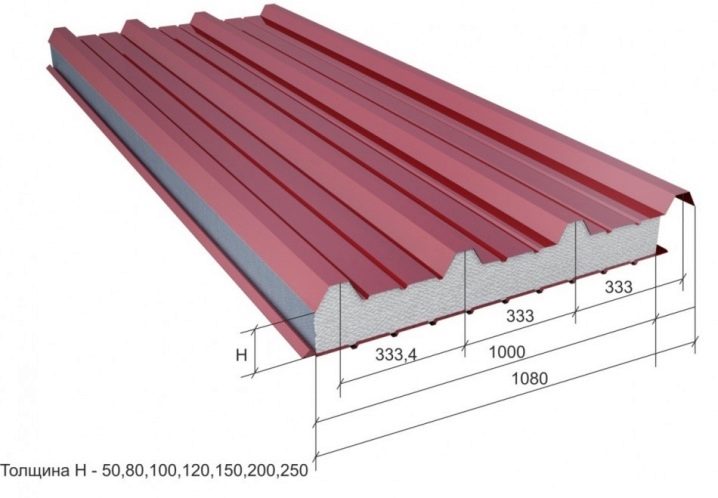

How to calculate?

When developing a project for an autobox and choosing the size of a future structure, it is convenient to start from the typical sizes of sandwiches, so as not to cut the material once again during the installation process. Their length varies within 2-12 m, the minimum working width is 0.5 m, and the maximum - 1.2 m. The thickness of the product is selected based on local climatic conditions.

One medium car is placed in an autobox measuring 4x6x3 m (width * length * height) and with a gate measuring 3x2.25 m.Calculate the number of sandwiches required for its construction, provided that wall panels filled with mineral wool (thickness 100 ), size 1160x6500 (working width * length) and an area of 7.54 m2.

To calculate the area of vertical surfaces, use the formula:

S walls = 2 (4 + 6) x 3 - (3 x 2.25) = 53.25 m2

To calculate the required amount of material:

m = S walls ÷ S of one sandwich = 53.25 ÷ 7.54 = 7.06 m2

That is, you need 7 panels.

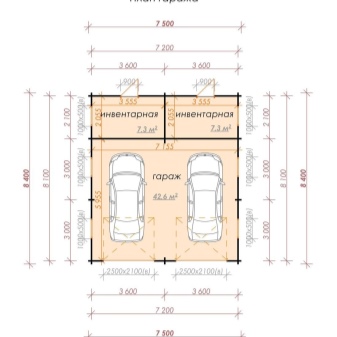

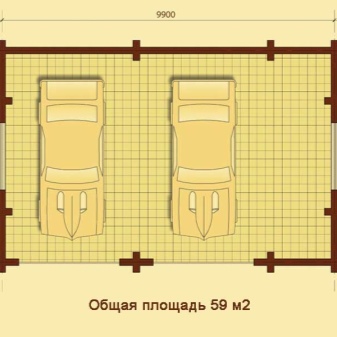

Building a two-car garage on the “a lot is not a little” principle is wrong.Empty space indicates a waste of money. A competent approach to construction implies a clear definition of the optimal size of a box for 2 cars with their subsequent inclusion in the project and an expense estimate.

During the construction of a double garage box, it is assumed that one parking space in accordance with building codes has the minimum overall dimensions:

- Width - 2.3 meters.

- The length is 5.5 m.

- Height - 2.2 m (taking into account the height of the vehicle).

The main guideline when calculating all sizes of a garage box is the dimensions of the vehicles that are planned to be stored in it.

It should be noted that:

- It is required to leave 60-80 cm between the side walls of the box and the doors of the car, so that you can freely leave the car without hitting or scratching the doors.

- Any garage layout assumes a gap between the vehicle with a width equal to the width to the end of the open car door with a margin of 15-20 cm.In the opinion of experienced car owners, it is most convenient to place vehicles at a distance of 90 cm from each other, which allows you to calmly open the doors without fear for their integrity.

- The front and back of the car also need a space for passage, which provides the convenience of moving the user to any point of the autobox without getting clothes on the car or walls. This condition is satisfied by a passage of 50-60 cm.

To calculate the height of the building for a convenient location inside it, add 50 cm to the average human height - 175 cm.The width of the gate is determined based on the width of the vehicle plus 0.8 m (0.4 m each on the right and left).

Guided by these dimensions, an accurate calculation of the size of the box for 2 cars is made, and then, using the above formula, the required amount of building material is calculated. The calculation of the size of a large garage such as a mini-hangar for 3 or 4 cars is carried out in a similar way.

Here are the dimensions of ready-made modular boxes with a different number of parking spaces and the same gate size 3x2.25 m.

Dimensions:

- Double garage - 8x6x3 m.

- Quadruple garage with two gates - 8x10x3 m.

- Quadruple garage with two entrances - 8x10x5 m.

One of the advantages of building a garage on your own is the choice of any building size, taking into account your own needs. It can be a spacious garage box with dimensions of 6x12 m with extended functionality, where you can not only store two cars, but use part of the premises as a mini-workshop or repair shop. In this case, the project of a typical box is taken as a basis and its dimensions are increased, based on the task at hand. The height of the building from the side of the entrance is 3.6 m, and from the rear side - 2.2 m.

Another practical and profitable solution is a two-storey garage box., for example, 5x4x6 m in size. Many motorists like to spend most of their free time in the garage, invite friends there and even stay overnight. A spacious second floor is the best for such a pastime, where you can equip a living room with a home theater, a billiard room, etc. If you wish, you can make an extension where a shower stall and a bathroom will be located.

Site preparation

To install a garage made of sandwich panels, a solid foundation is not required, which automatically saves the owner from having to dig a pit and spend money on buying a centner of concrete mix. If construction is planned in the country house or in the local area, then at the chosen place you need to remove any vegetation, remove the sod and level the ground. For the installation of the autobox, gravel filling or a concreted area will be required.

How to build?

Anyone who understands the design and technology of metalworking will be able to build a garage box, lined with sandwich panels, which is not much inferior to ready-made solutions.In the case of a do-it-yourself construction, a detailed project development and the creation of a drawing of an autobox will be required. The structure consists of a frame, for the manufacture of which a steel profile is used (equal-flange angles, hot-rolled 75x75, channel bar 140x60), concreted in the foundation.

If the plans include disassembling the box, then they do without concreting the racks of the frame part into the foundation and connect the sandwiches with threaded fasteners instead of welded ones. When assembling prefabricated struts to the base using support plates, they are screwed to stud anchors (bolt thread diameter from 14 to 16 mm), concreted at a depth of 50-80 cm. The advantage of this solution is easy panel detachment with subsequent dismantling of the frame.

If you are going to attach a garage to a house, then you need to adhere to some rules and comply with a number of requirements:

- The most important thing is to get official permission from the appropriate authority. Since information about real estate is contained in Rosreestr, you should be aware that illegal transformations of a residential object subsequently exclude the possibility of making transactions with such property.

- Position the garage extension on the right or left side of the main building.

- It is undesirable to build an extension on a foundation of shallower depth than at the base of a residential building. If the soil swells, then this will provoke a noticeable deformation of both buildings.

- Ideally, the construction of both the garage and the house is carried out at the same time. The advantages of this solution are the general underground supporting structure, as well as the same time for concrete shrinkage and soil settlement.

- It is recommended to equip the autobox with two exits: one communicating directly with the house, the second leading to the street.

- The common wall must be insulated with non-combustible material, since the extension is an object of increased fire hazard. For the same reason, the box must be equipped with a fire alarm.

Foundation

Before carrying out any excavation work, you need to make a markup of the site for construction. The easiest way to solve this problem is with stakes, deepened into the ground, and twine. The stretched cord creates a straight line. Let's take a look at how to install the strip base.

Sequence of work:

- Digging a trench. A ditch with a depth of 0.4 m and a width of 0.4 m is dug along the perimeter of the site and in the center of the future building. In conditions of unstable soil, the depth of the foundation is increased by means of screw piles or a columnar-strip base.

- Creation of a sand and gravel cushion. First, wet sand is backfilled and tamped so that a uniform layer 10-15 cm thick is obtained. Then the sandy layer is covered with gravel to a similar thickness. When the freezing soil swells, the cushion acts as a shock absorber, neutralizing the deforming effects on the concrete base.

- Formwork manufacturing. For these purposes, small shields 15-20 cm wide are hammered from the edged boards. Using spacers, stops and slopes, formwork is installed along the edges of the ditch.

- Organization of isolation. To do this, use dense polyethylene or roofing material. The insulating material is spread at the bottom of the ditch, completely covering the walls and formwork from the inside.

- Reinforcement of the base. A volumetric structure is made from reinforcing rods, which consists of four rods connected to each other. The foundation posts are also reinforced with reinforcement. Connecting elements are made from fragments of reinforcement, welding them or fastening them with wire.

- Laying of metal structures. Correct installation of a metal structure in a trench means placing it on a small elevation, which is built from fragments of brick or other suitable material, and not at the bottom of the ditch.

- Pouring concrete.Pouring the concrete solution is accompanied by the formation of air bubbles, which must be removed by bayoning the uncured mixture with any even object - a rod, rod, stick.

At the end, the liquid foundation is leveled along the upper edge and left for 24 hours. After a day, the base is covered with plastic wrap. In the spring-summer season, it takes 3-4 weeks for the concrete mixture to harden, while in conditions of low temperatures it takes up to one and a half months.

You can also make a slab foundation.

Procedure:

- Dig a pit 0.3 m.

- Level the soil, tamp the base.

- Sand is poured into an even layer, then a gravel layer is formed. The thickness of both layers is 0.1 m.

- Formwork is made and installed.

- The pit is covered with plastic wrap with a sufficient margin on the walls.

- A pair of metal gratings is made from reinforcement with a mesh size of 15x15.

- Place the grates in the pit on the bricks. The grids are also separated from each other by checkerboard bricks.

- Concrete is poured. For uniform pouring, a sleeve is used through which the solution is fed.

- Uncured concrete is spread. After 24 hours, cover with foil.

To ensure uniform hardening, the base is moistened for a week. Further construction work can be started after 3 or 4 weeks.

Frame construction

It must be said that not only metal, but also wood is suitable for making the frame. The wooden frame is made of 100 to 100 beams. The wood requires preliminary treatment with an antiseptic and antifungal composition. For fastening and connecting the bars, use metal pads and corners.

The construction of a metal frame, as already mentioned, involves the use of a steel profile. You can use corners or a rectangular pipe. Structural elements are welded or bolted together. You will also need several galvanized U-shaped profiles, for fastening or connecting which rivets or self-tapping screws are used.

Before installing the metal frame racks, the foundation is covered with two layers of roofing material to create waterproofing. Fastening to the base of the plinth ledger is carried out by means of anchors and dowels for working with hard materials. Careful balancing of the plinth along the vertical and horizontal axis is the key to obtaining the correct geometry of the entire frame part.

The installation of the bearing racks is performed from the corner. Installation of intermediate racks with a horizontal lintel is carried out at regular intervals of 0.5-0.8 m.In general, racks in metal structures may be placed at a maximum distance of 3 m.

Each wall is assembled on a flat base., and then the assembled elements only need to be lifted in order to fix them in the corners of the metal frame and the basement of the garage structure. The roof frame is assembled and installed in the same way. When the structure is assembled, you need to make sure the integrity, strength and reliability of the assembly. Then you can start installing the sandwich panels.

Final assembly

Before cladding the structure, the foundation is covered with a plastic insulating material to exclude the possibility of the edges of the slabs touching the base.

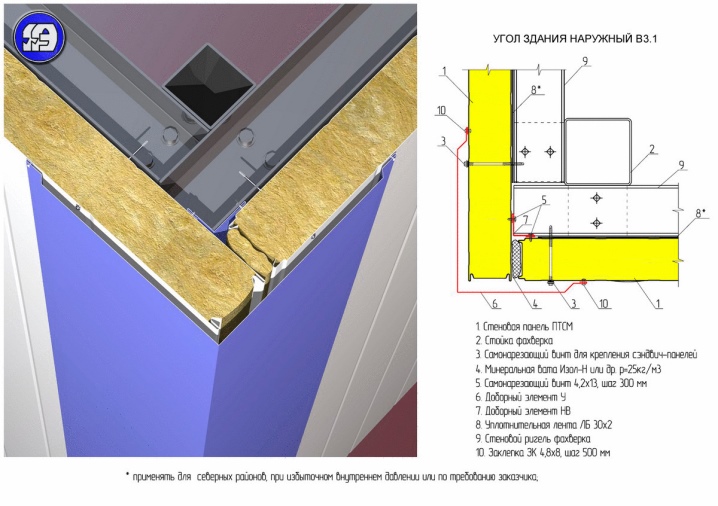

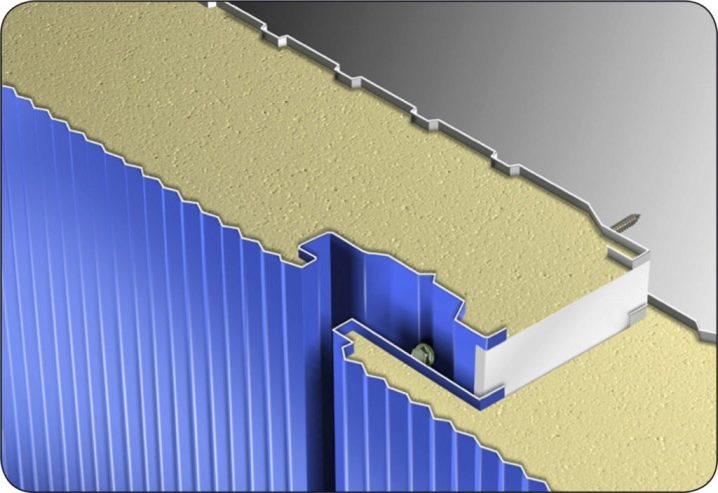

The vertical installation of the panels is carried out by fixing them to the upper and lower profiles using self-tapping screws. The sandwiches are fixed with special self-tapping screws, which have a gasket next to the press washer. They are screwed in clearly at right angles to avoid the formation of gaps that provide direct access of moisture to the insulation of the panels. To further strengthen the slabs and create a reliable waterproofing layer, the joints, like the lock joints, are treated with a sealant.

Sandwich panels begin to be mounted from the corners of the metal frame. The first plate is used as a guide for neighboring panels, always leveling it.The use of a clamp facilitates the task of leveling the slabs and speeds up the process of making the walls. Corner seams are closed with special steel elements. When all the plates are installed, they proceed to insulation and insulation work. Installation of strips is carried out at the joints of sandwiches and a moisture protection strip (basement ebb) at the junction of the basement and walls.

The cladding of the roof panels of the autobox implies the creation of an overhang that protrudes beyond the roof by a maximum of 30 cm. It is needed for the installation of gutters. To mask cracks or gaps, special profile elements are used.

Helpful hints

Tips for working with sandwich panels:

- Self-tapping screws must be screwed into the protruding parts of the cladding profiles, and not into the places of the "depressions". The optimal distance between fasteners is up to 30 cm.

- It is necessary to clamp the screws with such force as to achieve only a slight deformation of the silicone washer. You cannot press it in as a whole, as this deprives the structure of its "breathing" properties. For the same reason, at the joints of the sandwiches, it is necessary to have minimum thermal gaps.

- The protective film is removed from the boards upon completion of all construction activities. If you neglect this, then sooner or later it will provoke the formation of moisture.

- Using a ladder or other object to support the panels during installation increases the risk of damage to expensive material. Violation of the integrity of the polymer coating that protects the outer metal part of the sandwich reduces the corrosion resistance of the metal, which can rust.

- Experienced craftsmen, who have been dealing with sandwich panels for several years, recommend using a jigsaw with a special blade for cutting them. The quality of the cut made by the grinder will be lower.

You can watch the installation of a garage from sandwich panels in the following video.

The comment was sent successfully.