All about canopies made of shaped pipes

Canopies are different. They differ not only in their structure, but also in the materials of manufacture. So, one of the most reliable and durable are structures built from shaped pipes.

Peculiarities

The canopy is a useful and versatile structure. That is why such structures can be found in many adjacent areas. A canopy can highlight a parking area or serve as an addition to a recreation area - there are a lot of options and solutions.

You can make a reliable and practical structure from a variety of materials. Many people decide to build a high-quality canopy from shaped pipes on their site, and this is a very good solution.

Structures made of metal profiles are very popular. And it is not surprising, because these types of awnings have quite a few positive qualities.

- The main advantage of such structures is their high reliability and strength. The metal profile will not rot and dry out, which cannot be said about wooden structures. In addition, they are not subject to mechanical damage. It is not easy to do serious damage to metal.

- The considered types of awnings are durable. A well-built structure will last for many years. The visual appeal of a canopy with a metal frame will not suffer if it is properly cared for.

- There are such varieties of metal profiles that are complemented by corrugated or polymer surfaces. Thanks to such layers, the material turns out to be even more practical and durable, not requiring regular painting.

- A canopy made of shaped pipes will become a wear-resistant structure.

- Rolled metal is an environmentally friendly material. It does not emit hazardous and harmful substances, it does not emit unpleasant chemical odors.

- It is quite possible to build a metal frame for a canopy with your own hands. All stages of work will take relatively little time.

- A well-made canopy made of metal profiles can become an effective addition to the local area. Its design can be anything. Each owner decides for himself how the canopy should look like on his site.

The considered designs have not only advantages, but also certain disadvantages.

- Before starting construction work, it is very important to draw up a detailed project of the future shed. All calculations must be perfectly correct. Errors in this case are unacceptable. For this reason, many people have to turn to specialists for such services, and this is an extra expense.

- Despite its practicality, metal is still a material that needs proper care. If the profile pipes are not made of stainless steel, or they do not have additional layers on their surface, then the material will need to be treated with anti-corrosion solutions.

Periodically, such metal will need to be painted. Many of the protective compounds for metal profiles are not cheap.

Types of material

Various types of shaped pipes can be used to build a strong, attractive and durable canopy. Different types of materials have different performance characteristics and features. All this is important to consider when buying a certain type of pipes for the construction of a high-quality structure.

Nowadays, awnings made of aluminum profiles are very popular. These are practical structures with a number of features:

- able to withstand severe mechanical stress;

- they are not so expensive, they differ in a small consumption of material;

- the aluminum profile is convenient to transport and store;

- aluminum pipes of square or circular cross-section are quite malleable, so it will turn out from them to create a structure of any shape and modification.

And also for the construction of a canopy, high-quality steel pipes are perfect. They can also have different sections and shapes, like aluminum specimens. Structures assembled from steel pipes have their positive aspects:

- ease of installation work;

- an impressive margin of safety;

- resistance to adverse weather conditions;

- high indicators of wear resistance;

- attractive appearance.

However, the steel profile is more difficult to bend than the aluminum one. Without the use of special equipment, it will not be possible to bend such a pipe.

Projects

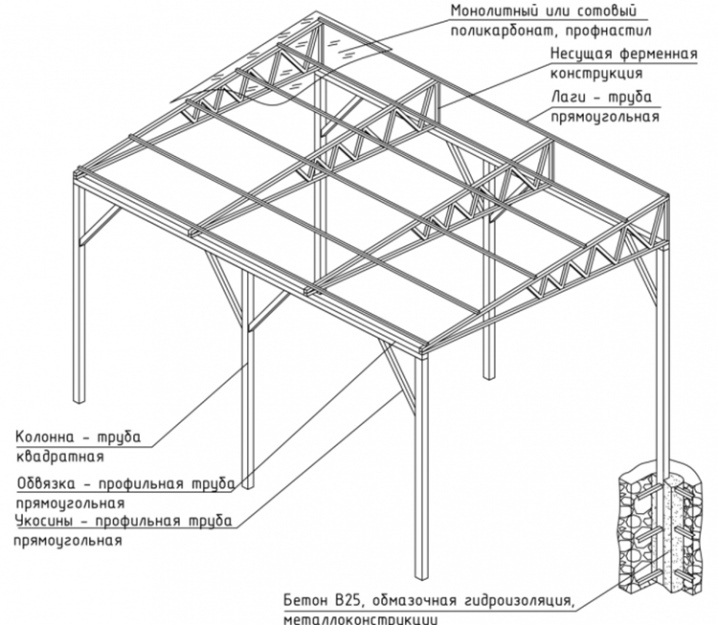

Before constructing a canopy from shaped pipes, it is important to draw up detailed drawings and diagrams of the future structure. The preliminary design must be prepared with all dimensions.

It is very important to carry out the most careful and accurate calculation - if the parameters are calculated incorrectly, then a high-quality structure cannot be made.

It is advisable to draw up a project of a street shed, which will be located in the courtyard of a private house or farm, on your own, if you have experience in such matters. If you have never drawn up such drawings and diagrams, it makes sense to turn to professionals, or use ready-made solutions. Let's take a look at some of them.

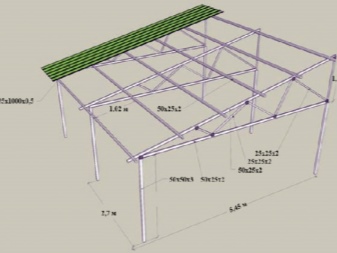

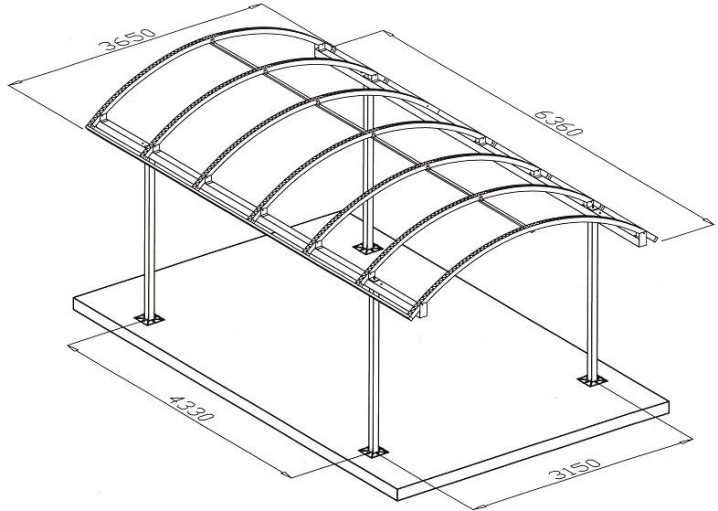

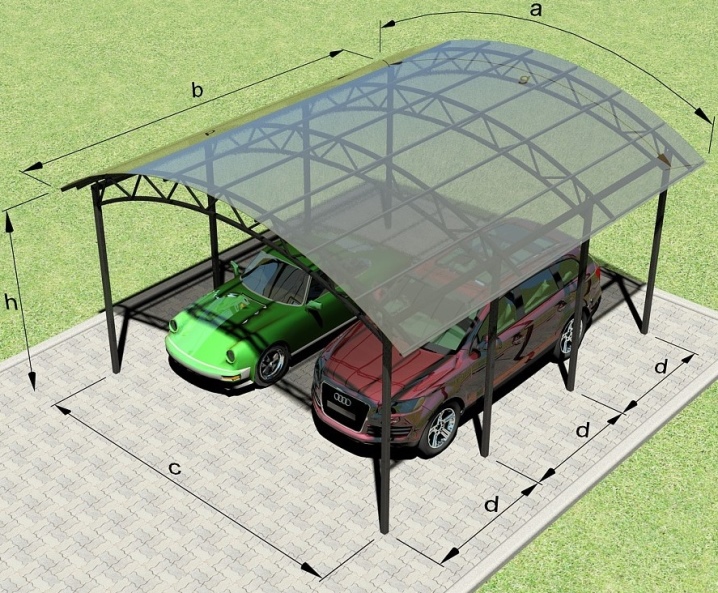

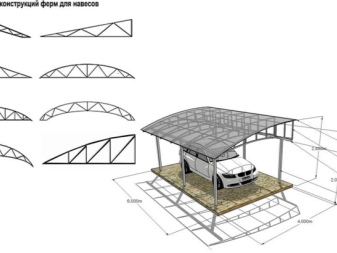

- An excellent solution would be an arched structure with a semicircular polycarbonate canopy. Such a structure can have different dimensions depending on the free area of the site. One of the options is sketched on the diagram, which can later be used as a parking zone or an entrance group.

- From a professional pipe, you can build a simple lean-to shed with a slope only in one direction.

Such a structure can be finished with polycarbonate or profiled sheets.

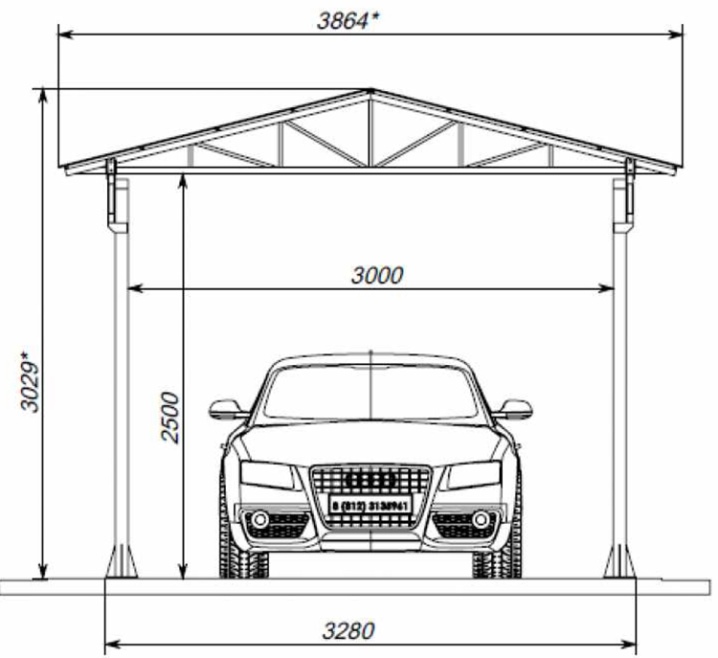

- With dimensions of 3x3 or 3x4 m, you can build a gable type metal canopy.

Such a structure can be used as a recreation area or parking space for one car.

- A high-quality hinged structure from a metal profile can be built not only for one, but also for two machines. Of course, such a structure will have more impressive dimensions, for example, 6200x7200 mm and a height of 2.5 m. In such an area it will be possible to park two cars, while leaving the necessary distance between them and the side bases.

The plan of the finished structure may be completely different. When drawing up a project for a future metal canopy, it is very important to take into account the available free space. On the diagram itself, it is imperative to indicate all the dimensions and design features, for example, the thickness and section of the metal from which it will be built.

With a detailed plan at hand, it will be much easier to purchase the necessary materials, as well as to engage in construction work without making mistakes.

How to do it?

It was previously mentioned that a pipe canopy can be built with your own hands. Such work should be carried out in accordance with a previously drawn up plan. Different types of structures are built in different ways. Let's consider step by step how to make canopies of various modifications yourself.

Single slope

The design and installation of lean-to buildings is as simple as possible. Usually, when erecting such awnings, there are no special difficulties. Let us analyze in detail the step-by-step instructions for the self-production of a lean-to building.

- The first step is to install the support bases, and then fill the previously dug wells.The distance between the support posts should be from 1 to 1.5 m.If it is planned to install slate, corrugated board or tile as a roofing, then a gap of 1.2 m will be optimal.

- Next, you need to mark the position of the support pillars, stretch a special rope between them strictly along a straight line. For each of the racks, you will need to dig a hole with a depth of at least 60 cm and a diameter of 20 cm.

- Pipes should be reinforced with special strips. These will need to be welded to the bottom half of each pipe. After that, they are poured with concrete mortar.

- A not very large layer of sand should be poured and tamped at the bottom of each pit. After that, the support parts are installed clearly vertically, using the building level. Now you can start pouring concrete. Now the support should be raised several times, and then lowered so that the entire solution gets inside the profile.

- You will need to carefully check the vertical arrangement of all parts using a level. Further, the structures are left until the concrete dries. This usually takes 3-7 days.

- Next, you can start forming the upper part of the lean-to canopy. For this purpose, it will be necessary to weld 2 pipes located along the legs of the structure. Then, making the necessary measurements, the profile is cut to the appropriate length. It is welded into place. If a pipe with a rectangular cross section is used, it must be mounted so that its large side is directed upwards. Then the installation of the cladding will be easier.

- Now the finished hinged structure needs to be reinforced.

- It is necessary to calculate and install all the details of the frame structure.

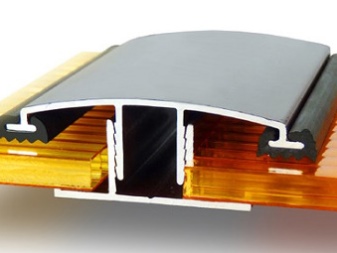

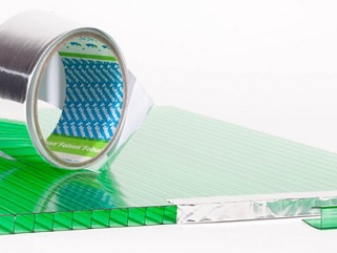

- When the frame is ready, you can proceed to attaching the selected material to its roof. For example, it can be polycarbonate sheets. They will need to be joined using a special profile. The bottom of this part is screwed to the lathing even before the installation of the roof.

- After that, the side cuts of the polycarbonate will need to be closed with a special perforated tape. This stage can be considered final.

Arched

The construction of a beautiful canopy in the form of an elegant arch is carried out in almost the same way as in the situation with a lean-to option. But it must be borne in mind that it will be very difficult to build such a building on your own. To carry out such work, a special hand or electric tool is required. Without such items, it will be problematic to bend metal parts on your own.

The most successful solution is to turn to professionals who will quickly and efficiently make a reliable arched canopy.

Multi-slope

Basically, these types of awnings are installed to cover large areas. This could be a car park, an exhibition pavilion, or some other similar type of location. In fact, a multi-slope canopy is a set of sequentially placed structures with two slopes.

In this case, in addition to the ridge part, which is located in the upper part, it will be necessary to mount a drainage system.

Gable

The installation of such a canopy will be the same as in the case of a structure that has only 1 slope. Only here there will be 2 triangles, which will need to be mirrored in relation to each other. The roof of such a canopy will be formed by means of two planes with a slope at a specific angle.

Since a special ridge knot will be present in such a design, it will turn out to be more complex in execution, but it will cover the impressive quadrature of the site.

The designs under consideration are more ergonomic and useful than single-slope options.

External finishing

When the frame base of the metal canopy is completely finished and ready for further stages of work, it will be possible to attend to its finishing. This is an equally important stage, which should also be treated with maximum responsibility.

Before finishing the finished base, it must be thoroughly cleaned, get rid of all scales, if any. And also metal parts will need to be thoroughly degreased before painting. Degreasing must not be neglected, since this may cause the coloring composition to lie incorrectly on an unprepared surface. For the degreasing process, an ordinary solvent, acetone or gasoline is suitable. Such formulations should be allowed to dry after application. Only after this is it possible to proceed to painting the pipes.

It will be useful to use a light gray primer mixture. Such a composition will work seamlessly for almost any type of paint. The dark option is used for brighter and more saturated materials. There are also white solutions. They are used for pastel colors.

The primer is a very useful and practical product. Thanks to it, the metal will be reliably protected from premature corrosion, thereby increasing its service life. At the same time, paint consumption will be significantly reduced.

Useful Tips

If you decide to build a canopy from a professional pipe with your own hands, then you should take on board a few useful tips.

- When self-erecting a canopy, you need to take a responsible approach to the choice of the type of roof. It should be borne in mind that the snow should not linger on it, but freely fall to the ground, without loading the structure.

- If it is necessary to connect metal structures from a profile, the wall thickness of which is more than 3 mm, then gas welding will be the best solution. Electrical counterparts may simply not be able to cope with such a volume of work.

- To make an arch, you will need to bend the profile pipe. Bending can be done with a pipe bender. If there is no such equipment, then you can use a grinder and welding.

- If you selected a wavy material to decorate the roof of the structure, then during its laying the necessary holes will need to be made in the crest of the wave.

- Before starting the installation work, it is important not only to draw up a detailed design plan for the structure, but also to determine the level of soil freezing. It is from this indicator that the depth of the foundation of the supports will depend.

- If self-tapping screws were chosen as fasteners, then you should make sure that they are intended for mounting the roof and are equipped with special rubberized washers.

- Absolutely all installation work must be started from the lower parts, gradually moving upward.

- It is best to cut the sheet profile with special metal scissors. It is recommended to avoid exposure of such materials to the grinder, as it can cause serious damage to the upper protective layers of the sheet metal profile.

- During the installation and laying of the roofing material, it is strongly not recommended to tighten the screws too much. This is due to the fact that the rubber insert in these elements deforms very easily and quickly, which will subsequently increase the risk of leakage.

- For self-assembly of a metal canopy, it is important to choose only high-quality, new materials. Under no circumstances should you buy a profile with traces of rust, damage or deformation. From such details, a high-quality and durable canopy is unlikely to work.

- During the assembly of the structure, it is very important to take care that there are no distortions. In order not to face such serious defects, it is recommended that all welding work be carried out on perfectly flat surfaces.

- If a metal canopy is built adjacent to the sunny side of the main building, then it is advisable to use corrugated board as a roof covering. This is due to the fact that, unlike the same polycarbonate, it does not transmit light at all.

- If you do not have the skills to work with a welding machine, then it is better not to take up the independent connection of metal parts by welding. It is advisable to contact specialists who are well versed in welding.

Beautiful examples

A professionally made canopy made of shaped pipes can easily become an effective addition to the local area. Such buildings can have a variety of designs in accordance with the style of the surrounding space. Let's look at some beautiful examples.

- An arched canopy made of a profile pipe painted to match the color of a nearby fence will look neat and soundly on the local area. The rounded roof of such a structure is best finished with transparent or brown polycarbonate.

A structure of this type is suitable both for a private house and for installation on the territory of various organizations / enterprises.

- The entrance gate leading to the courtyard of a private house can be continued with a high gable canopy. Here the owners will be able to park their car. The photo shows a solid structure, painted black and complemented by a green roof (matching the color of the green gate and fence).

- Many owners of private or country houses on their plots allocate a recreation area by means of awnings with a metal frame. For example, it can be a high and large structure, the roof of which is made of yellowish polycarbonate sheets. The structure can be made arched, and under it you can equip a barbecue area, arrange tables and chairs.

If the area allows, it will also be possible to store various household supplies, tools and devices here.

- Shed sheds will always be very popular because they are easy to make and look attractive. So, a high-quality metal canopy can be attached to the facade of a private house or cottage, which has only one slope, descending from the line of contact between the main building and the hinged structure. The image shows a very attractive structure made of metal profiles, painted in a dark chocolate shade. Sheets of a suitable color are selected here as a roof.

- A beautiful arched canopy made of snow-white profile pipes can be installed over wide garden paths and paths leading to a private house or cottage.

Such a design of the local area will look very rich and impressive. Transparent polycarbonate will look great as a roof against the background of white metal parts.

For information on how to make a canopy from a profile pipe, see the next video.

The comment was sent successfully.