All about arched canopies

If you need a canopy to protect you from rain and sun, but you don't want to spoil the appearance of the courtyard with a banal building, pay attention to the arched structure. The beautiful geometry of the roof will decorate the suburban area, and its functionality will help households and the car to protect themselves from difficult weather conditions.

Advantages and disadvantages

The arched canopy has a beautiful type of shape, given by a special frame design. To repeat its contour, the roofing material must be flexible enough.

To build a semicircular canopy, it is necessary to perform accurate calculations to withstand the roof load, reinforced by snow, wind and other meteorological conditions.

Arched awnings are ambiguous in their characteristics, they contain pros and cons that should be clarified in advance, before construction begins. The advantages include the following points:

- beautiful appearance, suitable for any landscape design;

- the arched canopy is installed from light materials, it does not need a reinforced foundation, a building permit, cadastral registration;

- the hemisphere protects against slanting rain better than other canopies;

- the material is completely laid on the canopy cover and has almost no scraps.

The disadvantages of an arched roof are in a complex calculation, where there should be no errors, otherwise distortions will lead to deformation and cracks of the roofing material.

Besides, bends have an additional load, over time they can burst if the installation is done unprofessionally.

Flexible material is more susceptible to temperature fluctuations, therefore, small gaps are left between the polycarbonate sheets.

The arched structure is difficult to do on your own, you need helpers and the work of a welder.

Materials (edit)

Arched awnings, in view of the specifics of the design, cannot be made of every material.

The roof covering must be plastic and bend or soft and consist of small fragments.

To make a suitable choice for yourself, you should familiarize yourself with each product in more detail.

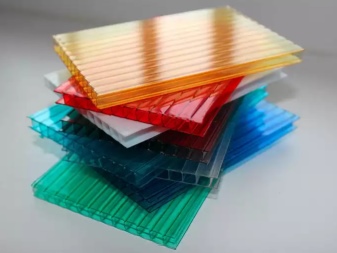

Polycarbonate

This material is the most successful polymer for creating a canopy roof, as you can see by studying its characteristics:

- the polycarbonate coating transmits light by almost 90%, while blocking harmful ultraviolet rays;

- types of monolithic products are more transparent than glass and twice as light, and the honeycomb material is 6 times more lightweight than glass;

- polycarbonate is 100 times stronger than glass, and even acrylic is inferior to it in strength;

- arched canopies are effective, light, airy;

- at the same time, they are wear-resistant and durable;

- the material belongs to fireproof products;

- it can withstand a large temperature run - from -40 to +120 degrees;

- its plasticity allows you to create an arch with a deep bending line;

- the material has a loyal value and a large selection in structure and color;

- polycarbonate is easy to care for;

- it has low thermal conductivity and high sound insulation properties.

Corrugated board

This material is galvanized steel, it is less ductile than polycarbonate, therefore, not too large sheets are used to create arches. The optimum thickness for a canopy roof should be within 1 mm. The material contains the following characteristics:

- it is durable and resistant to mechanical stress;

- reacts well to moisture and ultraviolet rays;

- mounted quickly and easily;

- the corrugated board is light enough, it will not create a large load on the supports and will not require a solid lathing.

The cost of the material is low, but it has certain disadvantages: the product makes noise in the rain, has poor thermal insulation performance and does not look very attractive.

Bituminous shingles

It is called a soft roof. Small fragments and flexibility of the material make it possible to build structures of any complexity from it. The product includes bitumen, stone powder and fiberglass. Fragments of the canopy are easy to change if you have to repair it. Shingles have other positive aspects:

- it is lightweight and does not create a special load on the supports;

- the material does not allow water to pass through at all;

- does not create noise during bad weather;

- easy to assemble, but you need to be patient to fold small pieces.

The disadvantages include additional costs for plywood, which is placed under a soft roof.

How to do it yourself

We will tell you how to cover an arched canopy with polycarbonate. Before proceeding with the manufacture, it is necessary to carry out a number of preparatory work. Choose and clear a place. Perform drawings and structural calculations. Purchase the required materials.

- Material. Based on the calculations, polycarbonate is purchased, preferably cellular, 10 mm thick. The smaller size is not strong enough to withstand the snow cover, while the larger one is inferior in plasticity and will be more difficult to bend. Profiled pipes for the frame and metal posts as supports are purchased.

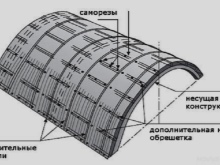

Farms making

The trusses are assembled using bolts and welding. First of all, a one-span template is made. Metal parts are fitted and welded to it. All other arch runs are made according to the template made. The parameters of the arcs and the number of trusses of one run depend on the calculated load. Each intermediate support supports the truss. But sometimes their design focuses on fitting to the roofing material, especially polycarbonate. The joint of the sheets of this material must necessarily fall on the metal profile. It should be remembered that each farm will weigh at least 20 kg and will have to be installed by three people.

Installation of supports

With the help of a rope and a peg, markings are made on the terrain for supports. Depressions up to 60-80 cm are dug or drilled. Sand, pebbles are poured at the bottom of the pits, and stands are installed. They are carefully leveled and poured with concrete. Further work should be started in a few days, when the concrete is completely dry.

Polycarbonate coating

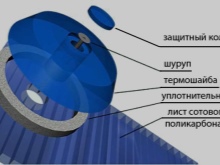

On polycarbonate sheets, markings are made according to the drawing with a felt-tip pen, according to which the material is cut. When cutting, the directions of the polymer channels are taken into account, for the correct removal of moisture during the operation of the canopy. The cut pieces must exactly match the metal profile to which they are to be attached. After cutting, it is necessary to free the cellular edges of the material from dust and chips.

The sheets are fastened with the film facing up using temperature compensating washers. The fastening should be 4 cm away from the edge, 3 mm gaps are left between the sheets, this will save the canopy from deformation when it is heated in the sun. The joints of the sheets are covered with an aluminum or plastic profile with a sealant matched to the color of the roof. A perforated tape is mounted on the ends from below, which helps not to retain condensate in the roof structure.

Service features

You cannot build a canopy and forget about its existence, any structure requires periodic maintenance. Precipitation, dust, flies, birds leave their marks on polycarbonate. The unkempt appearance is especially evident after the snow melts.

The structure can be washed under the pressure of water from a hose.

If you can access the shed from an adjacent roof or a ladder, you can do a more thorough cleaning using a long mop with attachments. For maintenance, use a soapy solution or alcohol-based detergents to deal with oily stains and give the surface an extra shine. When cleaning plastic, do not use abrasive products.

Good, timely maintenance will extend the useful life of the multifunctional canopy.

How to install a simple arched canopy under polycarbonate can be seen in the video below.

The comment was sent successfully.