Making a canopy with your own hands

Canopy - a functional structure, which is often installed in private houses or in summer cottages. Often it becomes a decorative addition to the courtyard, bringing new colors to the atmosphere. You can build a high-quality and attractive canopy with your own hands, following all the necessary rules. In this article, we will learn how to make such a design yourself.

Design

As is the case with many other superstructures in a private house, when erecting a canopy, you must first draw up a detailed project plan... The owners should pay a lot of attention to the design so that later they do not face unnecessary problems and alterations.

When developing a detailed project of the future canopy, the owners must take into account several basic parameters, which include:

- features of the site and the very design of the future superstructure;

- precipitation that falls annually, possible loads on the canopy from wind gusts, snow;

- direct purpose and dimensions of the future building.

A competently and carefully designed project allows you to accurately calculate the amount of materials for building a canopy. In addition, having a detailed plan and drawings at hand, it is much easier to properly think over the design and structure.

As mentioned above, it is necessary to take into account the purpose of the future canopy. For example, if this street superstructure is designed to protect a car parked in the courtyard, then it will be necessary to take into account the passage of a car with a load under a shed. This is especially true when the owners have large cars at their disposal.

Also, the canopy can cover the pool, be installed over a well or a platform where the owners have allocated a place for storing firewood. In each case, it will be necessary to take into account all the nuances and features of the future project in order to get good results of the work.

A canopy that is attached to one of the existing structures on the site will have several features, which the owners will need to take into account in its preliminary design. Height parameter such superstructures will be limited by the height of the roof of the building to which they are attached. Because of this, it will not be possible to build a full-fledged beautiful arch Is a popular type of canopy. As a rule, by attaching a structure to another structure, it can only be made very small due to the limited surrounding space.

Choice of materials

Design - one of the most important stages in the construction of a canopy, but it is equally important to choose decent materials from which it can be made. High-quality superstructures of the type in question are made from different raw materials. Let's consider what materials are used most often.

- Slate... Inexpensive, but quite sturdy material. Several different types of slate can be used to build a canopy. So, the fiber-cement version can boast of wear resistance, since it can easily endure even very strong loads. However, in domestic construction, such material is used extremely rarely. There is another type of slate - asbestos-cement. This material is sold in the form of corrugated or flat sheets and is very popular. Asbestos slate is widely used in the construction of residential buildings, utility rooms, as well as for the manufacture of fences.

- Polycarbonate... No less popular, multifunctional material. It is used in many areas. It can be cellular or cast. Experts strongly recommend using polycarbonate honeycomb sheets, since they demonstrate higher strength and wear resistance than their flat counterparts. Also, polycarbonate sheets can have a matte, transparent or colored surface - there are a lot of options.

- Metal tile / corrugated board... Materials with excellent strength characteristics. Their base is covered with a special powder paint that does not suffer from aggressive UV rays. The materials in question are designed for a long service life, and also have an attractive appearance.

- Metallic profile... Many owners of private houses choose a metal profile for making a canopy. It is a hollow material that has a rectangular, circular, or square cross section. Based on the dimensional parameters, the metal profile can be used to erect support parts and rafters.

- Lumber... In the manufacture of a high-quality canopy, materials such as plywood sheets, boards, wooden blocks, OSB can be used. Supports, rafters, beams and bars are often made of wood. Plywood and OSB sheets are most often used as filing under roofing material.

- Soft tile, roofing material... Roofing material itself is used in rare cases. Basically, it serves as a waterproofing layer. Much more often people choose light and soft tiles for arranging a canopy, which are designed for a long service life.

- Awning, moisture resistant fabric. Such materials are rarely used. It is advisable to use them only as a temporary or only seasonal option. Often, it is fabric coverings or awnings that are used to equip a small folding canopy.

All materials must be of high quality, free from defects or damage.

Only then will it be possible to make a really strong and durable canopy. If you save a lot on materials, you can get not the best and most durable structures that will often have to be repaired and put in order.

Preparation

Having made a detailed project of the future construction, as well as having purchased all the necessary materials, you can gradually move on for preparatory activities. This is an equally important stage of work, on which the quality of the result will depend.

First of all, the master must decide on the type of foundation for the future canopy. The foundation must be chosen based on the relief and the characteristics of the terrain on which construction work will be carried out.

If there are slopes, it is advisable to lay the piles - this will be the best option. If the site on which the canopy will be built is flat, then a strip foundation can also be built here. The number of supporting components directly depends on the mass and severity of the structure. In order for the structure to turn out to be quite strong, then the foundation for it needs to be made as strong.

Also, at the preparation stage, it is worth considering some of the nuances of further construction work in order to avoid mistakes. So, in the places where the supporting parts will be installed, you cannot immediately dig holes for them.

First, you will need to fix the pegs to mark the territory. Only after making the necessary markings, you can dig holes under the pillars, so there is no need to rush.

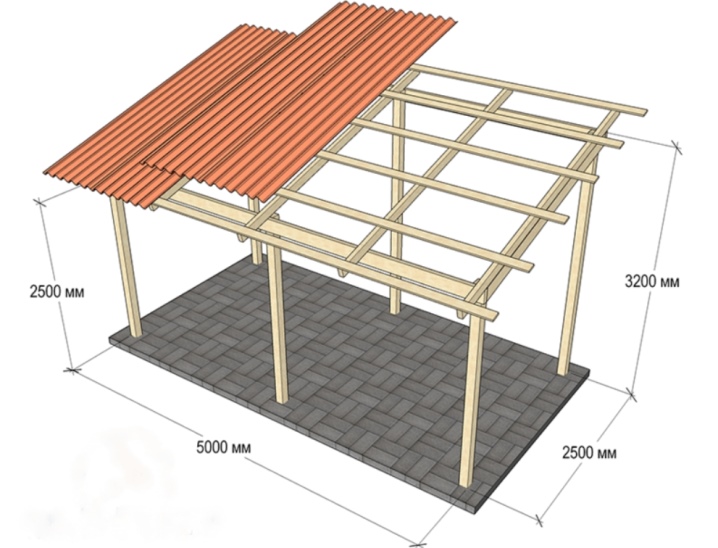

If it is planned to build lean-to construction, then the pillars behind should be longer than those in front - this must be foreseen when preparing all the necessary materials. The difference should be approximately 30 cm. The degree of evenness of surfaces must be checked by means of a building level... The best results will show laser instrument, but you can use the usual bubble - these are the most popular and easy-to-use devices. At the preparatory stage, it is recommended prepare all tools and materialswith whom you will work when building a canopy. It is advisable to place all the tools in one place so that, if necessary, you do not have to look for the right tool for a long time, wasting time.

Construction

Making a good and strong canopy with your own hands is not as difficult as it might seem at first glance. The master only has to work strictly according to the instructions and in accordance with the ready-made plan. Let's consider how to act correctly using the example of making a canopy to shelter a car.

Foundation

The manufacture of the canopy will begin with the construction of the foundation. It has already been indicated above what will need to be paid attention to at the preparatory stage, and now we will consider in more detail how to correctly build the foundation.

- The area under the canopy will need to be freed from all debris and plants. It is advisable to remove the top soil layer by about 15 cm, and then properly level the cultivated area.

- Next, you will need to designate the site (for example, 6.5x4 m), which will need to be poured with concrete. Inside this section, another square with a size of 4.33x3.15 m is designated. Supporting elements will be installed in its corners.

- The installation of the support parts will be carried out by concreting them directly into the ground.

- First, you need to dig 2 holes at an approximate distance of 4.33 and 2 m, as well as 2 holes at a different distance - 3.15 m.Their depth should be 1 m.

- Further, gravel is poured onto the bottom of the pits. A layer of concrete is poured there.

- A pipe will need to be installed in concrete, and then secured with spacers. Ideal vertical alignment must be provided.

- This is followed by the stage of pouring concrete. After that, you will need to wait until it hardens to the end and becomes quite durable.

After completing the installation of the supports, you can start concreting the entire dedicated area... This is usually not difficult at all. For this purpose, a plot with a size of 4x6.5 m should be fenced off with a board - this will be a kind of formwork. Then the ground should be sprinkled with sand, crushed stone, and a 5 cm concrete solution should be poured over it. Without waiting for the concrete to dry completely, a special reinforced mesh should be laid out. Then another layer of concrete 5 cm is poured. Next, you need to wait until the solution hardens.

Frame

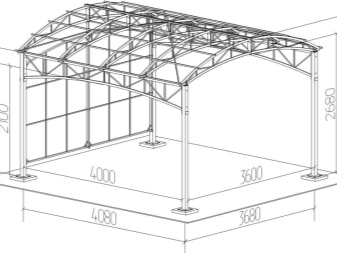

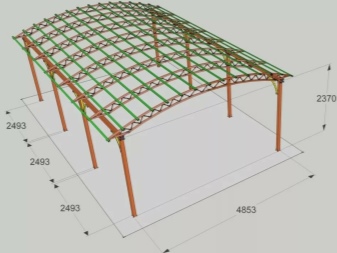

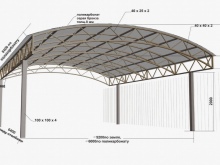

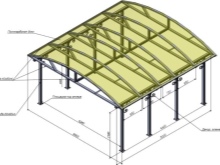

Having completed the construction of a strong foundation, it is worth moving on to the construction of the frame base of the canopy. A homemade frame can only be made correctly using a welding machine. It will be difficult for an inexperienced master to build such a structure, therefore, in this case, it is advisable to turn to professionals.

- The first step is to weld the stiffeners. They will connect the legs of the frame along the length. For these purposes, a 50x50 cm pipe is suitable.It should be laid out on the racks so that the ends of about 1 m remain at the edges.

- Then arcs are welded to the stiffener. Between them, you need to leave gaps of 106 m, without taking into account the parameter of the arc thickness.

- Further, along the tops on the inner side of the arcs, for additional rigidity, it will be necessary to weld a 40x40 cm profile pipe.

- After completing the assembly of the frame, its supporting parts will need to be coated with a special primer to protect against corrosion, and then paint.

Roof

The next stage of building a canopy is roof construction. This step is no less responsible and significant. You can also make the roof yourself. If you are determined to build this part of the canopy yourself, you should first decide on the material that you will use for flooring on the frame base.

Suitable for arranging a carport over the car polycarbonate... It will need to be divided into 3 parts with a length of 3.65 m.This material will need to be attached to the metal arc pieces using bolts installed in the drilled holes. A bolted thermal washer will be needed so that moisture cannot get onto the material and lead to its further cracking. Do not overtighten the fasteners, but they should not be too weak either.

Polycarbonate sheets should be joined using a special profile. The joint must necessarily pass along a metal frame arc. At the edges of the polycarbonate, you will need to expose a special end profile. If everything is done correctly, you will get a very reliable and durable canopy.

Finishing stage

If a carport is being built for a car, then you can stop at the construction of the roof. If we are talking about arranging a recreation area on the site, then it is also advisable to prepare the floors and make a small cozy gazebo under a brand new canopy.

If the canopy was made of wood, then the floors underneath may not need to be prepared. If this foundation is necessary, then the simplest and fastest-erected option, as in the previous case, is the pouring of concrete mortar. It is allowed to decorate the gazebo under a canopy with artificial plants.

At the final stage of building a canopy, it is necessary conduct electricity. It is worth installing several lamps. They will be useful in any case, whether it is a recreation area or a place to park your car.

Useful Tips

Making a good canopy with your own hands is not so difficult. The main thing is to correctly design it and select high-quality materials. You can also take on board a few useful tips and tricks for carrying out such work.

- It is recommended to design the future canopy yourself if you know how to do it correctly. If you do not have the proper experience and you are afraid to make serious mistakes, it is better to look for a ready-made project / building drawing or contact specialists.

- Supporting components can be made not only from wood or metal. Good strength characteristics are demonstrated by supports made of brick or stone. Pillars made of natural stone look especially expensive and presentable. If you want to transform the site, this will be the best solution. But we must remember that stone structures will cost more and for them it will be necessary to build very strong foundations.

- If the canopy is made of boards, logs, wooden pallets or wood in any other form, then it must be treated with a protective compound - an antiseptic. Such a mixture will protect natural material from rain and other precipitation, prevent its deterioration and decay. If this is not done, the wooden structure will quickly cease to be as beautiful, it will begin to dry out and rot.

- A good portable shed can be built from shaped pipes. This is a modern and interesting idea that many homeowners have liked.

- If the supports are planned to be made not of metal, but of wood, it is recommended to give preference to extremely hard, high-strength species that can withstand heavy loads. So, the most affordable are simple pine beams.

- If the floor under the canopy is made of wood, then you cannot put a brazier on it without taking care of installing an additional protective coating. In the place where there is a direct source of fire, you can lay a tile or install a metal sheet, securing it with self-tapping screws.

- If you want the area under a canopy to be quite light, it is advisable to use colorless polycarbonate as a roof. If, on the contrary, this zone needs to be darkened, then the roofing material should also be dark.

- You can make awnings with your own hands even from scrap materials. Interesting buildings are obtained from round plastic (PVC) or polypropylene pipes.Before making a structure from such unusual materials, it is worth making sure that they will withstand the loads that will be applied to them. If frequent and heavy precipitation is common in your area of residence, then it makes sense to consider other, more durable and reliable options.

- If you are afraid to build a canopy on your own site or do not want to spend a lot of time on it, it makes sense to contact a specialist. Of course, this will lead to additional expenses, but you will get good results, do not make serious mistakes and do not translate the purchased material in vain.

Beautiful examples

A well-made canopy can become not only a functional, but also an aesthetic component of a home. A beautifully crafted structure can beautify a local area. Let's look at some good examples.

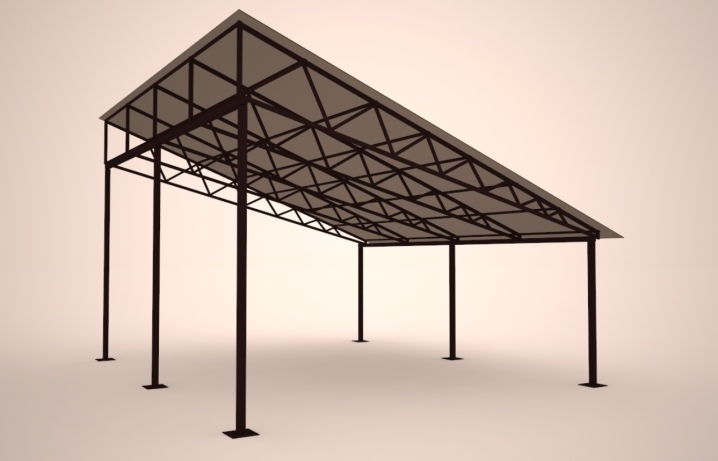

- Simple, but neat and presentable will look high canopy on a solid black painted metal frame. It is advisable to place such a structure at the entrance to the house. The floor area should be laid out with beautiful paving slabs, and polycarbonate sheets should be used as roofing material.

- If on the site you want to equip a cozy recreation area and arrange tables, chairs and a grill there, you can install high detached canopy on 4 strong supports, painted dark brown. Tiles of a dark color are perfect as a roofing material. The device of such a canopy will turn out to be quite simple, but also neat. It is better to decorate the floors here with plain light gray paving slabs. The combination of a dark roof and such floors will look harmonious.

- You can build with your own hands a canopy that looks more like a tent. The supports of such a structure can be made of metal or forging with decorative details. Such buildings look especially impressive if they are made in light colors and have a beige or light gray floor. Here you can put forged tables and chairs, as well as a grill - this combination will look luxurious.

- They turn out to be very cozy and hospitable. awnings made of wood... There are tons of ideas on how to make them. For example, it can be a reliable lean-to construction near the entrance to the house. It is advisable to preserve the natural wood texture on the beams - it will create a special atmosphere. In such a dedicated area, you can arrange chairs and tables, and put tiles or stone on the floor.

- It will turn out to be gorgeous a canopy with a gable roof, attached directly to the entrance to a private house... The support beams of such a structure can be made of sturdy wood with a stone base. Spectacular erection will become even brighter and richer with decorations in the form of forged patterns on the ends. In such conditions, you can park the car.

In the next video, you will learn how to build a carport with your own hands.

The comment was sent successfully.