How is the barn structured and what should be taken into account when building it?

If you decide to acquire cattle, then you should carefully prepare for this. It is necessary to keep such animals in the most comfortable conditions for them. If you plan to keep cows, then you need to build a good barn for them. Today we will analyze in detail how such erections are arranged and how they can be built with our own hands.

Requirements and norms

The barn must meet a number of requirements. Only in this case can we talk about its quality and reliability. Let us consider in detail in accordance with what standards it is necessary to build such structures.

The Ministry of Agriculture of the Russian Federation published order No. 551 of 13.12.2016 "On the approval of veterinary rules for keeping cattle for the purpose of their reproduction, rearing and sale." Owners of one or two cows do not really need the requirements listed in it. But if we are talking about farmers who plan to sell the products obtained from livestock, then they will need to bring the buildings for them in proper condition. This is due to the fact that such structures will more than once undergo thorough inspections by Rosselkhoznadzor employees. Of course, financial losses can be minimized by building your own barn.

So, the design of the future structure will be determined in accordance with the direct direction of the farm. Cows can be bred for the purpose of obtaining meat or milk. Also taken into account and the way the calves appear - natural or by acquisition. Equally important is the location of the barn on the site. In this case, the presence or absence of access roads, the level of groundwater, the distance to residential buildings are taken into account.

In accordance with the recommendations of specialists, you can build a barn with your own hands only for a small number of cows (no more than 10). If you want to increase the livestock population, then it is better to turn to experienced builders who know everything about the construction of such buildings. If you still decide to design everything yourself or turn to an inexpensive but inexperienced master, then the consequences can be dire. In the wrong conditions, living creatures can start to hurt or end in death.

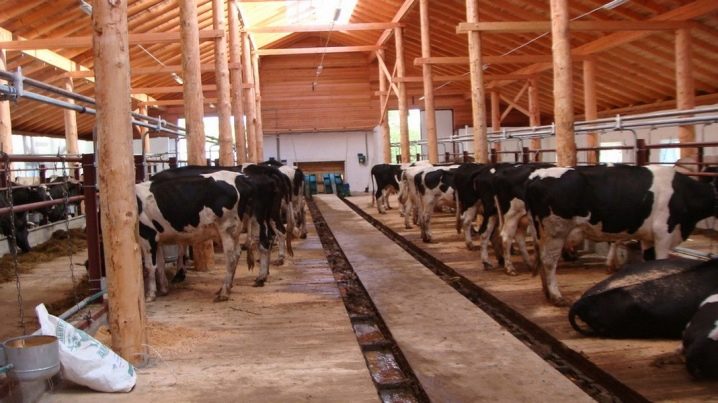

There are also a number of rules for keeping cows. If you do not plan to tie them, then 6 square meters will be enough for one animal. m. This method of keeping is called loose. However, most farmers keep such animals in stalls.

The allocated living area for the cow is equipped in accordance with the following standards:

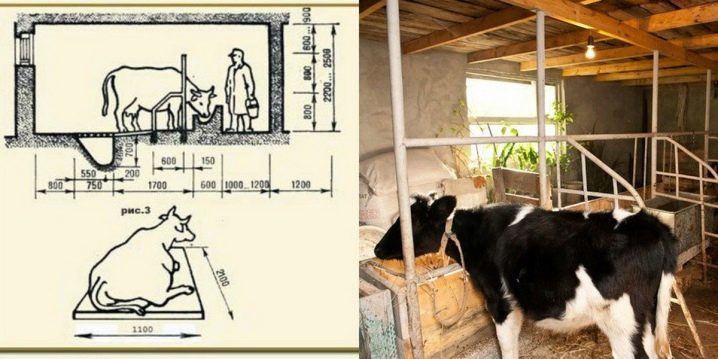

- an adult cow will need a compartment (box), the area of which is 2.2-2.7 square meters. m;

- for an adult cow and calf, a stall is required, the minimum dimensions of which are 3 square meters. m;

- for one calf, a dedicated space of 1.5 square meters will be enough. m;

- for an adult bull, a bigger box is needed - not less than 1.75 sq. m.

Adolescent calves are generally held off the leash. They are in a common paddock.

The area of this territory is calculated as follows:

- calves under 1 year old will need 4 sq. m;

- older animals - 4.5 sq. m.

Such animals are quite comfortable if the ceilings in the barn are at least 2.5 m.However, one should not rely only on the given dimensions.Dimensions may vary based on the breed of cattle raised.

Project creation

Before the direct construction of a high-quality barn, it is very important to draw up its correct and detailed plan, choosing all the necessary materials (as in the manufacture of a residential building). Before proceeding to the development of the project, it is necessary to determine the budget for the future construction. For example, if you can spend about a million rubles on all the work, then you will have a very simple structure for a small number of heads. If you are ready to spend more impressive amounts (20-30 million), then you can turn to a larger-scale project using high-tech materials. Thus, without knowing the exact budget for the construction, it will not be possible to proceed to the creation of the project itself.

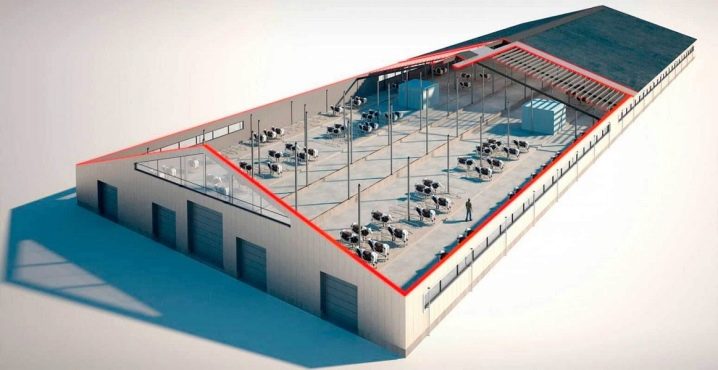

Not all farmers equip small barns on their plots. Today you will not surprise anyone with the development of a large barn for cows. Such structures are good in that they do not require large labor costs in order to obtain impressive milk yield. This is due to the fact that many farmers use high-tech equipment that makes caring for cattle as easy as possible. But it must be borne in mind that in order to draw up a plan for a large barn, it is better to contact specialists who have experience in similar work.

So, for the preparation of both large-sized and mini-barns, you should especially carefully select building materials. It is also extremely important to comply with all the necessary technologies based on the conditions of the climatic zone where the cows will live. It is also necessary to take into account the geological characteristics of the soil on which the construction of the barn is planned. Only on the basis of all the listed data will it be possible to draw up a competent project.

When creating a barn plan, it is very important to consider the dimensions of all the components of the building. Based on all the calculations done, detailed drawings are drawn up. Based on them, it will be much easier to buy pre-selected building materials in the required volume. In addition, experts recommend taking into account not only the floor area of the future construction, but also the ceiling height parameter. Remember that for cows to live comfortably, this value should be at least 2.5 m.

Preparatory activities

After going through the design stage of the barn and having all the necessary drawings / diagrams in hand, you can proceed to the preparatory work. Do not think that this step is less important. They cannot be neglected. If you immediately start construction work, then the lack of preparation will lead to the fact that previously made mistakes will make themselves felt and cause a lot of problems.

At the preparatory stage, you will need:

- decide on how many heads will live in the future barn;

- prepare all the building materials that you plan to use in the construction of the barn;

- purchase all the necessary consumables (fasteners), as well as pre-determine all methods of fastening the main structural elements;

- study of the space allocated for future construction work.

Preparing a place for a barn is one of the most important preparatory stages. It should be borne in mind that the site for such a structure must be perfectly flat. Experts strongly recommend preparing sheds in which cows will be protected from the wind (regardless of the number of heads - there may be 5, and 10, and 50, and 100 of them). That is why you should not build barns in those places where the winds are especially strong.

If there are no flat areas on your site, then it is worth choosing a place that can be smoothly leveled with the involvement of special equipment. In addition, when selecting the optimal area, you need to take into account the possibility of supplying water and electricity to it.

Construction stages

If all the drawings are ready, and the preparatory work is completed, then you can proceed to the direct construction of the barn. Let's consider in stages how to do it correctly.

Foundation

First you need to prepare the foundation. It can be columnar, tape, or monolithic. So, for a monolithic type foundation, you will need to dig a trench, where the formwork with reinforcing parts will subsequently be laid. Next, you will need to pour a layer of gravel, sand and start pouring concrete mixture. When the composition sets, the surface of the future floor will need to be supplemented with a layer of roofing material and mastic with waterproofing. This type of base is best suited for a brick or stone barn.

If the shed is planned to be built from a tree or a log house, then it is better to turn to the design of a columnar foundation. It is done in the same way as monolithic, but only here the pillars with reinforcement are poured with concrete, supplemented with roofing material insulation. Gaps of no more than 2 m should be maintained between the posts. For small sheds, strip foundations are often built. In this case, the concrete solution is poured into the reinforced formwork.

Absolutely all types of foundations require high-quality waterproofing. You also need to remember about the water slope. It is advisable to prepare a concrete base. It is ideal for heavy adult bulls and cows. In addition, the concrete does not damp and does not absorb unpleasant odors. Also, rodents and other parasites will be indifferent to such a basis.

Floor

The floor is also the significant foundation of the barn. It needs to be made warm and moisture resistant in order to prevent the accumulation of liquid waste on its surface. To drain water, urine and manure, the floor is usually made higher than the soil level, with a slight slope of 3 degrees towards the drain system. Too large a slope should not be left, because this can negatively affect the limbs of livestock and the reproductive function of cows.

It is best to make a concrete floor, because it is not afraid of dampness and moisture. But we must not forget that such a base will always remain cold, so it will need to be covered with warm material, for example, wood flooring. This component will need to be changed from time to time.

Walls

Barn walls can be made from a wide variety of materials.

Most often they use for this:

- tree and its frame;

- silicate brick;

- cinder block;

- stone;

- foam concrete;

- sandwich panels.

The choice of a suitable material depends on the size of the room, as well as the planned cash costs. For a large shed, silicate brick or foam block is most often used. Wooden walls are more suitable for small barns. Of course, such structures will cost much less, but they cannot be counted on for a long service life. Compact structures designed for the maintenance of 1-2 cows are very often erected from adobe bricks. This building material is cheap, and also has good thermal insulation qualities. The basement masonry in such sheds is made of baked bricks.

A stone cowshed is characterized by the fact that it warms up very slowly during the day, but quickly cools down with the onset of night. Because of this, condensation constantly appears on its surface. For this reason, instead of stone, it is better to turn to brick, which is recognized as a "breathing" building material, which is why moisture almost does not accumulate on it. Modern 3-layer sandwich panels are a good option for designing barn walls. They include mineral wool insulation. Thanks to this building material, an optimal and comfortable temperature can be maintained in the shed - it will be warm in winter and not too hot in summer. From the outside, such bases are sheathed with steel or painted.

It should be borne in mind that the walls inside the barn must be whitewashed and plastered in order for a good light reflection to be present in the structure.

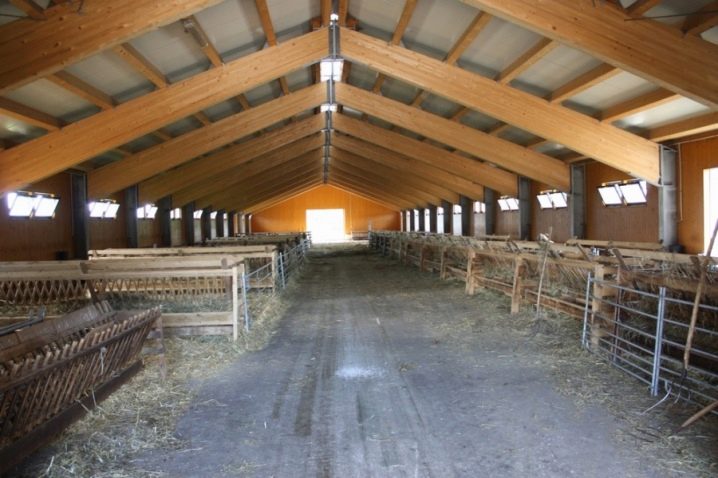

Roof

After the walls have been erected, you can proceed to the next stage - designing the roof. Most often in barns, it is built in the form of wooden floors and gable roof structures. They are usually trimmed with tiles or inexpensive slate sheets. An attic can be made under such a structure. As a rule, hay or equipment necessary for caring for animals is stored there.

Single-slope options are most often built when it comes to a small barn, because they are not designed for heavy loads.

Doors and windows

The main lighting of the cow shed is natural. It breaks through the windows. In accordance with the standards, their total area should be at least 10% of the floor area of the structure. The lower part of the window in most cases is at a height of 1.5-1.6 m above the floor surface.

Shed windows can be:

- hinged with double-glazed windows;

- hinged with a polycarbonate insert;

- sliding with transparent polycarbonate.

As a rule, PVC products with polycarbonate are mounted in sheds. As for the doors in the barn, they must be hinged and equipped with insulation. Thanks to such canvases, the barn will be warm even in winter. The gate must be lifting.

Ventilation

The barn requires high-quality ventilation. This is due to the fact that in the same summer heat, poorly performed ventilation can negatively affect milk production in cows. In addition, at temperatures of 25-30 degrees, such cattle lose their appetite, which negatively affects their condition as a whole. For this reason, the barn must be equipped with forced ventilation. It will remove polluted air from the building and provide fresh air. As for small and pre-fabricated structures, it is enough to install only vents in them. On a mini-format farm, it is recommended to build a hood with dampers and ventilation distribution boxes.

Communications

A good barn should have both natural and artificial lighting. For this, various lamps should be used in the building. All electrical appliances must meet all fire safety requirements. Even at the stage of project development and the first construction work, you need to plan the supply of cold water to the barn, as well as sewage, if necessary.

How to arrange inside?

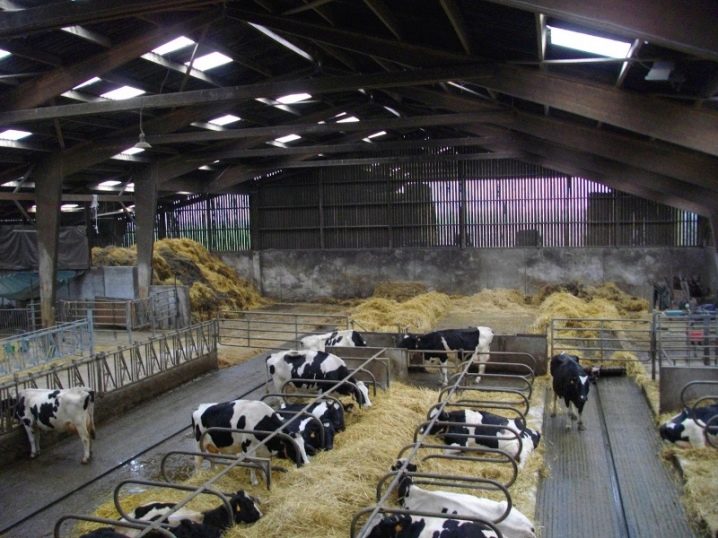

When the work on the construction of the barn is completed, it will need to be equipped with the following necessary components:

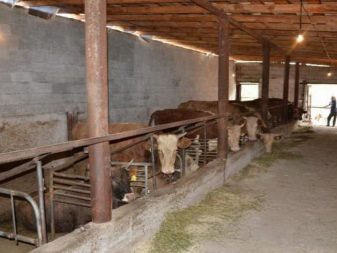

- stalls for cows (for their tethering);

- feeders and drinkers;

- maternity and postpartum wards;

- utility rooms;

- manure removal system.

The overall dimensions of the stalls directly depend on the specific breed of livestock. For example, meat breeds weigh about 50-70 kg more than dairy breeds. But it should be noted that in dairy breeds, the sizes of animals often differ significantly. Experts recommend equipping stalls from metal structures. The alternatives are regular boards. As for drinkers and feeders, they are mainly made of stainless steel. The mash is brought to the cows in separate buckets. Feeders are used for laying out dry food. It is desirable that cows and bulls always have access to water and food, so it is worth putting special automatic drinkers.

Tips & Tricks

If you do not want to make the floor in the barn concrete or wood, then you can use metal plates. Such options will also not worry rodents and all sorts of parasites. At the bottom of the feeders that are present in the barn, it is worth making special holes. Such a device is required to drain excess water during the washing process.It is advisable to buy or design your own separate structures for dry and wet food, if you do not want to bring the second one in a bucket.

The barn should not have a low ceiling, however, it should not be too high. So, in an unheated space, where the height of this base exceeds the mark of 2-2.5 m, there are significant heat losses. Often, barns are complemented by various utility rooms. It is to them that the sewage system is supplied, if the owners want it. However, there is no need for these buildings. The same can be said about the genital and postpartum compartments.

The manure removal system in a barn for keeping cattle can be represented by the following options:

- self-alloy system;

- hydraulic washout;

- systems operating as a belt conveyor;

- delta scraper.

If desired, the barn can be made more impressive - two-story. At the same time, a stall for animals should be organized on the first floor, and a hayloft on the second. In order for the calves to grow and become stronger as soon as possible, it is necessary to fence off that half of the structure in which they will be constantly located during the construction of the barn. When designing a future construction, many factors must be taken into account. These include possible severe frosts in the winter season.

Maintaining an optimal microclimate should be especially careful if you are keeping pregnant cows. During gestation, they become very sensitive to temperature changes and other changes in the environment. Choosing the best building material for the construction of a barn, you need to rely not only on the planned budget, but also on the climatic situation in the region. For example, in the northern regions it is recommended to build such structures from the strongest, most reliable and preferably insulated building materials.

During construction work on the construction of a cow shed, it is customary to use cement marked M400. Remember, the concrete in the substrate must always set naturally. After a day, it will need to be treated with water. Moistening will prevent cracking of the concrete. It is also permissible to make a special slatted floor in the barn. Under it are equipped with small baths required for drainage. Through it, sewage flows into highways and into special manure collectors.

Do not place cow feeders and drinkers near a wall, as this will cause moisture from cow breathing to form sediment on the edge of the structure.

For information on how to build a cowshed with your own hands, see the next video.

The comment was sent successfully.