How to build and equip a bull shed?

Any animal requires not only food, water, but also special conditions for keeping. Bulls in this regard are noticeably more difficult than cats or dogs, of course. Everyone who is going to grow them must carefully prepare, take into account the slightest nuances.

Requirements

Pens for bulls are about the same as housing for humans, even more. They cannot take proper care of themselves. Everything rests on the shoulders and heads of the owners, everything needs to be foreseen and thought out, carefully fulfill the basic norms. In the dwelling reserved for livestock, he will spend at least 10 hours out of 24 every day.

In cold weather, sometimes animals are there around the clock, or they make only rare exits.

When preparing a stall economy, you need to focus on your own material capabilities, available area. However, there are also standard technical requirements.

These include:

- the safety of the animals themselves, their owners and other people;

- high-quality fixation of livestock during various works;

- unimpeded access to water and feed, but at the same time the ability to stop feeding and drinking;

- the opportunity for each bull to get up and lie down, get out and get in;

- reduction to the possible minimum of the number and duration of work.

Even in the worst weather, you should try to get your livestock outside. To minimize the harmful effects of meteorological conditions, it is required to prepare a paddock for walking. It is recommended to make it in the form of an area of at least 500 m2. Such a platform should be covered with a deaf canopy from above and partitions from the sides. The fence is designed to exclude the arbitrary departure of the bulls; boards or bars are used to build barriers.

Dimensioned plan

Suppose you want to plan a convenient shed for bulls for 10 heads (for ease of calculation). When talking about size, one should start not with the buildings themselves, but with how far they should be from other objects.

It is recommended that the distance to a residential building and to a well or water pump, to ponds, lakes, streams and rivers is 20 meters. Only in case of urgent need can this distance be reduced to 15 meters.

If possible, they bring the barn closer to orchards and vegetable gardens - then you will have to carry less manure and it will be easier to saturate the soil with natural fertilizer.

Standard sizes are 110-120 cm in width and 170-210 cm in length if you plan to keep an adult bull. For your information: for a fully developed cow, the standards are the same. Oddly enough, the requirements for young bulls are much stricter. They need a width of at least 125 and a length of at least 140 cm. Although, if you think about it, it becomes clear - it's all about increased physical activity.

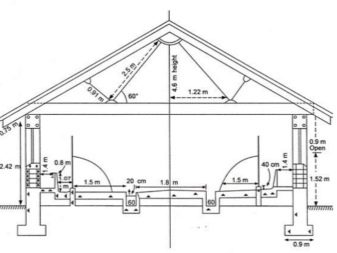

The double-sided sections are equipped with passages, which are usually 1.5 m wide. The usual height of buildings is not lower than 250 cm. But if they are made 300 cm in height or even a little more, this will not cause any negative consequences. It should be borne in mind that the feeders must be separated from the stalls. If the fumes escaping from the bull's nostrils begin to condense on the feed, they will rot constantly.

Construction stages

Floor and ceiling

Building the floor and ceiling with your own hands means doing perhaps the most important part of the work. Everyone who has seen livestock at least once knows that it constantly serves as a source of solid and liquid mud in various forms.As soon as this dirt accumulates, normal development is immediately inhibited, meat productivity and stamina decrease. Pets become lethargic, prone to all sorts of ailments, including those of infectious origin. Each outbreak of such diseases severely hits both the reputation of the owners and their wallet, disorganizing the raising of animals.

Therefore, care must be taken that all kinds of pollution do not linger on the floor. In this regard, careful selection of materials is extremely important. Many of them are able to absorb liquid or become covered with hard-to-remove stains. What can we say about those products that are easily saturated with smells. There are already enough of them in the stable.

The floor covering is mounted 100 mm above the ground, trying to make it completely waterproof. The recommended slope level for drains is 30 mm, but it is also important that it is not recommended to exceed this figure, even if it is obvious that the amount of drains will be quite large. The risk to the health of the animals themselves with an excessively large slope of the floor makes them ignore such considerations, it is better to work a little more.

Over the centuries that a person devoted to cattle breeding, many options for the execution of the floor have been proposed. However, one of the best types is the combination of clay and wood. In most cases, they are limited to driving boards into a layer of clay. This solution allows you to perfectly remove manure and guarantee a long service life. It is not always possible to take this approach.

Then you need to consider an alternative method - laying out wooden panels. Their advantage lies in the fact that it is possible, without violating the integrity of the base, to remove the shields and clean them, and then put them back in place. Important: it is unacceptable to cover the floor with 100% concrete. It looks practical, but too high a hardness poses a threat to the hooves. In addition, the concrete layer allows heat to pass through.

But even the best solutions are of little help when there are many animals to be kept. In such cases, it is necessary to equip the floors with special slurry collectors. The reservoir must be very large, its minimum width is 120 cm. A special trough is formed for the liquid to enter the container.

Usually it is built in the part of the stall farthest from the entrance (since there is the most dirt there, and it is very difficult to remove it).

It is impossible to confine oneself simply to the floor in its pure form. Even the best boards and clay, if the building for the bulls is delivered in the warm regions of the country, do not completely cope with the thermal insulation. It is imperative to prepare a special bedding.

To obtain it, the following can be used:

- peat;

- straw;

- sawdust.

The protective layer is always approx. 300 mm thick. Among its options in the first place are sawdust. They absorb water well and do not harm livestock. Subsequent cleaning is not difficult. When choosing an option, you must immediately give preference to the one that is easier to maintain dry.

Foundation, walls and roof

Professionals believe that, in terms of technical properties, monolithic foundations are preferable. The bases have no equal rivals in strength and stability. However, its use costs a lot of money. Therefore, in practice, an indissoluble base is prepared only for brick walls.

If the building is made of wood or even on the basis of a metal frame, the load-bearing capacity of the monolith is excessive.

Wishing to save money, reduce the complexity of the work, it is necessary to fill the pillars. A similar foundation forms quickly. If the load turns out to be large, the structure will not withstand it. Therefore, pillars are used when it is planned to keep a small number of bulls in a wooden shed. This means that a compromise option is most often used - filling the tape according to the classical technology.

Regardless of the type of foundation, waterproofing is required. What kind of material to make it depends on personal preferences, there is no particular practical difference between them. As for the walls, there is one subtlety.

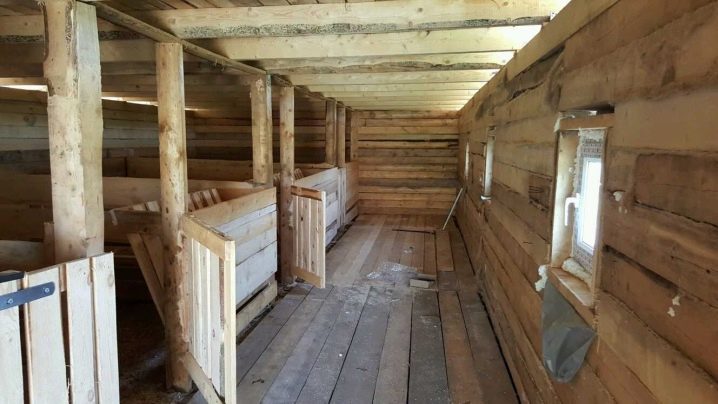

A wooden shed is made only for a maximum of 8-10 head of cattle. In addition, the disadvantage of the tree is its very rapid degradation.

You can get away from this problem without facing expensive bricks by using foam concrete and aerated concrete. When forming walls, from any material, you still need to take care of ventilation. The holes for it must have a small size, which is sufficient to maintain optimal thermal conditions. For the winter, the ventilation ducts will have to be blocked. Therefore, they must be made from the very beginning in such a way that maintenance is easier.

As with the floor already described, the roof of the bull house must be impervious to water. The slightest drop of rain or snow that melts will adversely affect the livestock. Most cowsheds and bull sheds are covered with slate. It will last a long time and is relatively cheap. When the attic is not created, the roof is thoroughly insulated from the inside.

Windows and doors

The minimum glazing area is 1 sq. m. for every 10 sq. m. of the area of the barn. It is, of course, impractical to install very expensive and exclusive double-glazed windows. However, it is quite rational to use well-insulated double structures.

Any room where animals are kept must have two doors. They are placed on opposite sides to facilitate evacuation in case of fire and other extreme situations.

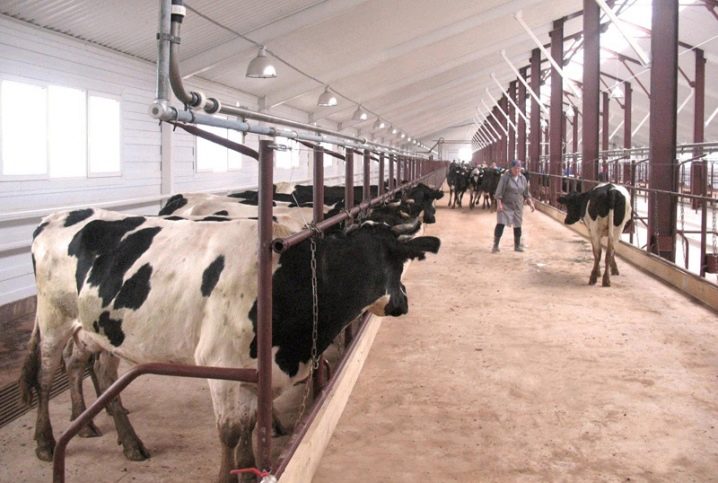

Conducting communications

In tethered stalls, you cannot do without high-quality lighting, because in winter, short daylight hours are badly reflected on bulls. And that is why it is required to perform electrical wiring in accordance with all the rules. Most often, LED lamps are used as the most economical devices. It is recommended to mount them on walls and ceilings where animals are guaranteed to be out of reach. At the same time, it is necessary to take into account the convenience of service.

Any stall must be equipped with drinking bowls and feeders. It is quite justified to bring water pipes to these places, since it is there that a lot of dirt collects. It is useful to provide for a hose connection with which you can water and wash the barn. If possible, the pen should be connected to the central sewerage system. After all, even if all the manure is collected, you still need to drain the water somewhere after washing the bulls and the floor on which they stand.

Internal arrangement

When preparing a stall (corral), attention is paid not to one width of the structure, but also to its other dimensions, as it may seem. It is very important to select materials that will help ensure the safety and calmness of the animals. One cannot ignore the fact that tethered and loose content require quite different approaches. When a room is being prepared for tethered placement of bulls in small numbers, boards and pipes can be used.

Occasionally, in such cases, a brick is used. It is imperative to have the animals face to the feeder and tail to the drain ditch. But even with such a device, it is necessary to take into account the specifics of the breeding of various breeds. The tethered technique assumes that the stall is the main platform for the bulls to live. As a result, the requirements for its quality are significantly increased.

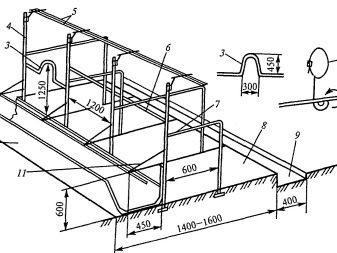

The most favorable option is a stall with a width of 1.2 m. If necessary, it is easy to repurpose such a pen for other animals or change the breed. One row contains up to fifty stalls. They are positioned so that the forehead looks into the forehead, and the tail fits the tail. Unlike a barn in the proper sense of the word, for bulls you need to form a fairly strong structure, equipping it with a stable position to secure a shortened leash.

The stall for the loose keeping of adults and young bulls looks different. Since in this version it is needed mainly for resting animals, for the most part they lie there. It is enough to form a well-fenced area, which is selected according to the size of the animals. If the stall is located close to the wall, its length should be at least 3 meters.

Too short an area contributes to continuous contamination of the most contaminated organs of the animal.

Often, the paddocks for unleashed bulls are made sliding, which allows you to adjust the size. The width changes when the side pipes move. To influence the length, you need to manipulate the bar. The disadvantage of this solution is that it is impossible to build a suitable steel pipe stall without the use of welding. Obviously, this requires special equipment and special skills.

For information on how to build a cowshed with your own hands, see the next video.

The comment was sent successfully.