How to do electrical wiring in the garage?

A well-equipped container for a car or other transport must have well-thought-out electrical wiring. And even if someone managed to establish an apartment (home) electrical network, to fix more than one device with their own hands, there is no need to rush to work. First you need to find out everything and thoroughly understand what exactly needs to be done.

Peculiarities

Electricity in the garage is always needed. Even those who are not going to repair their car or motorcycle are forced to recharge the batteries there and light the room at night. If the garage is also used for repairs, for car maintenance, you will have to sharpen tools, drill and cut, grind, solder, cook metal ... But the inevitable placement of fuel and lubricants nearby, constant dampness and contact with the ground require very careful wiring.

It is recommended to find out everything about the electrical safety standards and about the basic provisions of the work technology.

Not every garage owner has enough free time and knowledge.to learn building codes. Unlike electrical work in a house and in an apartment, it is imperative to obtain permission from the board of a garage cooperative or from the owner of a rented parking space. Connection to three-phase 0.4 kV networks will also require agreement with the electricity supplier, the same organization must draw up a project at your request.

Important Requirements

Using a 220 V network imposes much less restrictions on the garage owner. However, he must definitely purchase a meter that can withstand 50 Amp electricity and the appropriate cables. The energy supervision closely monitors the provision of a margin for the loading current. In the event of violations, he has the right to issue an order to dismantle the illegal power grid and even impose a fine on “initiative electricians”.

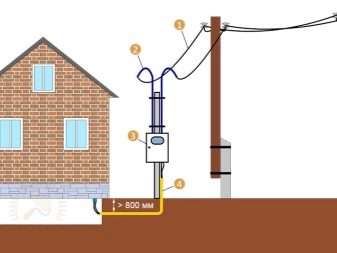

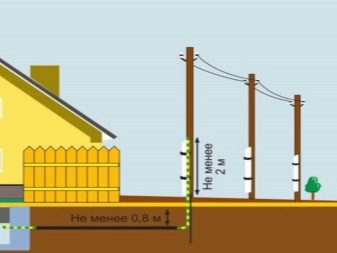

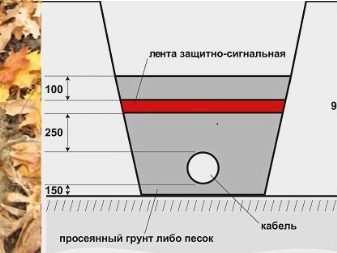

It is possible to conduct electricity from the house by air and underground methods.

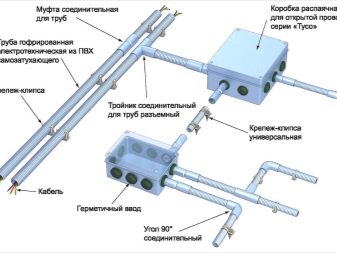

Cables are suspended in the air, held in place by a supporting steel wire 0.3 cm in diameter. According to current regulations, underground lines are supposed to be pulled in corrugated plastic pipes laid in trenches 0.8 m deep. The bottom of the excavation is sprinkled with sand (layer 0.1 m). A similar line is connected to a personal meter, the segment is protected with a special machine.

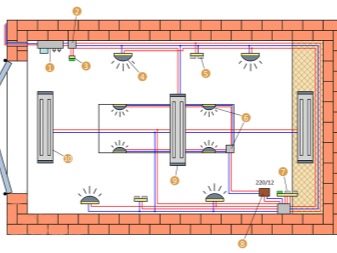

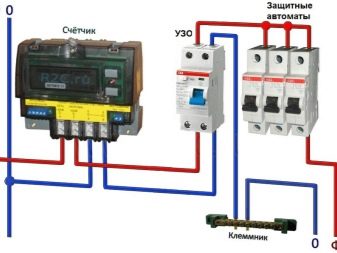

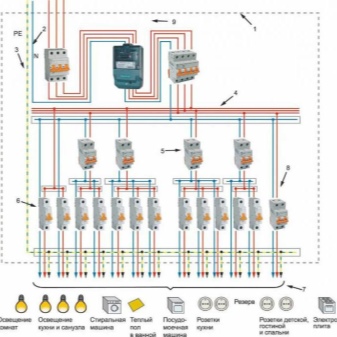

To distribute electrical energy, a special electrical panel is used, installed directly in the garage itself. A main machine is provided for it, the same type as installed in the apartment (house). These requirements are key, and all other points depend on the used scheme.

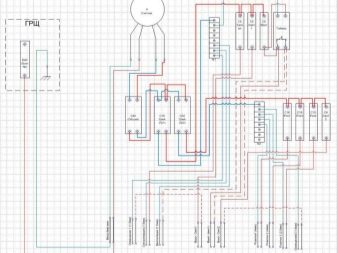

Installation diagram

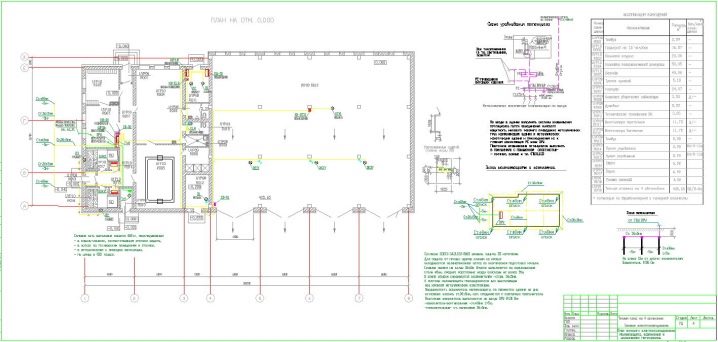

A high-quality, well-thought-out wiring diagram is the main guarantee of successful work. It is important to distinguish between so-called schematic diagrams and layouts; the first describes the electrical circuit itself, and the second describes the location of consumers (with a note about distances or with an exact scale). For the greatest convenience and to eliminate errors, the wires are denoted with the same colors that they have in real life.

Phase conductors in networks carry hazardous voltages with respect to earth. But connecting an RCD without a protective earth will not work in any way.

It is strictly forbidden for safety standards to connect protective earths and neutral, this is contrary to the basic requirements for wiring currents.

Residual current devices are differential transformers, adding the input (from phase) and exported (through neutral) currents. In case of insulation damage, when a short circuit to the case occurs, these currents differ and do not mutually extinguish each other.

The leakage current protection will work successfully only if it is directed along its special grounding line. With the help of the main machine, it is possible to de-energize the network when short circuits occur on the main line or when all lines have been simultaneously overloaded. This device is indispensable for repairing, testing the system, and troubleshooting it.

It is recommended to supply electricity through one line, because there will still only be one power consumer in the garage.

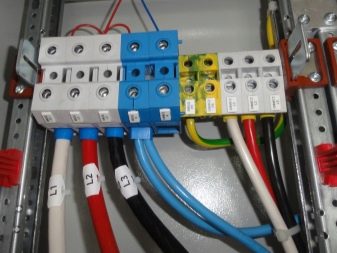

Separate groups are connected to "their" machines in phase circuits. The tires located in the shields are structurally made as strips or bars of copper, brass. Holes are made in them for the wires to be tightened with screws.

The work of an electrician with a three-phase garage network does not differ significantly from the procedure already described. It should only be mentioned about two auxiliary phases and triple automatic machines, RCDs instead of the usual ones designed for one phase. The phases are wired as in conventional 220 V lines, together with neutral. The voltage of any pair of phases must be 380 V, with a phase angle of uniform load of 120 degrees.

To build a power grid competently, you will need:

- create a diagram with clear and crisp images (symbols);

- mark vertical sections of the wiring with "+" signs with the assigned height;

- strictly observe the selected signs for sockets, lamps and other elements.

When the diagrams are formed, you can start completing the garage electrical network.

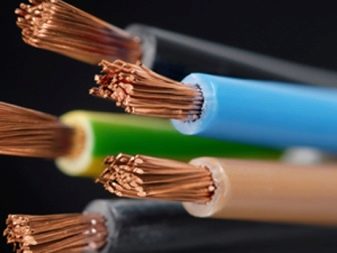

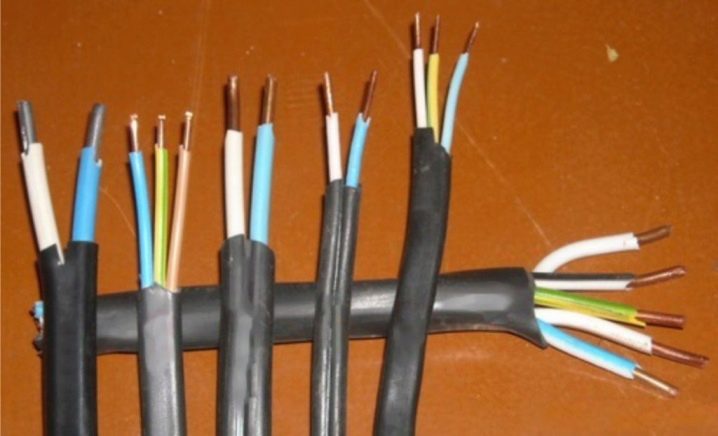

Selection of cables and wires

When selecting any cable and wire, you should focus on the voltage of 230 V (it is replacing the old 220 V and will soon become the generally accepted standard).

In most cases, it is assumed that:

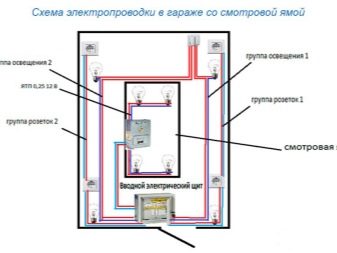

- ceiling lights are rated for 80 W each;

- in the inspection pit there are 3 fixtures for 36 V, 0.1 kW each;

- sockets for connecting working electrical equipment for 5 kW in total are displayed in the same pit.

Starting from the transformer, it is worth using closed format copper wire.

If at least part of it is held inside a concrete floor, a 4.5 sq. mm. For sockets in the inspection pit, closed-circuit wires with a cross-section of 1 sq. mm more. More detailed information about the properties of electrical wiring in relation to your garage can always be obtained using special formulas. The thinnest cable is used to connect ceiling lights - 1.5 sq. mm (thinner does not exist).

To save money, it makes sense to buy aluminum wires, especially in the least congested areas.

As in any other room, copper and aluminum should not be bonded - this also needs to be taken into account when selecting wiring. Only double-insulated cables with insulating conductors can compensate for the harmful effects of negative conditions in garages.

The selection of machines is made "by current". Ceiling light sources need 2.5 A, pit ones - 15 A. The formula for calculating the required power of the transformer is the same as usual. A residual current device designed for a current of less than 20 A and for tripping at more than 20 mA is completely unsuitable, because leakage from serviceable devices is almost invisible.

To place cables and buses you will need:

- closed shields;

- boxes;

- cable channels;

- sealed trays.

Most often, such products are made of metal, but an increasing market share is occupied by round and rectangular plastic pipes. Corrugated products should be resorted to only as a last resort, using them is rather tedious.The most modern and practical solution for electricians is the cable tray with a snap-on lid. The metal-plastic pipes proved to be quite good - the same ones that are usually used in plumbing and heating systems.

Installation technology

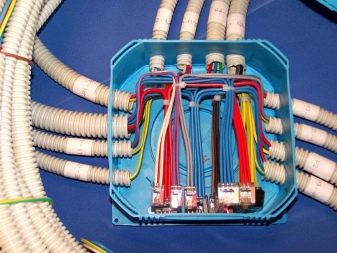

Having purchased all the necessary materials and tools, you can start pulling the wiring. Where it is impossible to make a bend in the form of a large radius of pipes, boxes should be used. They will help to distribute branches and arrange switches properly. It is necessary to fix both boxes and connecting pipes and pipes on the supporting structures as carefully as possible. Responsible garage owners, both installing wiring with their own hands and turning to professionals, always evaluate the tightness of the joints of any pipe and box.

It is important to remember that even the simplest and most carefully thought out materials and structures by engineers are installed only with careful, painstaking work.

Correctly pulling the cable through the pipe means putting the wire inside first. For this, special heads are used that will prevent sticking and pinching. Only then comes the turn of tying the cable to the wire and passing it through the pipe. It is advisable to use trays on vertical wiring segments, ceiling lamps are suspended on tension cables (not energized!).

To make the fastening of the wires in the boxes reliable, it is recommended to either clamp them with screws or to solder the copper strands. Where aluminum and copper wires have to be joined, they are separated by terminals or washers made of other metals. Great attention should be paid to grounding. No step-by-step instructions for installing wiring in the garage can go around it.

A typical workflow is as follows:

- next to the capital structure, a steel pipe, covered with a zinc layer, 2 m long is driven into the ground;

- a round steel block with a diameter of 0.6-0.8 cm is welded to this pipe;

- a circle of steel is painted with hydrophobic paint and brought into the garage;

- it must be laid to the shield, next to which the terminal is placed;

- behind the terminal there is a thick copper wire (thickness is a guarantee of low resistance).

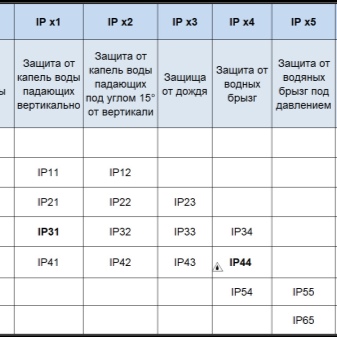

Since the garage is a damp and dangerous room, where the risk of electric shock is great, so here it is worth choosing sockets and lighting fixtures that meet the IP44 protection class.

To make a full-fledged workshop, you will have to dissolve three-phase wiring based on a copper cable, the cross-section of which is at least 6 sq. mm. The cable is placed so that the ceiling is at least 11 cm, and the socket and the floor must be separated by 50 cm.It is advisable to maintain the gap between the laying and the heating pipes at least 15 cm.

Many garages are equipped with a cellar, and this part of the room also requires special lighting., that is, laying wires and connecting them to lighting fixtures. The cellar already belongs to damp spaces, where you have to install the power grid as carefully as possible. And when it is also located in the garage, the severity of the requirements only grows. Step-down transformers with a 12V output current should be used.Only after making sure that the room is completely dry, it is permissible to use standard 220V electricity.

It is advisable to show the garage to an experienced electrician before starting work and coordinate the purchase of all components with him. This will allow you to take into account the specifics of the network being created as accurately as possible, avoid mistakes in its construction and failures in operation.

Useful Tips

According to those who have already had to create hidden wiring in the garage, the best solution is to stretch cable channels made of non-combustible materials. A smooth surface on the inside is much more comfortable than a corrugated sleeve. If suddenly the wiring does not hold up, it will always be possible to open a small section of the wall and change the burnt-out wire or even part of the channel.

For all the importance of electrical wiring, you need to take care that there is a window in the garage.

With its help, natural light is provided and the most economical mode of use of the devices is maintained. This means that the same wires and distribution units will work longer.

Electricity supply to the garage is traditionally provided by "gander" - inch pipes made of metal, placed on roofs. The tops of the posts are used to secure the pins fitted with ceramic insulators. Such a connection method is permissible only when it is mentioned in the technical specifications issued by the power grid companies. The standard height of the "nibs" is 2-2.2 m, the hanging end of the cable should not fall below 2 m.

Connection through an outrigger support pole means that the cable will be pulled directly from the line to the lead-in box. In residential buildings, such a scheme is justified, however, placing the meter on the outer wall of the garage is a temptation for vandals and non-ferrous metal hunters.

Therefore, insist if power engineers want to use the remote method so that the connection goes through an underground cable.

Before pulling the wires, you need to prepare:

- a sharply sharpened knife (it will allow you to strip the wire);

- nippers (preferably with insulated handles);

- flat and Phillips screwdrivers;

- tester (helps to detect the presence of current in various sections of the network when checking it).

When selecting a cable, it is worth considering not only its own characteristics, but also the insulation parameters.

It is very important that it is both elastic (it is more convenient to work this way) and durable (the service life and safety of use depend on this). You cannot start working with individual sections of the wiring without making sure that they are reliably de-energized. It should also be noted that the installation of external wires and their connection to the entrance to the garage should be done only by professionals. The inlet should be high enough and slope outward to avoid sediment flooding and infiltration.

The sockets should be distributed evenly, unless their different location is dictated by the characteristics of the room and the desired connection points of the instrument. If you have to work at a height (for example, pulling wires on the ceiling and to the top of the walls), you only need to use goats, platforms or stepladders.

It is strictly forbidden to stand on barrels, boxes, chairs, or other improvised items.

Before starting work, it is advisable each time to check the tool for serviceability, and the wires for the integrity of the insulation.

For information on how to make electrical wiring in the garage yourself, see the following video.

The comment was sent successfully.