Metal collapsible garage: features and benefits

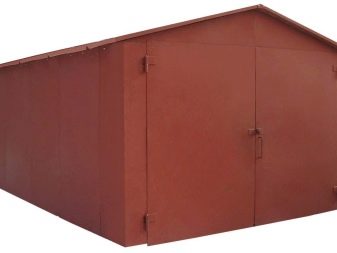

A metal garage assembled from corrugated board or metal sheets with a thickness of two millimeters is the simplest and most reliable design, which is very popular among motorists. There are several good reasons for this. First of all, it is economic feasibility, as well as reliability and ease of assembly.

Such factors have a decisive influence on the choice: collapsible metal garages can be found both in the Far North and in the southern latitudes.

Types of garages

There are the main types of such garages:

- Wireframe Models - they are based on a wooden or metal frame. Frame car garages, as a rule, are sheathed with a professional sheet. This option is good in that it does not require the creation of a powerful foundation, it is very easy to install, it weighs a little.

- Sandwich Panel Garages... The metal or wooden frame is sheathed with special panels. This option is a prefabricated structure, the main building block of which is a sandwich panel, in which there is a layer of insulation, sheathed with profiled sheet or durable plastic. Panel garages keep heat well and are easy to install.

In prefabricated garages, it is not necessary to do any expensive finishing work, from an economic point of view, they are not very expedient.

The foundation for such structures can be:

- tape;

- pile;

- in the form of reinforced concrete slabs.

Tent garages also have some advantages, for example, they are very easy to install.

It is enough to make a simple frame, digging in and concreting 4 pillars, and pulling the awning. One person can do this kind of work. Such models are perfect for temporary car parking, for example, in the country.

Pros and cons of collapsible models

A quick-assembly metal garage is very popular today, it has the following advantages:

- Ease of installation... Equally quickly, you can build both a factory garage kit and a do-it-yourself structure.

- Installation speed... It takes two working days to create an object.

- Versatility... Metal garages can be operated in any climatic zone.

- If desired, you can decorate the garage with any material and insulate.

- Affordable price... From the point of view of cost, such designs are the most democratic.

- Metal garages have excellent resistance and resistance to negative environmental influences.

The garage can be used as a repair shop and at the same time serve as a vehicle storage facility. It can also be used as a storage room.

The main disadvantage of collapsible structures is that in the cold season the temperature in the garage will be almost the same as outside.

The gates in such structures can be:

- lifting;

- sliding;

- swinging.

The easiest way to make a swing gatebut they have some disadvantages. They require at least 3 sq. meters of space in front of the garage. In the winter season, after heavy snowfall, such gates will have to be "dug out" willy-nilly.

Materials (edit)

You can sheathe the inside of the garage with a variety of materials.

This could be:

- drywall;

- wooden or plastic lining;

- plywood;

- metallic profile.

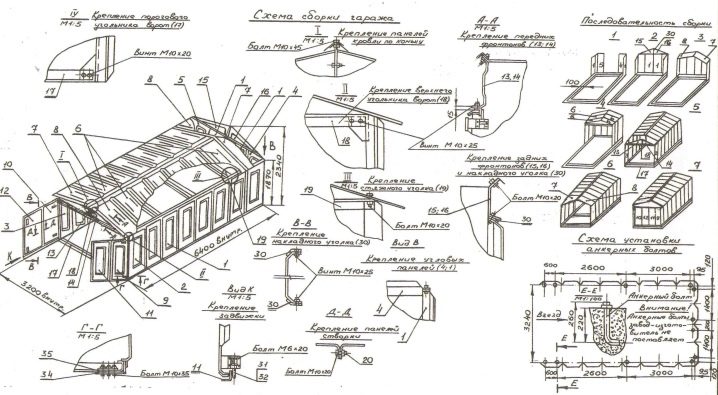

Before proceeding with the installation of a metal garage, it is imperative to draw up a plan diagram. It is very important to calculate in advance all the main dimensions, then it will become clear how much material is required.

A collapsible garage is most often 3.5 m wide and 5.5 m long.The base for the structure should be 15 centimeters higher than the ground levelso that water does not enter the room during precipitation.

The foundation is poured immediately, this will greatly increase the strength of the floor. Before making a concrete slab, it is definitely recommended to add gravel, thus creating a "pillow", which will represent a slight rise above the ground level. This will protect the room from moisture in rainy weather and in the spring when the snow melts.

To install a concrete screed you will need:

- cement grade at least M 200;

- metal rods 6-8 mm for reinforcement;

- sand and crushed stone.

With no less efficiency, it is possible to carry out the installation of a pile foundation, which will withstand heavy loads. The pile foundation is much cheaper, in terms of strength, it will not be inferior to a concrete structure.

The main material costs will fall on the purchase of material for the frame.

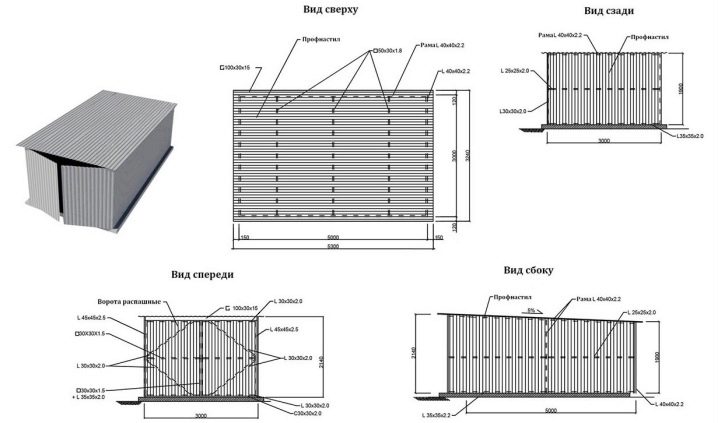

If the garage frame is metal, you will need to buy:

- corners;

- pipes;

- galvanized profiles.

If the frame is wooden, then you will need to purchase:

- timber;

- boards;

- plywood.

Most often, pipes are used for construction, which easily lend themselves to bends, while maintaining strength. To work with such material, both welding and threaded connections can be used. It is best to develop an iron garage project on the basis of a modular model, when the frames of all the walls are made separately, and after that all the elements are assembled into one whole and installed on the prepared area.

To install the frame of a metal product you will need:

- metal pipes, their parameters must correspond to the dimensions of the future structure;

- welding equipment or corners - the choice depends on the fastening of the profile;

- grinder with cutting discs or drill with drills;

- fasteners;

- puncher;

- water level;

- corrugated board.

Reinforced concrete elements can also be used, they can withstand heavy loads, but they are much more expensive. When installing a reinforced concrete product on concrete, a waterproofing layer must be placed between the metal and the screed. Metal profiles must be primed with a primer, then colored.

The best option is to use an alkyd primer., it is relatively inexpensive and effectively protects the metal from corrosion.

Components

To make the design as stable and reliable as possible, the fastening of all parts must be given special attention... Each node performs its function, carries a certain load. When installing, be sure to take into account all the nuances.

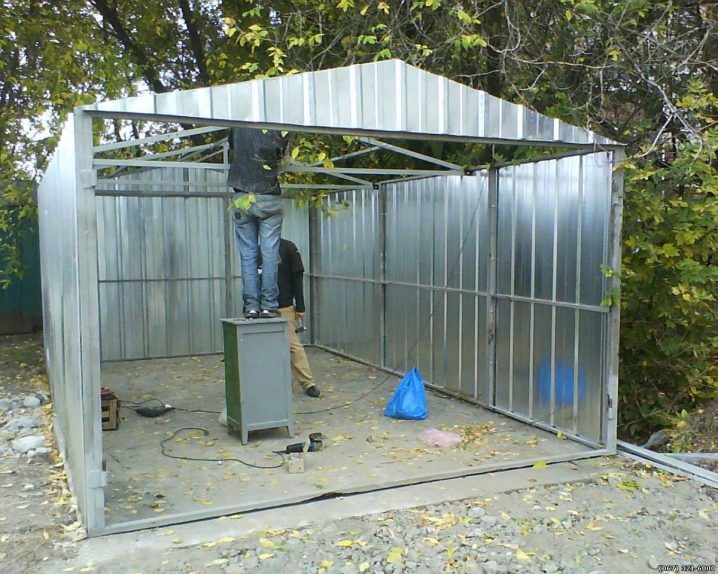

When installing the frame, the vertical posts are fixed with profile corners both at the bottom and at the top. Often the frame is welded, but it is also permissible to use special fasteners.

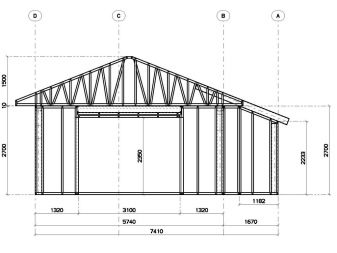

The roof can be either gable or pitched. In a metal collapsible structure, a gable roof is often used..

After installing the frame, the structure is sheathed with metal sheets, which are attached by welding or screwed to the base with self-tapping screws. Despite the fact that all elements are fastened securely, the garage can be disassembled at any time if necessary, and transport to another site.

Assembly guidelines

In order to prevent even minimal mistakes in the installation of the structure, it is recommended to take into account the advice of experienced specialists and follow the procedure:

- When installing a collapsible metal garage, you do not need to make a powerful expensive foundation.

- The frame of the metal garage includes corners and channels, galvanized profiles.The assembly of the structure begins from the floor, perpendicular posts are formed, which are interconnected by horizontal corners. When the "box" is assembled, you should start installing the roof rafter profiles.

- When building a garage, a two-meter building level is constantly used.

- For fastening the units, self-tapping screws or galvanized bolts are used, which will not be exposed to moisture.

- When creating a drawing of a future structure, it should be borne in mind: the roof must have a slope of at least 20 degrees so that water does not accumulate on its surface.

- When finishing the frame with sheet metal, the elements are mounted from bottom to top and from right to left. The sheet is fixed to the base with self-tapping screws.

- It is best to insulate the garage with foam. With its help, a monolithic insulation structure is created. Polyfoam is sold in the form of 1x1 m slabs with a thickness of 3 and 5 centimeters. The material is inexpensive and very effective, the fastening is carried out using polyurethane foam and galvanized anchors.

- In order to have comfortable conditions inside the garage, it is necessary to take care of ventilation, which will effectively remove condensation and carbon dioxide. Supply and exhaust ventilation is the most popular. If you plan to warm up the vehicle in the garage, then you can make a hole in the wall and bring out a rubber hose through it, its second end is fixed to the car's exhaust pipe.

- Shelves and racks must be attached to vertical and horizontal rails. They weigh a lot, therefore, in order to avoid deformation of the garage body, it is better to fix them to the supporting structures.

- When using paint, metal sheets must be primed with an appropriate primer.

- All sheets are rigidly attached to the supporting structures of the frame; there must be rubber gaskets between the bolts and the metal.

- In the case of installation of automatic vertical gates, this factor should be taken into account in advance, even at the stage of planning the structure.

- The side wall of the garage is made of two pieces, which are bolted to each other, thus forming a strong stiffener.

- To make the roof more durable, pile trusses are used, which are distributed along the length with an interval of 50-80 cm. Then the roof can withstand even a significant layer of snow.

- Visors should be provided, which should protrude at least 30 cm, thus, another element of protection against atmospheric precipitation will be formed.

- When using swing gates, all parts should be adjusted as much as possible so that the gaps are minimal.

- The swing gates are additionally locked from the inside with pins both at the top and at the bottom, which effectively increases the level of protection.

The timing of installing the garage in each case is individual and depends on various factors. If all the preparatory work is carried out correctly, then the installation of the frame takes two to three days.

The assembled metal garage is a compact and reliable design. With proper insulation, you can fully work in such a room even in the winter season. Such an object reliably protects the vehicle from negative environmental influences.

The dimensions of the building can be varied:

- 6 x 3 m;

- 8 x 5 m;

- 4 x 5 m, etc.

To assemble a metal garage, you do not need to be a great specialist, it is enough to be able to handle the tool. The advantage of such objects is also that metal garage can be made for two or even three cars.

Assembled examples

- The optimal roof slope (at least 20 degrees) and small canopies reliably protect the garage from bad weather.

- A metal garage with a lifting gate is sheathed with painted corrugated sheet.

- The most economical garage option with swing gates.

You will learn how to assemble a metal garage from the following video.

The comment was sent successfully.