Braziers-diplomats: features and manufacturing methods

Most people associate going out into nature with cooking a barbecue. However, when hiking in a small company, it is inconvenient to lug a large brazier - it is hard, and it takes up a large volume, and using logs or bricks is also not a good option. In such a situation, a folding brazier in the form of a diplomat is best suited.

Preparation for manufacturing

Before making a brazier diplomat you need to know about its main parameters and advantages over stationary models:

- ease of use;

- good size;

- the ability to make and repair such a grill with your own hands;

- reliability of the design.

The last parameter is determined not only by the thickness of the metal (usually for such structures, metal with a thickness of 3 mm is used), but also by the quality of all individual parts. It is also necessary to properly treat all surfaces before working with them.

The quality and properties of the metal may be the main disadvantage of this design: with the wrong choice or when choosing a rusty material, the brazier will quickly become unusable. It is also worth considering that it is difficult to cook a large amount of meat in a folding barbecue - its area is small, there will not be enough coal even for two portions of a barbecue. And rarely do such designs stand out for their beauty - they are needed only for the sake of convenience.

In the process of preparation, you can not only draw on paper all sizes of the barbecue when folded and unfolded. The layout should be made of cardboard, preferably dense. This stage will allow you to understand all the design flaws and redo them at the stage of creating a layout.

It is best to check the availability and condition of tools and materials in advance.

During the manufacture of the barbecue, you will need the following tool:

- electric jigsaw with stainless steel blades;

- Bulgarian;

- drill;

- scissors for metal;

- welding machine;

- tape measure and ruler;

- level;

- sheets of metal or stainless steel;

- set of dies.

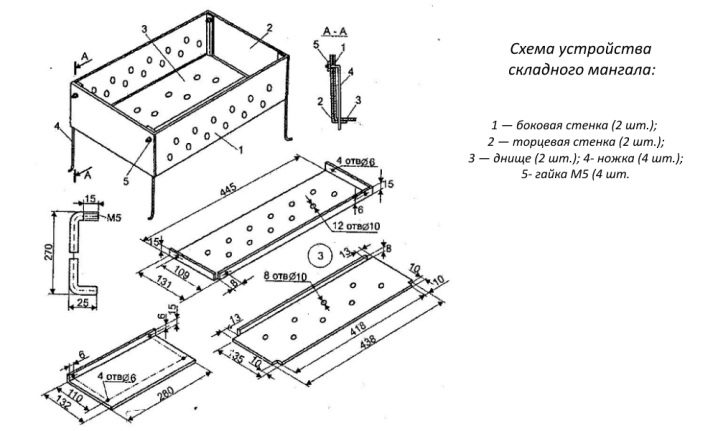

Assembling a brazier-diplomat

The assembly of such a structure takes a little time, but at the same time the product is comfortable and durable. All dirty surfaces are inside during assembly and external parts will not be able to harm other objects.

The folded brazier has a thickness of 4 cm, which, with a handle, makes it easy to carry. With skillful use and competent calculation, skewers or a grill grate can fit inside such a case.

When transferring skewers inside such a diplomat, the length of the barbecue should be greater than their length. The standard parameters for a portable barbecue are 40x65 cm. It is of these sizes that ready-made models are most often sold and our own products are made.

The manufacturing procedure looks like this.

- The first step is to make the bottom. Usually stainless steel with a thickness of 3 mm is used - such a sheet is able to withstand high temperatures for a long time and not deform. Many people use sheets with a thickness of 5 mm - this increases the weight of the structure, but makes the bottom completely resistant to high temperatures.

- Holes must be made in the side walls with a thickness of 2 or 3 mm for air to enter. It is best to do them in two rows at a sufficient distance. Sheds are fastened by welding or bolts. The size of the side walls depends only on the vision of the finished structure and a previously prepared drawing.

- Cross walls are made without holes. They are not attached to the base and must be collapsible.This is usually done with short side folds.

- Then a structure is performed to secure the legs. Nuts with thread 8 are screwed to the bottom. The support itself is an eight-millimeter rod with a length of about 60 cm. This length is typical and may vary depending on the height. It is also necessary to take into account the fact that too narrow legs can sink in sand or mud - it is best to make any flat additional supports below.

- After the entire structure is made, it is assembled and a place for the handle is selected.

- It is imperative to come up with fixing elements in order to avoid spontaneous opening of such a case.

Useful Tips

Many people who make such a construction with their own hands dream of making a very light and "eternal" brazier. Therefore, 1 mm thick stainless steel is used. Not only will such a thin metal bend quickly under the influence of temperatures, but the quality of the stainless steel itself may be low. Checking the quality of the material in the store is quite difficult, but if possible, it is best to do this.

It is also necessary to clearly understand the difference in manufacturing and use heat-resistant steel. - it is able to withstand the amplitude of temperatures, and also has high resistance to various deformation. Heat-resistant steel can also withstand high temperatures, but at the same time it is easily subject to deformation.

It is best to use ferrous iron - it does not deform much at high temperatures. Even if the iron is less solid, but with a sufficient thickness of the canvas, such a brazier can be used for many years.

If you have time and desire, then you can cover the grill with paint or varnish for metal. It is best to paint only the outer sides - the paint will quickly fade inside.

Making a barbecue with your own hands is a simple process, but it takes effort and time. With the right choice of means and a competent approach, the brazier-diplomat will serve its owner for many years.

After watching the following video, you can easily make a brazier diplomat yourself.

The comment was sent successfully.