Wrought iron barbecues: features and beautiful examples of design

The smell of fried meat with smoke cannot be confused with any other. A delicious, aromatic and juicy barbecue can be prepared on a warm summer day or at any time of the year, having a stationary or portable grill available. Forged barbecues are rightfully considered the most interesting designs.

Peculiarities

You can cook fried meat in the usual way in a pan or in the oven, but a fragrant barbecue cooked on a grill is more than just a delicious dish. Cooking such dishes is a fascinating process where there are no trifles. A master of his craft will cook them in an elegant dish, serve the cooked meat on a platter. A kebab cooked on a wrought iron grill will complement the overall picture and make the rest more beautiful.

A wrought iron grill made by an experienced craftsman is truly a work of art. Such models are made to order, you just need to provide a drawing and a sketch, according to which the blacksmith will be able to implement the idea and complete the work.

Barbecues are installed more often in summer cottages or in private households. Such an original thing will perfectly fit into any landscape and will delight with functionality.

To make a forged brazier, use:

- Metal sheets that are highly durable.

- Thick stainless steel. This material will perfectly cope with the very high temperatures that the product is exposed to during cooking.

- Cast iron, which also has a high resistance to high temperatures and is not afraid of fire. But cast-iron barbecues have their own peculiarity - if the surface is strongly cooled, cracks may appear on it. Work with such a structure should be more careful.

- Heat-resistant steel is the most commonly used option and is optimal in terms of price-quality ratio.

If the grill is made of less durable materials, it will quickly burn out. Such a product is useful only for infrequent barbecue cooking. If smoky meat and barbecues are very often cooked for the table, it is worth choosing forged structures from a more durable material.

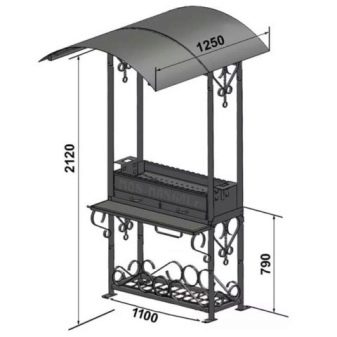

These models differ in both their design and functionality. In manufacturing, the master relies on the customer's sketches. Often, at his request, additional accessories are made, for example, barbecue makers. Often, wrought iron barbecues are stationary, they can be equipped with a roof or they are placed in a wrought iron gazebo. A distinctive feature of the barbecue is their unique image, which the masters of their craft manage to create.

Artistic forging allows you to give the product a variety of fancy shapes. Such forged products will always be relevant and attractive.

Types of structures

Today you can find various types of barbecues that are made by forging.

Portable

These structures represent a brazier that can be easily transferred to any place. Such products are not heavy, they can be transported in the trunk of a car to barbecue in nature. For portable designs, graceful forged curls and unusual designs with original elements are rarely used. Most often, such designs are simply functional, without unnecessary design.

Portable structures can have collapsible legs, they are easily removed and taken to any place; during storage, they take up little space.Such a collapsible brazier is suitable for summer cottages, going out into nature.

Portable structures include a forged product on wheels - they can be easily rolled out of storage and hidden back after use.

Stationary

The stationary design is not used for carrying, these are classic models for cooking juicy meat with an open top.

For stationary structures, steel or cast iron is used.

It is very convenient if there is a cutting table nearby for meat products and vegetables, convenient shelves, a cupboard for dishes, and a basket for firewood will also not be superfluous.

Stationary structures are the most spectacular, they can be designed in various original versions, for example, in the form of a carriage, a luxury carriage or in the form of unusual figures. It can even be fairy-tale characters or animal figures.

Such products look very unusual, but due to the presence of forged parts, it is difficult to care for them.

Multifunctional

Multifunctional devices allow you to cook barbecue, barbecue, grill using barbecue makers. These include:

- Brazier combined with a cauldron. To secure it, a forged chain with a ring is installed.

- Shashlik maker with hood. Consists of a brazier and a smoke extraction hood. They are made with a special coating that protects the brazier from dust and debris, rain.

- Braziers with a stove. In this design, dishes are baked, which are immersed in heat or cooked in a cauldron. Such products have a roof. The multifunctional device allows you to prepare many delicious and varied dishes.

- Brazier smokehouse. This design is indispensable for those who love smoked meats. They are equipped with a cover that covers the firebox and prevents smoke from escaping, it can also be equipped with a metal box with a grate and a drip tray.

Braziers with a roof allow you to shelter the product from sunlight and rain. Such "umbrellas" will protect the carved grill from any natural surprises. Such devices are more often stationary and designed for a long service life.

The roof for the barbecue is made in different ways:

- with continuous coating;

- with a hole for smoke;

- by type of hood.

By purchasing such a product, you get an excellent device for cooking.

It is important to properly care for a wrought iron barbecue. If the device is portable, take it to a storage room at the end of the season. The grill should be pre-cleaned and washed with water, to which the dishwashing detergent is added. The surface is cleaned with a brush and left to dry.

After the surface is completely dry, it is greased with vegetable oil. It is easy to take care of such products, since all structural parts are cleaned.

To make the cooking time comfortable, it is better to purchase special appliances. They can be used to determine how cooked the meat is. Various spatulas and forks are also useful, as well as a special hairdryer that will blow up the coals.

Manufacturing technology

Each master of artistic forging has certain secrets in the manufacture of forged products, although the basis of the work is practically the same. The brazier is a rectangular box, inside of which coals or firewood are placed. It is most often made from metal or steel. The sides are welded to the bottom. There should be no gaps in the structure.

For the outer part of the barbecue, other materials are often used., for example, wood, therefore, the structure is treated with fireproof impregnation, and the installation is carried out taking into account safety rules.

Metal rods of various shapes are often used as a stand. Sometimes they are made in the form of openwork plexus, geometric shapes or wavy lines. To give the rods their original shape, cold forging is often used, and hot forging is often also used.

The whole structure is decorated with all kinds of decorative details in the form of leaves, buds, and relief forms. They are made from a thin sheet of metal, then they are applied by welding to the structure.

After making a forged product, it should be sanded. Thus, blemishes in the form of sharp edges or burrs are removed. The surface is treated with anti-corrosion compounds to protect the metal surface from environmental influences. At the final stage, the barbecue is painted.

You can make a design yourself. For such a product, it is better to choose cast iron. This material is very reliable and durable, it will not burn out and will not warp. Such a grill will serve for a very long time.

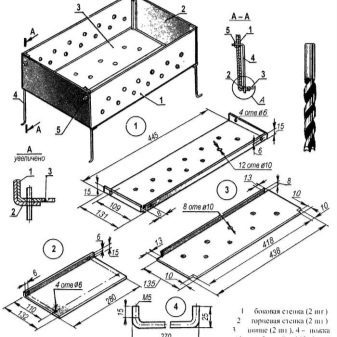

When deciding to make a product yourself, you should create a drawing. Using sketches makes it much easier to complete all the manufacturing work. When determining the size of the product, one should take into account its functionality and ensure the desired comfort during its operation.

If you plan to make a barbecue for 10 skewers, the optimal length is 1 meter. On average, 8 pieces of meat are placed on one skewer, so it is better to choose a width of 30 cm, which will ensure maximum heating of the meat. The depth for the barbecue is chosen about 15 cm, in this case the coals will not touch the food.

To determine what should be the distance from the earth's surface, you should bend your hand with a skewer, the optimal height will be at which it is convenient to hold your bent arm. The brazier is made, taking into account the growth of the brazier. The height of the sides is made at the level of his belt.

The end side should be made removable in order to be able to remove ash. They also make a fixation for the skewers so that the meat is evenly fried on each side.

If you make the device yourself, you can make the sides higher, thereby making it safe to use, and it will also improve the process of cooking meat dishes. To make the grill more stable, the firewood shelf is placed at the bottom, thereby shifting the center of gravity.

To decorate the metal, laser and plasma cutting is used in the manufacture of forged products. Laser-cut products can be an alternative to expensive forged products. They are robust and easy to assemble. For manufacturing, they take solid sheets of steel, decorate them with patterns and decorations, which are made by laser cutting.

The main characteristics of laser cut products are:

- getting beautiful decor and patterns;

- manufacturing of various parts in shape and size;

- these designs are much stronger than forged products.

Often for the manufacture of forged barbecues, hot forging is used, which requires special skill in their manufacture. In the process of plasma cutting, such physical costs are not required. With the help of artistic cutting, the process will be much faster, and the shape of the product will turn out to be thinner and more delicate.

During operation, the metal is heated to a very high temperature for a short period of time, while the technical characteristics of the metal remain the same. In the process, no sagging is formed on the product, so there is no need to grind the finished product.

Plasma cutting is carried out on metal of various thicknesses. The cutting device can provide temperatures up to 30,000 degrees, and the cutting depth up to 20 cm. Shaped cutting is used for convex products and stencil sculptures.

Beautiful design examples

When choosing a forged barbecue, you can opt for the simplest portable structures that are quickly installed and conveniently used.

A small portable grill will allow you to enjoy a delicious barbecue not only at home, but also when you go out into nature with friends and family.

Owners of their own homes often choose exclusive models. The forged carriage looks very unusual. Such unusual models will become a decoration of the garden plot.

Lovers of sea travel can decorate their summer cottage with an original structure in the form of a ship.

Such original barbecue areas can also become a street decoration.

A brazier resembling a chest looks rather unusual and original.

In the manufacture of barbecues, artistic forging is often used, which makes it possible to make each product in a single copy.

In the next video you will see how to make a forged brazier with your own hands.

The comment was sent successfully.