Design features of a metal fence

Initially, the protective structures were only a means of protecting the territory - the fences clearly defined the boundaries of private ownership, therefore they were simple and unprepossessing. Today, the functionality of the fence has acquired a more aesthetic character - the owners want not only to define their territory, but also pretend to be sophisticated and even aristocratic when choosing the appearance of the fence. It is because of this that metal fences have gained popularity in the modern world, and a wide selection of materials allows you to bring to life the most bizarre and original solutions.

Peculiarities

Fences have a number of advantages due to which they are relevant and very common in the modern world. Any fencing systems, whether they are sectional or individual, are distinguished by reliability and strength, which is achieved through the use of metal in the structure. And with proper care, iron structures become more durable, which is less of a hassle during their operation.

Another feature of steel fencing is its versatility. It manifests itself both in the purpose (defining the boundaries of the personal plot, the territory of production facilities, building objects) and in the forms (openwork weaves, lightweight mesh options or heavier monolithic varieties). All these forms are in perfect harmony with other elements - wood, brick, stone, which allows you to design the appearance more individually, functionally and in accordance with the established budget.

Views

The modern market offers a huge number of options for fencing for the territory. They fall into the following categories:

- Forged. A wrought-iron fence is considered elite due to the elements of decorative art forging, made of steel and cast iron by hand or by industrial stamping. It is the curly details that give the fence a unique, attractive look and raise it to the rank of a work of art.

The main advantage of such a fence is its incredible strength. Forged structures are quite resistant to mechanical damage and various deformations, which increases the service life of the product. However, due to the complexity of manufacturing, they are one of the expensive pleasures. Most often, artistic forging does not represent a fence as a restriction of space, but, on the contrary, favorably emphasizes the architecture and style of the building.

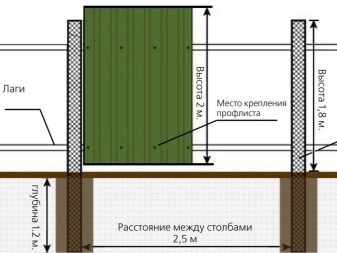

- With monolithic spans. This type of fences is represented by racks or pillars between which monolithic panels of the span are attached. The vertical supports are made of various types of materials such as steel pipe, brick, wood. The most common type of panel is profiled decking, which is a perforated sheet of metal of various profiles. The corrugated board is covered with zinc and other polymeric substances, thanks to which there is a huge selection of colors of this material, as well as the anti-corrosion properties of the metal are preserved.

Another option for a span shield is metal siding, a solid steel or aluminum panel. The siding surface is made not only in different color palettes, but also with all kinds of patterns and textures, for example, wood or stone. Thanks to this, the fence acquires a more expensive and presentable appearance.

Since fences with monolithic openings are solid fences up to 3 meters high, they have good sound insulation and protect the area from excessive dust and dirt. Such structures are easy to install and operate, they are easy to repair, and the surface can be washed with a hose.

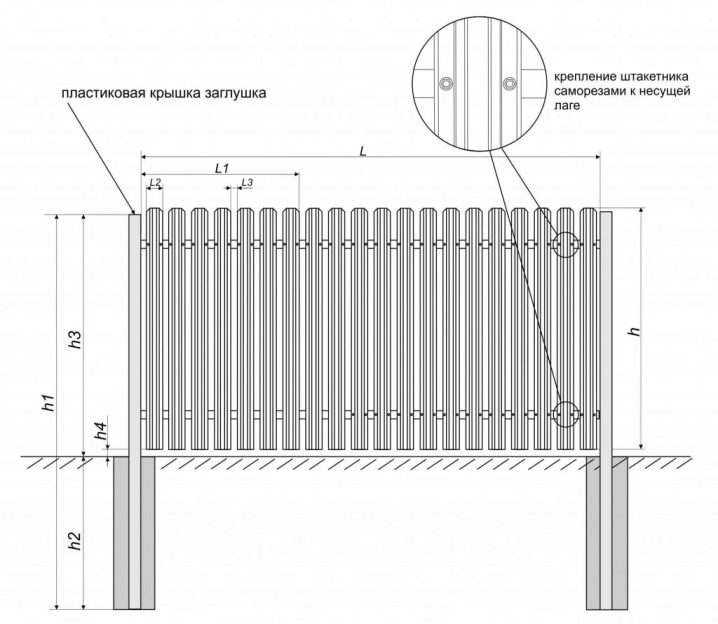

- Metal picket fence. Picket fences are ready-made vertical strips made of steel profiles, which are fixed on longitudinal beams. Initially, the picket fence was made of wood, but its modern metal counterpart has become a more popular tool for landscaping household plots, garden areas, flower beds and front gardens. The market presents a wide range of this type of fencing, which allows you to choose interesting and original solutions or make an individual order according to your own sketches.

A picket fence has high performance characteristics and does not require constant maintenance to maintain a beautiful and aesthetic appearance, including painting. Also, the advantages include the relatively inexpensive cost of the material and ease of installation.

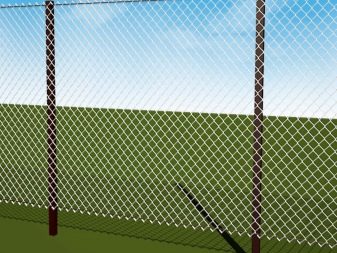

- Lattice fence. There are two types of such fences: a chain-link mesh and welded fences from a lattice. The latter can be made from a ready-made factory structure or a homemade welded wire mesh.

- Mesh is a great option for fencing the site, as it is an inexpensive way to protect the territory from stray animals and intruders. It has good light transmission and does not deprive the area of additional sunlight and heat. It is also effective to use mesh fencing in public areas: parks, schools, kindergartens and office buildings.

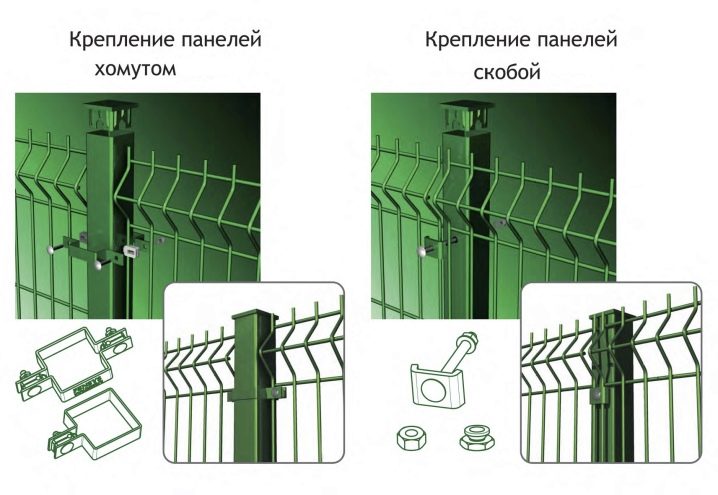

- Gaining popularity sectional lattice structures from a bar... They are separate sections of rods that are welded together in the form of a lattice. The surface of such a fence is not only treated with a zinc layer, but also covered with a special polymer compound, which gives additional protection against metal corrosion and gives the structure color. Such fences are easy to install and operate, stable and decorative.

Advantages and disadvantages

Advantages of metal products:

- Stability - metal structures are highly resistant to damage, almost do not deform, especially if there are forged or welded elements in the structure;

- Durability - metal products are invulnerable to atmospheric precipitation, temperature drops, ultraviolet radiation, which makes it possible to operate them for more than 10 years;

- Unpretentiousness - iron structures are practical and do not get dirty, and if necessary, they can be easily washed;

- Affordability - in most cases, the cost of a metal fence is acceptable and justifies its quality. Based on the established budget, you can choose an inexpensive solution (mesh fence) or a more expensive option (artistic forging);

- Wide assortment - the market offers the buyer a huge selection: from monolithic panels to lighter varieties of fences made of strips, tapes and even blinds. You can buy products both in specialized places and make an individual order according to your own sketches;

- Ease of installation - the erection of the fence can be carried out by the buyer independently. Due to its small massiveness, the installation of the fence does not require special education, skills and tools. Otherwise, there are many special services that will help in this difficult matter;

- Decorative - due to the variety of shapes that can be made from metal, such fences are quite popular in modern society.They can be used both on the ranch, and for the design of garden and park areas, and for the improvement of the territories of administrative buildings; both vertical and horizontal design. At the same time, there will be no hindrance to the review and consideration of green spaces.

Corrosion is the main enemy of metal structures. This process is inevitable, since frequent contact with precipitation, temperature extremes, minor scratches or damage during installation can disrupt the protective layer of the coating and start corrosive processes. However, this minus is not difficult to fix: timely surface treatment with special anti-corrosion agents is needed, and, if necessary, the elimination of rusty areas. It is important for owners of metal structures to remember that the service life of the fence depends on how it is looked after.

Manufacturing and installation

To build a fence, you will need the following set of tools and equipment:

- Roulette;

- Bar or wooden pegs;

- Measuring cord;

- Hydro level;

- Shovel or drill;

- Angle grinder;

- Welding machine;

- Perforator;

- Screwdriver;

- Spray gun and brush;

- Hacksaw and scissors for metal.

The installation of any fence begins with the installation of vertical support posts that are well fixed in the ground. The most versatile material for support pillars is round or rectangular welded pipes of various profiles. However, when choosing racks, it is necessary to take into account the mass of the future fencing. This is necessary in order for the supports to withstand the mechanical load of the fence itself, wind and other damage.

Fence installation work involves the step-by-step implementation of the following actions:

- Before starting work on the installation of poles, it is necessary to clean the site of debris and vegetation, and also to plan the territory. The ground should be leveled whenever possible.

- Territory marking. With the help of a measuring cord around the perimeter of the territory, it is important to determine the places of the vertical supports and put a peg or rod. The optimal step between the posts is 2.5-3 meters.

- Development of soil for pillars. The sizes of the pits can be completely different: the diameter is from 20 centimeters, the depth is from 100 to 130 centimeters. The size is selected individually for each type of support, depending on the diameter or perimeter of the metal support. The depth of hole drilling is selected depending on the area of residence, the depth of soil freezing and the height of the support pillar.

- Installation of poles with careful leveling. In each pit, it is necessary to pour crushed stone or gravel 20 centimeters thick and fill it with a cement or concrete composition with layer-by-layer compaction. The optimal drying time for the composition is 3-6 days. This type of fixing the support post in the pit should be used when installing massive metal fences.

The second option for installing steel supports is to drive them into the ground. This method is most often used in soft soil, where there are almost no rocks or when installing light fences that do not require a large mechanical load on the vertical supports.

Another way of attaching poles for light fences is bucking. With this method, the pit is filled up with crushed stone or gravel with ramming or just soil developed earlier.

After installing metal racks, you can proceed with the installation of the fence.

Due to the massiveness of forged products, for additional stability of the fence to the support posts, transverse joists are welded using a welding machine. If the height of the fence does not exceed 180 centimeters, then two crossbars are sufficient. The hedge pattern itself is usually formed separately and mounted on a metal frame ready-made. If the fence is of low height, then forged sections are most often used, which are welded to pre-installed steel posts or other supporting structures.After installing the structures, it is important to clean the seams well and treat them with anti-corrosion primer and tint these places with paint.

As with the installation of a forged fence, when installing a fence from a profiled flooring, horizontal crossbars must be welded to the support posts. In connection with the windage of the corrugated board, for greater stability of the metal frame, it is necessary to install three transverse parts with a fence height of more than 160 centimeters. The crossbeams, like the racks themselves, must be treated with an anti-corrosion compound to protect the frame from rust.

Profiled decking sheets are mounted vertically with an overlap in one wave. From the horizontal surface of the earth, you should retreat upward by 10-15 centimeters so that in the spring the material does not come into contact with water. The sheets are fastened with self-tapping screws for metal with a length of at least 35 millimeters, which can be matched to the color of the corrugated board. Therefore, it is not necessary to drill holes in metal sheets in advance.

To hide the unevenness of the upper edge of the structure, you can install a fence bar on top. Then the fence will have a more aesthetic and finished look.

It is better to use a hacksaw or metal scissors to cut sheets. When using a grinder, zinc spraying on the surface of the material may be disturbed and lead to corrosion. Also, during the installation process, scratches can form on the corrugated board, which can be easily removed with paint in the color of the material. This paint can be purchased at any specialty store.

When installing a fence from a picket fence, to fix the strips, crossbars from a professional pipe measuring 40x20 millimeters are welded. The surface of the steel supports and beams should be painted in the color of the hedge. This will improve the performance properties of the metal and give an aesthetic appearance to the fence as a whole.

The strips are fixed to the transverse jumpers in four places: two self-tapping screws in the upper and lower parts. In order to prevent the material from bursting and becoming unusable during the installation process, it is necessary to pre-drill holes at the top and bottom of each strip of a smaller diameter than the diameter of the attachment. Instead of self-tapping screws, you can use special galvanized fasteners, which will extend the service life of the fence and simplify its operation.

For a more presentable view of the fence, before installation, you need to calculate the distance between the strips. For this, the length of the fence between the posts is measured and divided by the width of the picket fence. The pickets should be fixed at the same level in height and with the same distance in width, unless otherwise provided by the project.

A metal picket fence for a fence can be presented in the form of sectional parts, which are welded to the support posts by welding.

When installing a mesh fence between the vertical posts at the top and bottom, on each span of the fence, two veins of steel wire rod are tensioned and welded. This is to prevent the mesh from sagging. After that, the mesh is stretched, the fabric of which is fixed with a wire with a diameter of 6.5 millimeters. The wire is threaded through the cells and welded to the support posts. At the end of the work, the supports and the mesh should be coated with paint.

The installation of a sectional fencing made of welded lattice is surprisingly simple. When installing such a fence, the main factor is the good depth of the support posts. Otherwise, the fence will deform when exposed to strong winds.

The surface of the grating sections and supports are treated at the factory with a special zinc phosphate followed by a polymer coating, which not only provides protection from atmospheric agents, but also gives the fence a rich color. All components of the fence can be purchased ready-made in a specialized store.

Fence sections are attached to the support posts using bolts, special brackets and nuts.The most essential tool for installation is a socket wrench. You will not have to use any additional materials during installation. Finally, the mounting holes are closed with special plugs.

If you wish, you can make such sections yourself. For this, a steel wire with a diameter of 5 millimeters is used. It is necessary to cut rods of the required length from wire, lay them perpendicular to each other and weld at the point of intersection. The result is a welded grid with square or rectangular meshes. With individual production, the width and height of the sections depend only on your own sketch.

To give the manufactured product color and improve its performance, it is necessary to cover the surface of the lattice with special compounds based on zinc and polymer compounds.

Useful Tips

- When installing a fence from a mesh, do not mount the material with an overflow on the ground, you need to leave an air gap. This will save the material from corrosive destruction and remove the load from the mesh;

- Metal structures made of galvanized material do not need additional processing with special compounds or painting. If the surface of the mesh or grating does not have a galvanized polymer coating, subsequent painting is required. Painting work is best done with a brush, since the spray gun will waste a lot of paint, and the roller will not paint over the mesh weaves;

- When building a fence from a profiled flooring with your own hands, you should not take on combined solutions if you do not have experience in laying bricks and pouring a concrete foundation;

- Before making an individual order for artistic forging of a fence, you need to decide not only on the size and material of the fence, but also on the patterns. Together with the designer, you should look through the albums with examples of work and select elements that are suitable for the style of the building. It is necessary to decide whether the structure will be prefabricated or sectional. To make the process of making a wrought-iron fence move faster, draw sketches in advance and provide them to the masters;

- During operation, do not use powder coating when caring for forged fences. It will be difficult to distribute the coating evenly over the figured fragments; there may be a risk of corrosion in certain areas due to a thin layer of staining or its absence;

- In home gardens, a metal fence can be combined with polycarbonate. This material, due to its transparent structure, has good light transmittance, which gives the area additional light and warmth.

Beautiful options

If we talk about artistic beauty, then the undisputed leader in this will be decorative forged fences. But due to the high price for this type of product, few can afford to install a fence made of artistic forging. However, you can also consider ready-made options for fences, which can harmoniously fit into the overall style and emphasize the beauty of the territory.

Decor

A modern fence serves not only to define the boundaries of the site and protect private property, but also as a certain element of home decoration, which emphasizes the individuality of the owner. For the original decor of the fence, designers recommend not only combining various materials, but also applying various paints and compositions that will refresh the structures and give a more well-groomed look.

The main decorative elements are:

- The main decoration is color and texture. The fence can be made of metal siding with a textured coating or profiled sheet, the surface of which is coated with a colored polymer composition;

- Carved forged items. Traditional figures are flowers, balusters, spikes, curls, rings, monograms. Such iron parts on fences will not only look decorative on any fence, but also very individual;

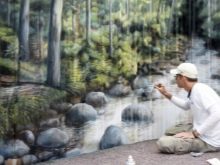

- Drawing.It is carried out with special paints that are resistant to fading and atmospheric precipitation. On any panel surface of the fence, you can apply plot drawings, ornaments, patterns and even reproductions of paintings;

- Combination of forms and materials. One of the most common decors in the world. It can be a combination of brick and picket fence, openwork forging and stone, iron bar and polycarbonate, wooden elements and steel bars. There are a great many options and nothing can limit the author's imagination.

Various variations of decorating fences will not only emphasize the individuality of the idea, but can also reduce the cost of the product, especially if you used your own hands in the implementation of the idea.

For information on how to make a metal picket fence, see the next video.

The comment was sent successfully.