Metal fence posts: features and installation

Fences surround homes, shops, offices. They can be different in design, height and purpose. But they all serve to perform the same functions - marking the boundaries of the site, protecting from the environment, dividing space and providing a zone of psychological comfort. All this cannot be done without such an important part of the fence as its support. The most versatile among them are metal. They will be discussed further.

Characteristic

All supports must have the following properties:

- Strength. Since, in fact, it is they who bear the entire load that the fence experiences from the side of weather phenomena, the actions of people and animals.

- Stability. In addition to external influences, they must withstand the weight of the structures attached to them.

- Versatility. Since the fence spans can vary in type and material of manufacture, the posts must withstand any of their types.

In addition to the fact that metal pillars meet all of the above requirements - that is, they are strong enough, stable and suitable for different types of fences in terms of technical characteristics and style, they have another important advantage - they have a fairly long service life, during which they do not require large investments for repairs and restoration. We can say that such an acquisition is really profitable, since the ratio of their price and quality is optimal.

Among the disadvantages can be noted the complexity of installation for people who do not have the skills and experience in this area. In order for the entire structure to be installed really correctly and problems during operation did not arise, you need to resort to the services of a specialist.

Views

The modern post is a hollow pipe inside, the end (section) of which has the form:

- Round... Have the most affordable cost. People who are ignorant of this issue may have a question about how to attach a fence to a rather sloping side. For this, stabilizing parts in the form of plates are welded to it. In addition to them, plugs are needed that will prevent moisture from getting inside.

- Square or rectangular... They are the most convenient to use and are suitable for completely different materials. In addition, another advantage of this shape is the design features in the form of additional stiffeners. This increases their cost and, importantly, reliability.

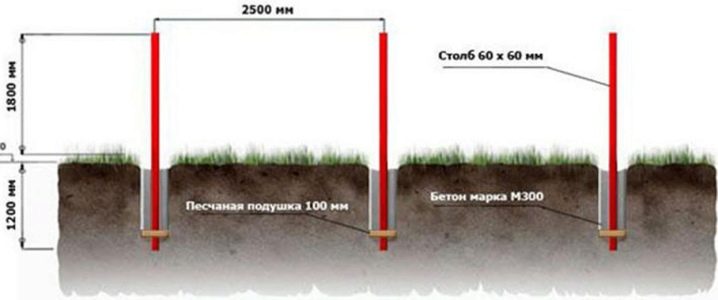

The thickness of the metal also varies. The most popular options are from 2 to 4 mm. The pipes are available in lengths from 2.5 to 6 meters. A non-standard is made by cutting the product to the height you need. The length of the product that you need is equal to the sum of the height of the fence and the depth of freezing of the ground with an increase of 15-20 cm.If you cannot find this indicator, please note that at least a third of the entire length must be underground.

Pipe diameters range from 5 to 10 cm. To select the correct pipe thickness, you need to measure the estimated distance between two adjacent posts and calculate the mass of material consumed for each span.

If there are no funds for the purchase of special pipes, you can use any other suitable ones, even used ones (for example, from a water supply and heating system). The main thing is that they are in good condition and resistant to corrosion.

In appearance, pipes can be:

- Unprocessed.In addition to the unaesthetic appearance, the surface can oxidize under the influence of oxygen and water or react with chemical elements contained in the soil.

- Coated. In production, the surfaces of future metal posts are coated with polymers or galvanized (there are models with both types of protection). Such measures effectively protect against corrosion. Immediately before installation, the support can be treated with bitumen or a mastic specially designed for metals.

Enamels or varnishes are used for decoration. Today their choice is huge - they can be ordinary or combine the functions of a primer (which greatly facilitates the painting process itself). In addition to creating an image that matches the overall style of the house, such paints will significantly extend the life of the fence. Special attention should be paid to processing of welded seams. They must be painted over especially carefully.

Mounting

Before installation, it is imperative to make calculations of the required amount of material and draw up a diagram of their rational arrangement. In accordance with building codes, the optimal span length is a value not exceeding 2.5 meters.

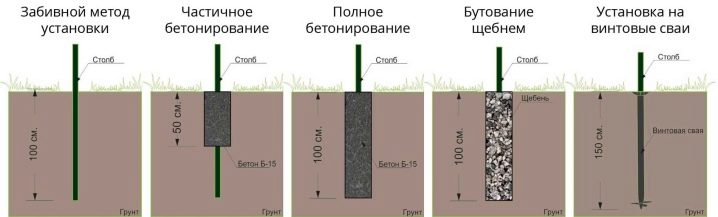

Driving, screwing, butting, concreting are used as the main methods for installing metal supports for a fence.

The choice of one or another option depends on the condition of the soil and the total weight of all materials in the fence.

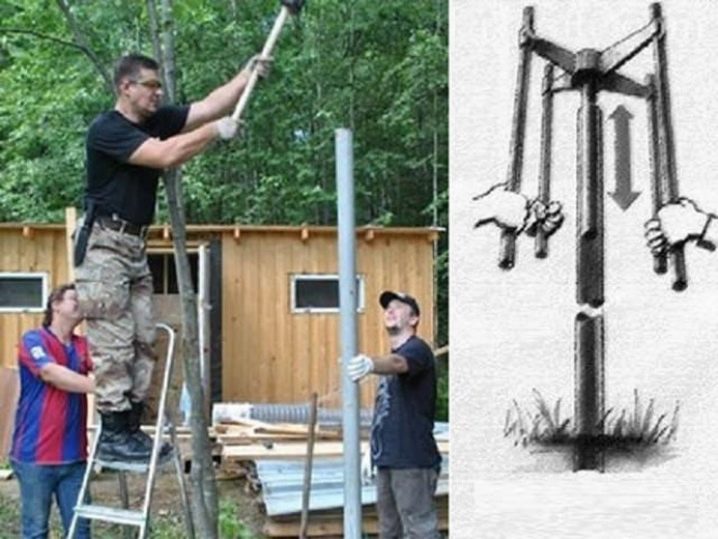

If the fencing system is light and the soil is sandy, the pole can be driven in with a sledgehammer or other technical means. This option is suitable for temporary structures, as it is easier to dismantle. The process itself takes place as follows: first, a pillar is placed in a small depression (in accordance with the markings) and they begin to strike, periodically checking the correctness of its position.

Wherein you can't just hit the top. So that it does not deform, special devices are used. It is better if someone else is present at the same time, who could control the slightest deviations from the vertical. It depends on this not only how the fence will look, but also the possibility of its correct installation in general. A few degrees of deviation can make installation of other parts impossible.

Poles with threads or blades can be screwed in if the soil permits. In this case, it will not be easy to take them out, so the construction must be durable.

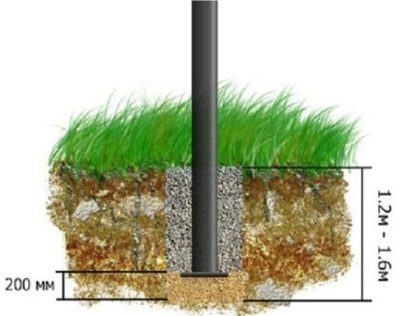

If the soil crumbles, the problem will be solved buzzing... Crushed stone, broken brick, sand or other suitable building materials are poured into a hole wide enough for tamping. The use of construction waste can reduce the cost of the process. Such a layer should be at least 15 cm. A pillar is installed on this base and leveled. Each subsequent layer must be carefully tamped and watered. You can alternate materials in layers. The last 15 cm are concreted.

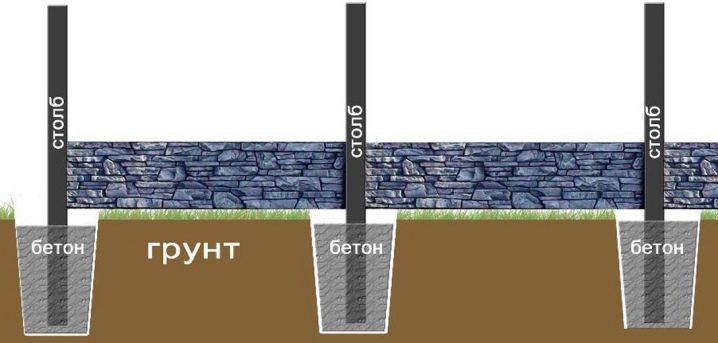

Full concreting is suitable in cases where heavy loads are expected (the weight of the materials is quite large and plus the soil is unstable, prone to swelling). The width of the pit should be 15-20 cm greater than the diameter of the pillar. Rubble is poured into it and tamped. Then formwork is made of wood and poured with concrete. After a week, the formwork is removed. If a foundation is made for a fence, the pillars are installed when it is poured.

A mixed method is sometimes used. Its essence lies in the fact that the hole is drilled only to half of the estimated depth. The pillar is driven in to the required mark, after which the building material is poured, the formwork is erected and concrete is poured from above.

Selection rules

Focusing on the appearance of the fence, the pillars can be selected in such a way that they practically do not stand out against the general background. This is also facilitated by painting the entire fencing system in one color.

In addition, they can be completely hidden from the views of passers-by behind the corrugated board, which is so popular in our time, which they ideally complement and provide the entire structure with reliability.

Another option in which a large load falls on the supports is a fence with forged parts. In this case, it is important to maintain one style of performance and decoration for the entire ensemble.

The use of metal pillars does not imply that the fence itself should be made of the same material. It looks especially impressive contrast of metal frame and timber sections. When decorating the territory of a country house in the style of a ranch, sometimes it is worth replacing the wood with more reliable metal. This will not worsen its appearance at all, but it will increase its service life.

Most often they are placed at gates and gates, that is, in places of greatest stress. In this case, their shape can be more intricate, and the tops are decorated with curly details.

If the fence performs a more decorative function than a protective one, the requirements for small posts remain the same. The whole structure must be safe and at the same time beautiful and elegant, especially if we are talking about fencing a building with an attractive facade.

For information on how to install fences on driven supports, see the next video.

The comment was sent successfully.