Caps on posts for a brick fence

For the fence to be strong and reliable, support posts are needed. If such pillars are made of bricks, they are not only beautiful, but also durable. But they are the ones who most need protection. The fence will be protected from environmental manifestations by special protective structures, otherwise called caps. You can mount and install them yourself.

Peculiarities

Having made the decision to purchase caps for brick pillars, you need to understand what is required of them, and what they are intended for:

- Protection function. They protect the fence from ice freezing, destroying masonry joints, as well as from other precipitation - rain, hail, snow. They also prevent wood supports from rotting.

- Aesthetics function. The fence looks much prettier with caps.

- They serve as the basis for installing light sources. With a lamp, the fence becomes both much more functional and, again, aesthetic.

- If the plugs are in the shape of a peak or other pointed shape, they also perform the function of protection - climbing over the fence is difficult.

The surface of the hood is angular, in the form of a slope, due to which the water falling on it easily drains away. And if the size of the nozzle is larger along the perimeter than the pillar, then each of the lateral surfaces of the pillar will be protected from the effects of precipitation.

It should be noted that it is much easier and faster to mount the overlays on the fence than to overhaul the entire structure. Indeed, the service life of the entire fence depends on the stability of the support. In addition, the price range depends on the material from which the caps are made, so, for example, plastic ones will not cost so much, while maintaining the integrity of the fence.

Materials (edit)

A brick fence can be decorated with hats made of different materials. The assortment on the market is extremely diverse both in price and in appearance. Each site owner will be able to find something to his taste and wallet.

According to the material from which they are made, the caps can be divided into:

- concrete;

- metal (stainless or galvanized steel, copper, brass, sheet metal);

- wood;

- plastic;

- stone;

- ceramics;

- polymer-sand;

- clinker is a durable refractory and waterproof brick.

It should be noted right away that wooden lining is of exclusively decorative value. Ceramics are very beautiful, but extremely fragile during transportation, installation and use. Plastic is cheap, but according to external data it loses to its more expensive counterparts.

Clinker hoods are frost-resistant for 75-100 cycles, durable and wear-resistant, retaining their original appearance for a long time. In addition, the clinker hat is characterized by low water absorption. Concrete caps are very original, durable, strong and easy to install, but fragile and quickly lose their attractive appearance.

Forged plugs look impressive, but, like everything metal, they are prone to corrosion, from which even painting does not save. In addition, the metal burns out in the sun, seams and irregularities may be visible on it, and it may also be a problem for some people that raindrops or hail, hitting such plugs, make strong sounds.

Also this category includes metal profile covers. Their main advantage is the price. The plus is that you can do them yourself if you have some skills and the appropriate tool.

Polymer-sand hoods are frost and direct sunlight resistant, durable and moisture resistant. They retain their attractive appearance for a long time and can be used in various climates.

Design

The fence posts are made of different materials. The design of the fence can involve posts of different configurations - thick or thin, hollow or solid, with a round or square section, but the top of the post should always be horizontal.

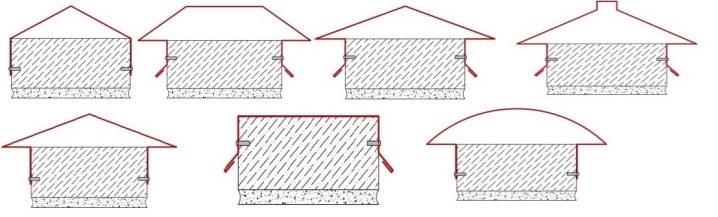

Currently, there is a wide range of hoods on the market, which can be classified according to the following criteria:

- by the material from which they are made;

- by the form they have;

- in the place where they are applied (on support pillars or on spans).

In accordance with the financial situation and your own taste, you can choose and purchase caps that are best suited, or you can make them yourself.

Whatever form the overlays have, they all have in common in their device:

- "Skirt" at the bottom, needed to be securely attached to the post. It covers the top of the post around the entire perimeter. If the post is empty inside, there should be holes between the overlap and the skirt.

- Uniform overhangs located around the perimeter of the product help drainage and prevent erosion of the material from which the fence is made.

- Service life and resistance to external factors are the main characteristics of industrially manufactured hoods.

- The attachment of the pad should not be conspicuous.

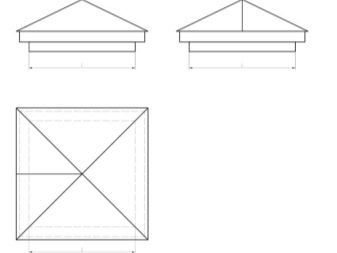

According to their shape, the caps are divided into:

- round (spherical);

- square;

- in the form of a pyramid;

- resembling a Chinese roof;

- with a built-in light source - a flashlight.

The shape of the cap can be two-slope (pyramidal) or four-slope (cone-shaped). There are also curly shapes, for example, a wind rose, petals.

Ideally, the fence and headings should be combined with the design of the house, other buildings on the site, make up a single ensemble with them. Pole covers can be made to order by casting or forging, as well as using different materials and their combinations. Stone caps are not only gray or black stone, but also marble, malachite, and red granite. Such caps will look good on a fence around a mansion in a simple style.

If the entrance to the site lies through a wrought-iron gate, metal heads are suitable here, the curls on which will be in harmony with the pattern on the gate or wicket.

The tile pattern will suit those houses whose roofs are covered with tiles. Such a pattern is made, for example, on polymer-sand caps.

The pillars look interesting, at the same time they are the bases for the lanterns. The covers thus serve as a support for the luminaire. Placed at the same distance from each other, the lanterns not only ennoble the fence, but also exude light around the entire perimeter of the territory.

The subtleties of manufacturing

Any product that is used to protect fence posts must meet the following requirements:

- The material from which it is made must be resistant to any environmental influences.

- Be strong and durable.

- The slope on the surface of the cap should be designed in such a way as to ensure that the water flows off evenly. The overhangs should extend beyond the pillar.

- The fastening of the "skirt" to the post should be firm and invisible.

- If the post is empty inside, then it is imperative to provide ventilation inside its cavity.

Depending on the material used, the size of the pommel and its functionality may vary. For example, almost any shape and size of caps can be made from fiberglass. Lanterns are easily mounted on them, and they themselves are also easily installed on the fence columns.

Metal caps can also be of various shapes, they are practical and durable, to increase their service life, they are coated with a special compound. Metal can also be used to make custom-made forged heads with the desired decorative elements. However, they can only be mounted on poles that are at least 80 x 80 mm in size.

The stamped galvanized plugs are the most affordable. It is also possible to make a so-called stepped hood from galvanized steel, which has an additional base and a protruding drainage part.

Wooden caps are the most impractical of all, since, firstly, they have a considerable cost (especially decorated with carvings), and their manufacture is impossible according to a template, each element is made separately, and secondly, they do not protect the post from environmental influences, performing only a decorative function.

Installation

The cap can be fastened to the post in different ways, depending on its design. You can use cement mortar, glue, as well as self-tapping screws that are screwed into parts of the fence.

Several rules must be followed:

- Metal covers (galvanized, tin, metal profiles) are attached using dowels. At the upper level of the support, bricks are drilled 3-5 cm, similar holes are made in the skirt of the cap. Next, the head is put on the post and fastened with dowels.

- If the cap is installed on an adhesive base (ceramic, concrete types of heads), it is imperative that its edges go beyond the contours of the post. Otherwise, the composition will be washed out during the rainy season.

- Whichever technology is used, the side seams must be tight.

The glue mixture can, for example, consist of sand and cement, and you can make it yourself.

The following sequence of actions is used to mount the hoods on the adhesive mixture:

- Dust is removed from the top of the column and primer is applied.

- A glue mixture or cement is applied to the cleaned part, leveled.

- The hood is installed horizontally. The correctness of the installation is controlled using a level.

- The seams between the head and the support are rubbed.

- If the design does not provide for overhangs, the seams are additionally treated with a moisture-repellent solution.

- Until the glue mixture has completely solidified, the caps must remain completely motionless. After that, you can install decorative details - balls, tips.

- If the installation of lamps is provided, it is imperative to prepare holes for the wires. For this, metal caps are better suited.

Regardless of what material is used to make the cap, it is important that it can completely cover the top of the post, thereby securing it.

Professional advice

To avoid mistakes when choosing caps, you need to use simple rules.

- Inspection of the product from each side. Assessment of its proportions and symmetry.

- Checking with the help of special devices the correspondence of the angle of inclination of the head to the one indicated by the manufacturer.

- The overhang of the eaves must be tightly closed.

- The quality of the packaging must be such as to avoid damage during the transportation of the products.

- Before buying, make sure that the purchased products are suitable for the fence, as well as for the rest of the buildings on the site.

If all of these points are met, then there is a high probability that the choice was made correctly, and the caps are ideal for purchase.

Illustrative examples

The variety of designs and shapes of fencing caps can be seen in a small photo gallery.

What is not here:

- these are different types of caps for fence posts;

- galvanized caps;

- clinker fence hat;

- and even a wooden cap decorated with a ball.

How to make a cap on a fence post with your own hands is shown in the video below.

The comment was sent successfully.