Description of sheet piling and its installation

In order for the structure to be reliable, strong and durable, builders should take into account the peculiarities of the soil of the territory. The wrong approach to building often leads to the collapse of the structure. Various technologies are used during construction to strengthen the walls of the pit. One of the most common methods in this case is the installation of sheet piling.

What is it and what is it for?

The sheet piling of the pit is a special enclosing structure, which is erected from piles driven into the ground. The construction of a monolithic wall compacts the soil in an area that is prone to deformation and shear.

To equip this type of formwork, no earthwork is required. Each of the component parts is dug into the ground and fixed in the trench.

A monolithic wall does not require the presence of a strip foundation; it can be placed on any type of soil without taking into account the depth of freezing. Sheet piles are held in the soil by friction rather than foundation strength. The difference of this system from the others is that in this case significant loads on bending and displacement are maintained.

Strengthening the walls of the pit with sheet piles performs the following tasks:

- pit walls are protected from spilling;

- the construction site is localized;

- the sides of the recesses under the base of the structure are strengthened;

- the coastline is maintained;

- the foundation becomes stronger;

- treatment facilities are being developed;

- railroad tracks are being strengthened;

- sealed containers for industrial waste are being organized.

This type of pit fencing is necessary for the safety of workers, equipment and passers-by. This design is simply irreplaceable when it is necessary to strengthen the soil, especially near water sources to protect objects from negative consequences:

- erosion of the coast;

- washout and rock collapse;

- silting, shallowing;

- destruction of the coastal slope;

- preventing soil advance.

Sheet piles are considered to be effective, fast-erecting, cost-effective fences that are used everywhere. Thanks to these structures, sealed and watertight walls are obtained.

With the help of this device, they equip hydraulic facilities, as well as qualitatively protect communications. Sheet piles have found their way into fencing landfills, sewage collectors and much more.

Device

The device of sheet piling fences is directly influenced by the material that is used in their manufacture. Wood products can only be used if there are no coarse stones, wood waste and other debris in the soil. The pile driving depth in this case should not be more than 600 cm. The arrangement of such structures is strictly regulated by GOST, if the requirements are ignored, the fencing will be ineffective and will also quickly collapse.

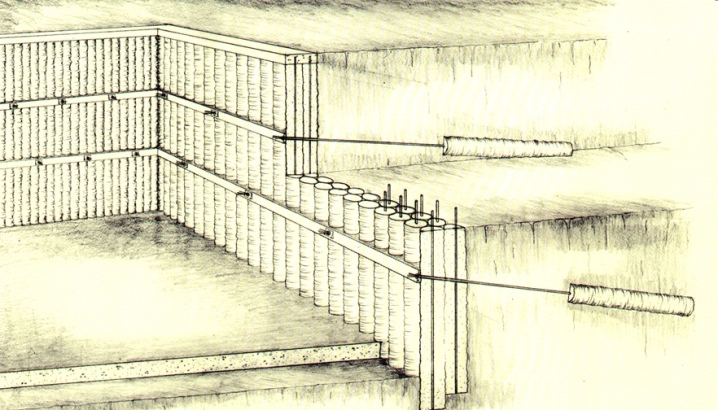

The grooves are immersed in the ground close, at this stage, the masters should exclude the formation of voids, cracks. In the case of using a double system, a distance of 100 cm is maintained between the grooves. Installation of the fence on the bottom of the water source is carried out at a depth of more than 200 cm.To minimize the washout of the backfill, it is recommended to use high-density sheet piles. If the depth of the pit is from 300 to 500 cm, then the recesses formed between the walls should be closed with a clay mixture.

For solid ground, steel dowels must be used. They should be driven to a depth of 700 cm.

Such products can be used repeatedly, but only if safety rules are followed. Dismantling steel products is also simple and quick. To complete the procedure, craftsmen use harness belts and corner braces.

The basic requirements of SNiP regarding the installation of tongue-and-groove structures have the following provisions.

- The selection of equipment should be carried out taking into account the length of the constituent elements of the system. When it reaches 26 meters, marks for the tongue should be provided. To calculate the equipment, special calculators are used based on the theory of wave impact.

- The pit can be washed away, and based on easy fixing of the tongue and groove, only if the site is located close to residential buildings. In this case, it is recommended to double the immersion depth.

- Work on the fencing of foundation pits is necessarily regulated by GOSTs and needs to be documented.

Description of species

The sheet piling is in the form of separate elements, which are assembled into a single structure. In this case they can be of different types and differ from each other not only in characteristics, but also in the period of operation.

Larsen steel sheet piling

The Larsen sheet pile is used when it is necessary to protect the foundation pit from earth collapse, groundwater and rainwater. The name of this design comes from the name of its creator. This fence has the form of an element in space with a box section and locks along the edges. The component parts are connected with clamps located in the sheet grooves.

Larsen grooves are made of strong metals with an admixture of carbon. Copper is added to prevent corrosive processes in the production of billets.

When using this method of forming a pit fence, you can solve the following problems:

- build a treatment plant;

- protect the construction site from water;

- to strengthen the shore of the reservoir;

- build a pier or dam;

- to strengthen soils that are prone to landslides.

From polymers

Plastic sheet piling is made from PVC and composites. These are reusable materials. They are often installed as permanent fencing in coastal areas. This option is considered economical, but at the same time not highly durable.

From the pipes

In addition to the profile, a tubular metal sheet pile is used for the installation of the pit fence. The latter is a hollow thick-walled pipes with a large cross-section. Such structures have a high bearing capacity. In addition, they are quite stable, so no one will be able to overturn such a structure.

Wooden piles

Wooden sheet piling is considered an inexpensive and practical option. After some time, the piles may deteriorate due to exposure to moisture. Wooden piles are not recommended to be used as a reinforcing foundation frame.

Reinforced concrete piles

Reinforced concrete piles are installed one-time. They are characterized by high energy costs during installation, as well as unprofitable dismantling. Reinforced concrete piles can also be used as additional foundation reinforcement. This option is considered the most durable and at the same time versatile.

Technology

A certain technology is used to install sheet piling. It is necessary to build a wall and immerse it in the ground in accordance with the calculations performed.

In the design project, the fastening method, the depth of the fence, the pick-up from the boards, the option of the spacer system are always spelled out.

Installation diagram of sheet piling:

- marking and fixing the guides;

- equipment delivery, well drilling;

- immersion of the components in the ground and their installation in specially designated places;

- fasteners in accordance with the prepared project.

It is possible to immerse piles in the ground in several ways, one of which is indentation using special installations. As a rule, vibrators, a hydraulic hammer, and sometimes a combined immersion option are used. Often, when arranging a pit, a pick-up from boards is used, which will become a formwork for further construction. In some cases, the optimal solution is considered to be the use of a strapping belt, which is represented by horizontal beams fixed with tongue-and-groove piles along the entire perimeter.

There are situations when, when forming sheet piling, it is necessary to strengthen the finished wall. To complete the task, a diagonal brace is installed that supports the piles. In other situations, you cannot do without using a spacer.

Payment

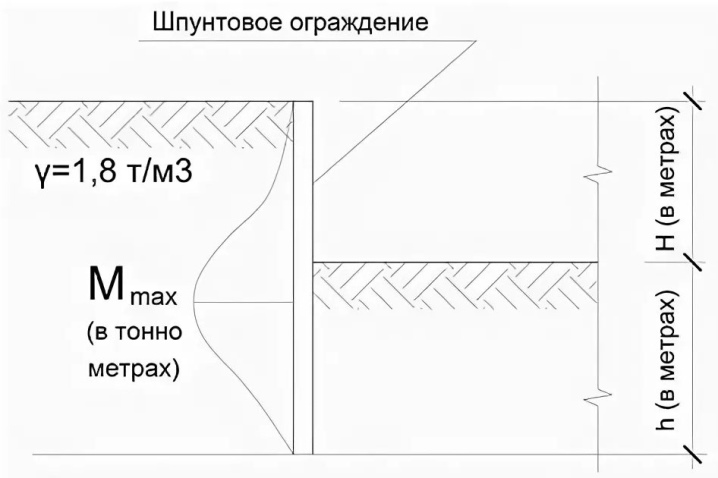

During the design of sheet piling, it is necessary to carry out calculations to determine the configuration of the structure, the dimensions of the wall, as well as additional reinforcement that may be needed if additional loads affect the foundation.

When calculating, one should take into account the overturning rate, the holding force of the walls, the coefficient of the structure's work. The reliability of the wall is also taken into account, but this indicator may depend on the soil and the type of fence.

When determining the strength, the resistance of a meter of the wall to the effects of loads, the resistance of the strapping, the standard resistance indicator, and the coefficient of functioning of the structure in the soil are taken into account.

Mounting

There are no special differences between the vibration and shock mounting options for sheet piling. The only difference is the presence of features in the functioning of attached types of equipment. There are no differences in sequence and slinging.

Technology for forming the pit fence:

- supply of materials to a construction site;

- distribution of the sheet pile with a sheet pile crane along the entire construction perimeter;

- implementation of contour marking with a pile driving unit;

- slinging and moving the tongue to the site where the installation will take place;

- fixing the headgear and installing it in the place of driving;

- vertical and directional alignment of the tongue;

- dismantling of slinging, immersion of the sheet pile to the depth specified in the project.

Performing the above actions is the formation of each of the grooves. Work continues until a closed fence is formed along the perimeter of the pit. To solve various problems during the installation of the pit fencing, the following equipment is used:

- hydraulic unit SVU Titan DTZ;

- Sunward ZYJ 120 system;

- stand-alone installation SVU-V-6.

A sheet piling is called a strong and durable structure, with the help of which pits are equipped and the banks are strengthened near water sources. Thanks to this reinforcement, the structures can withstand significant loads, and the grooves do not deteriorate from moisture and temperature changes.

In this video you will learn how the sheet piling is installed.

The comment was sent successfully.