Horizontal fence made of profiled sheet

A horizontal fence made of profiled sheet is an original design solution that allows you to create a reliable barrier around the site for prying eyes or unauthorized entry. Installation of sheets with a longitudinal arrangement of stiffeners allows you to quickly cover significant distances, but it has other features that are not mentioned in the brochures. A detailed story about what you should pay attention to when the owner of the site chooses a profiled sheet to put the fence in a horizontal position, about the installation method and other points will help to understand everything in full.

Peculiarities

Steel sheet materials with galvanized or polymer coating have managed to significantly press other types of coatings on the market. A horizontal fence made of corrugated board has a number of significant advantages that other materials cannot boast of. With the longitudinal arrangement of the stiffeners, the fence looks unusual, but does not lose its protective properties. Other points can also be attributed to the obvious features of this installation method.

-

Possibility of measured climb. With the horizontal arrangement of the modules, it will be a multiple of 1 m.

-

Overlapping by a section of a considerable distance. Such a fence is assembled much faster than a vertically oriented one.

-

Minimization of mounting elements. With this method of attachment, the risk of corrosion formation at the attachment points is reduced.

-

Aesthetics. The horizontal arrangement of the sheets looks more interesting than the vertical one, it goes well with brick pillars when mounted on a foundation.

-

Functionality. It is easier to make swing gates in a fence of this design. In addition, the windage will be less, and the sound insulation is higher.

Besides, regardless of the method of fastening, the profiled sheet also has a number of important differences from other materials. In the construction of fences, sheets of the C21 brand are used with a width of 1 m and an increased height of the ribs. Such a corrugated board has the highest strength. And also sheet C20 is considered suitable for use, but its width is 110 cm.

By the type of finishing, horizontal fences made of corrugated board can be galvanized - with a budget anti-corrosion coating. Options with a spraying of polymer materials are also in demand. They are tougher and more durable, available in several color options.

The most prestigious options for horizontal fences have plastisol spraying, imitating stone, leather, and other complex textures.

Preparation for work

In order for the corrugated sheet for the fence to be selected and mounted correctly, you first need to carefully calculate all the desired parameters. Depending on the presence or absence of a foundation, the width and type of pillars, the material consumption will be different. It is worth considering not only the perimeter of the fence, but also the presence of gates, wickets in it, as well as the installation method - the overlap takes 40 mm from each side of the sheet.

As part of the preparation, you will also have to decide on the type of corner and additional pillars. They are made from:

-

round or square wood;

-

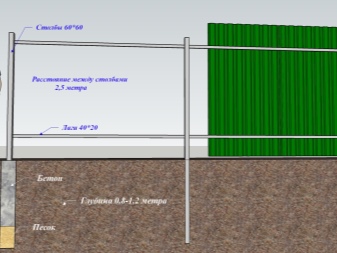

steel pipe with a diameter of 50 mm with plugs;

-

bricks;

-

metal profile.

And as part of the preparation, you will have to take care of horizontal lags for the frame part. They will need 3 for each section. It will not do without a tool: a welding machine, metal scissors, a screwdriver.To install the pillars, you will need a drill capable of making a hole of the required diameter in the soil. In addition, it is necessary to purchase fasteners in advance - hardware and brackets.

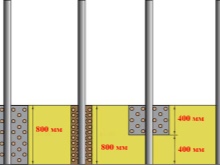

Marking the perimeter for the fence will be impossible without a tape measure, cord and pegs. It is carried out before the start of the practical stage of work, noting not only the general outlines, but also the areas of the location of the pillars. Here, with the help of a shovel or a drill, holes are made of sufficient depth - 1/3 of the height of the support.

Required are corner posts, as well as those that frame gates and wickets. The number of intermediate elements is calculated based on the distance between them in 2-3 m.

Mounting

The horizontal arrangement of the elements of the corrugated sheet fence makes the installation faster. The most simple version is considered to be with a continuous coating. In this case you need to put the sheets so that their edges overlap each other by 4 cm on each side.

Below is the procedure for installing a fence made of corrugated board in a horizontal position.

-

Clearing the site. At this stage, you need to free the perimeter, perform the markup.

-

Installation of a foundation or support pillars. The presence of a base under the profiled sheet is highly desirable - with direct contact with the soil, the risk of corrosion increases. It is enough to equip a shallowly recessed strip foundation, but you can do with the usual fastening on the pillars, leaving 5-10 cm between the lower edge of the fence and the soil. The support posts are buried, the pits are covered with stone, concreted completely or superficially.

-

Assembling the frame. At this stage, logs are attached to the posts. Most often, by the welded method, if all structural parts are steel, but hardware and plate-holders can be used.

-

Installation of a profiled sheet. It is carried out with the cover side up, so that the next element overlaps. In this case, the jumper - the horizontal lag - will become a support for the joint area. And also hardware are screwed in at the corners. Additionally, self-tapping screws or rivets are placed every 2 waves.

-

Hanging wickets, gates. They are hinged and assembled separately. These structural elements are attached to the fence after the main canvas is mounted.

-

Installation of plugs and decorative strip. These elements are optional for use, but they help protect the fence from corrosion, give it a more aesthetic, complete look.

Installing a horizontal fence from a profiled sheet with your own hands is a task that is quite feasible for most people. To increase reliability, extend the service life of the structure, it is supplied with a foundation, made sectional. Such fences are more respectable, do not look like a temporary solution on the site.

For a horizontal fence from a professional sheet, see the video.

The comment was sent successfully.