Fences made of corrugated board: pros and cons

Corrugated board is a comfortable and very attractive material based on durable steel that can withstand harsh weather conditions. It is from it that you can make a strong and reliable fence in the shortest possible time, and do-it-yourself installation will not be difficult. In order to purchase high-quality materials, it does not hurt to find out in advance what kind of fences are made of corrugated board. The pros and cons of such structures should be the main selection criteria.

Features: advantages and disadvantages

Any corrugated board is a steel profile (or profiled sheet), which has already been painted and processed using special chemical compounds that provide it with anti-corrosion protection. Polymers are used as coloring materials, which are quite resistant to direct sunlight. A fence painted with high-quality polymer paint does not fade for a long time and does not change its original color.

Among the main advantages of fences made of corrugated board, high wear resistance during operation should be highlighted, however, it should be borne in mind that in the process of cutting the sheets, they should not be damaged.

In order to properly and accurately cut this material, you only need to use a hacksaw or special scissors designed for cutting metal. Of course, the jigsaw cuts much faster, but it cannot be used: the steel heats up quickly, and the galvanized steel will be damaged, which will lead to further corrosion.

The colors used to paint the steel sheets are both universal (brown, dark green) and any other - it all depends on the wishes of the customer. You can choose any shade of the fence, even multicolor, and this is another undoubted plus. It is also always possible to order sheets according to individual sizes, which will ensure a high-quality installation of the fence on an area where there are natural irregularities or slopes. A fence made of corrugated board is quite resistant to various weather factors, it withstands the wind well to a certain extent (provided that the installation is reliable).

Since the sheets are sold immediately painted, there is no need to paint the finished fence, which is also very convenient and practical. In addition, at a price, any corrugated board is always more affordable than a steel, wooden or stone fence. The corrugated sheet fencing is both durable and lightweight at the same time, so no heavy foundation is required under it. If any parts of such a structure are damaged, they can be easily replaced, and the installation time, on average, does not exceed one day.

It should be noted that the soundproofing properties of the corrugated board are also good, which can be another reason for choosing just this type of fencing.

Of course, along with the advantages, corrugated board has a number of disadvantages and features that you need to pay attention to. Since the sheet steel from which the cladding is made has a small thickness (no more than 1.5 mm), it is unfortunately easy to cut it with a knife. If the sites are not guarded, thieves can easily enter them.Moreover, if the self-tapping screws, with which the entire structure is fastened, do not have additional fastening, it will not be difficult to simply unscrew them with a regular screwdriver. Therefore, it is important to take care to protect the structure as much as possible from burglary. There are several good ways to do this.

You can avoid the fact that the screws will be unscrewed by intruders. To do this, you should install profiled sheets with rivets, which will increase the price due to the laboriousness of this work for specialists (all logs will need to be additionally drilled). Another original way was recently invented: the fence itself is installed on ordinary self-tapping screws, but each profiled sheet receives additional fasteners in several places at once. As fasteners, either the same self-tapping screws with drilled edges, or rivets (from four to six pieces per one sheet of corrugated board) are used. The edges of the self-tapping screws are reamed at the end of the installation process so that they cannot be unscrewed with a screwdriver. If you manage to purchase self-tapping screws with non-standard "heads", they will also work well as additional protection. The owner will receive a kind of "secret" for his fence, by analogy with protecting car wheels from twisting.

Since the corrugated structure is characterized by a solid sheet metal sheathing, in strong gusts of wind, it will "behave" just like a large sail, which is fixed on several poles. This is called big sailing: if a gusty wind rises, it creates a large force that is directed horizontally. This force can easily unscrew the entire structure. As a rule, such a nuisance occurs if the support pillars are not securely fixed, are at a shallow depth and cannot keep the sheets from strong gusts of wind. Over time, the fence begins to "lead" and warp, and at first the main functions of the wicket and gates will suffer: they will jam, because the locking tongue will not fall into the receiving hole.

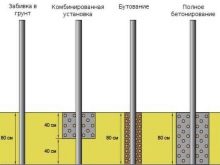

In order to best protect the structure from the winds, during its installation, you need to be guided by the rules for fixing the pillars in the ground. The pillars must be dug into the ground to a depth of at least one meter, and the base of the fence must be securely strengthened using concrete for this purpose. Concreting is a prerequisite for any soil, especially when it comes to loam or sandy varieties.

The cross-section of the fence post is usually small (about 60x60 mm), therefore, if it does not have concrete reinforcement, then in case of gusts of gusty wind, the structure will "dangle" from side to side. Reliable fixation is required, not only of the part of the pillar going into the ground, but of the entire base, along its entire length underground (not partial, but complete concreting). It is these measures that will help the owner of a fence made of corrugated board to avoid its deformation due to severe weather and climatic conditions.

Sailability can be reduced if, during installation, not a solid corrugated board is used, but a picket made of it. The picket fence can be made in two rows, shifting them in relation to each other so that the site is completely closed from the views of strangers. This option is much more reliable, looks better aesthetically, but its cost will be higher.

Span rust is one of the undesirable but typical features of all metal fences. The corrugated board itself is coated on the outside with special compounds that protect it from rust, but the pillars, along with the logs, are made of ordinary steel, and sometimes even a preliminary primer does not save from rust. This is due to the fact that the integrity of the protective coating is broken at the points of the fasteners (in the holes that are made for self-tapping screws).After moisture gets there, corrosion can occur in the first few months after the start of operation of the structure.

A similar problem begins where the horizontal logs are joined together, namely in the places where they are welded. It is known that any welding work is accompanied by high temperatures, due to which scale appears on the logs due to the burnout of the primer. In such places, even very resistant paint quickly begins to flake off, and inevitable corrosion processes occur.

The owners of fences made of corrugated board have a fair question about its complete protection from rust. Unfortunately, there are no ways of complete protection, but there is a method that will help slow down this process, and it should be applied already during installation work. When installing the frame, all metal elements must be primed, and the frame itself is painted, preferably in two layers. There are varieties of fences with parts that have undergone full anti-corrosion treatment during their production, but all this costs an order of magnitude more.

The steel frame and all its elements must be painted at least once every few years, which means facing technical difficulties. The fact is that it is unrealistic to paint the frame perfectly without touching the sheet itself with a paintbrush, because it is very tightly attached to the elements of the frame base. There is a good way out, which consists in the use of masking tape during staining. This will help to maintain accuracy by preventing paint from getting on the profiled sheets.

Despite the specifics of corrugated board fences and the disadvantages associated with their use, you should not refuse to purchase and install them, because both the pros and cons are inherent in any fencing. If we are talking about installing a metal-profile fence, which would be inexpensive and serve for a long time (provided that it is properly installed and maintained), then corrugated board is still the most suitable option. As for the disadvantages, if you apply skills, they can be minimized.

Views

Fences made of corrugated board are very diverse, and it is customary to divide them into at least three main types.

The most common option is solid fences, the height of which does not exceed 3 m. Among them, there are also very light two-meter welded fences, consisting of metal inserts and columns, which are closed from above with plugs to prevent moisture and dust from getting inside. The plug can be designed as an attractive decorative element.

High fence (its height varies from 3 to 6 m) is used as a reliable fence for any production plant or warehouse. This design reliably protects the area from prying eyes and reduces the likelihood that vandals or other intruders can enter it.

Highest fences (up to 6 m) are placed along high-speed highways, performing a noise-insulating role. Panels of such fences are made in the form of "sandwiches", inside which a layer of mineral wool or foam insulation is laid. Low fences (no more than 4 m in height) are installed as fences for small cottage villages. Regardless of the height, any fence can have a different degree of sound insulation and strength of the supporting structure and its individual elements.

Dimensions (edit)

Regardless of which profiled sheet is chosen for the construction of the fence, the first step is to know the exact standard dimensions of the flooring. This will help build a fence and minimize waste. It is better to purchase the material, having one running meter in stock and remembering that they overlap the profiled sheets - one on top of the other. If you plan to put up a long fence, the stock should be more than a meter. Below are the standard sizes of the most common types of corrugated board used in construction.What sizes have other varieties, you can check with the manufacturer.

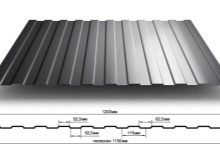

Sheet C-8:

- overall width - 1.20 m;

- useful (working) width - 1.15 m;

- sheet thickness - 0.4-0.8 mm;

- wave height - 8 mm;

- the distance between the waves is 115 mm.

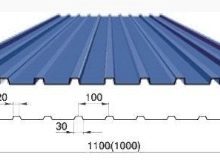

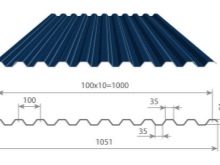

Sheet C-10:

- overall width - 1.16 m;

- useful (working) width - 1.10 m;

- sheet thickness - 0.4-0.8 mm;

- wave height - 10 mm;

- the distance between the waves is 100 mm.

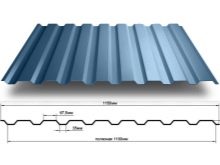

Sheet C-20:

- overall width - 1.15 m;

- useful (working) width - 1.10 m;

- thickness - 0.4-0.8 mm;

- wave height - 18-30 mm;

- the distance between the waves is 137.5 mm.

Sheet C-21:

- overall width - 1.51 m;

- useful (working) width - 1 m;

- profile thickness - 0.4-0.8 mm;

- wave height - 21 mm;

- the distance between the waves is 100 mm.

Constructions

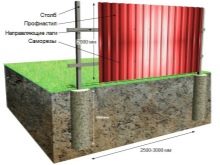

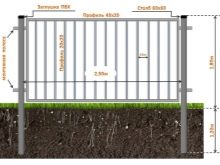

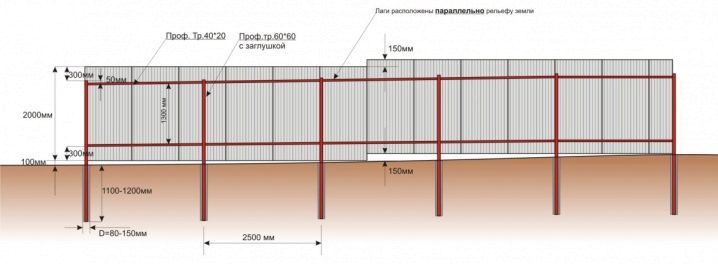

A fence with metal pillars implies that a pipe made of metal of a certain length and diameter will act as each of the pillars. Corner posts are installed in the marked places, and the post itself must be deepened into the soil by one third of its length. This will provide the best possible resistance to strong winds. All holes after installing the pipes must be completely filled with high-quality concrete mortar. The pillars are connected to each other using formwork from the same concrete. It will provide the fence with a longer service life.

The markings should be carried out in such a way that the posts are at the same distance from each other. You should always ensure that the first sheet of corrugated board is fixed evenly. This is necessary so that in the future the structure does not "leave" sideways. A modular or sectional fence is called so because in this case a certain number of sheet profiles are ordered. The structure itself can already be partially assembled: for example, on sale you can often find sheets that are already attached to the posts. Each individual sheet is a module (or section). The advantage of the modular version is that the post can be either hidden with a sheet from the outside, or left as it is (at the request of the customer).

Any design can be horizontal or vertical. A horizontal fence looks so that the longitudinal lines are always visible either from the street side or from the inside. In simpler terms, the "waves" of the fence look like convex horizontal lines. The installation of the pillars is carried out in accordance with the length of the corrugated board. Profiled sheets are attached to the posts, but you can also attach them to horizontal lags. They will fully withstand the load, because, being attached to the pipes, they represent a strong frame of the fence. A vertical fence looks like its "waves" are in the form of vertical lines, and its installation is carried out by analogy with a horizontal structure. The only difference is that all the posts are placed at a distance from each other equal to the width of the profiled sheet.

There are fences made of corrugated board on screw piles. The method will cost a little more than ordinary poles, concreted along the entire length, but the installation of such a fence will be much easier, and the ability to withstand heavy loads during operation is much higher. In addition, if the building stands in conditions of unstable soil, this is the only method that is unique and the only correct one for the supporting structure to be as reliable and durable as possible. A fence on screw piles can be used repeatedly and in the event that it is necessary to install a high-quality temporary fence.

To assemble such a fence, piles of the SVSN marking are usually used. Their maximum length is 5 m, excluding the head. If the length of the span is planned to be up to 2 m, then the diameter of each pile is selected 57 mm, and with the length of the spans from 2 to 3 m, the diameter of the pile is 76 mm. The screwing of the piles into the soil is carried out so that the screw part is located even below the depth to which the soil freezes.

Some people think that special construction equipment is required to install a fence on screw piles, but this is not entirely true. Work can be done manually. The main thing is that there should be three people for this purpose. The first task is to support the pile and make sure that it stands strictly upright, not leaning in any direction. The other two, using a special key with levers, press on the pile axis, scrolling it inward from left to right. Thus, the support post slowly sinks into the ground. After the installation is completed, for greater reliability, you can apply concrete pouring, install plugs in the form of plugs made of strong plastic.

Materials (edit)

As the simplest material for the fence, an inexpensive chain-link mesh made of durable metal is very popular. The installation technique is very simple: first, rounded pillars burst into the ground, and then the mesh itself is stretched. The chain-link is attached to the posts necessarily with a stretch, so that later it does not sag under its own weight. The structure is fastened using ordinary metal wire, and for aesthetic purposes, it is best to make a small curb before installing the mesh. The distance between the posts should be no more than 2.5 m, which will also prevent it from sagging. It is better to use concrete pillars, but they can also be made of wood or metal. In any case, the pits must first be covered with rubble and sand, making sure that the pillars maintain a strictly vertical position. Concrete pouring follows.

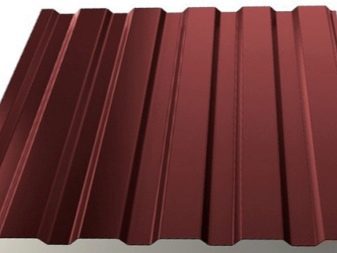

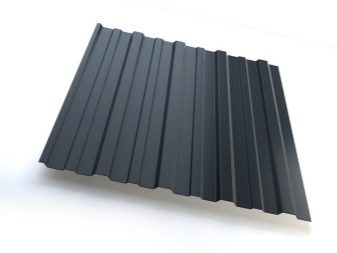

Color solutions

As an additional protection of profiled sheets, in addition to anti-corrosion coatings, they are painted with persistent polymer dyes of different colors. Due to this, not only the resistance of the material to external factors increases, but the sheets themselves look beautiful and pleasant. By the way, the price for a painted fence will not be much higher than for simple sheets coated with aluzinc or other protective material. Colored corrugated board is much more resistant to sunlight, because the paint does not fade and is not afraid of sudden temperature changes. In addition to the reliability of coloring, the main advantage is the color palette, thanks to which it is always possible to choose the most suitable tone or shade in accordance with the general style in which the house and the plot are decorated.

The colors of metal profile sheets are now determined according to the German RAL standard. This palette helps customers figure out which shade will be the most preferable in a particular case. The color space was divided into several zones, each of which it was decided to assign a simple digital combination. Classical standardization provides for 213 colors and their shades: for example, only yellow in it - as many as 30, and green - 36. Each color code consists of four numerical designations. This is what makes it much easier to select any desired color for the fence. Separation by RAL always turns out to be an indispensable "assistant" when you need to choose a profiled sheet for materials that are already available, or if you need to replace or extend several sections of the fence.

Usually, painting is done only on one side of the metal sheet, but it is possible to order a double-sided option, when the paint will be on one side and on the other. You can also order and paint in different colors, which will open up space for the most daring design ideas. If the fence is light, then this will help to visually expand the space in the event that the site is of modest size. Applying a dark color helps to distract attention from the fence so that it is not too conspicuous.The classic dark green version of the fence will be a harmonious addition to trees and shrubs, and if you buy a white fence, you can paint picturesque graffiti or other drawing on it.

Which one is better to choose?

In order to choose the right metal profile, it is important to know that each professional sheet has its own technical designation based on the level of strength. Also, the durability of the fence and its resistance to environmental influences directly depend on the quality of the protective coating. As already mentioned, depending on the requirements that may be imposed on the fence, wall profile decking is divided into several categories... Each of them received the initial designation with the letter "C" ("wall"), because a similar type of material is used as wall cladding. It differs from roofing in that the height of its wave, which acts as a stiffener, can be greater. The “C” designation is always followed by a number. The higher it is, the more rigidity the profiled sheet has, which means that the load in the form of strong gusts of wind will be less terrible for it.

- Decking brand S-8 it was originally planned for wall cladding. 8 is the height of the symmetrical wave in millimeters. This is the most inexpensive option of all on the market, but the level of its reliability may be insufficient: if the fence is too high with long spans, such material is easily deformed under the influence of wind or mechanical stress.

- Sheet grade C-10 more durable than the previous one. It has a symmetrical wave configuration, weighs a little and protects the area much better from intruders and winds. As for the cost, it is an order of magnitude more expensive than the C-8, but it also lasts much longer, retaining an attractive appearance and not succumbing to accidental blows.

- S-14 professional flooring - the best option for installation on a frame base and is suitable for fences that are planned to be created where the weather conditions are more severe, and mechanical influences are more frequent. Unlike the previous types, this brand has higher anti-vandal characteristics. Its trapezoidal shape is especially attractive to buyers. This uncomplicated figured version is often used for decorative purposes when facing the main gate.

- Brand S-15 - a versatile option, easily recognizable by its wide ribs. It is from number 15 that the designation of those types of material that can be installed on the roof, and for the fence, and on house facades begins. If you arrange a fence in this form, it will look very original and unusual.

- C-18, C 20 and 21. All three varieties are characterized by an increased degree of strength, which allows them to be used as fences in the most unfavorable weather and climatic conditions. Outwardly, they are virtually indistinguishable from each other, but if you need to create a fence more than 2.5 m in height, it is best to use S-21 corrugated board.

To make the right choice of material, you should also take into account the features of the area: not only the climate, but also the relief and landscape characteristics. For example, if you need a fence of small height, and there are few winds in a given area, then you can use the most inexpensive brands C-8 and C-10. If the space is open and the fence itself is high, it is best to choose the C-14 or higher grade. If you plan to install a fence with an increased degree of stability and strength, you should choose exclusively the C-20 or C-21 brands. When choosing, you should also know about what protective coatings are used for metal profile sheets.

You cannot apply an expensive type of coating on low quality steel, and cheap paint on expensive steel.

Before finally deciding on the choice, it does not hurt to get acquainted with the fact what protective compounds can be covered with profile sheets:

- Zinc - the cheapest option, which does not differ in a presentable appearance, but is rather durable, lasts a long time. Galvanized steel sheeting is rarely used as a fencing for residential premises. Most often, fences are made from it for industrial premises, warehouses and temporary zones (for example, if large residential or commercial construction is being carried out in one place or another). Galvanized profiled sheet is the best way to protect a large area: it is reliable, durable and inexpensive.

- Aluzinc - a mixed coating consisting of zinc and aluminum. It looks beautiful, but it is used exclusively for production purposes. It differs in that it can be subjected to repeated staining or repainting, however, it is recommended to use only high-quality acrylic paints for metal, which is accompanied by additional financial investments.

- Polyester - ideal coverage if you plan to design a fence for a private house or summer cottage. Polyester is a unique synthetic material with high resistance to all weather conditions. He does not care about solvents and dirt, and if it does appear, it can be easily washed off with a water jet sprayed from a hose or pump. Polyester gloss looks cozy, presentable and pleasing to the eye and always looks new and tidy.

- Pural or Plastisol - the most expensive types of coatings, but also the most reliable, due to which they are widely used in the field of luxury construction. The service life of such a fence is calculated for 10 years or more. If you calculate its cost, multiplying it by the time of application, it may turn out that this fence will eventually cost the owner much less than a cheap structure that can quickly become unusable.

How to calculate?

In order to correctly and quickly calculate materials for the construction of a fence made of corrugated board, it is recommended to use a special calculator program. The program is affordable and easy to use. It is necessary to enter in turn into the electronic estimate such parameters as the length, height of the fence, the type of lags and pillars, whether the foundation is planned, whether there are turns on the site, and so on. After all the necessary data is entered, the calculator will calculate the approximate cost of materials itself.

Installation work

In order to build a fence made of corrugated board with your own hands, you first need to determine what perimeter the fence will have, then install racks and support pillars. Only then can the foundation be made and the profiled sheets themselves can be fixed. The height of the fence should be immediately noted on the drawing, keeping in mind the quality of the profiled sheets used. As you know, it is recommended to plan a large height of the fence only when a good quality metal profile is used.

That's all the stages of work to create such a fence.which, with proper assembly and good care, can last for over twenty years. Moreover, if you have the skill and desire to do everything yourself, no complicated technical means will definitely be needed. All that a master will need to make a fence is the necessary set of tools and building materials. Of course, you will need the metal-profile sheets themselves, support elements (they can be made in the form of pipes or pillars of various shapes), long ropes for marking the territory, a primer and sand, an apparatus for welding and a screwdriver with drills of various sizes. The riveter is also a very important tool when working with sheet metal. It will help to fix the sheets on the support pillars and correctly connect them to each other.

The posts used to securely fix the profiled sheet are made of different materials.You should immediately exclude and not use wooden supports: they are unstable to water, react poorly to temperature changes and quickly dry out and deform under the influence of direct sunlight. In case, nevertheless, it is decided to opt for wooden supports, they will need to be pre-treated with a special compound for protection. The best option is always considered to be steel supports, which, in terms of operating time, are in no way inferior to the corrugated board itself. In order to protect them from corrosive processes, they should also be treated with a composition in the form of an impregnation or a persistent coloring agent. Supports made of concrete are rarely used, but they can increase the reliability and stability of the structure. To use them, it will be necessary to make a solid foundation, which will cost the master a little more than could have been planned in advance.

The installation scheme for a metal profile fence is quite simple and usually includes three stages: the process of marking the territory, creating a foundation and installing pillars and installation work on fastening the profiled sheet itself.

The markup must be carried out as accurately as possible. In its process, it must be determined where the gate, the fence itself and the gate will be located. It is important to know that the distance between the supports in the form of pillars should be no more than 3 m.The length and height of the fence, as already mentioned, should be determined based on the characteristics of the soil, the quality of the profiled sheets and the purposes with which this or that type is installed fencing. The diameter of pipes (or pillars) with a circular cross-section should be 77 mm, and if the cross-section is square - 5x5 mm. To prevent water from penetrating into the pipe, the holes on top should be welded with the installation of a decorative cap for greater reliability and decorative effect.

The recommended width of the pits for the supports should be about 15 cm, and their minimum depth should be one third of the length of the post. If we neglect these simple but important calculations, the structure will turn out to be very flimsy, and it will quickly "lead" to the side under its own weight of metal sheets. The pillars themselves should be additionally reinforced with sand filling along the bottom of the dug trench. Gravel should be used as a second backfill layer: this will prevent the pillars from contacting the soil, which tends to swell. After carrying out the preparatory work, you should put the pole in the pit, controlling its straightness, and fill it with a solution of good quality concrete. You can use reinforcement as additional reinforcement, while it should be borne in mind that the pillars are fastened with steel supports with double-sided welding (the structure cannot be left in these places without welding). The concrete fill will completely harden only after 3-5 days.

After the foundation is dry, you can start installing the lags. Usually the logs are made of a metal pipe with a cross section of 4.0x2.5 cm.If you plan to build a fence not higher than 1.70 m, two logs will be enough, and if the fence is higher, then you will need to install three pieces. The upper and lower strips are mounted with a distance of 50 mm from the supporting edge, and they are fixed to the posts with an electric welding machine. To prevent corrosive processes in steel structures, remember to process them with a special chemical composition. It should be noted that the liquid must be applied exactly when the lags are being installed, and the sheets are not yet attached to them. Otherwise, it is simply not possible to evenly apply the composition to all steel elements.

When installing a fence, it is also important to consider what type of soil you have to deal with. In the presence of soft-textured soil, there is a great risk that the structure will begin to sag over time.To avoid this, you should build a foundation throughout the entire perimeter of the fence installation. Experienced craftsmen strongly recommend in this case to build a fence on a strip foundation. A shallow strip foundation is installed as follows. A 20 cm deep trench is dug over the entire perimeter of the site, then wooden formwork is made, and waterproofing works are carried out using roofing material. A pre-prepared concrete solution will need to be poured into the pit. Thus, the fence will acquire additional resistance to seasonal soil movement.

Finally, the profile sheets themselves are installed, which are fixed to the logs with rivets and dowels. The metal profile is overlapped. In order not to injure yourself on sharp metal edges, all work should be carried out with gloves, and in order to accurately cut the metal, you need to use special types of scissors or a hacksaw.

How to decorate?

Competent decoration of the fence begins with the foundation. Both the appearance of the entire future ensemble and the durability of the fence itself and all its elements depend on how accurately and efficiently it will be executed.

By the way, if a solid strip foundation is installed on the site, this means that problems with a gap under the fence will never arise due to its technical absence.

Of course, the construction of this type of foundation requires time and certain financial investments, but it will fully justify itself in the future: there will be no weeds on the site that spoil the overall appearance created by the owner, and the fence itself will not be subject to deformation and distortions.

If there is still no strip foundation, then the gap between the soil and the fence can be closed with the remnants of the corrugated sheet, wooden or plastic panels or boards, which can be independently painted to match the fence or in another color that will be in harmony with the main one.

In order to disguise the "hole" completely, it is recommended to plant shrubs under a fence: beautiful, and environmentally friendly, and reliable. Shrubs that look best along the fence are recommended to plant climbing types: honeysuckle, various bindweed, boxwood. Magnolia blooming in yellow will look very beautiful, especially in combination with a green fence. From the inside, the fence can also be decorated in a variety of ways. You can hang the shelves and paint patterns on them with persistent acrylic paints, and then arrange flowers in pots beautifully, hang climbing plants in a flowerpot. Shelves can also serve as a place to store garden tools during the warmer months.

Many owners of such fences are worried about how to decorate from the inside of the rack, because they may look too official and not very aesthetically pleasing. In this situation, it is recommended to attach a metal structure in the shape of the letter "P" to the posts, on which you can hang the same pots or a basket with plants. This uncomplicated technique in the design environment is called "the technique of creating vertical greenery." In addition to decoration, it also serves as a source for creating a spatial expansion effect on the site.

When creating decorative elements for the fence, it is important to remember that they serve as an additional way to decorate the site. First of all, you should take care of the proper design of the house itself and the main entrance. In this case, harmony is ensured by the fact that both the central house facade and the fence are decorated with similar elements evenly distributed over the entire area. The pillars or posts themselves are often decorated with “caps” that have a resistant clinker coating. There are many similar parts on sale, and the size can be ordered individually.You can decorate the pillar from the inside by applying good lighting with LEDs that are resistant to the influence of the external environment.

If the profile sheets are monochromatic, and their colors are classic and not too bright, forged patterns can be placed on their background, having any shape, from options in the form of plants to geometric shapes. Fences with elements of forging, placed in the form of curly elements above the sheets of the metal profile, and not only against its background, look very impressive. If the owner is not satisfied with the too simple and strict look of the fence, you can cut off the upper part of the profiled sheets, and then the fence will take on a very attractive look. Most often, trimming is done in the shape of an arc, and the middle part of the sheet is left higher than the rest. The figured method of trimming the metal profile is most successfully in harmony with forging.

Reviews

The company with the attractive name "Fences" has long been engaged in installation work on the installation of fences of various modifications, including fences made of corrugated board. The work is carried out both in St. Petersburg and in the Leningrad region, and, according to customer reviews, there have never been any complaints after installation. Work is underway to install both simple structures and fences on strip foundations. The company actively practices the installation of fences on screw piles using the latest construction equipment, indispensable in cold weather conditions. Installation is always carried out at the time desired by the client, and the reviews on the construction forums about this company of installers are extremely positive.

The firm "Reliable Fences" also fully justifies its name. The works are carried out in the Leningrad region and St. Petersburg, they are carried out efficiently and on time. Customers are especially pleased that "Reliable Fences" specializes in the installation of forged decorative elements, in cooperation with the workshop in the city of Pushkin. If the client has a desire to decorate the fence with beautiful and original forging elements, then the company "Reliable Fences" will be the best choice in order to carry out this efficiently and in the shortest possible time.

The company "Kupizabor" is famous for the quality of any type of work and very humane prices with regular discounts for regular customers (both individuals and legal entities). The specialties of this company are its extensive experience in the installation of brick posts for fencing, as well as specialization mainly in "weighty" types of building materials. However, if the client needs the simplest option for fencing, the company will quickly and efficiently install both the Rabitz mesh and an inexpensive option on steel posts, which will serve for a long time and will never let its owner down.

As for the direct production of metal profiles used everywhere, then the leading position belongs to the St. Petersburg company "Metal Profile"... The productive volume of corrugated board per year here has long exceeded the figure of 100 million cubic meters. This is not just a separate plant in one city, but a whole network of factories, most of which have been successfully operating for at least twenty years. The history of Metal Profile began, as usual, with a small factory in the amount of one workshop rented by the owner. Today there are factories under the name "Metal Profile" not only in Russia, but also in Kazakhstan and Belarus, and their total number is about twenty. The range of production is constantly expanding and has long since reached a decent European level.

Plants "Metal Profile", which were opened recently, carry out work on modern European equipment, and those of them that were once the first, keep up with new enterprises and are constantly being modernized, producing goods that fully meet the standards adopted in the company as a whole.The main secret of this huge and constantly developing company is that its suppliers of raw materials are the most reliable. Moreover, the joint work is not only in the supply of raw materials, but also fruitful joint development with suppliers of the most optimal methods of raw materials production.

The production of metal-profile sheets itself is carried out under the strict control of the leading specialists of the company. The European equipment, on which the workers work, has a high accuracy and level of automation, and the consumption of electricity is at the same time as economical and efficient as possible. The quality control of products is carried out strictly at all its stages, each of which is of equal importance, therefore the quality of the profiled sheeting of the "Metal Profile" company is always impeccable.

Employees regularly undergo advanced training courses, and work is carried out in decent conditions, reliably provided with professional protective equipment. Even the packaging of profiled sheets is noteworthy: it is designed so that the goods do not lose their properties even in conditions of long and "harsh" transportation to different cities, countries and their regions. The company provides products with a reliable guarantee, so customers, most often, choose the corrugated board right here. The scale of production, its level give solid grounds to give preference to Metal Profile.

Successful examples

On the outside of the fence, figures of birds and animals are often placed, which are cut from durable steel sheet using the plasma cutting method. The shapes of these figures can be very original and unusual, especially when painted in exotic and vibrant colors. To give the figures additional volume, they are performed with several layers of metal, placed in the center of the profiled sheet and along its contour.

The fences are also decorated with drawings and whole paintings. It provides an attention grabber and is ideal for home owners with creative professions. On professional sheets, you can draw a whole panel (flower or landscape). Also, images of scenes from famous cartoons are still very popular. It is recommended to use acrylic as a paint, you can also choose an airbrush method of applying the image, which, as you know, is perfectly “friendly” with metal, but looks airy, light and beautiful.

For those who do not know how to draw, but want to decorate their fence in a more colorful way, decorative options for a professional sheet can always be offered. The easiest way is to use and combine single-color sheets of different colors with each other. There are varieties with different heights and wave types that harmonize perfectly with brick and concrete foundations. There are very beautiful sheets of corrugated board, skillfully made under a tree and under a stone. A novelty in 2017 was the profile with the application of textures imitating dark and light wood species, as well as masonry made of stone and brick of different shades.

Decorative profiled sheets are widely used for covering steel posts of fences. The imitation of stone or wood is so natural that it can be distinguished from natural material only upon detailed and close examination. On sale there are panels made for white, red or yellowish brick. If desired, they can effectively decorate a gray concrete foundation. They are easy to install, lightweight and require minimal maintenance. At the request of the client, any sheet can be subjected to a combined painting in different colors, which is especially important if you plan to install a fence near a house made in a modern eclectic style.

Since high-quality corrugated board is an unpretentious material, you can decorate and decorate it in almost all ways, without exception.One notable and inexpensive method is to install a wooden wattle fence around the entire perimeter of the fence inside the site. A handmade wattle wicker reliably and effectively closes all the pillars, looks cozy and home-like. Its only drawback is the laboriousness of creation, but if the owner likes to do something with his own hand, there is always an opportunity to install a wattle fence inside the site.

Only at first glance it may seem to an inexperienced buyer that an iron fence made of corrugated board is impractical, official and very boring. The variety of modern technologies makes it possible to turn both the choice and the installation of such structures into a real creative process, and in order for the fence to serve for a long time, it is strongly recommended not to skimp on the quality of the profiled sheets and foundation. There are situations when it is he who is a reliable support for the fence, which is especially typical in places with the movement of groundwater and swampy spots. If you competently and scrupulously approach the choice of building materials, correctly calculate their cost, then such a fence will faithfully serve for tens of years, without causing complaints from the owner.

For information on how to choose a fence made of corrugated board, see the following video.

The comment was sent successfully.