How to build a simple gazebo for a summer residence with your own hands?

One of the main buildings in the country after the house and outbuildings is the gazebo. This is a place of rest from the bustle of the city and communication with nature.

Features of a gazebo for a summer residence

Gazebos for summer cottages can be different, depending on the needs and capabilities. If the gazebo serves as a decoration for the site, then it is built thoroughly and elegantly, with a Russian or Finnish stove, with a fireplace, barbecue or barbecue. But in most cases, an inexpensive gazebo is needed, which you can build with your own hands. How it will look and what it will be made of depends on the taste and skills of the owner, as well as on the availability of the material.

The design of the gazebo consists of four main parts:

- floor;

- frame;

- roofs;

- finishing.

The gazebo can be made:

- stationary - concrete, brick, wooden beams, iron corners and pipes, slate are used for it;

- portable - PVC pipes, aluminum structures, polycarbonate, tarpaulin can serve as the material;

- collapsible - can be disassembled completely, or only the frame can be left stationary;

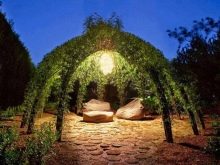

- grown - to create it, trees are planted instead of a frame and climbing plants instead of walls and a roof.

Construction technology

To begin with, they choose a place where they will put the gazebo. It can be attached to a house, a barn or a fence, be located in a secluded corner of the site, be a dividing structure between the courtyard and a garden or vegetable garden, be located opposite the kitchen windows of the house or next to the pool.

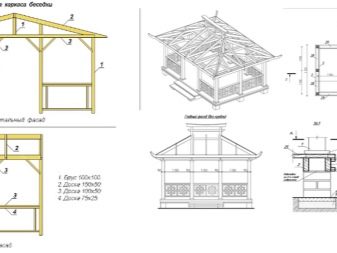

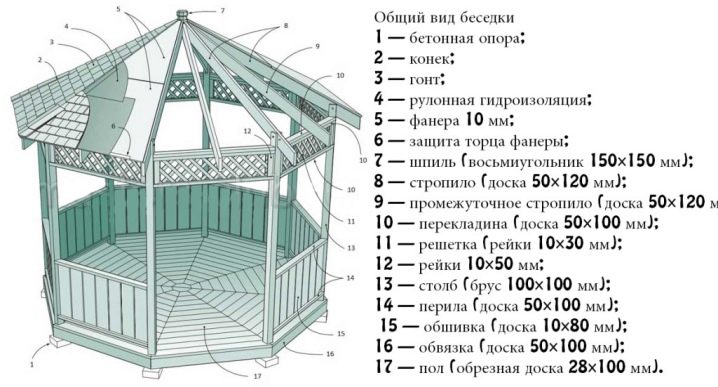

Then find out the composition of the soil: chernozem, gray soil, sandy, peaty, clayey. This will determine what kind of floor is needed and whether it is needed at all. Then the material from which the frame will be made and the finishing are selected. They make drawings of the floor, frame and roof, taking into account the size of the purchased material, so that there are a minimum of scraps.

An estimate is made and accessories are purchased: fasteners and tools.

Gazebo floor

Work begins with cleaning the place. With the help of a tape measure, the markings are made according to the plan. To do this, pegs are driven into the ground, on which a nylon thread is pulled. The marking is checked with a rope stretched diagonally - the two diagonals must be equal.

If the soil is sandy, you need to remove the top fertile layer of earth to sand, and cover the perimeter with the same sand. On such a pillow, you can simply put boards impregnated with protective compounds. The service life of such a floor is short, but it is easy to replace. Typically, a well-soaked and painted 1-inch board on a sand cushion is worth at least 5 years.

The perimeter with the harvested soil can be covered with fine gravel or the floor plane can be laid out with well-soaked wooden hemp 10-15 cm thick. The hemp is sprinkled with sand mixed with fine gravel.

If there is a natural stone in the area, which has one side flat, then the floor can be laid out of it. Brick or paving slabs are also suitable. They can be laid on a grinder (dry cement mortar) using a rubber mallet for leveling.

One of the ways to install the floor, if the gazebo is stationary, is to fill it with concrete. This will be one of the foundation options. This approach makes it possible to use the fill as a finishing floor and as a rough base on which tiles or logs for a wooden floor are laid. The fill thickness must be at least 8 cm.

Along the perimeter, after cleaning the top layer of the earth, a formwork from an unedged board is placed. It is simply inserted at the edges, and after the concrete hardens, it is removed. For durability and strength, a cushion of gravel or sand is made in the prepared perimeter of the gazebo and is well rammed using water. Such a pillow will act as a drainage.

Pegs are cut from iron reinforcement with a diameter of 8-10 mm and driven into the ground every 0.5-1 m to fasten the strapping from the same reinforcement. The supports are tied with burnt wire. A standard concrete solution is prepared: cement, sand, crushed stone in a ratio of 1/3/6. The perimeter is poured, tamped in the pouring process to avoid air bubbles. If the gazebo is closed for use in the cold, you can make a warm cement floor. To do this, when mixing the solution, wood sawdust is added instead of crushed stone.

Pouring a floor is a rather time-consuming and time-consuming process. It is much easier and faster to apply a columnar foundation. This is the most common type of fixed installation. A wooden floor is placed on it, or it simply serves to fasten the frame, and the floor can be anything.

A variety of raw materials are used for the columnar foundation.

- Asbestos-cement or metal pipes. Large diameter PVC pipes can be used. With the help of a construction drill, a hole is made at the location of the frame pillars and the pipe is fixed in it by butting or pouring concrete. The bottom of the pipe is insulated with hot resin or bitumen mastic. A wooden log is driven into the center of the pipe, which will be the place for fastening a horizontal or vertical frame.

- Concrete. For this, a hole is dug, around which a formwork is built. For heaving soil, the depth of the pit must reach the level of freezing of the soil, otherwise the gazebo can "walk". A frame pre-assembled from iron reinforcement is inserted inside and poured with concrete. A threaded pin can be welded to the frame to secure the outer frame.

- Brick. In this case, the pin is driven into the hole and bricked.

- Materials at hand. For example, used car tires can be used. They are simply laid on a cleared horizontal piece of land and covered with sand. On them, a horizontal frame is assembled from a wooden bar along the perimeter of the gazebo, which is the basis for the installation of the remaining parts of the gazebo.

The frame of the country arbor

For a person who knows how to handle a welding machine, it is easiest to make an arbor from iron. For work, you will need the device itself, a level, a grinder and a screwdriver. Such a frame will fit any roof. Used pipes, corners 30x30 or 50x50 mm, metal strips can serve as material. It can be decorated with wrought iron spans. Polycarbonate, profiled sheet, wood, PVC products are easily attached to it.

The simplest summer cottages can be made from a common and affordable material - wood. It is easy to process and looks beautiful. It does not require special construction skills, therefore it is suitable to make a gazebo quickly with your own hands. For the construction of the frame, rectangular beams, round timber and fasteners in the form of brackets, metal corners, nails and screws are used. For an owner who knows how to carpentry, such a building can be assembled without a single nail. It is even easier to sheathe such a frame than one made of metal. It will withstand a roof of any material.

In city apartments, repairs are often made, in which the doors are replaced. Old doors are usually taken to trash cans as unnecessary. But 8 second-hand doors are already material for the frame of the gazebo. They are placed at an angle of 90 degrees, with the end of one door to the plane of the other and pulled together with self-tapping screws. This creates four reliable bases for any type of roof.

You can assemble the frame from any material at hand, for example, from plastic products. In plastic bottles, the bottom is cut off and columns are collected, putting one bottle on top of another. When assembling, you can use Moment glue.If the roof is of medium weight, then the containers during installation are filled in stages with sand to increase strength. Such pillars can simply be dug into the ground. There is an option to lay out a whole wall in this way, tying the posts together with a nylon twine.

Plastic pipes are also easily and quickly dug into the ground and filled with sand. For a massive roof, cement mortar is poured into the pipe instead of sand.

Plastic boxes are also suitable for the frame. They are well inserted into one another and fastened together with a soft wire or nylon twine. They can also be used to assemble benches and tables.

Stepladders can also be attributed to the materials at hand. If the gazebo is needed only for the weekend, and work on the site using ladders is not planned, they can be used as supports for a gazebo with a light roof. For this, one tree growing on the site and two stepladders or two trees growing side by side and one stepladder are enough. The stepladder is installed using rope struts with pegs, which are driven into the ground in an interference fit according to the principle of setting up a tent. The edge of the tarp is tied to the tree and thrown over the ladders. Secure the tarp with a rope. This method is very simple, the structure is quickly assembled and disassembled.

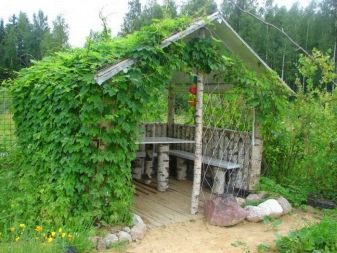

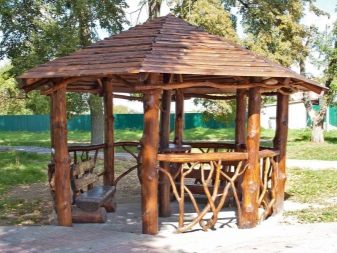

If you cut down several trees while clearing an area, they do not need to be immediately thrown away or burned. They are used to make charming supports for the gazebo. To do this, the tree is cut as low as possible near the ground, small branches are removed, and an exclusive column is formed from thicker ones. You can install it on any floor by insulating the heel of the tree with roofing material or mastic. Depending on the condition of the bark and the type of wood, it is either removed or left and varnished.

Of course, a brick frame looks beautiful and reliable. If a place in the village is chosen for a summer cottage, a house with an old stove is often given along with it, which is dismantled as unnecessary. It is not at all necessary to throw out the brick, because a good gazebo will come out of it. True, this option is not suitable for simple buildings, but cost savings and good quality are guaranteed.

Gazebo roof

The top of the gazebo is covered in order to hide from rain and sunlight. The roof is light, medium and heavy. For a light roof, dense woven panels, awnings, polyethylene are suitable. It is not necessary to make a frame for them. The advantages of such structures are the simplicity and speed of installation, but the design and functionality leaves much to be desired.

For a light fixed roof, materials of natural origin are suitable. It can be covered with reeds or small sheaves of hay, braided with hazel vines. A covering made from living climbing plants will provide excellent protection from sunlight and wind, but will not help shelter from the rain.

Medium roofs include fixed roofsmade using lightweight materials such as roofing material, polycarbonate, plastic slate, bituminous shingles. Most often these are pitched roofs. For roofing material and shingles, a complete roof frame is needed, and for plastic slate, only guide joists are needed. Polycarbonate has a size of 2.1x6 m, it is enough to fix it along the edges or partially. It is quite dense, but it bends and cut easily. The only drawback of such roofs will be the rumble of raindrops.

Heavy roofs are the classic roofing option. They do not belong to simple options, but such a roof will allow you to use the gazebo all year round.

Finishing

The gazebo, grown with climbing plants, needs only the care and formation of plants. A simple gazebo may not need additional decoration at all - four canopy posts, a bench and a table are enough.

The gazebo can be decorated with carvings on wooden parts or forged patterns on metal. Another decor option is the bright sunny colors of the gazebo.

How to build a gazebo with your own hands, see the video below.

Not a bad article.

The comment was sent successfully.