Ventilation in the garage: the subtleties of the device

Ventilation in the garage performs one of the most important functions - it provides a healthy microclimate and helps to keep the car in optimal condition. How to properly equip an inflow and an exhaust hood in a cellar or basement with your own hands and make ventilation holes? Answers to these and other questions can be found below.

Peculiarities

A garage is an enclosed space that requires effective ventilation to completely and timely remove condensing moisture, toxic exhaust gases, and other harmful fumes.

Here are some of the functions that a properly designed ventilation system should perform.

- To remove moisture that inevitably gets into the garage from the tires and the underside of the car, since drying the car is practically the only way to prolong its life.

- Remove hazardous to human health exhaust gases, chemical vapors of oils, varnishes, gasoline or diesel, car care products that are often stored in the garage.

- Prevent the formation of condensation on the walls and ceiling of the garage, as well as inside the cellar, which can lead to damage and even destruction of the very structure of the garage.

- Responsible for the rapid removal of moisture from the surfaces of the car, which will prevent rust.

- Protect not only the car itself from corrosion, but also the tools that are often stored right there.

Views

There are only two principles of garage ventilation - natural and forced. From here, you can naturally deduce the types: natural, mechanical and combined.

Natural ventilation is based on aerodynamic laws and does not imply the use of mechanical devices, air flows naturally, obeying the laws of physics, through the supply and exhaust openings in the walls or garage doors due to the temperature difference inside and outside the box. This type of ventilation is easy to construct with your own hands.

Of course, in any garage, the air temperature inside the box will be higher than the ambient temperature during the warm season. And this circumstance is used to stimulate air circulation: physically warm air tends upward, and cold air tends downward due to the difference in temperature and density.

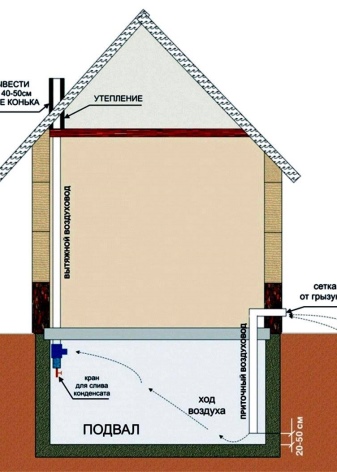

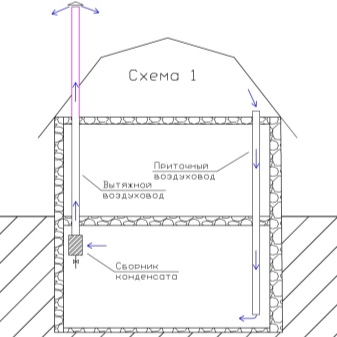

Accordingly, two homemade ventilation ducts are made in the walls of the garage. It is recommended to place them diagonally. Outside air enters the air inlet. At this moment, a temperature difference arises in the garage box and warm air rises up, then enters the exhaust duct and goes outside.

Basic principles of system placement.

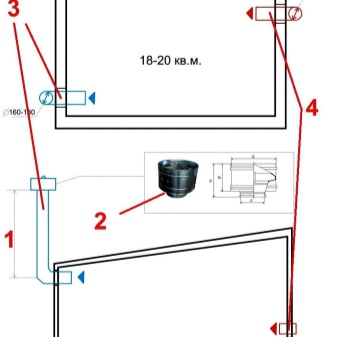

- The supply air duct is usually placed on the windward side and as close to the floor level as possible - usually not higher than 10-15 cm, but not lower than half a meter from the surface. The simplest and most effective solution for this type of ventilation is standard ventilation grilles that simply fit into the garage door.

- The hood must be arranged at a distance of 10-15 cm below the junction of the wall with the ceiling. It is installed 10 cm below the ceiling seam, the other end of the duct is located outside the box at a level of about half a meter below the edge of the roof.

- It is important to observe the placement of the supply and exhaust openings in different corners of the room opposite each other with a difference in height of at least 2.5-3 meters.

- If the ventilation duct is released onto the roof of the box, do not forget to provide a pipe height of 50-60 cm.As a rule, it is covered with a curly lid on top and equipped with a mesh or lattice in order to protect it from insects.

In addition to the simplicity of equipping the natural ventilation system and the low cost of it, it also has disadvantages.

- In the warm season, a small temperature difference makes this type of ventilation ineffective - there is insufficient mixing of air masses, including due to different air densities.

- The location of the air inlet and outlet vents plays an important role.

- Another disadvantage is the appearance of ice on the open parts of the system in the cold season due to a too strong drop in temperature inside the garage box. This problem can be easily eliminated by installing insulated shut-off gates.

Artificial (forced) type of ventilation is characterized by the provision of mixing of air masses using exhaust and supply fans and mechanisms similar to them. The air in the garage box is mixed with the help of artificial supply and exhaust systems. We can say that, to some extent, this view can even replace heating. The most advanced systems use a variety of software.

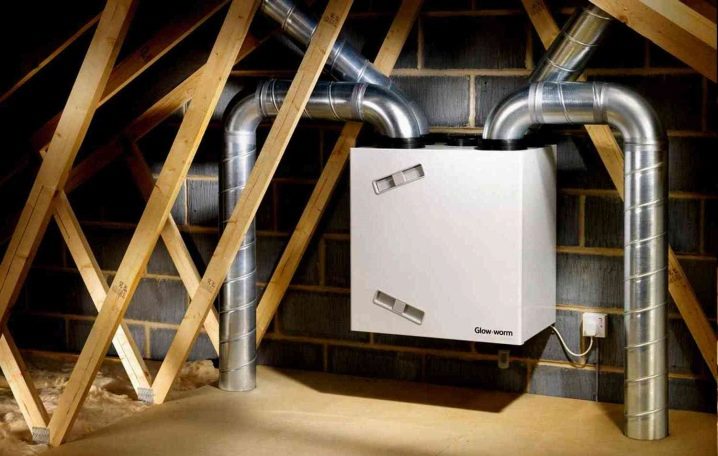

Structurally, this type of ventilation is distinguished into monoblock (a single unit provides both a fence and an exhaust hood) and modular (all of the above is done by two different device blocks).

This type is relatively expensive as it requires a certain degree of mechanization. You will need at least two types of devices - to organize the flow of air and its exhaust.

Supply equipment can include a heater or fan heater, or an air filter or duct fan can be added.

The sucked-in air passes through the filter, is heated by the air heater and enters the air ducts. After fulfilling their functions inside the box, air masses are discharged into the atmosphere through the exhaust system.

It is also possible to mount a single-block version. It can be even more efficient since all equipment is enclosed in a single housing and functions as a whole. In addition, it is the most economical to operate, since usually the plate heat exchanger works "for itself", heating the air drawn in from the atmosphere.

The advantages of mechanical ventilation:

- the mechanical type of the ventilation system provides internal humidity and air temperature regardless of the atmospheric conditions outside the garage block;

- with its help, it is easy to provide ventilation of the basement, create correct air circulation;

- if you have a garage box that is completely below ground level, this is the only way out for this type of garage when storing a car.

The combined type of ventilation operates on a separate principle - the air enters the box on its own, and is thrown out by means of mechanical devices.

If the ambient temperature is higher than the internal one, and the natural type of ventilation is implemented (without the use of mechanisms), the structure does not function. In this case, air mixing can be stimulated by installing conventional fans. They are economical to operate and will not greatly burden the family budget.

The only drawback of this type is manual control, since it becomes necessary to visit the garage frequently.

How it works?

The supply system works in accordance with the natural type of ventilation described above. The exhaust system is mechanized and an exhaust fan provides air outlet to the atmosphere.

The advantages of the combined type of ventilation:

- it is relatively independent of the season;

- ease of installation.

Disadvantages:

- in the cold season, the air inside the garage cools quickly;

- the electric fan requires regular maintenance;

- air taken from outside is not subject to cleaning.

Of course, each garage owner will choose the type of system independently and based on their budget and the purposes for which the garage is used. One way or another, it should be noted that the installation of a ventilation system of one type or another in the garage is very important for the owner from an operational point of view.

What can you equip with?

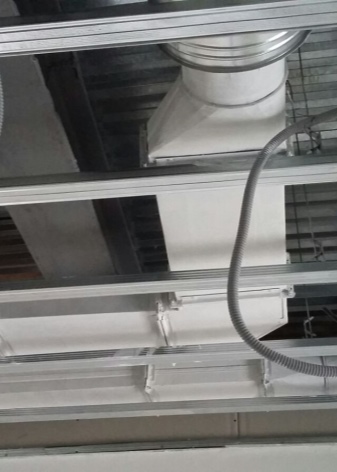

Installation of air ducts for ventilation systems of any type nowadays can be done using a wide variety of materials, ranging from plastic or metal-plastic pipes for sewage and ending with the use of a corrugated hose from a vacuum cleaner.

Let's consider some options.

- It is possible to make ventilation ducts in the box using pipes made of asbestos. Such pipes are not fire hazardous, they do not need to be painted, or vice versa, if the owner is a creative person, they can serve as material for creating a certain entourage when painting.

- As mentioned, plastic sewer pipes are also a good option.

- And finally, the simplest solutions are old hoses from a vacuum cleaner, garden hoses, and other pipe structures.

It is a natural desire of any garage owner to have a cellar in it, and may be faced with the need for a separate ventilation system in it due to design errors. This can not only lead to spoilage of products due to high humidity inside the cellar, but also to sad consequences in the form of corrosion of the car body. For this reason, ventilation of the cellar should not be neglected in any case.

With a natural type of ventilation, the cellar is dried due to thermal mixing of air masses - in accordance with the laws of physics, the lighter heated air in the upper part of the cellar rises up, and the air entering from the outside through the supply air duct fills the rarefied space.

The second option is to install fans and create forced ventilation. This is a scheme with a higher efficiency, but it will require significantly higher money and energy costs.

Preparation of drawings

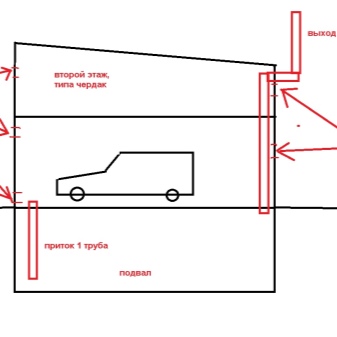

The ventilation system must be supplied to one- and two-storey garage premises, as well as residential premises, regardless of the presence or absence of a heating system in it, taking into account the uniform ventilation of all volumes.

In order for ventilation systems to work stably with the design capacity, at the design stage, air ducts are calculated for the throughput and duct diameter. Actually, air ducts are channels through which air passes. They are widely used in a variety of devices, both in the household and in the industrial-technological sphere, in the production of chemicals and medicines, in other industrial enterprises.

Calculating the volume of a garage ventilation system is quite simple.

The main figure is the number of changes in garage air volumes by the volume of air flow from outside (multiplicity). If their number is 6-10 volumes and the total volume of the garage box is known, it is necessary to calculate the air consumption per hour: L = nхVg

Where:

L - consumption per hour, m3 / h;

n is the standard for changing the volume of air in the garage;

Vg is the total volume of air in the box, m3.

To determine the volume of the garage, it is necessary to multiply the width by the length and height according to the internal dimensions of the box.

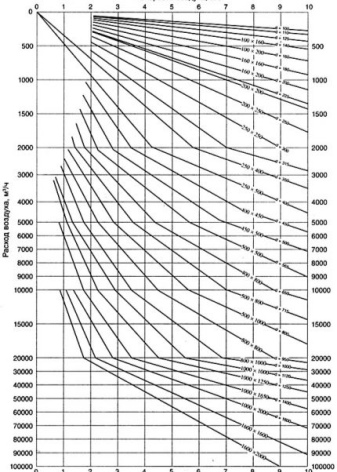

For example, a garage 4 by 6 and 2.7 m according to the formula Vg = 4x6x2.7 = 64.8 m3. If the number of changes in garage air volumes is required for the volume of air flow from the outside, equal to seven shifts per hour, then this box needs L = 7x64.8 = 453.6 m3. Accordingly, the air flow and speed can be set according to this diagram:

To select the cross-section of the supply and exhaust air ducts, round L up to a multiple of 5. Accordingly, our calculated number increases to 455 m3, since it is a multiple of 5: 455: 5 = 91.Comparing it with the diagram and knowing that the air speed in the ducts when natural ventilation is used is approximately 0.5-1 m / s, for the above volumes, circular channels with a diameter of more than 500 mm or air ducts with a different cross-section of more than 450x500 mm with bends or not.

If a decision is made to improve the air flow, this can be achieved by installing a grate or mesh inlet instead of a solid wall pipe. Its diameter should be 2-3 times larger than that of the hood. This will give a significant improvement in ventilation, but there will be a high probability of significant freezing of the garage during the cold season. To avoid this, it is necessary to install dampers on the supply and exhaust air, which, if necessary, will reduce the air permeability.

Always make sure that the hood is not oversized.than the air inlet of the supply air, since the so-called overturning of the draft, or reverse draft, can occur. For this reason, if you partially block the supply air duct, be sure to reduce the diameter of the hood as well.

In the case of the manufacture of a ventilation system for an inspection pit or a cellar for underground rooms, separate pipes are required for the air supply and another one, passing vertically, for the exhaust. Exhaust air ducts must be isolated from the main garage room - the air in them must not come into contact with the main volume of air masses inside the box.

The volume of the supplied air mass must be at least 180 m3 / h at a temperature inside the garage of at least 5 ° C above zero. The frequency of complete air exchange is 6-10 times a day.

The functional diagram of the air ducts is drawn up when creating a room project, since the installation of a ventilation system in an already finished garage will entail a lot of difficulties. The diagram should contain the location of the ventilation holes, their number. It should also provide for the dimensions of the garage, the passage of pipelines and air ducts above and below the surface of the ground / floor, the amount of circulating air volumes.

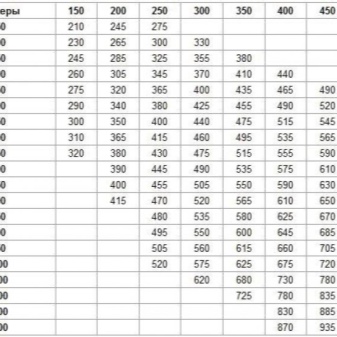

Calculation of the diameters of the ventilation holes is performed as follows.

- With a tube diameter of 15 mm = 1 m2. Accordingly, for a 10 m2 box, 150 mm tubes are required.

- With the sum of all ventilation openings equal to 0.3% of the entire garage area. This formula is used for a single channel circuit with a mechanical type of ventilation.

There is a difference between Russian and foreign building codes. If the Russian regulatory documents establish the rate of air intake from outside for a garage with one passenger car at 180 m3 / h, then in foreign standards this figure is increased by 100%.

In addition to calculating the required air exchange capacity, air ducts count on pressure loss and stiffness. Such calculations are convenient due to the use of flexible air ducts made of various plastic for ventilation in garages, which are less durable and rigid in comparison with metal structures, which are used in most cases.

FAQ

How to arrange a camera for painting a car in a garage?

A paint garage is a very specific area that presents its own requirements to the owner.

They are complicated by the fact that you need to have in the garage:

- basement of considerable depth;

- improved powerful ventilation system for intake and exhaust of air and exhaust gases;

- it is necessary to remove the camera from any living quarters;

- it is very important to exclude contact of air from the painting chamber with any food products;

- the chamber room must be perfectly isolated from the external environment;

- heating elements, filters, like all other equipment, must comply with fire safety standards.

How to equip a garage for welding?

In various works related to the repair or modification of the car, the owner often uses welding.A good option is a welding machine that uses tungsten electrodes for welding in a gas-shielded environment.

Winter season: open or close garage doors?

It may seem strange, but in winter, corrosion eats away at the metal of the car more than in summer, so in the warm season, in the absence of a ventilation system, a metal garage is ventilated by opening the gate wide open, but in winter at low temperatures, the gate does not need to be opened, which again associated with humidity. Note that insulating a metal garage does not solve this problem.

Helpful hints and tips

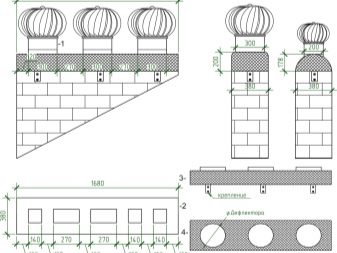

A deflector is a device that is installed above the exhaust air duct and is used to increase the flow rate in it due to the so-called Bernoulli effect, which increases the efficiency of the ventilation system. According to the principle of operation, the deflector can be stationary (fixed) or rotating (rotary).

The turbo deflector is an improved and much more efficient version of the conventional deflector., in other words, it is one of the names of a rotary turbine. In fact, this is a conventional impeller installed on the upper cut of the exhaust air duct.

It helps to naturally remove exhaust air from the garage box.

The turbo deflector operates using only the laws of physics, without the use of mechanical devices, electricity or fuel costs. As already noted, humidity in the garage plays an important role, and its elimination is the most important task of the ventilation system. The turbo deflector is an original, cheap and very effective part of the exhaust duct, helping to establish correct and efficient air exchange in the garage box.

The principle of operation of a turbo deflector - passively using the movement of air masses, it creates an area of reduced pressure, promoting air flow and increasing draft in the duct. It works regardless of the wind, its strength and direction.

The ability of its impeller to rotate in the same direction prevents the thrust from overturning and increases the efficiency of air exchange in the hood.

It can be noted that this is also an additional protection against the ingress of precipitation, foreign objects into the duct.

This device will be able to increase air exchange in a garage or other room by 20% without any additional mechanical or financial costs.

The shape of the impeller and the casing of the product varies according to the aesthetic wishes of the owner. Its service life with proper maintenance is more than 10 years.

Of course, besides the advantages, the turbo deflector is not without certain disadvantages:

- Higher price of the device, which depends on the material from which it is made.

- In the absence of air flow in the duct during the winter season, the blades may stop and become covered with frost and ice.

- The maintenance rules for the turbo deflector are simple and elementary. Frequent maintenance is not required.

The worst thing that can happen to it is the cessation of movement of the impeller blades due to the lack of air flow or skewing and jamming of the bearings.

Let's summarize some of the results.

- Installation of a ventilation system in any type of garage is required. It allows you to preserve and extend the service life of a car, reduces the impact of harmful vapors of fuel, oils, chemicals in an enclosed space on human health.

- You need to choose one of the different types of ventilation - natural, forced / mechanical, combined, depending on the purpose of using the garage.

- Insulating the floor will help to avoid condensation on the walls and ceiling of the garage, made of metal. It is first covered with roofing material, then a concrete screed follows and linoleum is covered on top.

For the intricacies of the ventilation device in the garage, see the following video.

The comment was sent successfully.