How and from what material is it better to make the floor in the garage with your own hands?

Each car owner is happy to have his own garage and is ready to spend almost all his free time in it, sorting out his iron horse. In order for such a pastime to be as comfortable as possible and bring only pleasure, it is also necessary to decorate the garage from the inside with due care, thoroughness and practicality, creating the same atmosphere and atmosphere as in a living room.

Garages must be kept clean and dry. In addition, do not forget that flammable liquid and similar substances often become contaminants, which is not at all soothing, since such stains are difficult to remove and can damage surfaces.

The most vulnerable surface in this regard is the floor covering. The garage floor must be strong enough to withstand objects, tools and spare parts placed on it and falling on it. Even after being exposed to great severity, it must maintain its integrity.

All of the above can be achieved by using the right materials, as well as understanding what the positive and negative traits of different options have. Manufacturers in the market provide customers with a wide range of materials and coatings with different lifetimes and prices. In this regard, making such a decision is a rather serious step. Let's figure out how to make the right choice and what criteria should be used to judge this.

Criterias of choice

Good finishes should be visible and felt throughout the entire space - walls, roof, and floors. The latter is a particularly problematic issue, since it is the floor that is constantly mechanically influenced with great force. For example, serious consequences can be caused by car wheels, heavy objects or even ordinary shoes. But this is not a complete list.

Because cars are often repaired, washed or painted, chemicals can often get on the floor as well. Floor coverings can be easily damaged due to this effect. Therefore, making a good floor in the garage for car owners is really important, in this regard, solving the issue with the choice of material and type of coating requires a particularly careful approach. This will ensure a long service life of such a floor.

When choosing the most suitable and most necessary materials, you should pay attention to a number of criteria. The floor must be distinguished by the characteristics of durability, strength, high quality, and so on. When considering such criteria, their cost is often not taken into account. Also, when choosing the type and material of floors in the garage, it is important to understand whether an inspection pit will be equipped in the garage, since this determines the features of the floor installation. In this regard, one or another coverage will be selected. In addition, it will be important to take into account the climatic conditions and structural features of the room.

To choose the right coverage, several criteria are taken into account. It is important what the soil will be under the room. Its features may require the creation of additional conditions for installation and maintenance of the floor covering. Take into account the climatic conditions - it is necessary to take into account humidity, precipitation and temperature.

It is also important to take into account the expected loads - mechanical shock and exposure to chemicals (including oil, fuel and acids) should not be detrimental to the floor covering and should not destroy it.

Garage flooring must be guaranteed to be easy to clean, that is, the material must be characterized by moisture resistance and ease of cleaning. Moreover, the floor in the garage should be lined with non-combustible or low-combustible material to ensure safety in the garage. When choosing, be guided by the ratio of presentable appearance and cost. Usually, cheap material looks simpler, while expensive material looks more refined and luxurious.

Thus, the choice of a suitable material for a garage for a car should satisfy all needs, serve faithfully for a long time and help with saving money. This result can be achieved using modern materials or more traditional methods.

But traditional, usually earthen and sandy floors, have a number of negative aspects. For example, when arranging and operating such a floor, there will be a lot of dirt, which will certainly affect the internal cleanliness of the car and can contaminate the living space as well. Even more mud is formed if the climate is characterized by high humidity and an abundance of precipitation. Therefore, an earthen floor in the garage is far from the best option.

A sturdy wooden floor is also a traditional construction. It is worth noting that it is also characterized, rather, from the negative side than from the positive. Prices for material for wooden floors are quite high, they are usually compared with the price of a self-leveling floor. At the same time, the tree does not differ in wear resistance, which is typical for a self-leveling coating. But for a tree, the most characteristic property is flammability. Therefore, a wooden floor can rightfully be considered the worst option for a garage.

The use of combustible mixtures can become destructive when they hit the floor, as a fire can occur, and this will entail significant damage to property and endanger the life and health of the car owner and his family members.

More modern structures include a coating of concrete, as well as other moisture-resistant materials. It is worth noting that such a floor can behave differently in different situations and under different conditions. It is not difficult to take care of concrete floors, maintaining perfect cleanliness will not be difficult for the owner. Therefore, it will be comfortable to spend time in such a room.

But concrete does not have an aesthetic appearance and not all stains can be wiped off. For example, fuel. Such contamination is much easier to remove from ceramic tiles. The same can be said about acids - ceramics are more resistant to them, like polymer coatings. The concrete floor is likely to begin to collapse, crack and crumble.

Thus, there are many criteria for choosing a coating. To better understand this, we recommend that you study the features of installing different types of garage flooring from different materials.

Installation of structures

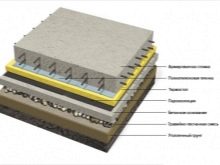

As a rule, it is necessary to install coverings of any type after the equipment of the base for such coverings. The material for the latter is usually concrete. So before installation, you always need to install special screeds, which will be a preparatory stage. As a rule, the requirements for the grade of concrete for such screeds are the normalized level - from 200. The base layer should be from 15 centimeters.

At the same time, such a base must be reinforced with a special grid 50 to 50. And under the screed, you need to install a special cushion of sand and gravel, and also make grooves so that water can drain. Let's consider separately the features and installation of each type of garage flooring.

Earthen

The simplest version of an earthen floor covering is installed as follows - you need to level and tamp the area under the floor. As a rule, this is the end of the installation of the floor in the garage. In this case, the garage will be threatened by exposure to moisture and low temperatures. To increase the resistance of the floor to such effects, you can cover the earthen floor with a clay mortar. This manipulation will make the flooring in the garage more durable and frost-resistant.

If you intend to make garage floors inexpensively, then there are several options for how to increase its resistance to moisture without much cost. From above, a layer of soil with a depth of 15-60 centimeters should be removed, more precisely, this is determined depending on the soil. Further, for a more thorough tamping and obtaining a flat floor, water it with liquid.

If the groundwater is high, then additional protection from water will be required. For this, several layers of clay mortar are applied on top of the soil, while before applying the next layer, you need to wait for the previous one to dry.

And when moisture spreads to the walls of the garage, clay should not be used. This layer can be replaced with sand and red fired brick or slag. It is also possible to use a layer of gravel, and on top of it - paving slabs. The disadvantage of such a layer will be that it does not protect well from moisture, but it will significantly insulate the floor. You can also reduce the amount of moisture in the garage using ventilation, which is located in the corners of the room. Ventilation can be forced or exhaust.

As mentioned, the earthen floor is quite cold. However, you can insulate it with, for example, old linoleum. In this case, it is recommended to overlap individual layers on top of each other. The linoleum coating is rather slippery, but you can compensate for this disadvantage with a wooden board under the linoleum. On these boards and will need to drive a car. Instead of planks, you can also compensate for slipping with an old vinyl banner ad or plywood.

Concrete

Such a floor is the most popular among car owners, since it has a long service life, does not need frequent repairs and, moreover, has affordable prices.

So, the positive aspects will be complete immunity to high humidity, ease of care - you can simply water it with water using hoses. Another plus is resistance to any mechanical stress. It is impossible not to mention an affordable price among the advantages. By choosing this flooring option, the garage owner can save a lot.

When installing concrete floors, you will need reinforcement, sand, gravel and cement. It is necessary to make a concrete floor starting from the ground layer. This layer needs to be removed, the depth will be 30 centimeters. At the bottom of the resulting pit, crushed stone about 10 centimeters thick is laid. This layer needs to be properly leveled, saturated with moisture. Also, the crushed stone must be thoroughly compacted. A screed is poured onto a layer of crushed stone, which is represented by a mixture of sand with cement, and the first component should prevail in quantity over the second.

Ceramic

Classic options include ceramic tile garage flooring. The installation of such a floor covering requires a particularly careful approach - it must not be allowed that empty spaces remain under the tiles. For this purpose, the tiles are fixed under the comb with glue, which is specially designed for outdoor work. You only need to apply the glue in a thin layer. Installation of ceramic flooring is carried out from porcelain stoneware. Such material is distinguished by resistance to low temperatures, including frost, as well as indelibility.

At the same time, the cost of tiles and stones is high, that is, it is practically the most expensive material that requires significant financial investments.And the installation of such a coating is laborious, which is also not an advantage of this option. The laboriousness is justified by the fact that the base under the tiles should be leveled as much as possible. In addition, a primer is required. For proper installation, a building level is required. Do not forget also that the tiles must be laid, keeping the gaps between the individual parts.

The choice of the tiles themselves also requires a responsible approach. There are an endless variety of options on the construction market. The best of them is porcelain stoneware. This option is also suitable for a garage without heating, since the material is frost-resistant.

However, in terms of appearance, this option is one of the most chic. Despite this, not every car owner agrees to spend time, effort and money on this.

Polymeric

By all its characteristics, such a flooring is ideal for garages, however, the cost of a polymer floor is certainly high. In the modern period, such floors are best installed in a large garage or in a car wash. The composition of the polymer floor covering is represented by a number of different substances, and when it begins to harden, a monolithic floor that is distinguished by plasticity and moisture resistance is formed.

A number of mixtures contain special additives with additives, due to which the polymer floor covering is resistant to chemical attack. At one time, this technology of flooring was considered a revolution in the construction industry. But now this method of installing flooring has been proven for more than one decade. The beginning of the use of technology can be attributed to the period of the Soviet Union. It was used mainly to cover the floor of a production workshop and factories.

The indisputable advantages of polymer floors include simple installation, ergonomics, and resistance to damage. And the only drawback of the polymer coating will be the high cost.

Bulk

It is worth noting that self-leveling garage floors are considered the most optimal option. This option appeared relatively recently, but quickly became popular among consumers. This state of affairs is due to a set of positive characteristics that car owners and garage owners usually take into account.

Firstly, this characteristic is wear resistance. This makes the floor covering maximally resistant to impacts, high humidity and low temperatures (including frost). Choosing the best option for the floor in the garage, it is worth remembering that self-leveling floors do not have an unpleasant odor, do not form dust, do not require painting, varnishing and other substances. Self-leveling floors will serve their owner for a long time, retaining an aesthetic appearance and a high level of plasticity for the entire period of operation.

But you can find flaws in self-leveling floors. So, the price of self-leveling flooring is really high. But this disadvantage is fully compensated for by the long service life, besides, a minimum of time and money will require caring for such a floor. Therefore, a number of car owners prefer to spend money right away in order to save it later. The service life will be about fifty years.

The basis for the self-leveling floor should be a concrete screed. You will need to cover this layer on top with a primer and a special polymer mixture. Such a mixture is made from resin and hardening agents. It is necessary to mix the substances in full accordance with the instructions in the right proportions. When equipping a self-leveling floor in the garage, remember to observe the temperature regime - in the garage it should be more than ten degrees Celsius. It takes two weeks for the self-leveling coating to dry completely.

I would also like to call the advantage of the self-leveling floor versatility in terms of design. The modern approach even allows the use of paintings in 3D format.

Other popular options

One option is a rubber covering, which is usually in the form of tiles. Such a coating is not distinguished by durability, however, it is a budget option with maximum ease of installation and unpretentious use.

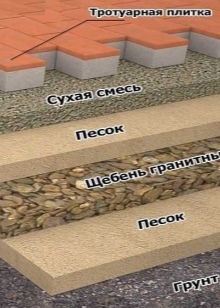

The next popular garage flooring option is paving slabs. Each of the layers requires careful compaction during installation. This may require a vibratory rammer, which can be rented or purchased at a fairly reasonable price. This will give the best result. It is worth noting that tamping must be done every 5 cm of the floor. Whether the floor is tamped down enough can be judged by one sign - if you can walk on the floor and not leave a single trace.

It is necessary to lay paving slabs using a series of sequential actions. First, a layer of sand five centimeters thick is laid on the earth's surface. On top of the sand, sprinkle with a layer of 10 cm medium gravel. The next layer is again sand, the thickness should be about 10 cm. Then follows a layer of cement, suitable for the paving slabs. Clean sand can be used instead of cement. The layer thickness should be five centimeters. Then you can do the finishing coat.

Do not forget that layers lined with sand and gravel must have several layers of waterproofing material between them. Waterproofing can be made from roofing material, a dense polyethylene film. A good and reliable option would be to use geotextiles. To connect the waterproofing material to obtain an even layer, use tape or soldering by overlapping layers on top of each other. And the joints must be additionally waterproofed with mastic.

The layer thickness should be five centimeters. Dirt can accumulate in the cracks; for this, sand and cement mixed together should be poured into them in a ratio of 3: 1. The excess mixture must be removed. Such a mound must be sprayed with liquid and allowed to dry. It is worth remembering that if the mixture gets on the coating, then it must be removed immediately, otherwise the appearance will deteriorate. Also, do not forget that you do not need to use a hose, the maximum is a spray bottle. This is due to the fact that, due to the strong jet, the mixture of sand and cement can be washed out of the cracks.

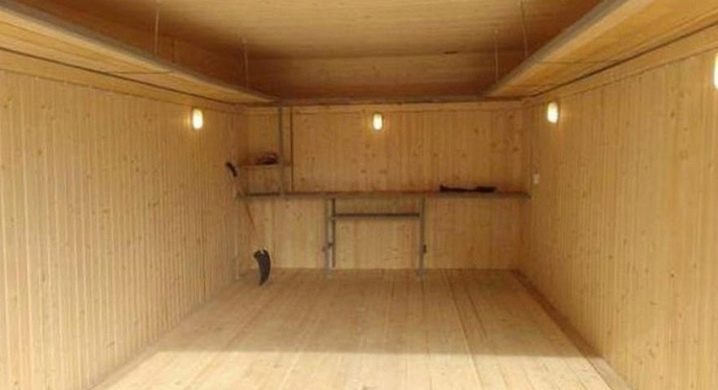

Wood flooring is also a fairly popular option. The service life of a wooden floor will be about twenty years. You can extend the life of a tree by treating it with a special compound.

In order to lay out a wooden floor yourself, you need to adhere to certain stages of construction. First you need to remove the topsoil. After that, you should use a vibratory rammer in order to properly tamp the layers. In this case, it is advisable to moisturize each layer. Next, you need to lay the waterproofing.

As this material, the use of rolled roofing material, film, geotextile or a special membrane for waterproofing is best suited. The next layer is better to apply sand or gravel, the layer thickness is ten centimeters. This layer also needs to be tamped with special care. Then you can start laying wooden logs.

Their dimensions are usually 50 or 40 millimeters. At the same time, each element requires treatment with an antiseptic, a primer mixture, resin or flame retardant impregnation is also suitable. This is done in order to reduce the flammability of the wood. It is good to supplement the track with railway sleepers, since their processing with the help of factory impregnations makes it possible to ensure their resistance to moisture and fungus.

Each wooden log is installed in a special recess. You need to install it exactly with the floor, you can use a level for this. It can also be leveled with wooden wedges, for which bituminous mastic is used. Anchors or gypsum are used to fix the lags in relation to the walls.It's simple and doesn't take a lot of time.

It is worth remembering that when entering the car, the wheels must hit the logs. Therefore, they need to be located at a distance of a meter or a half meter from each other. Moreover, if the distance between them is reduced, then the floor covering will be much more stable. Focusing on the logs, the floors need to be sheathed with boards. It is optimal to use 40 or 50 boards. They should be fixed from each other at a distance of about five millimeters. This is because boards can expand or shrink when exposed to moisture and temperature.

The advantages of wood will be environmental friendliness, the ability to retain heat, as well as aesthetics, resistance to chemicals. This floor can be painted or varnished. The lifespan of the wood can be extended by regularly replacing the planks. In the garage, it is quite possible to create modular coatings with your own hands. The garage floor can be redecorated without any special knowledge. It is also not difficult to lay polyurethane and epoxy floors or install metal floor coverings.

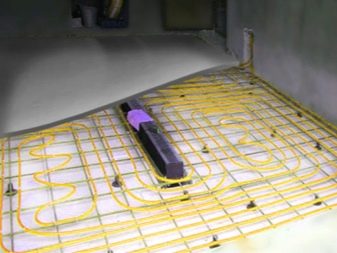

Heating and insulation

Whatever the flooring, it is better to insulate the floor or equip it with heating. Everyone will feel more comfortable if they have a warm floor under their feet. In addition, underfloor heating is a guarantee of dryness in the room. This will protect the flooring from moisture and cold temperatures.

It is recommended to use extruded polystyrene foam for insulation. At the same time, such a heater will allow you to get a double effect - to waterproof and at the same time insulate the room. For an optimal result, the expanded polystyrene is laid in a minimum layer of 5 cm. The next option, which also combines the two necessary effects of insulation and insulation from moisture, is represented by granular foam glass.

The cheapest option would be insulation in the form of broken brick, expanded clay or glass. But it will not be possible to isolate such a layer of insulation from moisture. Therefore, this option is not the best, although it is quite attractive.

It must be remembered that the insulation must not be placed over the entire free space between the layers. It is necessary to leave ventilation holes of about 5 cm. The air inflow will create an additional waterproofing effect. The heated floor is very popular today.

Helpful hints

Experience has shown that high moisture levels in a garage can be associated with groundwater near the floor surface. It is they who add moisture to the room, as they seep through the floor covering. This can create areas of high humidity and even small puddles on the floor. In this regard, it is better to ensure the outflow of water using ditches.

It will also help against precipitation, melting snow and liquids falling on the floor during a car wash or repair. Good waterproofing will provide protection from all of the above. If we talk about concrete coating, then we must not forget that dust will appear in the room from this material. It is possible to reduce its amount by using special impregnations or paints.

You can only get the right floor by checking each of the pillows with a level. A water-based level or a laser level is suitable. Laser levels are quite expensive, so it is easier to rent such a device. That is, the evenness of the layer can be determined without using pegs and markings.

The lifespan of any of the flooring options can be significantly extended due to proper care and maintenance of a positive temperature in the garage. Low temperatures cause the floor surface to crack. Because of this, the floor begins to collapse. You can also increase the lifespan by reducing your exposure to moisture and chemicals - for example, not washing a car inside a garage during the winter.

And if you can't do without it, then you will need to dry the coating afterwards.Keeping your garage dry can help reduce temperature changes. To make the flooring of high quality and last longer, choose options that are time-tested. To do this, it is not always worthwhile to obey fashion trends, since if you make the wrong decision, you will have to spend extra time and money on laying new floors.

Pay attention to alignment. If the cement floor is not completely flat, it will shorten its lifespan, as differences in height will contribute to the accumulation of moisture.

Reinforcement will help strengthen the covering and raise it slightly off the ground. In this case, it must be remembered that the floor will need to be thoroughly dried after pouring, and only then will it be accepted for covering, if it is supposed to. You can lay a floor of cement or concrete using linoleum or wood. The device of such a floor was described above. You can also finish it with porcelain stoneware, which will significantly improve the characteristics of the coating and extend its service life.

In this video, you will find a master class from professionals on pouring a self-leveling floor in a garage.

The comment was sent successfully.