Wood-fired garage oven: DIY making

Nowadays, many car enthusiasts install heating systems in their garages. This is necessary to increase the coziness and comfort of the building. Agree, it is much more pleasant to repair a private car in a heated room. Often, a car enthusiast is faced with the task of choosing the best suitable type of oven. The most common and versatile are wood-fired garage ovens.

Furnace types

The most common wood stove designs are:

- Potbelly stove.

- Potbelly stove with a water circuit.

- Brick.

- Long burning time.

- Convector stove.

Potbelly stove - the most common wood stoveused to heat the garage. The simplicity of the design made it very popular back in the twenties of the twentieth century. Any available material is suitable for its manufacture: old iron barrels, propane cylinders, a simple iron box.

The principle of operation is very simple: when firewood is burned in the firebox of the unit, the body heats up and gives off heat to the room.

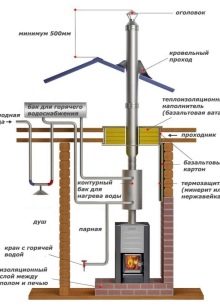

Potbelly stove with a water circuit is a modification of the potbelly stove. The main difference is the presence of a water circuit. It consists of a piping system, valves, expansion tank, heat exchanger, pump, radiators.

The principle of operation is as follows - the water in the heat exchanger heats up and enters the radiators through the pipeline system. As a result of heat exchange, heat enters the room. With the help of a pump, cooled water from the radiator is pumped into the heat exchanger for subsequent heating.

Brick oven - the most efficient in terms of space heating. Thanks to its design and the building material used, it has a high efficiency. Such a stove heats up quickly when burning with wood, and keeps it warm for a long time. The principle of operation is the same as that of a potbelly stove.

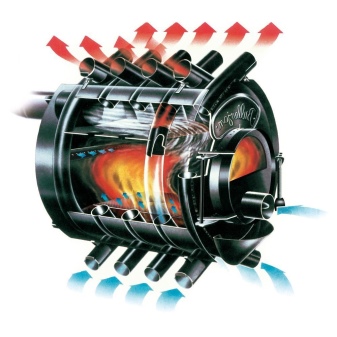

The convection oven is also a modification of the potbelly stove. Its design is distinguished by the presence of a forced convection system. It consists of a fan and a manifold.

Thanks to this system, the efficiency of the converter furnace is higher than that of a potbelly stove.

The principle of operation is similar to the principle of operation of a potbelly stove. The only difference is that the fan forcibly displaces the heated air from the collector into the room.

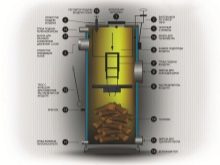

Long burning oven - this is also a modification of the potbelly stove. Its design uses an overhead burning effect. Due to this, this design has a high efficiency. Principle of operation: combustion in the furnace of the unit takes place under load, due to this, the fire zone has a small area. This ensures long-term combustion of solid fuel.

Advantages and disadvantages

Like any heating appliance, a wood-burning stove has its own advantages and disadvantages.

Let's take a look at some of the benefits:

- Relatively low fuel price.

- The versatility of the device during operation. You can use the heater to heat the room, cook and heat food.

- Installation and installation of a garage stove is very simple and does not require high costs.

- For the manufacture of the unit, materials at hand can be used.

- During operation, the use of additional installations and devices is not required.

- The small overall dimensions of the unit make it versatile when used in garages.

- The operation of such a device does not require the use of an additional type of energy (electricity).

The disadvantages of this design include:

- Such ovens have a high heat transfer, as a result of which they quickly heat up and cool down quickly.

- To maintain a high temperature in the oven, it is necessary to periodically add firewood.

- Constant monitoring of the heating process is required to ensure safety.

Peculiarities

For efficient operation of the furnace, its design must have certain qualities. Since the garage space is small, the stove must be compact first and foremost. Operating economy for a heater is also important. In addition, the cost of manufacturing the unit should be kept to a minimum.

It is necessary to provide for the possibility of heating with different types of fuel. This will make the unit cost effective. Making a stove with your own hands, you can make it as convenient as possible to use. Taking into account all your needs, you will create a unique and inimitable heating device.

First you need to choose the material from which you will make the wood-burning stove. Your skills in working with brick or metal will play a role here. But in both cases, it must be remembered that the heating device should not reduce the amount of oxygen in the room. It should generate heat for as long as possible to heat the room.

The basic rule during the operation of the furnace is the absence of emission of harmful substances.

When choosing the design of the heater, remember that it should not be fire hazardous.

DIY making

The most suitable material for making a potbelly stove is propane cylinders and a thick-walled pipe. Old metal drums will work as well. All options are possible. The main condition is that the wall thickness should be at least 2 mm and maximum 5 mm. If you do everything according to the drawings, then such a stove will serve for a long time and efficiently.

Which oven to make - vertical or horizontal, everyone decides for himself. It is more convenient to heat a horizontal stove with wood. But the vertical one is easy to use and takes up less space.

To make a vertical potbelly stove, we divide the pipe or cylinder into two unequal compartments. In the lower part we place the smaller one. Ash will collect here. At the top is a larger compartment for storing firewood.

Next, we do the following:

- Cut out rectangular holes in both parts. We do not discard the resulting rectangles, we will use them as doors in the future.

- We weld the grates to the most part. It can be reinforcement or any metal rods of the required size, with a diameter of 12-16 mm. The gap between the grates is 20 mm.

- We mount and weld the bottom.

- We make a hole at the top of the cylinder under the chimney. We make a pipe from a sheet of metal and weld it to the hole at the top of the cylinder. It is better to make a branch pipe for standard chimneys, so that later there will be no problems with its installation.

- We weld the hinges to the cut-out doors and set them on the stove. The unit is ready.

To make a horizontal potbelly stove, it is necessary to weld an ash box from below. It can be made from sheet steel. We make holes in the lower part of the furnace so that the ash spills into the ash box.

In the upper part of the heater (as well as on a vertical stove) we make a chimney pipe. We weld the hinges to the door and install it from the end of the product. The oven is now ready for use.

The design of the convection oven is an ordinary potbelly stove without a long burning modebut with forced airflow to evenly distribute heat in the garage. The unit is a potbelly stove with a built-in mini-fan in the back. It blows air through the guide pipes. These can be hollow metal pipes, a profile or a sheet steel box.

There the air is heated and blown forward. The garage space is heated quickly and efficiently. The oven is ready to heat the room.

Many people think that the best heating device for a garage is a long burning stove.Its design is based on a vertical potbelly stove. The main differences are the lateral location of the chimney in the upper part and the presence of a removable top cover with a piston. Cut a hole in the top cover and insert the piston. It presses on the wood inside the stove, providing "top burning".

Folding a brick oven in your garage is easy. It is necessary to have an ordinal masonry scheme and have skills in working with bricks. Be sure to strictly follow the ordering scheme. For masonry, fireclay mortar or clay with the addition of cement and sand is used.

Before installing the brick wall, you need to make a foundation with a height of 200 mm. A combustion chamber is laid out of refractory bricks. The door and the blower are located on the front wall. The grille is placed inside the appliance on brick ledges.

To make a furnace, 290-300 bricks are needed. The masonry is laid out on fireclay mortar. Gaps are left between the bricks. This is necessary for thermal expansion. The formation of cracks on the casing of the heater due to temperature differences will be minimized.

In order for the furnace to serve for a long time, the brick must be well fired and without cracks. If it is necessary to increase the height of the heater, this can be done by repeating the rows.

To make a furnace with a water circuit, you first need to build a heat exchanger. Various materials can be used: sheet steel or steel pipes. You will also need skills in working with metal and plumbing.

To supply hot water and return cold water, cut two holes at the top of the stove cover. We install a water tank at the back of the furnace, which can be made from a sheet of metal or an old steel barrel. The pipes for piping are installed in the openings of the water tank.

We are starting the installation of the pipeline. We consistently connect the pipeline with radiators and an expansion tank. The size of the tank should be 20% larger than the volume of water in the entire system.

If the closed water circuit is assembled correctly, then the water heated in the heat exchanger, according to the law of thermodynamics, enters the radiators through the pipeline. After the heat has been removed, the water is collected again in the heat exchanger.

Helpful hints

Having installed the stove in the garage, it is necessary to check its operability and fire safety:

- We put the firewood chopped to the size of the stove in the combustion chamber. We fill it by 1/3.

- Close the air supply cover.

- We light firewood in the firebox. We are starting to operate the furnace.

The heater must be installed at some distance from flammable liquids. The oven must be sanitized at least once every two weeks. The diameter of the chimney must be larger than the diameter of the exhaust outlet. This design prevents soot from accumulating.

All options are unique in their own way. Manufacturing costs can be minimal if you use the material at hand. You can also envisage the operation of the unit on different types of fuel. In addition, you yourself can come up with the design of the heater. This will make it unique and unique.

With any heater, your garage will become cozy and comfortable.

For information on how to make a super-oven from a cylinder, see the next video.

The comment was sent successfully.