We make a foundation for a garage with our own hands

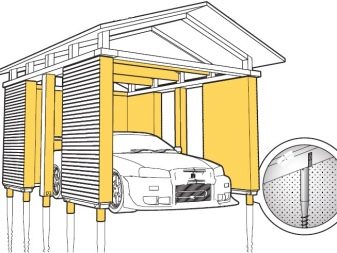

The construction of a garage, like any other structure, begins with the creation of a foundation - a foundation. A reliable base will provide the "home" for your car as long as possible.

Varieties

In construction, several basic types of foundations are common. They differ in the following parameters:

- by the method of resting on the ground and configuration;

- on the materials from which the foundation is laid.

Consider the four main categories of foundations.

Columnar

The construction of such a base is made of pillars made of stone, rubble (scrap stone) or brick. Supports are erected with a step of approximately 1.2 to 2.5 meters under the most important points of concentration of the loads of the future structure (intersections of walls, corners, in places where heavy boiler equipment is installed, etc.). In order to connect the separately standing pillars into a solid structure, beams are placed on top of them, connecting the heads of the posts, as a result, a finished base comes out.

Separately, it should be said about the columnar foundation made using the TISE technology. Its principle consists in drilling wells at the points of installation of supports, then strengthening them with reinforcement and filling them with concrete. Another name for this base is columnar monolithic. The lower segment of the pillar (sole) is widened.

Distinctive characteristics of the foundation:

- Can be used on light soils that are not prone to movement (displacement) and a strong increase in volume (heaving). Excellently proved itself in deeply frozen heaving soils.

- An excellent solution for the construction of low-rise buildings (timber, panel, frame houses).

- Reasonable price, minimum costs of working time (in comparison with other types of grounds).

- Does not require a waterproofing device.

- It is used for structures without basements.

- A solid, cheap foundation, intensively practiced in private construction.

Tape

The name of the foundation is entirely consistent with the visual representation of its structure. This is a tape of reinforced concrete, stretched under all the load-bearing external and internal walls of the building.

The manufacture of such a base requires the implementation of a large scale of earthworks and the cost of building materials, in comparison with the above-described analogue.

Distinguish:

- Shallow strip foundation - suitable for lightweight buildings made of blocks, logs, frame structures. The depth of the location is not more than 70 cm, that is, not below the border of soil freezing. Suitable for constant soils or heaving (dispersed), deep freezing soils.

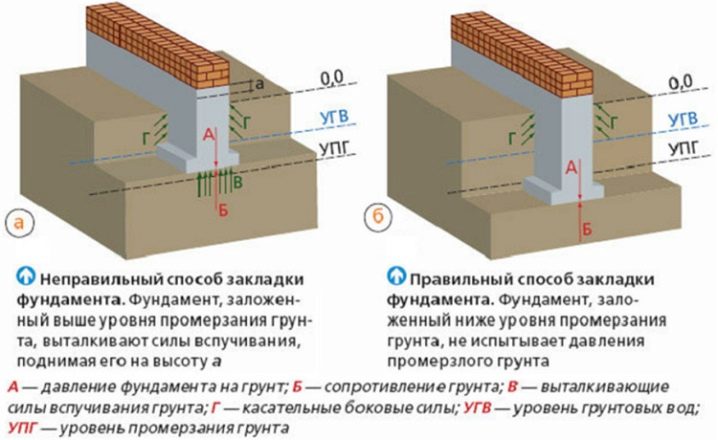

- Recessed foundations - settle down below the freezing depth. Able to withstand heaving (increase in volume) and soil movement. Suitable for heavy brick, stone and other buildings. If the structure is built of light materials and has a small mass, then it is better not to make such a foundation, since the weight of the structure will be very small for the stability of the foundation during the period of heaving and soil movement.

- Monolithic tape - the finished formwork, reinforced with reinforcement, is poured with concrete mortar. The precast belt is a base of large reinforced concrete foundation blocks.Weak point: when constructing a foundation of complex configuration, some inconveniences may appear. The main advantages of such foundations are: operational flexibility (suitable for almost all types of soils and types of buildings), as well as the possibility of building cellars, garages and basements.

Pile

This type of foundation is optimal for weak soils, when it is necessary to shift the load from the building to harder layers. In addition, the pile foundation is intensively practiced for the construction of houses on construction sites with slopes, large irregularities. Of course, you can lift the ground and level the construction site. Nevertheless, the use of piles will be cheaper.

The structure of the foundation consists of piles located separately, connected by a grillage (beam).

By lowering each pile to the calculated depth, you can easily get a horizontal surface of the beam for the construction of walls.

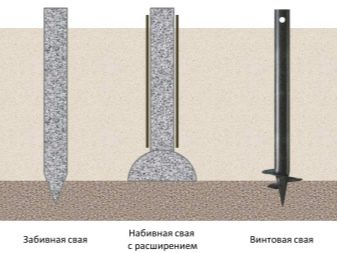

Types of piles:

- Hammered... They are not practiced for the construction of low-rise buildings due to economic unjustification. Special equipment is required to drive the piles into the ground. As a rule, they are used in the construction of industrial and civil structures.

- Bored... A well is drilled in the ground, which is filled with a concrete solution. The upper supporting parts of the piles are set at a certain height and connected with a grillage. Piles are reinforced and unreinforced.

- Screw... The piles are made of metal, at the end immersed in the ground, special helical blades are provided. They are widely practiced in the construction of low-rise buildings, since they make it possible to quickly prepare the foundation.

Plate (Swedish plate)

A strong and heavy base for the construction of structures from blocks, logs, bricks. This type of base is also called floating, and it can be used on almost any soil (including clay, peat and with an increased level of heaving). The slab foundation is cast on a sand and gravel cushion to the size of the structure or a little more.

When the soil moves, the base "floats", which saves the structure from destruction.

- A shallow slab base is constructed on the soil surface (only a pillow is being prepared). There is no possibility of building a basement.

- Recessed slab base. For its construction, a pit is being dug, on the base of which concrete is poured to obtain a slab. Suitable for buildings with a basement, cellar, garage. Separately, it should be said about the modern slab base - a Swedish plate or USHP (insulated Swedish plate).

Its feature is the side edges and bottom insulated with extruded polystyrene foam, conducting communications inside the platform, as well as the "warm floor". USHP is a heated basement for a floor covering, a foundation, a floor covering of the first floor.

On this slab, you can immediately erect walls, and upon completion of construction, lay the topcoat of the floors.

Which to choose?

The choice of a suitable foundation is an even more responsible and important task than the construction of the garage itself (except for a pencil case type garage). Since the service life of the entire structure will depend on the reliability, stability and strength of the foundation.

So what kind of base should you choose for your garage? Here's a rough set of simple rules:

- If the soil is swampy and the level of groundwater is high, then it is better not to build a basement and a viewing hole, but to arrange the foundation either slab or on piles.

- Do you live in a permafrost zone? Then build a slab or pile foundation.

- If you do not need a basement and a viewing hole, then you can arrange either a shallow strip foundation or a slab base.

- If the site has a complex relief, then a pile foundation with a reinforced concrete grillage is ideal.

- If a basement is required, only a strip foundation.

How to calculate?

Due to the fact that the capital garage can be built from cinder block, brick, gypsum block, foam block, from aerated concrete blocks, gas silicate blocks, foam block bricks, expanded clay concrete blocks, and, as a rule, has small dimensions, it can be built according to hand-drawn diagrams without detailed calculations ... But the foundation for the garage room must certainly be calculated, since the depth of the laying determines its durability and bearing capacity during operation.

This value depends on:

- the weight of the structure;

- groundwater level;

- the maximum depth to which the soil freezes in winter.

These indicators are constantly taken into account when calculating the foundation. The main factor is the depth of freezing, since it reflects the level of expansion (heaving) of the soil. Therefore, the depth of the foundation (d) is determined by a simple formula: d = the depth of soil freezing in the region + 20% (m).

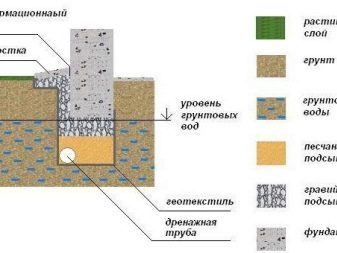

With an increased level of groundwater, the stock can not be calculated, but pay close attention to the waterproofing of the foundation parts.

Be sure to take into account the additional distance for making a sand or gravel cushion - 20-30 cm.

Dimensions (edit)

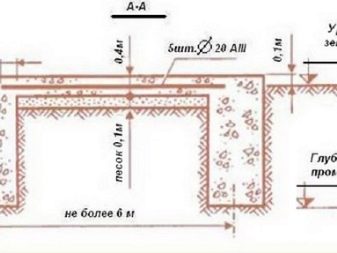

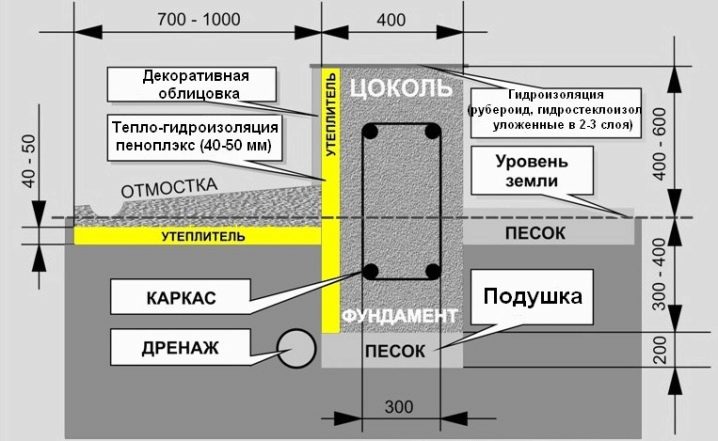

To calculate the width, you need to know what the garage walls will be built from. The thickness of the beam or foundation tape should be 20-30% greater than the wall thickness (for a wall of 300 mm blocks, a beam with a width of 360-390 mm is made along the length of all sides of the foundation).

To calculate the required height of the tape, you need to know what soils are at the base, what is the weight of the future building and machine. The base for the garage, the depth of the bookmark of which is revealed by the level of freezing, is considered to be + 20-30 cm high to the resulting value. For solid soils, approximately 60-80 cm is taken (the total height from the bottom plane of the foundation to the top, excluding the pillow), for heaving soils - 1-1.5 meters.

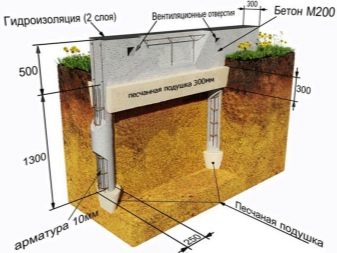

The length of the piles is calculated according to the principle: the level of soil freezing + 1.5 meters, approximately 2.5-4 meter products will be required.

The perimeter must be thought out in advance: the minimum permissible wall length is 3-6 meters. The best option for a garage 4x7 meters - in such a place there is enough space for the free dislocation of a car and the movement of a person.

You can set personal dimensions: add 1-1.5 m to the length and width of the car (or another value that is most optimal for you).

How to do it yourself in stages?

The most common type of garage foundation is tape. Using his example, we will analyze the step-by-step process of building the foundation.

Markup

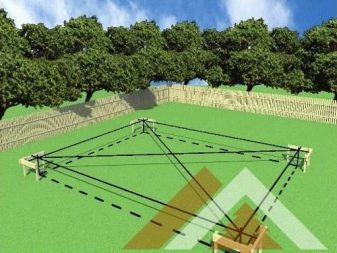

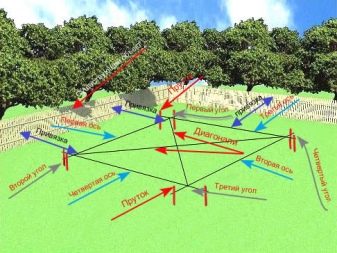

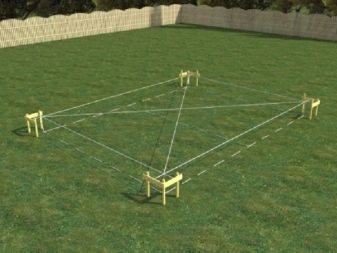

Strip footing involves creating an angle of 90 degrees. This is done like this:

- According to the plan of the future garage, we determine the location of the right front corner. We hammer in the first peg. This will be the front corner of the garage.

- From it we measure the required distance to the second auxiliary peg and drive it in.

- Pull the fishing line (rope) between the hammered stakes.

- Now from both pegs we pull the ropes at a right angle perpendicular to the first line. And we put the third and fourth marks (we drive in the stakes).

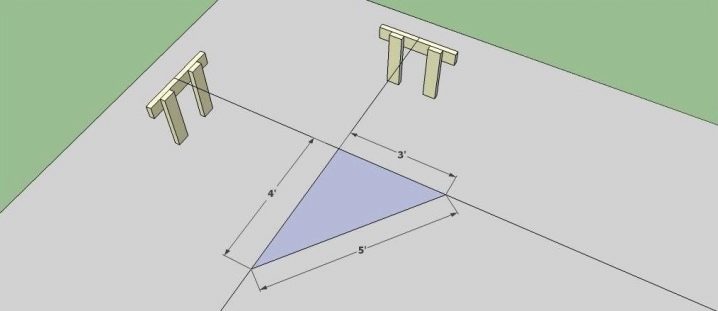

The result is a rectangle. To check the accuracy of the markup, you can use two methods:

- Measure the rectangle diagonally. They must be equal in length.

- From the corner, measure a distance of 3 meters in one direction and 4 meters in the other. With normal marking, the distance between the points will be 5 meters. The exact same check must be done at each of the corners.

If everything is marked correctly, you will not have to deal with rearranging the pegs from place to place, but you can proceed to the next stage.

Digging a trench. You can dig a ditch with your own hands using a shovel. The bottom of the ditch must be perfectly flat. Therefore, in the process of work, use a water level.

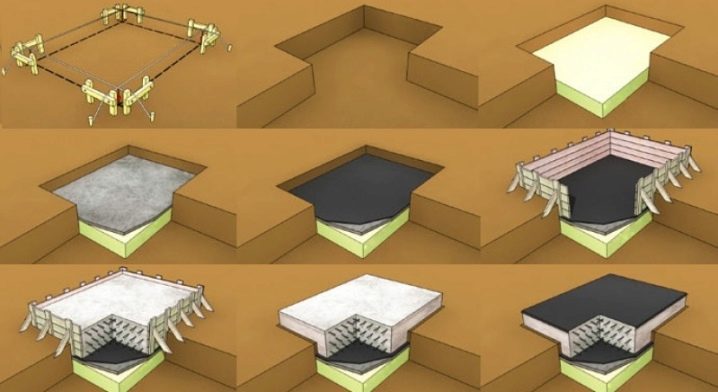

Formwork

To create the formwork, use sheets of plywood, boards or chipboard more than 2 cm thick.Knock off the shields and lower them into the ditch on both sides. Secure with wooden blocks. Install spacers of equal length between the shields. Thus, you will form the same formwork width around the entire perimeter.

Place supports on the outside of the formwork. Cover the bottom of the ditch and the side sections of the formwork with waterproofingto prevent leakage of liquid from the concrete solution.

How to pour concrete?

Concrete M 200-M 300 is suitable for the foundation for the garage. Concrete can be made independently or use factory material. A more reliable base will come out of the factory solution, because it is quite difficult to comply with the technology for its manufacture at the construction site.

Work can be carried out in two ways:

- continuous;

- layered.

The continuous technique ensures high quality casting of the structure. If you need to take a short break in the work, the concrete solution is poured in a layer-by-layer method.

Remember! The top layer must not be leveled; for a stronger adhesion with subsequent layers, it must be uneven.

When ordering a factory solution, the work process should not cause problems. The mortar is fed into the formwork from a concrete mixer, it is laid by means of specialized sleeves, compacted and leveled by vibration.

If possible, pouring concrete mortar should be carried out at temperatures from +15 to + 25 ° C... If the foundation is poured in a cold season, special additives are used and the construction site is heated.

Waterproofing

After removing the formwork panels, the concrete surfaces are treated with waterproofing materials.

For a tape-type base, 3 methods of protection against excess moisture are required at the same time:

- vertical;

- horizontal;

- blind area.

The vertical method is carried out by means of deposited or coating materials on the outer surface of the recessed section of the foundation. The horizontal one is made of weldable materials on the surface of a concrete strip.

Blind area (concrete strip) prevents rainwater from entering the structure... After completing all work below zero, backfill with sand or soil.

Laying the base from other materials

There are alternative options for the foundation:

- from tires - you can use tires for trucks and cars, tractors, buses, airplanes (suitable only for light structures);

- from sleepers - an excellent solution for the construction of the foundation when you need to do without the use of traditional materials;

- from FBS - has considerable advantages, including excellent quality, as well as a relatively low price;

- from road slabs - can be used on almost any type of soil and in all climatic zones.

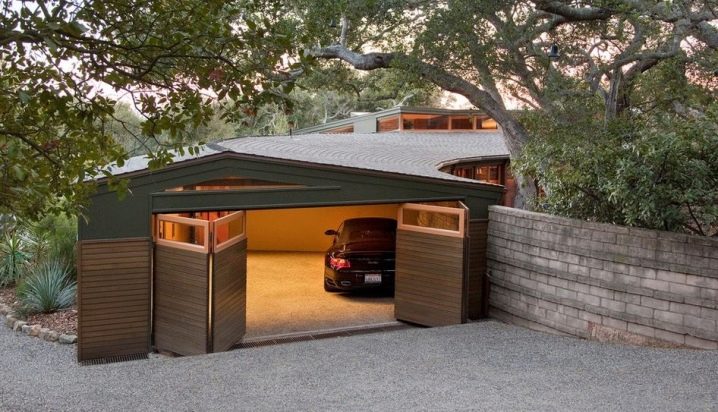

Features of docking with the house

Throughout his life, a person tries to form a comfortable and laconic space around him. One of the best solutions in this case is to add a garage to the house. The extension can be located on the left or right side of the house. It is important to choose the shortest distance from the entrance to the courtyard to the garage... Actually, the location of the gate determines the placement of the extension.

Ideally, an extension garage should be built even when the house is being built., then the house and the garage will stand on the same foundation. If you will be building a garage after the construction of the house, do not neglect the foundation arrangement. A strong foundation as an increase in strength will not hurt. Then the house and the extension will shrink at the same time.

The smallest distance of doors and windows in the house from the technical structure is 2.5 meters, and the smallest distance from the balcony to the ridge of the garage roof is 2 meters.Since the extension belongs to fire-hazardous technical buildings, during its construction, it is imperative that all the necessary conditions regarding fire safety be strictly observed.

If it is planned to install swing doors between the house and the garage, then you will need to observe the "blind zone" or free space for the movement of the canvases.

Advantages of the extension:

- Eliminates the need to lay a separate route for water supply, heating, electrical wiring.

- Saving building materials.

- Facility maintenance is simplified.

The extension allows you to equip the room with everything you need:

- a garage with a pit;

- basement;

- cellar;

- workshop;

- electric lift.

The nuances of building a garage on a slope

When developing a garage project, it is necessary to take into account the level of steepness of the site. With its increase, the creation of a building project becomes more difficult. Sometimes, the high steepness of the slope does not provide opportunities for the construction of a garage or a house. To create an underground part of a garage or a house, you will need a grillage pile, columnar, tape stepped or multi-level slab foundation.

You can set the slope level during construction with the difference in heights of the lower and upper points of the construction site, projected onto a line parallel to the horizon plane. This parameter is measured as a percentage. For example, if the horizontal distance is 100 meters, and the rise of the points is 15 meters, this means that the slope of this section is 15%.

In this regard, the territory can be conditionally:

- Smooth... When the slope of the surface is less than 3%. This is the most prosperous site with the lowest construction costs.

- With a slight slope from 3% to 8%... Such areas are suitable for the construction of structures without a basement. In order to expand the area from the submontane side, you will need to add soil.

- With an average slope of 9% to 20%... In such a situation, you can build a basement floor. The terrace does not need to be leveled, but the lower floor is constructed by removing part of the slope soil. This is a very good option for building an underground garage in the basement, with access to it from the direction of the slope.

- With a strong slope of more than 20%... This option requires a thorough development of the design of the structure for the possibility of the maximum exploitation of a gentle slope. The cost of such a project is quite high.

Helpful advice: for any slope of the site, the building must be located at its highest point in order to create conditions for the natural runoff of water. In this case, it should be taken into account: if there are still sections higher along the inclined plane, then it is necessary to arrange the water flow from these places not through ditches, but through specially provided pipelines, which minimizes soil erosion.

When constructing a building, the choice must be made in favor of a site on which the slope is directed to the west or south, this will affect the rate of heating of the soil, especially in spring. The greater the verticality of the inclined plane to the sun's rays, the more it will receive heat. This can be clearly seen when the snow melts in the spring.

In addition, at low temperatures and at night, when the air cools, it descends down the slopes and fog begins to collect. As a result, when the site for the construction of the structure is located near the lower point of the depression, there will be a night or seasonal temperature drop on it, which is formed by the upper and lower points of the site.

When constructing a structure at the highest point of the site:

- The foundation is minimally exposed to surface and groundwater.

- In this situation, it is easier to divert surface water from the upper point and, if necessary, use it for watering the personal plot.

- Building at the highest point makes it possible to optimally solve the problem of water drainage.

We must realize that on such a difficult terrain, financially beneficial construction will not work. The costs of a zero cycle, digging a hole, drainage and monolithic works, building retaining walls, and so on can offset the price of the garage itself.

Remember: regardless of the fact that the garage is not a responsible structure, it must be built on a reliable foundation in compliance with all rules and regulations... Only in this way will the "housing" for your car be ideally protected from the negative influences of nature.

You can learn how to properly dig a trench under a strip foundation by watching the video below.

The comment was sent successfully.