Greenhouses and greenhouses for summer cottages: features of choice

The cultivation of cultivated plants forces people to provide the necessary conditions for them. It is not always possible to do this outdoors. But in order for a greenhouse and a greenhouse to really protect vegetables and flowers from negative weather influences, you need to choose them correctly.

Views

Greenhouses and greenhouses are not synonymous. A real greenhouse is more expensive than a greenhouse, it is much harder and more expensive to build. You will have to choose materials as thoroughly as possible, since the service life of the structure depends on the decision made. And greenhouses are almost always temporary in nature; it will not work to operate them in the winter months, since heating cannot be organized.

Speaking about the properties of structures, several factors should be noted:

- The greenhouse is mounted in a strictly defined place. The greenhouse can be moved to one point or another every year.

- A greenhouse is larger than a simple greenhouse and has a different base. Its frame must be strong and solid (a prepared foundation).

- The upper part of the greenhouse for a summer residence should be made as reliable and high-quality as possible, because long-term work is expected.

- Greenhouse construction is invariably more expensive than greenhouse equipment.

When equipping a summer cottage with a greenhouse, one cannot but take into account the peculiarities of its specific types.

Graduation is carried out both on the frame and on the covering materials. The structure of the frame can be as follows:

- with vertically directed walls;

- with an inclined arrangement of walls;

- with one slope;

- in the form of an arch;

- with two slopes;

- with an attic roof type.

As for the coating, there are only three possible substances - glass, polycarbonate, and plastic wrap. Greenhouses are basically shallow pits, which are filled with soil or an artificial mixture of earth, and covered with a frame on top.

The most economical type of greenhouse is a buried building.

But such a structure cannot be put on loam or clay just like that. You will definitely need to take care of drainage and water disposal as follows.

The Scandinavian type of buried greenhouse is formed from simple plastic boxes (those that hold bottles of food liquids). An ordinary arched greenhouse helps to save money, the problem of which is only one - the rapid deterioration of the plastic film. Therefore, it is advisable to use the most available grades of material. Single-slope structures are needed mainly for the cultivation of root crops. They are made with three walls running along the outside of the garden bed. Improved varieties are equipped with fixed walls and glazed frames (alternatively, you can stretch a film in them).

Gable structure - these are paired frames drawn with a film or glazed structures connected by canopies. Depending on the customer's decisions, the sidewalls are made stationary or covered with a film in the shape of a triangle. Improvement of thermal insulation is achieved by overlapping the joints with polyethylene strips. If convenience comes first, you should choose portable greenhouses. The only problem with them may be the excess storage space.

Specifications

To cover greenhouses and greenhouses, you can choose any material that seems convenient. Polycarbonate buildings are filled with diffused light from the inside, keep the air temperature well and are very durable.Even more light passes through the glass, but it is heavy and fragile. It is most practical to equip portable (prefabricated) modifications of greenhouses with plastic wrap, it allows you to radically simplify the work. Regardless of the material of construction, solutions with self-opening vents are of great benefit.

The fact is that the weather can be not only bad, but also changing.

Sudden changes in temperature can slow down the growth of plants or even destroy them altogether.

Both cold and heat can have this effect. Thanks to modern technology, you don't have to track all the changes yourself. Automatic opening of the vents is provided by both mechanical and electrical devices.

Electrical devices are characterized by:

- excellent response to temperature changes;

- the ability to set a timer mode;

- attachment to sources of electrical energy.

The last circumstance is extremely important. In many cases, a sudden shutdown of the machine can ruin the entire crop. That is why it is desirable to have an additional energy block, and not only the main one. As for mechanical vents, they can be made in horizontal or vertical design, and it would be more correct to call them thermomechanical. Bimetallic complexes work due to unequal expansion of metals when the temperature changes.

The mechanics have both advantages and disadvantages:

- energy independence;

- elimination of unnecessary odors;

- the ability to ventilate a large greenhouse with two vents;

- the complexity of the setup;

- high price;

- slow response to changing conditions.

Materials (edit)

The construction of greenhouses and greenhouses made of film has its own characteristics. Planks, metal fittings, PVC pipes can be used as a frame. The connection is achieved through steel corners, self-tapping screws. It is very important to take into account that the film materials in the construction of greenhouses and greenhouses are far from homogeneous. Traditional polyethylene material roll type can have a width of 120 to 300 cm.

Experts recommend buying a film no thicker than 100-150 microns.

The thicker one is able to work longer, but it will no longer be possible to use it next year. For small greenhouses, such a solution can be considered the best. Reinforced options - essentially the same polyethylene, only denser and stronger, with a cellular frame. To grow vegetables indoors, you need to choose products with a density of 0.12 - 0.2 kg per 1 sq. m.

Fiberglass it is used extremely rarely, much more practical, according to operating experience, specially processed polyethylene and polypropylene. A more expensive, but also more effective subspecies is a "breathable" covering material, which has a special hole in the middle. PVC is preferred in places where the most intense lighting is required. It blocks the entry of harmful parts of the spectrum well. But one cannot fail to take into account that this material is expensive and does not tolerate severe frosts well (but without them it serves from 5 years).

By adding special additives, the covering film acquires different characteristics.

Some components prevent the destructive activity of light, while others prevent dripping condensation from occurring. There are also substances that block excess heat and dust accumulation. Phosphors play a special role, some of which absorb ultraviolet rays, while others reflect infrared radiation. To have several functions at once, the film is made multilayer.

In addition to polyethylene, ethylene-vinyl acetate copolymers are rarely used, which:

- serve over 7 years;

- tolerate cold temperatures up to -80 degrees;

- let in 92% of the light;

- perfectly tolerate tearing and abrasion;

- can survive gusts of wind up to 18 m / s.

There is only one drawback - a significant cost.Polyamide film is very good optically, it keeps heat stably, but as soon as it gets wet, the coating will swell and stretch. Such a film will not last more than two seasons. Three-layer air-bubble matter has polyethylene on the outside, and a bubble layer is created in its core. Coloring helps to identify the exact characteristics of a material.

So, it is best to use the black variety as a covering film. Blue and blue material is excellent at resisting condensation, but decomposes in soil in 3-4 months. Pink films with three layers transmit quite a lot of light and are mechanically strong, last 5-6 years. The black and white type is intended for the prevention of sunburn.

Dimensions (edit)

Regardless of the material used, the size of the greenhouse or greenhouse must also be evaluated. If they turn out to be too small or excessively large, the result will be the same - serious losses, discomfort and inconvenience. The main rule here is to focus on the size of the area where the structure will be located. An equally important point is the compliance of the greenhouse with the needs of the owners. Growing a huge crop for a small family is completely impractical.

It is undesirable to completely allot garden plots under a greenhouse or greenhouse.

Always leave a reserve of space for planting plants in the open field. When a design is chosen for commercial purposes (growing plants for sale), the estimated turnover becomes the main criterion here. In any case, it is undesirable to buy or build very small greenhouses, because with sufficient space, heat accumulates better in spring and less damage from heat in summer. The key parameter is width, all experienced summer residents know that it is harder to care for plants in a narrow space.

The ideal greenhouse width is 220-250 cm (for two beds), or 350 cm (when there are three beds inside with a couple of aisles between them). If we take into account the width of the doors, the minimum size is 2.4 m. When it is supposed to use wheelbarrows or carts, it makes sense to make doors from 90 cm or more. In the variant with a pair of aisles and a centrally located rack, constructions with a width of 370-400 cm are used. As for the height, it should be such that the plants have sufficient room for development; the length is chosen arbitrarily.

Forms

Consumers can choose a greenhouse of various shapes:

- hemispherical;

- rectangular;

- pyramidal;

- drop-shaped;

- trapezoidal;

- oval;

- triangular.

The oval shape is considered the best among builders, as it greatly simplifies the work. The only problem is that in the absence of strictly vertical walls, it is impossible to grow plants directly at the edge of the structure. A-shaped articles are preferred because they can be coated with relatively rigid covering materials, not just films. Rigid structures are becoming more and more in demand over the years, but the problem is that only professionals can build them properly. Therefore, the total cost of construction increases markedly.

Selection Tips

It is really useful to focus on the characteristics of materials and forms, on the reputation of manufacturers and even customer reviews. But all this will give a positive result only in one case - when consumers clearly understand what exactly they will grow. Seedlings require some conditions, while leafy greens require others. For tomatoes and cucumbers, a suitable microclimate is diametrically opposite, and it is impossible to keep them together. And even for each variety, it is necessary to select the optimal cultivation regime.

For zucchini, you need to use both film and polycarbonate greenhouses (hotbeds).

In the winter months, only structures installed on a solid foundation can be operated. The covering material in this case is glass.According to the majority of summer residents and experts, the height is not too significant. But equipping the greenhouse with vents is strictly required.

Manufacturers

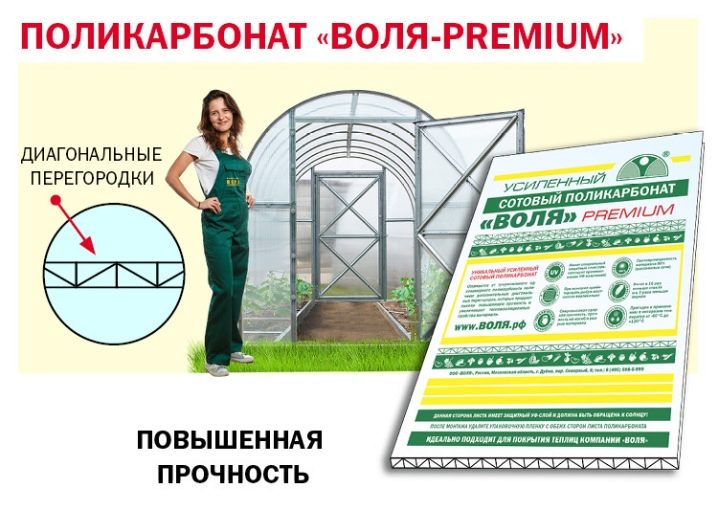

A greenhouse for any kind of crops can be made by hand. But products designed by trained engineers turn out to be much safer and more perfect. Company projects "Lotus" have long become popular among summer residents and gardeners. A striking example of the products of their competitors is the model "Will Premium"... The size of the structure is 89x80x210 cm.

For the manufacture of the frame, a zinc-coated pipe with a section of 20x20 mm was used. The product has a 24-month warranty and does not require foundation construction when using it. The main construction material is polycarbonate. To let air in or water the plants, you just need to open the lid. The greenhouse is very wide, but thanks to the ability to open the walls, it is quite simple to use it.

Volia has accumulated significant experience in the production of greenhouses and has its own industrial facilities, a modern engineering center.

Very good results are achieved with a greenhouse "Droplet". In its manufacture, only modern technologies and high-level polycarbonate are used, as well as a reinforced frame that can freely transfer significant loads. Even a snowy winter with strong winds will not cause the destruction of such a product.

The form of the structure is fully reflected in its name. In production, carefully selected anti-corrosion materials are used, which allows to increase the operating time of the product. The "Droplets" are based on rectangular tubular profiles, their cross-section is 2x2 or 2x4 cm. The designers have provided for both the lengthening of the structure and the division of its internal volume into compartments. There are vents at the ends, which improves the workflow many times over.

Best options

The rating of polycarbonate greenhouses and greenhouses will allow you to finally make an informed choice.

The undisputed leader in reliability is the model "Gift" from the Dubna company "Volia". It is equipped with a retractable roof; and even if users leave it in place, there is no risk of being destroyed by snow.

But Cherepovetskaya "Fortress" stands out for its unusual shape. It is not always possible to find a greenhouse with straight vertical walls and an arched roof on the market. Judging by the reviews, such a product is very convenient for a garter of plants.

In the production process, a square profile is used.

Carefully selected screeds and paired arc trusses can withstand pressures of up to 170 kg per sq. m.

The third well-deserved place is "Novator 5" - this design is convenient and lasts a long time, it is equipped with a removable roof and is well ventilated due to the extension of the compartments. The single section weighs only 8 kg. Piles can be fixed to the profile lugs. It should be taken into account that this greenhouse is unsuitable in winter, and for assembly it will be necessary to cut the cellular polycarbonate into many small parts. Connecting fasteners sometimes causes some inconvenience to users.

For how to easily and quickly make a greenhouse for the beds with your own hands, see the video below.

The comment was sent successfully.