How to make a greenhouse in the country?

In order to harvest a large crop of pepper, you need to know how to provide optimal conditions for its growth. Experienced gardeners know how to make a homemade greenhouse with their own hands. They know well which types of greenhouses are suitable for a particular plant variety, which materials are better and more profitable to use for arranging a structure that protects the soil and seedlings.

Appointment

Garden owners, by definition, are well aware of the purpose for which soil protection structures are used.

You should start with clarification. Not everyone knows how a greenhouse differs from a greenhouse. Let's look at the examples of the nuances of the device of these structures. Let us determine what tasks are solved by the specifics of these structures.

What makes a greenhouse and a greenhouse different?

A greenhouse and a greenhouse are similar structures designed to protect those planted in the ground. To clearly understand the difference, let's define what soil protection is. The thematic literature says that in order to protect the soil on which various plants are grown, special structures are used to ensure the process of natural or technical heating.

These designs include the products described below.

- Greenhouses with a frame of wooden and metal parts, with glazing or foil as a covering material.

- Greenhouses made in the form of recesses with strapping, or bases covered with window frames with glass or PVC foil.

- Frame structures, the supporting part of which consists of wire or plastic, covered with films.

- Frameless modifications in the form of frames covered with foil. These special structures play a protective role for the soil and the seedlings planted in it. In all cases, protection is provided by a covering material, which can be used as a cheap non-woven fabric, polymer film, polycarbonate or glass.

Views

Greenhouses are shared by:

- by service life (in winter, spring, summer, autumn);

- by the type of supporting structures (without a frame, frame, multi-span);

- by specialization (growing vegetables, sprouting seedlings);

- covering material;

- by shape (vertical / inclined walls, shed / gable, etc.).

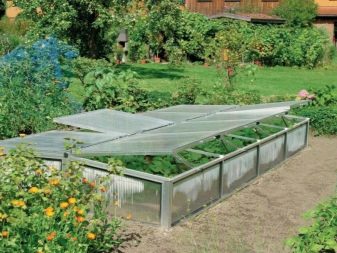

Individual considerations due to local requirements can vary significantly. Structures can look like small greenhouses in a garden bed, or, in a budget version, like a comb covered with a film. The main task is to make the plants feel like at home.

Modern budget solutions are of particular interest to domestic buyers - greenhouse "Snail" (portable version) and small greenhouse "Lotus"... To understand their installation will not be difficult even for a person who is far from technology. The instruction included in the kit explains all the nuances in detail and step by step.

The portable "Snail" can be installed in any area. The structure will fulfill the declared functions even when installed on the ground without a prepared foundation. There is the possibility of rotating the mini-greenhouse in the beds, for alternately growing seedlings in different parts of the garden. Installation of the structure will not take more than an hour, which is a significant bonus.

A competent gardener starts by growing greens and vegetables that can be protected by a greenhouse. Its dimensions are much smaller than a greenhouse, which does not make its protective properties worse. The supporting structure of the "Lotos" greenhouse is made of zinc-coated pipes.

The cover is cellular polycarbonate. Unlike a short-lived film, polycarbonate will last more than one season. It is easy to care for and provides maximum illumination for the plants. The airing of the structure is carried out using two flaps (like lotus petals).

The opening that opens with a slight movement provides the necessary supply of fresh air.

Materials (edit)

Installation of any type of product begins with the construction of the supporting structure. Consider the typical types of materials from which the frame for greenhouses is made.

Arcs

It is not in vain that arched greenhouses are respected by both experienced gardeners and beginners. It is difficult to overestimate the simplicity and speed of installation of this structure during a flash frost. Its dismantling is just as easy and simple, does not require special skills and special efforts.

The main components of the structure are arcuate elements that can be made in a handicraft way.

It is rather difficult to discuss the properties of a particular material. In certain conditions, disadvantages can become an advantage. Consider the main characteristics that necessary for the effective functioning of the structure:

- Strength... The arcs must withstand bending stress, rain and snow. They must also resist deformation of the coating material.

- Ease of care... The less attention is required from the gardener, the more time he will be able to devote to the garden plot.

- Low weight. This feature is especially important when growing seedlings alternately in different parts of the garden.

- Good flexibility. Gone are the days when the manufacture of arcs could not do without a pipe bender. This property is important for many factors. It affects the stability of the shape of the greenhouse, its rigidity.

- Fortress and durability.

Arcs are made:

- from metals (with various coatings);

- made of plastic;

- from improvised material (wood, boards, willow twigs, wire, fiberglass reinforcement).

Frame made of shaped pipes

Typically, a metal profile pipe is used for the installation of polycarbonate-coated greenhouses. Obvious advantages:

- special strength will allow you to easily withstand the weight of the plastic coating, resist climatic influences (snow loads);

- rigidity a metal frame made of a professional pipe allows you to easily fix additional equipment (irrigation, lighting and heating systems).

Among the shortcomings, one can note the inflated prices for the material and its tendency to corrosion.

Frame made of HDPE (polypropylene pipes)

Consider the pros and cons of this material.

Advantages:

- environmental friendliness;

- flexibility;

- ease.

Disadvantages:

- limited temperature mode of operation (fragility at -15 degrees);

- deformation under the influence of ultraviolet radiation.

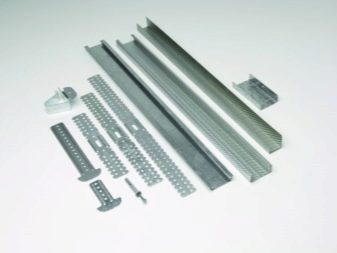

Metal profile frame

Pros:

- anti-corrosion (aluminum and galvanized profile);

- strength;

- design variability;

- installation on a foundation;

- efficiency in the winter;

- light transmission (large openings);

- long service life;

- versatility (all climatic zones).

There are also a few small drawbacks - high prices and not very reliable fastening methods.

Frame made of metal-plastic pipes

The basis of this construction is an aluminum base covered with a sheath (polyethylene). Bonded polymer layers protect the metal core. These components are flexible enough to provide the required functionality of the design.

Covering materials

Differ in structure to hard and soft.

The first type includes glass and various types of polycarbonate.The second - PVC films, reinforced films, non-woven material.

Until now, the most demanded covering material is polyethylene film... The source of such popularity is the optimal ratio of quality and price.

Technologies are rapidly developing and thanks to them, the characteristics of long-known materials are improved. Modern films have:

- hydrophilic properties (their surface does not allow condensation to accumulate);

- heat saving;

- resistance to ultraviolet radiation;

- antistatic ability - the film does not attract dust, increasing the light transmission feature;

- increased strength (reinforced film);

- the ability to stretch (stretch).

However, disadvantages can also be traced - such a film weakly resists impacts and cuts, and also quickly deteriorates.

Agrofiber

Unlike films, this material is more durable. Wear resistance is achieved through polymer fibers. Differs in lightness and ability to pass moisture, but does not keep warm enough.

Glass

Everyone is familiar with the glassy shine of greenhouses, especially industrial greenhouse complexes. The absolute light transmittance of glass is unmatched.

The main disadvantages are fragility and large mass.

Spunbond

The most popular greenhouse covers are made from spunbond. Consists of polymer fibers. It is considered the best covering material. Nevertheless, after each season, disinfection must be carried out - spunbond accumulates fungi and all kinds of viruses well.

Making homemade structures

Having familiarized ourselves with the key points and the main characteristics of materials for protecting the soil, we will consider, for example, the process of constructing a homemade summer cottage for pepper. What makes a greenhouse different from a greenhouse is that it does not provide heating. To make it convenient to use the greenhouse, it is necessary to think over all the technical points in advance.

The pepper guard must meet the following requirements:

- have adequate lighting;

- provide full access for regular watering;

- well ventilated (to exclude waterlogging);

- keep warm.

To ensure the most comfortable conditions for growing pepper, you need a lot of light and heat. In order for the installation work to result in a functional structure to protect soil and plants, it is necessary:

- decide on a place;

- make a list of materials;

- think over the stages of installing the base of the structure;

- choose a cover.

The choice of location is determined by:

- illumination;

- smooth surface (without bevels and ditches);

- optimal distance from trees and buildings;

- orientation of the structure from east to west;

- dry area without waterlogging.

Site preparation

It is recommended to install a greenhouse for pepper on warm warm soil, which can provide normal conditions for the functioning of the root system of plants.

We deepen the selected area to a depth of half a meter, level the bottom layer of the pit. It is recommended to remove all old roots from the ground.

We make a homogeneous mass from straw, clay and water. With this mixture, fill the cavity half the height, wait until it dries. We prepare humus - we mix dry leaves, scraps of paper, bird droppings. Pour the resulting mixture onto the dried clay solution and set it on fire. A depression heated by burnt humus can be covered with slate for greater ground warming. After the end of smoldering, the ash is evenly distributed over the area of the depression. A fertile layer of peat, sand, manure and black soil is poured on top.

The main determinants when choosing materials are financial capabilities and local conditions. The modern assortment provides high quality products for greenhouses of any price range and complexity. Traditionally, the following are considered optimal for peppers:

- greenhouse made of polycarbonate;

- glazed building;

- construction under the film.

An old window can play the role of a budget option for a greenhouse design. For example, a hinged wooden greenhouse is the most mobile way to protect your seedlings. It is easy to move around the site and is strong and durable. This is an example of how you can quickly make a greenhouse for a summer residence with your own hands. It will be cheap and reliable.

Analogs of this design are suitable for protecting strawberry and eggplant seedlings. If necessary, you can make a collapsible frame. For the base, trimming of a bar is quite suitable. The unpretentiousness of the building allows you to use the remnants of a wooden profile, drywall, an old window (frame) for its construction in order to make convenient opening sashes.

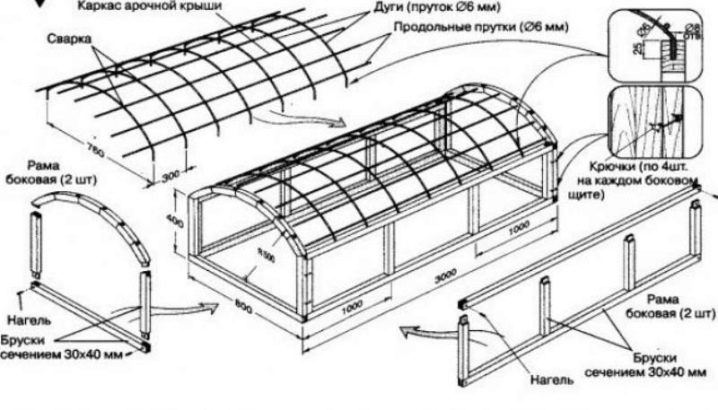

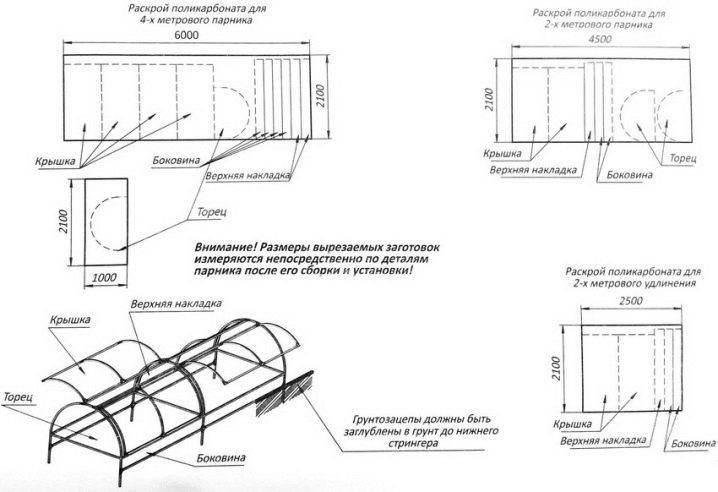

Drawing preparation

Usually, at this stage, the layout, the design of the greenhouse, and its dimensions are already taking shape. After checking the consumables, it remains to make a simple drawing. As a rule, this procedure is straightforward. Otherwise, you can take the finished drawing and substitute your dimensions in it. The diagram should be well thought out and contain as much visual information as possible.

Equipment and tools

The device of the greenhouse in our case involves working with a wooden structure, so we need the following tools and accessories:

- hammer;

- screws (nails for certain situations);

- corners (made of metal) of various sizes;

- loops;

- screwdriver;

- boards (of different sizes), glazing beads (slats);

- arcs (PVC pipe);

- coating (polycarbonate or film);

- staples;

- level (instrument).

The finished wooden parts of the structure are treated with antiseptic compounds before installation in order to avoid the appearance of pathogenic microbes in the future.

One of the determining factors when choosing a cover is the size of the greenhouse. With small dimensions, you can limit yourself to a film, in other cases polycarbonate is recommended. It is better to start cutting it after completing the installation of the frame.

Build and install

The main types of structures:

- from old frames;

- arcuate;

- on the foundation;

- with walls;

- wireframe.

The most common design and economical solution is a greenhouse made from old window frames.

To build a greenhouse correctly, you must follow the sequence of operations. First you need to install the box of our greenhouse on the foundation. A good option would be to make a cleared, tamped, flat place. The work required for this is carried out using a building level and tensioned ropes. We make a foundation (timber or brick) at the right angle. Box boards are fastened with nails or self-tapping screws, it is recommended to fill the seams with a sealant.

Fitted old window frames should be slightly wider than the frame to provide adequate protection from heavy rainfall. If the frame is covered with a film, the places of its attachment with the help of rails are carefully treated with a sealant. The junction of the box and the frame is located on the north side, with a calculation that allows full opening of the frame.

The production of a greenhouse can be of another device, for example, if plastic pipes are laid on top of the box, which must be pre-cut and bent. The construction of a greenhouse can be considered complete after fixing the covering material.

Arc structure

The arc greenhouse is lightweight. Installation is quick and easy. It is easy to move it to a new location if necessary. The arcs, which are the basis of the supporting structure, can be metal or plastic. The main thing is that the arcs are flexible and durable.

Today PVC (polyvinyl chloride) is in demand as a material for arcs. It is thermoplastic, resistant to aggressive environments, lightweight and strong enough.

Metal arcs are made from pipes, rods and wire of large diameter.

Polypropylene arcs are pieces of plastic pipe.In this case, the determining factor is flexibility, the ability to take an arched shape.

An arc greenhouse is a common ground protection that is used throughout the season. It allows you to successfully grow various heat-loving crops. The plant variety determines the size of the frame. At a height of about half a meter, cucumbers are grown. Greenhouse height up to one and a half is well suited for pepper bushes, tomatoes and eggplants.

Advantages:

- mobility and lightness;

- does not require a foundation;

- folds up for the winter;

- has a low cost.

Disadvantages:

- the covering material is short-lived;

- fragile construction;

- it is difficult to supply additional heating or watering.

From old hoses and wires (you can use willow twigs) arches for a greenhouse are easily made. The hose is cut into pieces, a base of wire or rods is inserted into it. The pieces are bent into an arc and stuck into the ground every 50-60 cm along the length of the bed.

Similarly, blanks from plastic pipes, which are worn on bases made of metal pins stuck into the soil. The length of the segments is performed depending on the purpose of the greenhouse. It should be warned against the desire to make a greenhouse as tall as a person - such a structure will be unstable, even when reinforcing the upper part of the arches. PVC arcs require a plank base to which they are attached.

Frame made of metal profile durable and stable. But its manufacture requires special equipment - a pipe bender. We dig the selected place to the desired width. We put arcs - we stick into the ground or attach to the base. We reinforce the structure with ropes, wire, slats, pipes. We cover the frame with covering material. We fix the place of contact with the soil with stones, slats or sprinkle with earth.

On the foundation

Often a foundation is made for frame greenhouses covered with polycarbonate. It ensures the strength and reliability of the structure and increases its service life many times over.

Types of foundations:

- from slag, brick, or concrete;

- made of wood (timber);

- pile.

The estimated efficiency of the greenhouse, time of use, variety of crops, cost are the main factors determining the choice of the foundation.

- Cinder block, brick, concrete. An excellent base for a greenhouse / greenhouse, consisting of a sand cushion and a layer of rubble. It is used on heavy, clayey soils, complicated by groundwater, in harsh climates. For industrial greenhouse complexes in warm and temperate climates, an expensive concrete foundation is made. Light soils are suitable for buried greenhouses. Tall brick or slag foundations suggest a drainage layer.

- Wood... The features of the material make such a foundation justified only in high, dry places with light soil and good illumination. Usually, a protective structure made of polycarbonate, which has a significant service life, is mounted on such a foundation. In order to approximately equal the service life of the bottom and top of the structure, blocks of wood are carefully treated with antiseptics and solutions that prevent decay. The tree is laid on a drainage cushion, wrapped in roofing felt, or geotextile.

A simpler option - the finished frame is laid on a leveled surface, on racks made of natural stone, or cinder blocks. The load-bearing components of the protective structure and the covering material are attached to it.

- Pile... For critical farming areas, this is the only way to build a reliable greenhouse / greenhouse. The pile construction is universal. Such a foundation is equally effective in areas with active groundwater, permafrost, and uneven surface. Piles deepened to the required depth are able to withstand any structure and provide the required strength. Metal pipes are installed in the wells, inside of which there are pipes of a smaller diameter, filled with concrete. A crate is placed on top of the piles.If necessary, either a heater or a frame made of wood is placed on top, to which the frame of the structure is attached.

Having insulated such a foundation, we get a greenhouse for a harsh climate, in which we can get crops all year round.

- With walls. Usually this is a box made of timber or planks, installed on a foundation or even buried soil. From above, this base is closed with a frame made of slats, PVC pipes. The construction is covered with foil or polycarbonate. For convenience, the frame is attached with hinges. Such structures can be pitched and gable. The main feature of such a greenhouse is the limited height of the walls (no more than half a meter to avoid a deficit of sunlight).

- Wireframe... The variety of modifications of such structures is limited only by the creative abilities of a person. The main types are stationary (fundamental) and portable (collapsible). For the framework and protection of soil and plants, materials that are relevant to local conditions are used. The frame is installed both on the ground and on different types of foundations.

Useful Tips

- To provide the right amount of sun and heat, the greenhouse should be located away from buildings and trees.

- The ends are located on the east / west line. This synchronizes the biorhythms of the plant.

- You should not choose a very low and high place for the greenhouse.

- The optimal dimensions for width, length, height are 1x3x0.5 m, respectively. Small size allows plants to more intensively absorb and store solar energy and heat.

- When choosing the design and materials for a greenhouse, attention should be paid to finding a healthy compromise in quality / price ratio.

- The pursuit of cheapness can lead to the destruction of the crop. Additional operating costs for replacing defective parts may exceed the original cost.

- To ensure the optimal level of illumination, the covering material must be kept clean.

Indoor ground is, first of all, a stable temperature regime, which is necessary for pepper. For the suburban area, two sources of heat are relevant:

- solar energy (intensity depends on the purity of the plastic / glass);

- biofuels.

Biofuels are an affordable and efficient way. Manure is used in its role. Ensuring the effectiveness of the technique depends on the correct placement of biofuels and site preparation. It is necessary to additionally insulate the side walls, laying the bottom with straw, on which manure is poured. Several of these layers can be made. The optimal material for insulating the sidewalls is polystyrene.

The choice of organic material for biofuels depends on the time the seedlings are planted. Horse manure is considered the most productive. In seven days, he raises the temperature in the greenhouse to 60 degrees and is able to maintain it for two months. After this period, the temperature rarely drops to 20 degrees. This biofuel is especially effective for early planting. Cow dung and others give a lower temperature.

The use of biofuels makes sense in a pre-prepared location. Sophisticated thermal insulation of a wooden or other base.

Let's consider a few more additional nuances.

- Growing peppers in isolated greenhouse conditions allows you to create the most comfortable environment and radically protect the crop from the effects of diseases and pests.

- The height of the foundation should not exceed half a meter, this will avoid drying out the soil and overheating on hot days.

- The recommended height of the arches is 50 centimeters. The semicircular design is optimal for the plants to get enough heat and light.

- An even distribution of the luminous flux is ensured by materials such as polycarbonate and glass.

- Protective structures with hot water heating are usually industrial greenhouse complexes that operate all year round.

- It is better to place single-slope structures so that the hinge line of the frame and the base is on the north side. In this case, the difference in the height of the sidewalls should be 50-25 cm.

- When installing arc frames, it must be remembered that the optimal amount is 1 arc per meter of the greenhouse.

- The walls of the greenhouse should be removed from the outer beds so that condensation does not fall on the pepper bushes - this can cause plant diseases.

- When installing a greenhouse on a foundation, it is recommended to lay out the outer wall of the trench with roofing material, or old slate - this will save the protected soil from weeds.

- All parts of the structure that are fixed in the ground need preliminary processing. The tree is covered with an antiseptic, metal with bitumen and its analogs.

- When erecting a metal frame, the preferred method of fastening the component parts is a bolted connection. Such a structure can always be disassembled and during storage it will not take up much space.

The difference in ambient temperatures can be significant, which negatively affects the growth of the pepper. Therefore, it is recommended to use heat storage devices. To do this, you can use different means:

- plastic pipes;

- "Sleeves" made of PVC films;

- plastic containers;

- a natural stone.

During the day, the device accumulates heat (the coolant heats up - water, stone), at night the heat is slowly transferred to the beds with seedlings. This method is especially effective in the spring, when sudden frosts can destroy the entire crop.

Best projects

We have already considered the type of greenhouse where the simplest materials are used. There are options that make it possible to economically and effectively protect the soil and plants in the summer cottage.

Shelter structure from arcs

It is a portable structure. We select the frame material (metal wire or polypropylene pipes) and its type. You can bend the pipes into an arc, sticking them into the ground, or fix them on a wooden base.

To position the arcs correctly, you need to position them in half-meter increments. The width is easy to calculate, these are four rows of plants. We cover the frame with plastic wrap or other covering material. At the bottom, the fixation of the cover is provided by heavy objects. The arcs are fastened between themselves with wire or wooden bridges.

Greenhouse made of PVC arcs based on wood

First of all, the size of the arcs is determined. If the task is to grow peppers before ripening in greenhouses, 0.7 m will do. The width of the greenhouse may differ in the number of beds. The optimal number of elements and their dimensions are determined based on the length of the structure (usually 1 arc per 1 m).

First, collect the base (timber, boards). Arcs are attached to the base with staples. The greenhouse consists of sectors (70-80 cm). For strength, the upper parts of the sectors are reinforced with PVC pipes. The structure is covered with a film, which is fixed at the bottom with a stapler.

Single slope design

In some regions, it is more expedient and cheaper to use polycarbonate. Such designs are simple. In many areas, ready-made greenhouses are available from the store at a reasonable price.

Small volume framework solutions

These structures are built both on foundations and on buried ground. The selected soil (10-15 cm) ensures the tightness of the abutment of the covering material to the ground.

PAT

One of the best covering materials is PET (polyethylene terephthalate). We are talking about the polymer from which plastic bottles are made. It is convenient to use the container completely, stringing it on metal rods. Designs that are distinguished by their simplicity are either a "book" or a "clamshell". But, they also collect greenhouses of the "house" type.

A greenhouse / greenhouse made of PET is quite highly efficient. Bottles play the role of light concentrators, ultraviolet reflectors, keep warm well. Additional protection of openings is necessary only in case of frost.

In the case of plastic containers, several problems are automatically solved. Such containers accumulate after the purchase of drinks, its cost is included in the price of the goods, which excludes the allocation of funds for the purchase. With free access to garbage collectors, the financial issue is removed.

The uniqueness of the source material allows you to quickly disassemble the greenhouse, replace its parts. Whole plastic containers have a high heat capacity and are distinguished by high light transmittance, scatter ultraviolet light.

Calculations

The dimensions of the cleared and leveled area, the type of foundation and construction of the greenhouse determine the required amount of plastic containers. There are two main types of such structures:

- from a whole container;

- from plates.

The bottom of whole bottles is cut off and placed on top of each other, collecting the "plastic log". This is the component from which the walls and roof will be assembled. The unique thermal insulation and ventilation through the natural gaps of the structure helps to maintain the desired microclimate. Double plastic slightly reduces the intensity of sunlight.

The plates cut from the bottles are stitched together. The resulting sheets cover the structure. This method requires half the starting material. In this case, the light transmittance remains high, but the thermal insulation decreases.

Depending on the type of containers (their displacement), it is calculated how many containers will go to cover one square meter of the greenhouse and multiplied by the entire area.

Preparing plastic bottles

We select a place for cleaning and processing plastic. The main accessory for this procedure is the bottle soak basin / barrel. The filled bottles are heated in warm soapy water and kept for several hours. Next, the labels are separated and the container is left to dry. After that, either the plates are cut out, or the bottoms of the bottles are cut off to assemble the plastic logs. The cut-out middle parts of record bottles will curl, which can be quickly corrected by placing them under an impromptu press.

All talk about growing peppers comes down to the functionality of a shelter to protect soil and seedlings. A huge number of existing modifications of greenhouses and greenhouses, when examined in detail, have their positive features and disadvantages. A clear understanding of local features and skillful selection of the required greenhouse design will help to make the optimal structure for soil protection. Having invested a minimum of funds, and having basic tools, you can make a highly functional greenhouse for growing peppers in your summer cottage with your own hands.

For information on how to make a greenhouse with your own hands, see the next video.

The comment was sent successfully.