Hiller: types, sizes and applications

The cultivation of the land and the cultivation of all kinds of vegetable and berry crops have become part of our life. Labor on the ground cannot be called easy, therefore a person is constantly trying to invent new mechanisms and devices to facilitate agricultural work. Anyone who annually plants potatoes on his six hundred square meters knows how much effort needs to be invested in order to get a good harvest. A potato will delight the gardener if it is planted in well-cultivated land, hilled several times and protected from weeds. Hillers help to facilitate hard work.

Initially, these devices were used for potatoes, but enterprising villagers found them more widely used.

Appointment

A hiller is an agricultural tool designed for hilling potatoes and other crops. It can be used for digging the earth, for the formation of boletus for planting seedlings, for loosening and fighting hateful weeds.

Hillers are useful for both gardeners and farmers, large agricultural formations.

They significantly reduce labor costs, save time on processing plants planted in an ordinary way, and increase productivity.

Views

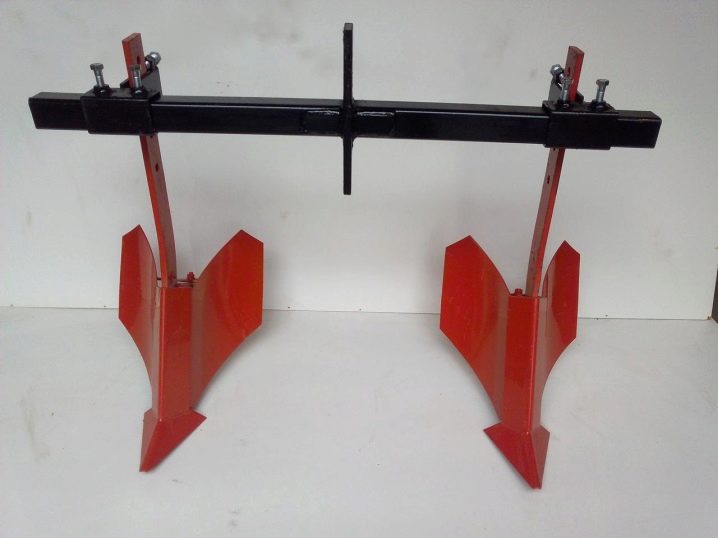

Lister hillers (they are "eared") have an unpretentious design. The simplicity of the device guarantees its reliability and long-term performance. Factory welded devices have an installed grip up to 35 centimeters wide.

Owners of small gardens often use a manual lister hiller when processing plots... The adaptation requires the participation of two people. The first pulls the tool behind him, the second ensures its position in the deepening into the ground. For the treatment of solid areas, a double or triple hiller is used, fixed on a walk-behind tractor or a motor-cultivator.

Not all crops are planted at the same distance. It is important to be able to change the working width. For this, hillers with the ability to adjust the width have been developed.

Standard hillers can be classified as single-row.

Disc design is more convenient... The efficiency of such a device is significantly higher. It is used for both manual and mechanized tillage.

It is possible to install multiple disks and adjust the following dimensions:

- working width;

- deepening of the disc.

Double-row hillers are most often used with walk-behind tractors... The hitch plays the role of attaching the attachment to the block. There are holes in the stand of the hiller that serve to change the depth.

In order for the hiller to constantly remain in the ground, it is recommended to use lugs.

Small electric models are good for summer cottages and backyards with a minimum amount of plantings. They are completely dependent on the availability of electricity and the length of the cable.

They are popular with women and older people for the following reasons:

- are lightweight;

- do not emit gases (like gasoline analogues);

- easy to maintain (require only cleaning of cutters);

- compact, allowing access to closely planted plants and easy transportation.

The propellers of the active hiller pull out weeds with their bladesrotating, they perfectly loosen the soil and at the same time throw it on the plants, creating a mound around them. It is possible to fully use the active hiller only when it is installed on a walk-behind tractor, which has not one, but two forward gears.Only in second gear is it possible to rotate up to 180 rpm, sufficient for optimum hilling.

Chisel devices (designated by the letters OCH) can be classified as light agricultural machinery... With their help, ridges are cut, pre-emergence and post-emergence processing of row spacings is carried out, harrowing and hilling of row crops is carried out. The chisel design is suitable for working on any soil with a moisture content of no more than 20%, provided there are no stones.

The peculiarity of rotary hillers is the blades. The presence of teeth on them allows you to actively fight weeds. The blades, rotating in the ground, grind the roots of weeds. Flat ridges can be formed for planting.

Two-disk rotor types of hillers perfectly "cooperate" with motoblocks of the "Neva", "Favorit", "Cascade" brands and others with similar characteristics.

Milling hillers are, first of all, ridge formers... They form high rows at a distance of about 70–75 cm, which is optimal for planting potatoes, cabbage and a number of other cultivated plants. They are adapted for hilling and fertilizing. In row spacings, they destroy weeds by almost 100%.

Advantages and disadvantages

Each type of hiller has its own advantages and individual disadvantages. For example, all species work flawlessly on clean, light soils. Soils with stones are difficult to work, and frequent breakdowns of cutting parts are possible. Devices are demanding on humidity. Damp land cannot be cultivated.

All metal parts are subject to corrosion and therefore require appropriate processing.

The simplest lister species with no grip adjustment are not suitable for all crops. In addition, like their adjustable counterparts, these types require periodic cleaning of adhering clumps of clay and earth during operation.

Some models work well only with walk-behind tractors of a certain power. So, for the effective use of a hiller capable of changing the working width, you need a cultivator or walk-behind tractor weighing at least 30 kg... At the same time, there is a condition for engine power - more than 4 liters. with. The main disadvantage of such a hiller is its low efficiency. It is visible with the naked eye: part of the land after the passage crumbles into furrows.

A rotary hiller, with all its indisputable advantages, needs not just a powerful walk-behind tractor, but only one that has two forward speeds.

Compact electric models are indispensable for women working on miniature plots and flowers. The device is useless where the electric wires have not yet reached.

The hiller does not tolerate voltage drops in the network, it depends on the length of the extension cord.

Brands

Today, a fairly large assortment of hillers from various manufacturers is presented. KON-2.8 - cultivator-hiller is an attachment to the MTZ-80 and MTZ-82 tractors.

The cultivator has more than ten different working bodies, which allows you to get a significant effect when processing root crops. Three working units are located on a massive frame frame. The hiller is regulated by several parameters. KOH-2.8 was designed for potato processing.

It is used not only for direct hilling of plants, but also for the following purposes:

- arrangement of row spacings;

- harrowing (before and after germination);

- fertilization.

For each pass, along with the assigned task, the hiller, installed at a given depth, carefully loosens the soil in the aisles. In addition, he uproots weeds.

The multi-row design is placed on a wheelbase. In addition to the wheels, it is supported by rubberized rollers. Wheels spontaneously clearing of soil are “shod” in rubber tires. The cultivator is capable of cultivating 2.4 hectares per hour if the average speed is 10 km / h. When capturing 2.8 m per pass, 4 rows of plantations are processed at once.

Polish hiller of the Bomet brand is available in several versions... It can be two-, three- or four-row. The purpose of the cultivator is the processing of root crops planted in an ordinary way. It can be either potatoes or carrots or peppers. The Bomet hiller is used even in the processing of corn, strawberries and tobacco.

The set of an implement installed on a tractor with a capacity of at least 22 horsepower includes the following elements:

- three support wheels;

- six loosening paws;

- three hillers;

- three lancet paws.

Patriot disc hillers are installed on walk-behind tractors... The hitch is not included in the set, it is purchased or manufactured separately. Device capabilities are limited. It works on loose soils, it is used for burying potatoes planted in furrows and for hilling.

The "Centaur" hiller also works with the walk-behind tractor... The unit has the ability to adjust the working width and depth of soil cultivation. It is resistant to breakage due to the fact that it is made of extra strong materials.

How to choose?

The choice of a hiller depends on its purpose. For example, a three-row option is unlikely to suit the owner of six acres, but in a farm it will become an indispensable assistant in the cultivation of root crops or berry crops. When choosing a product, you should focus on completeness. For example, disc types of hillers on a frame are often sold without a hitch. If you overlook the complete set, you will have to postpone work in order to buy or make a hitch yourself.

It is important to acquire a mechanism that is adjustable in height and width if you plan to process several types of crops. When buying a device for cultivating the land, do not forget to correlate their design with the characteristics of walk-behind tractors and other equipment.

It is clear that for a domestic cultivator and for MTZ it is effective to use different models of hillers.

Multifunctional Polish models have taken root on the Russian fields. They are suitable for large areas with a slight slope. For subsidiary farms, it is worth acquiring a universal mechanism that is compatible in parameters with an existing or planned walk-behind tractor or a walk-behind tractor.

For gardeners processing large potato plots, an active two-row type of hiller is suitable... The rotating blades will cope with three tasks at once: they loosen the ground in the aisles, chop the weeds, and form mounds over the lashes.

Evaluate the advantages and disadvantages of various models, compare them with your tasks and capabilities, only then make a decision about buying a suitable device.

Features of operation

The hiller is operated several times during the season. In the spring, before planting, it is used to loosen the earth.

But first of all, the following preparation should be carried out:

- inspect the walk-behind tractor;

- change lubricant, add fuel;

- decide on the wheel and lugs;

- check the operation of the internal combustion engine;

- carefully configure the device;

- set the dimensions of the grip, the depth of immersion;

- adjust the steering bar.

Work on connecting the hiller to a walk-behind tractor or tractor is carried out on a flat surface. After combining the two components into a single whole with the help of a hitch, make sure that the hiller's post is located strictly vertically.

For disc models, it is important to place them correctly among themselves, set the angles of inclination from the vertical and rotation from the horizontal.

Agricultural equipment does not require special maintenance, but it greatly simplifies agricultural work.

Video review of disc hillers, see below.

The comment was sent successfully.