The principle of operation and tips for choosing disc hillers

The disc hiller is a popular agricultural tool and is used as an attachment for small-scale mechanization. With the help of this unpretentious tool, it is possible to solve the problem of processing potato plantations, saving farmers from hard manual labor.

Feasibility of the procedure

Disc hillers are used for a very important agricultural technique - hilling. Carrying out this event is a mandatory procedure when growing potatoes. It performs a number of important tasks:

- elimination of weeds, which is quite problematic to perform manually with a hoe;

- hilling protects tubers from direct sunlight, which, when potatoes are close to the surface of the earth, can slow down their development, and sometimes even lead to drying out;

- correct and timely hilling leads to an improvement in soil air exchange and normalizes the evaporation of moisture from the earth's surface.

Hilled potatoes are less susceptible to rotting and infestation of parasites, which is due to the high drainage properties of the loosened soil and the free outflow of excess moisture. In addition, the size of tubers in a spudded potato is much larger than that of a crop that is not being cared for.

If there are several rows of potatoes in a summer cottage, there is, of course, no need to purchase a hiller, but if rather large areas are occupied with potatoes, then mechanization of this process cannot be dispensed with.

Device and purpose

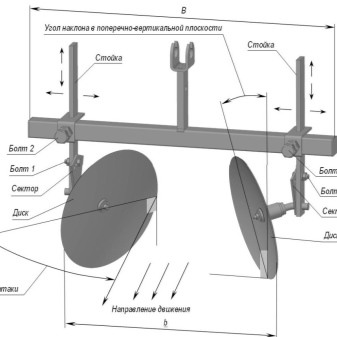

Structurally, the disc hiller is presented in the form of a frame equipped with two wheels, with spherical discs suspended from it. The angles of rotation of the discs are regulated by means of two screw lanyards, which move the discs around a vertically located axis. Moreover, the angles of attack for both discs must be exactly the same. Otherwise, the hiller will start to move aside and cut the bushes. The distance between the discs is regulated by the movement of the stands, and can be from 35 to 70 cm.

The height of the earthen ridge is regulated by bringing the discs closer together, changing the angle of inclination and deepening. So, when the disks move apart, the height of the ridge decreases, and when they approach, it increases. A walk-behind tractor is usually used as a traction for disc hillers, although work with mini-tractors and cultivators is also allowed.

To work with hillers, walk-behind tractors are equipped with grousers, which are metal wheels with deep tread. They are installed instead of the native wheels with rubber tires, thus ensuring reliable traction of the tractor with the ground.

The scope of application of the hiller is not limited to hilling potatoes. It can be used to process plantations of beans, asparagus and corn, as well as use it as a weeding machine. Thanks to the sliding design, which allows the adjustment of the working width of the land, it is possible to process plantings with any frequency of furrow arrangement. However, the hiller is used not only for hilling and weeding.

With its help, spring cultivation of the land is carried out before planting crops and the soil is prepared for winter after the last harvest.In addition, it is necessary to focus on the disc model even in cases where it is necessary to cut furrows for planting plants or cover them with a layer of earth after planting seeds. For such work, it is better to choose a model with a furrow cutter - a special wedge-shaped device located on the frame and designed for cutting furrows.

How does it work?

The principle of operation of the disc hiller is quite simple. The unit is attached to the walk-behind tractor using a hitch bracket, a stopper, two flat washers and the same number of bolts. Then they set the same angle of inclination of the disks, turn on a lower gear, and bring the walk-behind tractor to the lane. When the tractor is moving, the disks of the hiller grab the soil and place it in the swath. At the same time, small and large clods are crushed and the soil is deeply loosened. At the same time, the ridges are quite high and even, which allows you to close the tubers well and form beautiful and neat rows.

Varieties

The modern market presents two types of disc hillers. The first, the most common type, is represented by models with an adjustable working width, and is used on farms where, in addition to potatoes, they are engaged in the cultivation of other crops. The sliding design allows you to change the distance between the discs and set it to the desired furrow width. For example, when processing potato plantations, the discs should be spread at a distance of 450 mm from each other, while 350 mm will be enough for hilling beans.

In addition to multifunctional sliding models, there are also simple units with a constant working width., and depending on the model ranges from 20 to 30 cm. Hillers have a simple device and consist of two fastened wings with discs located on them. Such products are much cheaper than sliding ones, they are designed for walk-behind tractors with a low-power motor, weighing no more than 30 kg.

Features of operation

Before you start hilling potatoes with a hiller, you need to set it up correctly. To do this, the lower points of the discs are separated from each other by a distance equal to the row spacing, and the angle of attack is calculated, the value of which depends on the type and structure of the soil. So, for dry soil, the angle should be slightly increased, and for moist soil, set to the minimum position. Otherwise, there is a risk of damage to the stems of the plant with large heaps of wet, and therefore heavy soil.

It is necessary to adjust the discs absolutely symmetrically, otherwise the hiller will begin to lead to the next row, and it will damage the tops and tubers.

Processing a potato field with a hiller is not difficult even for beginners. The main thing is to carefully read the instructions for its operation, and follow a number of simple rules.

- So, the first hilling of potatoes is done immediately after they rise. In especially cold years, with the threat of recurrent frosts, it is recommended to make the ridges higher during the first treatment. This will protect the crop from freezing and ensure that the temperature inside the earthen rampart is maintained at a comfortable temperature.

- After the tops have grown to about 30 cm, the hilling should be repeated. In this case, you need to be especially careful, trying to do the work so that the stems remain upright and do not die.

- Hilling should be carried out in the morning or evening on a moist soil. In case of prolonged drought, the plantation is watered before processing.

- The removed weeds, as a rule, are not collected and left in the aisles. This protects the tops from unfavorable weather conditions and contributes to the preservation of a favorable microclimate in the soil.

Criterias of choice

Before proceeding with the purchase of a disc hiller, it must be borne in mind that, despite its high performance characteristics and the ability to work any type of soil,this type of attachment is quite expensive. So, if a lister single-row hiller will cost only 1,400 rubles, and when buying a two-row one you will have to pay 1,800 rubles, then purchasing a disc model with a VRMZ furrow-maker with the function of adjusting the working width will cost 4,200 rubles. Therefore, the purchase of a disc hiller is advisable only if it is necessary to perform large-scale work., for example, for processing fields with an area of more than 1 hectare and cutting furrows, as well as if there are several crops on the site at once that need hilling. For a field with an area of 6 acres, planted with one potato, you can limit yourself to choosing a one- or two-row lister model.

The disc hiller is a necessary tool that greatly facilitates heavy manual labor on a personal plot and contributes to an increase in yield.

For an overview of disc hillers for a walk-behind tractor, see the video below.

The comment was sent successfully.