Types of hillers for a walk-behind tractor and features of their operation

Attachments for a walk-behind tractor can speed up and facilitate the work of a summer resident when working with land and vegetables. One of the varieties is a hiller for a walk-behind tractor, which today is considered a key element of hinges and is quite in demand among buyers.

The material of this article will tell you what it is, what are the types of these nozzles, how to use and maintain them.

What it is?

A hiller for a walk-behind tractor is a device through which you can effectively plow and cultivate land of different lengths and degrees of soil complexity. With this attachment, you can huddle cultivated crops, as well as loosen, dig up the soil and fight weeds. In fact, this is a nozzle made of metal, which is characterized by a wedge-shaped shape. Depending on the type, it has blades or is equipped with rotating discs that are attached to the frame.

Hillers and weeding machines are installed on the walk-behind tractor by means of special fasteners. Attached equipment implies different hilling heights and depths of penetration into the ground. Simultaneously with loosening, the soil is lifted to the desired height and aerated. Depending on the type of model, it can provide for varying the width and height of the hillock, changing the angle of inclination.

However, the models are selected specifically for a specific type of walk-behind tractor.

They are distinguished by the efficiency and quality of soil cultivation.

Views

It is possible to classify the varieties of the hiller according to their design features and the principle of action. Based on this, 3 types can be distinguished: disc, lister and propeller. Each modification has its own characteristic features.

Lister

This option is considered the simplest from a constructive point of view. It is distinguished by a fixed width of capture, it looks like the wings of a butterfly. In the process, it lifts the soil and thereby creates the necessary earthen ridge. Due to the ends with a sharp shape, it descends to a previously adjusted depth, loosens the earth, raises it.

The disadvantage of the device is the need to adjust to the row spacing. Almost most of these models have a factory product width of no more than 30 cm.

More convenient are options with devices that differ in the ability to change the working width. They are convenient and allow you not to adapt to the peculiarities of the hiller. However, hillers of this type need more power of the walk-behind tractor.

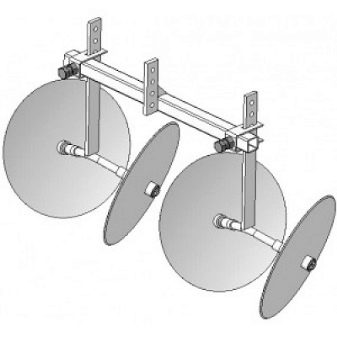

Disk

As the name implies, the leading elements of the hiller are discs, the rims of which are lowered to a regulated depth into the soil, while having minimal soil resistance. To work effectively, this linkage requires the most accurate setting of the spreading angle, as well as the vertical angle of inclination of the discs. In this case, the width of the capture is set taking into account the parameters of the cultivated row.

Such hillers are suitable for all walk-behind tractors and allow you to increase the power of the unit.... They are synchronized with the capabilities of the walk-behind tractor, allow for speed and power adjustment. Tillage with their help is more efficient, they are convenient and low-energy consumption. In addition, there is no need for a support from the back.

The models are universal, and therefore they can be used not only for plowing and hilling - they can be used even during the growing season of cultivated crops. In addition, this can be done several times per season (at different growth phases).

Propeller

Hillers of this type are often called active or rotary. There are 2 forces involved: rotation and translation. This attachment is much more expensive than previous counterparts due to its efficiency. but you can use hinges of this type only on walk-behind tractors equipped with two forward gears, as well as a power take-off shaft. Externally, rotary devices are similar to fans.

Structurally, they are more complex than the other two types of hillers. Their principle of operation is performed by one turn of the active disk. Initially, the soil is dug with the removal of weeds. Only after this does the hiller loosen the ground.

A feature of such tillers is the fact that they can not only huddle the crops grown, but also transfer the land from place to place.

Nuances of one- and two-row devices

Depending on the type, the models can be one- and two-row. Attachments of the second type are good in that in one pass the operator processes two aisles at once, raking up the soil to the crop and forming furrows.

Basically, a double row tiller is like a bracket post that attaches to the hitch and has 2 posts with hillers that are bolted to the hitch.

The convenience of such models is the ability to adjust the width of hilling, which allows you to adjust it to the desired parameters of the beds.

The single-row version can process only 1 row per pass. In principle, this is convenient, given that the operator has to spend less time monitoring the progress of the work being performed. So the position and movement of the unit will be more correct, which will reduce the percentage of damage to the crop during the hilling process.

Single-row models are especially convenient where the rows are crooked, moreover, they are easier to operate, although due to design features they differ in size and have a lot of configurations.

The auger hiller is considered to be low-productivity and is distinguished by the high energy intensity of the technological process of the hilling of agricultural crops.

As for the Dutch models, their wings are able to rotate vertically and horizontally. This leads to high-quality cultivation of the land with a reduction in energy consumption. These models are available to most buyers and work well enough.

Features of operation and maintenance

Installing a hiller on a walk-behind tractor requires adherence to the rules for adjusting the angle of attack and depth of immersion, while it should be less than a plow. Wheels and a hitch are installed on the hiller, after which it is attached to the main unit. The tiller is installed on a flat surface, while the tiller is lowered and connected by means of a hitch.

When installing attachments, the operator tries to make sure that the tiller stand is vertical. It is this position that is necessary for the correct setting of the optimal angle of attack. After that, the hinge is lowered to the ground or even slightly deepened into it. It is important that the equipment is positioned below the star support.

Before starting the main work on plowing or hilling the land, it is necessary to carry out a test run in a small area. It's important to work in good weather, having previously checked the sharpening of the working elements. In addition, before starting work, it is necessary to assess the condition of the soil.

In order for the hiller for potatoes or other root crops to work most efficiently, passing through a small area, they regulate the optimal indicators of the angles and depth of entry of the working elements of the hiller into the ground.

Along with this, it is necessary to determine the optimal speed of work, since a correctly selected indicator will contribute to greater efficiency and quality of work. For example, if the speed is high, the hiller will simply spread the ground in two directions instead of creating a slide and furrow. When the equipment in the process of work goes too deep into the soil, it is necessary to tilt the rack forward, for which the toe is raised.

If the hiller protrudes from the ground during work, you need to tilt the toe back. In order not to cut the crop, it is important to adjust the row width.

When it is necessary to plant potatoes using a hiller and a walk-behind tractor, marks must first be made with a distance of about 65 cm. After that, furrows are created and the planting material is laid out in them. After that, the wheels need to be replaced with rubberized ones, setting the wings to the widest possible position. Having put the unit in the aisle, they pass the entire row with a walk-behind tractor, covering the planted potatoes with earth.

Setting up the disc hiller primarily provides for its correct direction relative to the furrow. The device should be positioned parallel to the beds with a given angle and working width.

The screw adjustment will help to install the plow correctly, by means of which the unit itself is tilted relative to the walk-behind tractor.

This will determine the depth of tillage (furrow depth). If a moving type hiller is installed on the walk-behind tractor, it is necessary to adjust the width and height of the ridge.

In the disc model, the working width can be adjusted. To do this, the lower points of the disks are set aside by about 40–70 cm (the specific value will depend on the distance between the rows). When adjusting, make sure that the discs are located symmetrically in relation to each other.

With such devices, the soil is treated three times per season:

- when the seedlings grow up to 15 cm;

- when they grow up to 23–25 cm;

- at the time of flowering.

Rating of the best models

Today the motoblock market is rich in a wide range of offers. At the same time, from a rich list, several options can be distinguished that are most in demand among buyers, to which most hillers are suitable.

- "Type of. 2 " - disc sliding model that fits "Celina MB", "Cascade", "Kadvi", "Neva". Perfectly spuds, weeds, buries potatoes in the created in-depth strips. The model provides for the adjustment of discs in height, width and processing angle. Needs a hitch.

- "Celina 010417" suitable for motoblocks "Neva", "Celina", "Oka", "Favorit", "Salyut" (including "Salyut 100"). This is a two-row tiller without a hitch, which must be purchased separately. An adjustable version of the plow, customizable based on the characteristics of the soil and its processing technology.

- Hillers for walk-behind tractors Kipor (also for diesel version Kipor KDT 610) are made to order... These models have an adjustable opening angle, the tiller itself has a wheel. In addition to Kipor KDT, they are suitable for KAMA walk-behind tractors.

- Forma 2/4 - a forming device with an adjustable row spacing, which can be 70 and 75 cm. Equipped with an adjustable tilt of the forming device. Provides for the processing of the soil after germination.

- Hiller "STV NAP" designed for motor-blocks "VRMZ", "Neva", "Kaskad", "Oka". To achieve maximum efficiency, it requires preliminary loosening of the soil before cutting furrows. Single row model, without coupler, which must be purchased separately.

Reviews

According to customer reviews, the best hiller for a walk-behind tractor is disk-type attachments. It is convenient in that it allows you to create ridges on the cultivated land not only of the desired width, but also of the specified height.

You will learn how to make a hiller for a walk-behind tractor with your own hands in the video below.

The comment was sent successfully.