Wooden sheds

The construction of lean-to sheds is a simple process if you follow the detailed instructions for the design and assembly of the structure. Before making a structure, it is recommended to correctly draw up a drawing of the future structure. It is worth considering in more detail what is the peculiarity of wooden canopies, why they are so popular and how to install the structure on the site yourself.

Peculiarities

A distinctive feature of a shed made of wood is durability. Of course, wood material does not tolerate long-term humidity poorly. Standard timber can mold and rot when exposed to moisture. You can solve the problem today with the help of wood processing:

- antiseptics;

- varnishes;

- paints.

Also, for the manufacture of a structure, you can choose a breed in which the indicators of resistance to decay and bioinfluence from the outside are increased.

A building made of such wood will stand for several decades and will retain its original appearance.

An additional feature of single-slope structures is ease of installation. The assembly of the structure does not require welding, as is the case with a metal product. To fasten the canopy, it is enough to screw in a few screws, anchors or bolts. The same goes for preparing the material for construction.

Finally, the last feature of such structures is a low price compared to a metal profile. In this case, it is worth considering canopies, which are made of a simple bar, which is the most common design option for use in adjacent areas.

If desired, you can create an original building from wood, choosing the appropriate style and design. Wood canopies do not need additional decor, since the material initially has a rich texture and a pleasant shade.

Varieties

The canopies are performed differently. The difference may lie in the design, materials, installation method. One of the most common classifications is the division according to the method of construction. The following groups of canopies are distinguished here.

- Constructions that stand separately. This type of canopy is located near the erected objects. The products are used to organize the protection of the car from precipitation, as well as to equip recreation areas.

- Constructions adjacent to the house. They are mounted to one of the load-bearing walls. The purpose is to protect the selected side of the house from the sun or precipitation.

- Supporting and cantilever structures. Special elements are selected for assembly. Also, the erection of awnings can be carried out simultaneously with the load-bearing walls. A striking example is a shed flat wooden roof with a canopy. Basically, this type of structure is installed above the front door to provide protection for the porch.

Depending on the functional purpose, awnings are divided into decorative or protective structures.

If we consider the classification by the main purpose, then the sheds can be to protect the recreation area or the car from external influences in the form of precipitation.

How to build with your own hands?

It is not always possible to order a ready-made canopy or use the services of experienced installers. If necessary, everyone can install a shed wooden shed on the site on their own.

To do this, it is necessary to carefully approach the development of the drawing of the frame and the calculation of the amount of required materials. It is not difficult to calculate the required indicators. It is recommended to start with the selection of suitable dimensions for the future structure:

- width;

- length;

- heights.

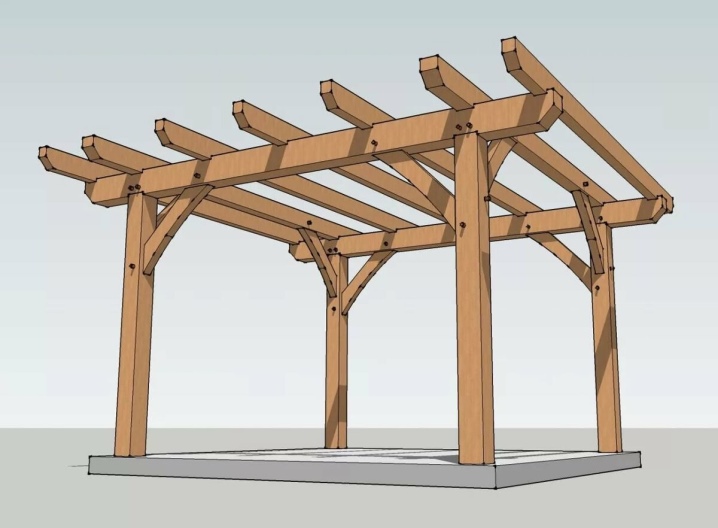

There are no special restrictions on the size of the canopies, it all depends on the preferences of the customer. However, in the case of long spans, experts advise to strengthen the structure by using materials with an increased cross-section or by installing additional racks.

When this stage is over and a diagram of the future structure has been drawn up, you can proceed with the installation of support posts. It should be noted right away that to create a lean-to canopy, it is necessary that two racks are longer than the others. The difference in height is easy to determine by calculating the angle of inclination.

The steeper the canopy roof, the greater the difference between the dimensions of the parallel posts.

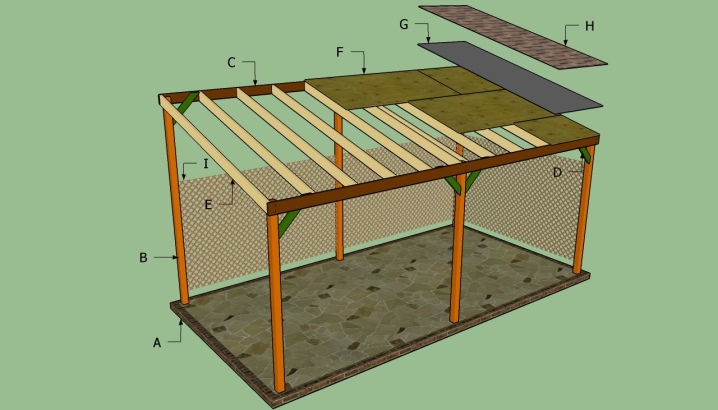

The assembly of the construction of a lean-to wooden shed is carried out in stages. Installation is carried out as follows.

- First, on the construction site, they indicate the places where it is planned to install the supports.

- Further, in the marked places, holes are dug with shovels. If you do not have the ability or desire to dig holes, you can drill wells using a hand drill. The maximum laying depth should not exceed 1 m.In addition, before installing the supports, it is recommended to fill in the crushed stone inside to create a reinforcing layer of 5-10 cm.

- The third stage is the installation and waterproofing of the supports. The lower ends of the pillars are lubricated with bitumen mastic.

- Next, a concrete solution is poured into the wells to increase the strength and reliability of the structure. An average of 7 days are allocated for the setting of concrete.

- The next stage of installation is the installation of the boards on the racks. For this, the supports are strapped in pairs. In other words, a beam up to 550 mm thick is attached between the posts of the same height. Rafter legs are mounted on the installed boards.

The advantage of wooden awnings is that they fit well with landscaping. A well-designed drawing and the correct approach to the installation of the future structure will allow you to get a strong and durable canopy, which will not only look attractive on the site, but also protect the space under it from external factors.

For information on how to make a lean-to canopy out of wood, see the next video.

The comment was sent successfully.