All about metal awnings

Today, high-quality and reliable awnings are made from different materials. Among the many options, metal structures are some of the best. They are durable, sturdy and durable. In this article, we will learn all about awnings made of metal.

Peculiarities

Canopies are different. They are designed for different purposes, in different areas. Many people prefer to build precisely metal structures, since they are highly practical, wear-resistant and have a long service life. A competently made metal canopy can serve for many years without causing unnecessary trouble and worries to the owners.

Both standard stationary and portable / folding canopy modifications are made of metal. Structures are more often mounted for placement on the street, but other options are also possible.

The main component of modern metal frames is the roof, which rests on a sturdy frame base. A similar structure is supplemented with high-quality roofing material. The latter can be flexible roofing, shingles and other waterproof materials.

Support pillars also play an important role in the construction of a metal canopy. In some cases, blank walls are installed instead. Metal canopies have many advantages over other options. Let's consider them.

- Metal structures are designed for a long service life. If the canopy was originally made according to all the rules, then it can serve for many years.

- Metal structures are fireproof, do not support combustion. The same cannot be said for awnings made of wood.

- Metal canopy - an environmentally friendly and safe design. It will not emit unpleasant chemical odors, will not have a negative effect on the health of households.

- Such types of awnings are not susceptible to deterioration under the influence of negative external factors. Of course, these structures must be treated with anti-corrosion compounds, but they still turn out to be more practical in operation than specimens based on bars and boards.

- A properly made metal canopy will easily withstand heavy loads without deforming, without losing its visual appeal.

- A metal canopy can be an original decoration for a private house. It can be decorated in a variety of ways.

- It will be possible to make many different modifications of canopies from metal. Structures can be of various shapes and sizes.

The main disadvantage of these structures is that they are susceptible to corrosion.

In order not to encounter rust on the metal, the owners will have to treat it from time to time with special protective solutions and paint, which seems to many users to be an unnecessary concern.

True, if the canopy is made of stainless steel, you will not have to resort to such procedures.

Views

Highly durable and reliable canopies made of metal come in many different types. Each of them has its own distinctive characteristics, device features and appearance. Let's consider by what criteria such constructions are divided, and what parameters are characteristic for them.

By design

All metal canopies are divided according to their design. Let's consider the main features of the most common options.

- Shed. This is the simplest type of canopy made of metal. It is considered convenient because it differs in the shape of an inclined plane located at a certain angle. Such a design can provide maximum protection for the area covered by it. Water and other precipitation will not be able to linger on the lean-to shed. A properly made shed canopy can look very stylish and modern.

- Gable. Many homeowners prefer to design canopies with 2 slopes on their plots. Such structures are especially in demand in those regions where it is difficult to determine the direction of the winds. Gable canopies have a lot of advantages when compared to single-pitched ones. True, to design such a canopy, you will need more reliable and high-strength fasteners.

- Multi-slope. More complex design with more welds and fasteners. Such structures ideally complement large playgrounds, car parks, exhibition centers. They look more remarkable and original, but they are also more difficult to construct.

- Arched. Attractive designs look very stylish and neat, but often come at a break. This is especially true for those options that are complemented by various kinds of decorative details. Many homeowners are repelled from arched awnings by their cost.

By appointment

Metal awnings are designed for different purposes. They can perform various functions.

- Very often, metal canopies are used to equip a parking space for a car. Thus, it turns out to make a kind of replacement for the garage. If there is not enough free space, awnings are often installed, attaching directly to the facade of a residential building. The result is a very comfortable and practical design.

- A canopy can also be made for specific agricultural needs. This can be a temporary shelter for animals or a kind of storage room where hay, firewood, fertilizers and many other things of this kind can be stored.

- Often, awnings are designed to highlight and close the recreation area. In such areas, a place is allocated for a grill, a gazebo, tables and chairs. The result is very cozy and hospitable corners where households and their guests can have a good rest.

Metal canopies can have a variety of purposes. Some people make them to cover the pool in the courtyard of a private house or some decorative components.

Projects

Before proceeding with the independent manufacture of a high-quality canopy from metal structures, it is necessary to develop its detailed plan, sketch the necessary diagrams and drawings indicating all dimensional parameters. It is not at all necessary to independently think over the plan of the future design - you can use ready-made sketches. Here is some of them.

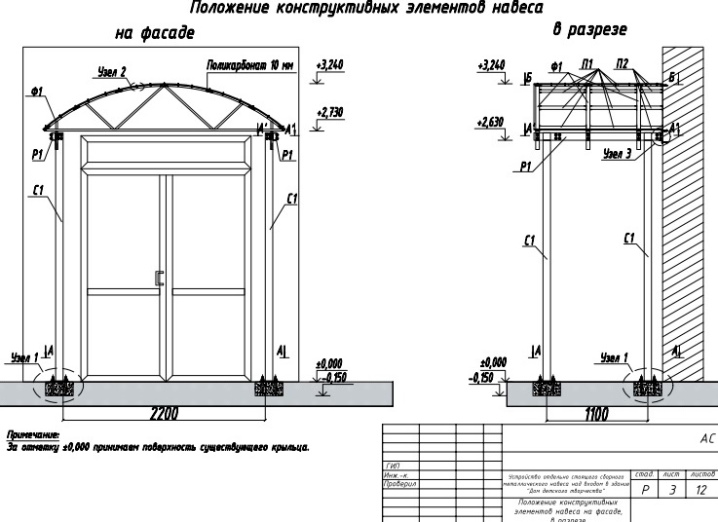

- One of the most expensive, but also the most beautiful, are the arch-shaped awnings. Such structures can be not only very large and wide, but also compact, covering only the area near the front door to the house. Polycarbonate can be used as a roofing material for such a small structure.

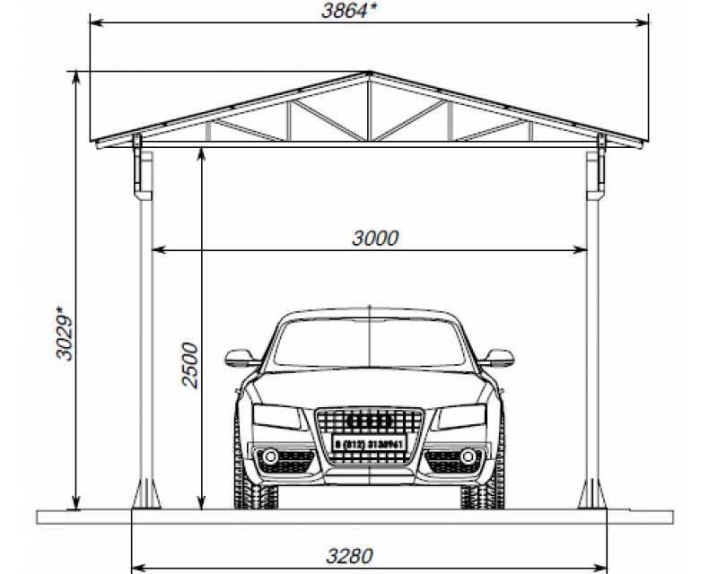

- To equip a parking space for a car, you can build a solid gable carport from iron. The dimensions of the structure should be selected in accordance with the dimensions of the machine. For example, it can be a canopy with parameters 3x3 or 3x4 m, as in the diagram.

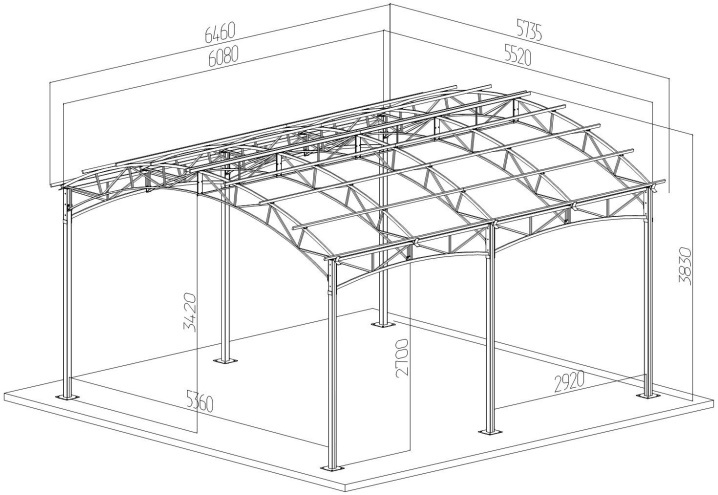

- Using a metal frame base, you can build a canopy that covers parking spaces for 2 cars. Such designs look more impressive and soundly if you make them arched. But such options are expensive, especially when it comes to a large canopy with dimensions of 6x6 m. Polycarbonate can be used to equip the roof.

There are many options for how to arrange an iron canopy. When drawing up a project for a future construction, it is necessary to build on the size of the territory on which it will be located, as well as the main purpose.

Where to locate?

The owners will need to carefully consider where exactly they will place the new metal canopy. Several locations are suitable for this.

- If the square of the site allows, the canopy can be built separately from the residential building. For example, it can be a large structure, under which 1 or 2 cars will fit.

- If the site is small, then it is better to attach a canopy to the house. It is best to attach it to a side or front facade. In this case, it is very important to comply with all the necessary norms and rules for installation.

How to do it right?

A high-quality canopy for a country house or summer cottage can be made with your own hands. The main thing is to make the correct calculation of all sizes and volumes of material. Having at hand a detailed plan of the future superstructure, it will not be difficult to make it. Let us consider in detail what stages the process of making a canopy from a durable and reliable metal frame consists of.

Preparation

Before proceeding directly to the installation work, the master must properly prepare for them.

It is very important to correctly design the future construction, as well as to purchase all the required tools, fittings and materials.

The toolkit that will be needed to carry out all the work consists of the following items:

- building level (a laser or bubble is suitable - these are the most convenient devices);

- roulette;

- a grinder or a special saw for working on metal;

- drill with a hammer drill and a set of drills / bits;

- special riveting machine;

- self-tapping screws for metal;

- rivets.

Having prepared all the tools and materials, the master must carefully prepare the area in which the canopy will be made. You will need to prepare the ground for installing the foundation. In accordance with the drawn up drawing, it is necessary to level the selected area, and then properly tamp it. Then you will need to dig holes along the perimeter for the subsequent installation of the support pillars. The depth of the pits should be from 50 to 100 cm. The indentations should be done so that the result is a rectangle, as a rule, in 2 rows of 2-3 pits.

Installation of supports

The next step is to install the supporting parts that make up the metal frame. For this, the metal profile is first cut in accordance with the number of support pillars. Their length should not exceed 3 m. Then it is necessary to determine the type of fastening of the racks. If a stationary canopy is being made, then the supports are set at a level, and then concreted, and for mobile options, additional pipes will need to be cut.

The prepared metal pieces must be placed in the dug holes and filled with cement mortar. Then a profile will need to be placed in each of the pipes.

Holes are drilled both in it and in the pipe itself, then the supports are pulled together by means of bolts. In order for the resulting foundation and frame base to add rigidity and reliability, you can use the installation of special protective covers.

Roof erection

The next step is the construction of a canopy roof. The roof can be solid or collapsible. Let's consider how to install it using the example of a collapsible gable structure.

- Pieces of a metal profile must be attached to the supporting bases by welding in order to end up with a rectangular frame.

- Next, you need to weld the rafters. The resulting structure should not protrude beyond the welded upper frame.

- Then the welded parts need to be placed on a rectangular support part and welded at the joints.

- Having completed the construction of the frame, you need to proceed to the installation of the roofing material. Sheathing with sheets of corrugated board is suitable. They are overlapped to the rafters.

Finishing work

The final stage is the finishing of a self-made canopy.

- The finished structure must be descaled and degreased. Acetone, thinner or gasoline is suitable for degreasing. Let the structure dry.

- This is followed by the priming of the structure. It will protect the canopy from corrosion and extend its service life.

- If you use a light gray primer, it will work with any paint color. Dark is recommended for brighter materials. White primer is chosen when it is planned to paint metal structures with pastel shades.

You can quickly and easily finish a metal canopy yourself. The main thing is to act carefully, thinking over the appearance of the superstructure.

How to repair?

Even the sturdiest and most reliable canopies made of metal profiles may require repair. This is important to consider if you set about making such a design yourself. In most cases, repair work for a metal canopy consists of the following:

- strengthening of metal structures;

- restoration of the attractive appearance of the canopy (it means fresh painting, removal of the appeared rust);

- replacing the roof covering if the old one is badly worn out or damaged.

Useful Tips

We will learn about some useful tips regarding self-construction of a metal canopy.

- If a metal canopy is built over a brazier or barbecue area, then the iron parts located in the immediate vicinity of the fire will be very hot. This should not be forgotten.

- When assembling a canopy in swampy areas, it is recommended to build a foundation in the form of pile supports. Concreting here will not be the best solution.

- During installation, all metal pipes will need to be cleaned with sandpaper. Only then can the primer and the selected paint be applied.

- When making a metal canopy adjacent to a change house or a residential building, you must follow all the rules and regulations that permit such work. Otherwise, you can face a lot of problems.

- If it is necessary to weld structures from a metal profile with a wall thickness of more than 3 mm, then it is recommended to use only gas welding, since the electric apparatus simply runs the risk of not being able to cope with such a volume of work.

- If an arched structure is being made and pipes are bending, it is very important to ensure that no cracks or creases appear during this. In addition, the profile should not be flattened.

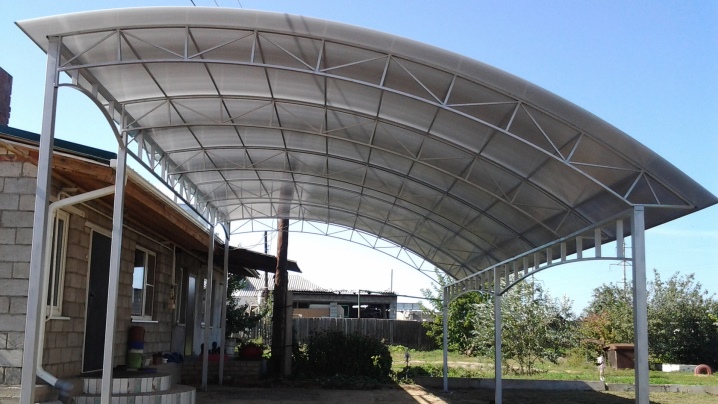

Beautiful examples

Consider a few good examples of beautiful metal canopies.

- Isolated from residential buildings, the option with a metal frame and a gable roof, trimmed with corrugated sheets, will be an excellent place to relax for household members and their friends / relatives. In this case, the details of the metal structure should be painted in a dark color and pick up green corrugated board. It is advisable to make a floor covered with paving slabs under such a canopy, and arrange everything here for a grill or barbecue.

- The frames of metal arched canopies look original and elegant, in which, instead of a roof, there are ties of wild grapes. You can also put polycarbonate as a roofing material. Such structures are bound to attract a lot of attention.

- Metal awnings, in which the roof is made of high-strength glass, look chic and modern. Especially stylish will be designs in which there is a thick metal frame, painted black - together with glass, the tandem will turn out to be wonderful.

How to make a canopy from a metal profile with your own hands, see below.

The comment was sent successfully.