All about the canopies from the metal profile, adjacent to the house

A canopy from a metal profile, attached to a residential area, is one of the most popular today. To make it, it does not take a lot of money, and such a structure will last for a long time. The basic rule is adherence to technology and the right choice of material. Otherwise, with a strong gust of wind or heavy snow load, the wall of the building, to which the canopy is attached, simply will not withstand and may be damaged.

Peculiarities

Corrugated canopies adjacent to buildings may differ in their design and materials. Installation of a metal canopy does not take much time (maximum 2 days), you can handle its installation yourself (you can save on calling a specialist). It is distinguished by its increased reliability and durability. This version of the frame fits perfectly into any general interior, suitable for rough architecture and standard classics.

Such awnings are used:

- for storing personal belongings and garden tools;

- as an additional recreation area;

- as a garage for a car.

Species overview

Especially popular are single-pitched canopies, arched or with a flat roof.

- Single-slope structures, attached to the house, are usually made from corrugated sheets, the frame material is made from a round shaped pipe or wooden beam. The easiest to assemble and install of all types of awnings.

- The canopy is in the form of an arch. When installing this type of extension, most likely, you will need the help of a specialist, here it is important to correctly design and fix all the components of the canopy. Such structures always look very impressive. At a cost much more expensive than the previous type.

- A canopy made of metal profiles with a flat roof is found in the southern regions. This is due to the fact that such an extension is not designed for a large snow load. It is carried out from a profiled sheet with a high wave, the slope is made the most minimal (up to 8 °).

You can find both a large, for the entire length of the house, and a compact corner canopy. It all depends on the amount of free space on the site and the purpose of the future shed.

Materials (edit)

Experts begin their choice with supports for the canopy, because it depends on them how strong and durable this structure will be. Metal supports will last longer; in addition, they must be covered with high-quality paint. Usually, such supports are made from a profile pipe. But many also use wooden supports. To prolong their life, you should use a wood preservative. Beams are welded (or screwed) to the finished supports, which will serve as a platform for mounting a metal profile. Of the tools, a welding machine or a screwdriver is used.

Using roofing screws (they have a special rubberized washer), sheets of metal are laid on the finished crate. First, the metal profile is mounted on the lowest level, the next sheets are overlapped with the previous ones. To fix the profile sheets, only hardware with rubber washers are used; when screwing in, they cannot be tightly clamped, since the rubber gaskets on them can be deformed, which will lead to a possible leak in the future.

All metal parts are treated with anti-corrosion agents, thus extending the life of the profile canopy.

How to do it yourself?

A step-by-step instruction on how to choose a location, weld a canopy and install a roof is very important for beginners. Experienced people can do without it, but first-time canopies have a lot to learn before getting started.

Seat selection

Before proceeding with the installation of the canopy, you should decide on the place where this extension will be located. Experts recommend refraining from building structures in the lowlands. If there is no other place, then you will have to make a storm sewer, which will pull additional financial investments. It should also be noted that the canopy should be protected from sunlight throughout the day. Perhaps for this you should change the degree of inclination of the visor.

The next step is high-quality canopy drawings. The calculation should be done not only for the size of metal structures, but also for the section of the profile material. Basically, for frames up to 6-7 meters in length, a section of 60x60 is chosen, if the size exceeds the above length, then a pipe with a section of 80x80 is suitable.

Installation of supports and battens

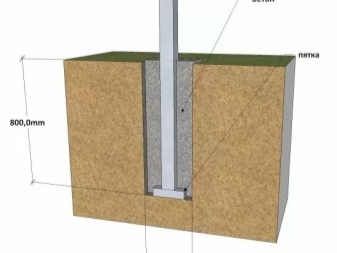

After a suitable place has been chosen, according to the ready-made scheme, they begin to install the supports. It is extremely important to install them evenly and with high quality, otherwise the frame will not last long. A level is used to check the correct position of the building supports. Further, the racks are concreted and left for several days for the concrete to harden. During this time, the crate is assembled or welded. For this, a metal profile or a profile pipe is used. Wooden beams are also used, but much less often.

The lathing performs an extremely important function. The stability and safety of the entire canopy directly depends on how correctly this structure is installed. If everything is calculated and installed correctly, then the roof will be able to withstand even the most ferocious snowfalls and showers. Completely the entire installation is easy to do with your own hands, without the involvement of specialists. The lathing, built independently, will be able to please with a long service life only with careful calculation and a high-quality approach to the performance of all work.

If the choice fell on a crate made of wood, then when choosing boards, you should pay attention to some factors:

- boards and beams should not be wet;

- conifers are considered the best species of wood that are used for corrugated board;

- in order to avoid damage by fungi and various microorganisms, the wood must be treated with an antiseptic.

When choosing a sheathing from a profile pipe, the most important thing is its strength. In order to ensure the endurance of all bearing parts, a pipe with the smallest dimensions should be chosen. The optimal section parameters for such elements are 40x20 mm. Absolutely all metal is treated with anti-corrosion agents.

Roof installation

In order to find out the amount of roofing material, you first need to calculate the entire surface area that should be covered. The resulting figure should be increased by 5-7%. The most popular material for canopies is corrugated board. It is a corrugated sheet coated with a polymer sheath and zinc. It is not afraid of temperature changes, corrosion and rust, undemanding in maintenance, has a variety of colors, is environmentally friendly and does not flammable.

It is divided into three main types: load-bearing, wall and roofing. Experienced craftsmen advise using the bearing corrugated board in the construction of frames, and not roofing, since it is distinguished by its increased rigidity and is able to withstand heavy loads (for example, snow). The finishing touch is to secure the selected sheets. For this you need self-tapping screws. Laying the corrugated board should be very careful so as not to damage the polymer sheath. The overlap is performed in one wave.

Craftsmen note that it is quite easy to build a canopy from a metal profile.It does not take much time, and in terms of money, it is the most budgetary option.

For information on how to make a canopy from a metal profile with your own hands, see the next video.

The comment was sent successfully.