Reducer for walk-behind tractor: types and self-assembly

One of the main parts of the walk-behind tractor engine is the gearbox. If you understand its structure and own the elementary skills of a locksmith, then this unit can be built independently.

What it is?

First you need to figure out what a gearbox is. It is a mechanism that ensures the movement of the cultivator. A walk-behind tractor gearbox converts torque into driving force. The device is sometimes referred to as a transducer. The operational life of motoblocks depends on it, therefore it is very important to pay attention to the quality of the parts when choosing.

The dimensions of the gearbox depend on the dimensions of the mechanized motor vehicles.

Equipment

The converter can be collapsible and non-collapsible. As a rule, budget modifications of walk-behind tractors are equipped with the last option. Their difference is in less expensive parts that cannot be replaced. In the event of a breakdown, you will have to change the entire gearbox. Manufacturers determine the service life of such models from one to two seasons, no more, provided that the device is used correctly.

More expensive equipment is equipped with a collapsible gearbox, which can be repaired by replacing failed components. Therefore, the service life increases significantly.

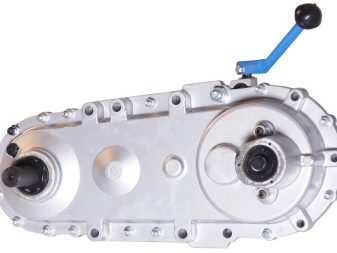

The following items are included in the package of the converter.

- Frame... Depending on the type of gearbox, it can be collapsible or not.

- Rotor shaftwhich provides torque.

- Gears different sizes.

- Chain or belt depending on the type of gearbox.

- With a chain drive, the movement is carried out using sprockets - toothed discs.

- With a belt drive, the mechanism is equipped with pulleyson which the belt is worn.

- Bearings... Since all parts rotate, it is necessary to reduce friction and allow the elements to rotate freely. The bearing is designed to cope with this task.

All parts are inside the case. In addition to the standard set of accessories, elements for lubricating bearings, for example, an oil pump or a cooling device, can be added inside the device.

Views

Depending on the type of transmission used in the gearbox, converters are divided into several types. Different devices are used in the mechanisms of different fields of activity.

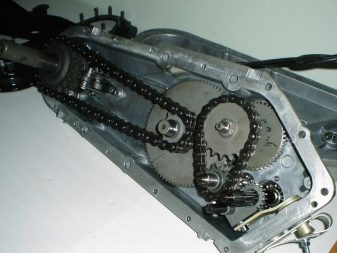

Chain

The name is due to the design of the gearbox, which is based on a chain as a transmission element. In one device, it can be more than one. The movement is provided by asterisks, the small one is the driving one, the big one is the driven one. The principle is similar to that of a system on a bicycle.... Performance and reliability are highly dependent on the quality of the materials used to manufacture the main driving parts.

Among the negative points, the need for regular maintenance should be highlighted: chain tightening, lubrication. Unlike a belt drive, the chain drive does not allow slipping and lasts longer.

Reverse

The reversing mechanism provides the technique with the ability to reverse. In this case, the reverse rotation clutch is installed between the bevel gears, which are located on the main shaft.

Unfortunately, the reverse gear is not suitable for high speed reproduction.

Belt

The simplest gearbox available on the market is of the belt type. As a rule, budget models of gearboxes use just such a device. The belt serves as a transmission element that is attached to the pulleys.Under heavy loads, the belt slips or breaks.

Slippage can be eliminated by installing toothed pulleys and a similar belt.

Belt converters reduce aggressive action on the propulsion system by reducing jerking. Moreover, their construction is simple and repairs are easy.

Among the minuses, unfortunately, there are more factors.

- The belt stretches at high temperatures. This is what reduces grip.

- Rapid wear (abrades).

- Belt drive rupture due to kinks or twists.

- As the speed increases, the belt starts to slip.

- The pulleys must be in the same plane.

Gear

Gear reducers are most often used in heavy equipment engines. The transmission consists of a gearbox, differentials and governor, gears and belts. The design of the device is simple.

The gear transmission contains bevel or spur gears. Due to the fact that several of them can be placed on one shaft at once, the dimensions of the converter are reduced.

Inside the transfer box, the gears work in pairs, so the ratio of the number of teeth on the driving and driven parts should be observed. Since freedom of rotating elements is required, the gear reducer requires regular lubrication and oil.

Among the advantages, one can also highlight the noiselessness of the engine on the specified type of gearbox.

Worm

The worm gear inverter is characterized by a long service life and a high degree of reliability. The design is considered not very complex, requiring qualified maintenance. The worm gear is already angular. In addition, it has a reverse, which allows the technique to move not only forward, but also backward.

The gearbox got its name from the presence in its composition of a special worm gear wheel, which moves along a screw having a trapezoidal four or two-start thread. By varying the number of teeth, you can change the rotational speed... All components are made of anti-friction steel, which is characterized by increased strength.

The converter consists of only two main components. In addition, it is quiet and smooth running.

Users appreciate it for its efficiency, long operating period. The worm gear has a unique ability, characteristic only of it, not to transfer rotation from the execution device to the motor.

Angular

One of the most efficient and reliable gearboxes. Therefore, it is used to equip production machines and equipment operating under heavy loads. In the automotive industry, this type of converter is also actively used.

The angular gearbox provides a connection between the engine and the transmission, which is designed for chain transmission. Please note that the magnitude of the load will depend on the quality of the lubricants and the temperature conditions.

Downward

The task of the reduction gear is to reduce the number of revolutions while increasing the power. This is achieved by using a gear system. As a rule, modern converters of this type are equipped with an air cooling system.

Motors based on them are reliable, multifunctional and can withstand significant loads. Therefore, they are installed on walk-behind tractors used for work on heavy soils.

How to choose?

A converter for a walk-behind tractor can be made by hand, but if you do not have the necessary experience, then it is better to purchase it at specialized retail outlets. Today on the market there is a huge range of quality modifications, the cost of which varies depending on various technical and quality characteristics.

The following factors can affect the price.

- The quality of the materials from which the components are made.

- The number of functions performed by the inverter.

- Manufacturer status.

- Reversible mechanism (its presence or absence).

- Reproducible power. When choosing, you should not chase after more power, but focus on the technical characteristics of the vehicle. Because the capabilities of the gearbox and the motor must match.

- Construction type (collapsible or non-collapsible).

- Design features. For example, the type of transmission or the type of clutch.

- Life time. As practice shows, a well-chosen converter can last from 7 to 15 years, depending on the type of transmission.

For small vehicles, a centrifugal clutch is often used in the transmission. Its mission is to prevent movement from starting and warming up the engine. This is convenient, because in winter regions it is impossible to get under way or start work without preparation. Engines without a centrifugal clutch are cheaper, so personal preference should be guided here.

When buying a converter, do not forget about the dimensions of the motor. It will be a shame to spend money on something that later will not be included in the corps. When choosing a gearbox, you must also take care of the oil that is poured into it. It plays an important role in ensuring the efficient and smooth operation of the mechanism.

There are several factors to consider when choosing.

- Climatic conditions... If the vehicle will be operated in the northern regions, then give preference to those vehicles that do not freeze at subzero temperatures. In the southern regions, you should not spend money on the purchase of such options.

- Loads... In the presence of heavy or virgin soil, the walk-behind tractor will work at increased loads, which means that the friction between the parts will increase, the torque will increase. To increase the life of the parts, you should select a lubricant that takes these features into account.

Be sure to pay attention to the oil seals when choosing a gearbox. If they are of poor quality, oil will start to leak. Its level will gradually decrease. If this is not noticed in time, the leftovers can boil from heating, the parts will jam.

When choosing a gearbox from a specific manufacturer, remember that when repairing, it is necessary to replace the failed components with similar... Therefore, you should choose a supplier that has a representative office in your area.

How to do it?

Enthusiastic craftsmen assure that a simple gearbox for a walk-behind tractor can be straightened with your own hands in a home workshop. To do this, you need to have a certain set of tools and a little bit of skills to work with them.

You will need:

- ruler and caliper;

- a set of different screwdrivers;

- hacksaw;

- pliers and wire cutters;

- vice;

- hammer;

- welding machine if necessary;

- spare parts and consumables (oil seal, rubber gasket, bolts, gears, chain or belt, bearing, shafts).

Of course, sketches are needed for construction. Therefore, in the absence of the skills to build them independently, you can turn to ready-made ones from the Internet or specialized magazines.

If the converter is created on the basis of an existing old one, then first it should be disassembled, removed unnecessary parts and modified.

If the gearbox is assembled from scratch, then the housing must first be made. For these purposes, a fitting square or metal plates are suitable, which are welded together. It should be sized to accommodate all planned gears and pulleys.

By the way, gears and shafts can be removed from an old chainsaw.

Next, you should calculate the gear ratio. It is necessary to select the number of gears and the length of the shafts. Usually they take the number of idle crankshaft revolutions as a basis and add 10 percent to it..

A simple home-made gearbox bypasses two opposite shafts.On the one hand, a gear is installed, in which you need to drill a hole, on the other, a shaft complete with a cage and bearings. Next, the output shaft is pushed onto the pulley. In this case, do not forget to insulate the shafts with oil seals so that the oil does not leak.

The assembled structure is inserted into the housing, where lubricant or oil is poured. The converter is connected to the motor. Then the setting is carried out, for which the mechanism is started.

Attention should be paid to ensure that all parts do not have deformations, do not warp.

The device does not need to be overloaded during testing, the components must be worn in, to establish mutual action. Only after checking and eliminating all defects can the gearbox be used for work.

For information on how to make a gearbox for a walk-behind tractor with your own hands, see the next video.

The comment was sent successfully.