How to make a do-it-yourself pusher for a motorized towing vehicle?

Motorized towing vehicles are a simple and relatively reliable technique... But it is important for all their users to know how to make a do-it-yourself pusher for a motorized towing vehicle. This will significantly save money and configure the device to fit your needs.

Tools and materials

For work you will need:

welding machine;

welding inverter (it can be an integral part of the welding machine);

file;

set of working keys;

turning and milling machines;

screwdrivers;

various small tools;

drill;

angle grinder.

In all models, including handicraft ones, the fastening of parts is carried out mainly in a hinged way. But a more practical method is to use a rigid ligament. The drawbar is assembled from a shaped steel pipe. Additionally you will need:

corners;

head tube;

trough;

silent blocks;

fork;

a beam connecting the trough with the fork protrusions.

Manufacturing

Before making a homemade pusher for a motorized towing vehicle with your own hands, you need to accurately select the main characteristics of the product. Particular attention is paid to:

sizes;

carrying capacity;

engine power;

the execution of the transmission;

starting method (manually or from an electric starter);

additional equipment.

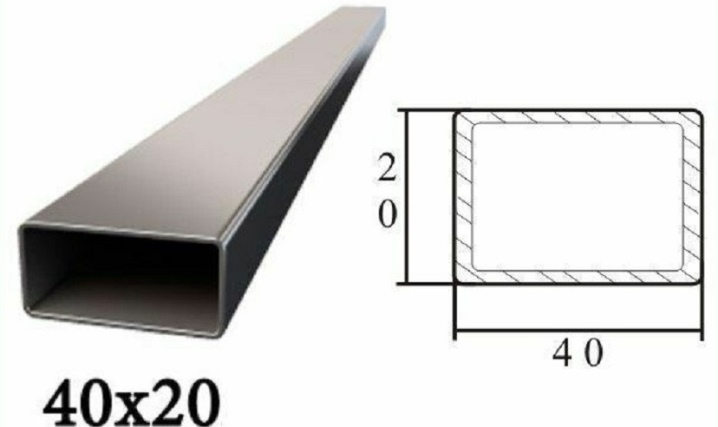

Properly Designed Motor Pusher guarantees very high cross-country ability even on deep snow. The sled must be oriented in such a way that it passes any part of the path before the ATV enters it. A typical pusher module is therefore placed at the front. It performs the tasks of conventional steering. The optimal profile dimensions for the drawbar are 20x40 mm.

Exactly the same profile is suitable for the frames and the cross member of the scraper. The steering assembly (or rather, the element for attaching the drawbar to the axle box) is made from the lower ear of the UAZ front shock absorber.

Such a part must be welded to the profile and a new silent block must be pressed in. The bolt must be taken 12x80 with a medium-sized thread; some experts advise using Volga stirrup bolts.

If everything is done correctly, the part devoid of threads will definitely be inside the silent block. Next, you yourself need to weld the nut for this bolt and the ear of the slip suspension. The bolt is counterbalanced from the opposite side of the ear using an automatically locking nut. The drawbar is attached to 4 bolts and auto-locking nuts are used in the same way.

When this is done, the wiring connector can be connected. After it, the throttle cable is attached for the pusher. The seats are selected quickly removable, which are placed and removed in one motion. The best seats, according to experts, are made of PCB. The steering wheel and the column for it are taken from Ural motorcycles, the fork is boiled from their own frame.

You can attach the pusher to the drag using a pair of bed corners. They are welded, measured exactly in the allotted place. A larger nut is placed at the bottom, which acts as a bolt centralizer.

This nut must be welded to the cross member. The bolt is screwed all the way into the same cross member.

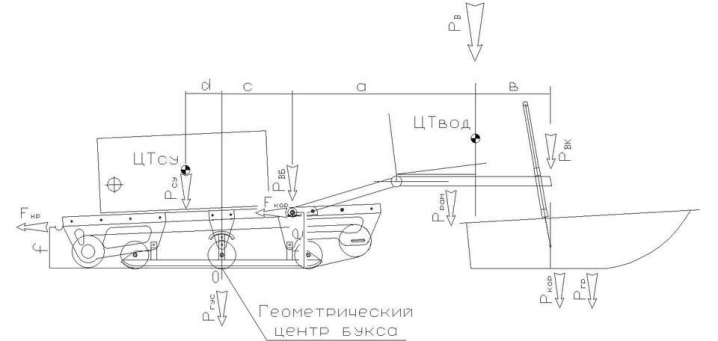

Speaking of the pusher blueprints, it is worth mentioning the schematic diagram of such a device. Shown here is the axle box geometric center, the general mounting arrangement, and the assembly as a whole. Sorry, dimensions are not specified.

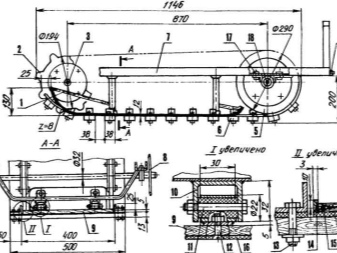

And here are all the necessary dimensions for a motorized towing vehicle as a whole. The attachment points of the main parts are also indicated.

Recommendations

The pusher (drag) should not be made too long. Its width should be greater than its length. It is recommended to keep the rider as low as possible.... Thanks to it, stability is maintained at the desired level, and it will be easier to manage the device. It is important to understand that devices with a high seating position are unstable, even at low speeds, if they encounter the slightest bumps.

Traveling in deep snow is also very difficult. In many designs, the pusher is attached to the balancer and made movable relative to the towing vehicle. Despite the advantages of a rigid design, the movable assembly is valued for its high cross-country ability. In addition, placing the rider between the two balancers makes the ride more comfortable. Important: the front drag is sometimes caught from behind; in skilled hands, control is not more difficult - you just need to use the rear steering wheel.

How to make a do-it-yourself pusher for a motorized towing vehicle, see below.

The comment was sent successfully.