Motoblock engine repair

Motoblocks are generally reliable and stable devices. But with active use, they still break down periodically. Even carefully thought-out motors can be malfunctioning.

How does it work?

To understand breakdowns and fix them, it is important to understand how everything works in a normal situation. For the sake of simplicity, let us dwell only on models with an internal combustion engine. Previously, there were two-stroke walk-behind tractors, but now they are increasingly being replaced by four-stroke counterparts. Diesel devices are also gaining popularity. As for the transmission, it can be made in three different versions.

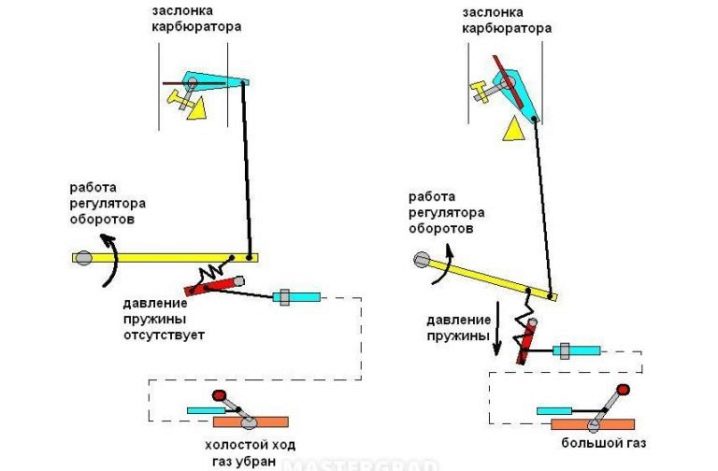

The traditional approach is to use a gear transmission. Despite a decent level of reliability, this device takes up a lot of space. Power transmission takes place using either a cone or a cylinder. Light motoblocks are mainly equipped with a gear-worm transmission. The typical principle of operation of the walk-behind tractor regulator contains:

- a device that monitors the number of revolutions;

- the rod connecting this device with the throttle valve;

- spring.

The control unit operates on the basis of a pneumatic or mechanical connection. "Pneumatics" means the presence of a kind of wing that responds to the speed of the air flow. Centrifugal options involve placing a special camshaft inside the crankcase. It is complemented by small weights and an easy-to-move stem. The pull is made from wire, and the spring sensitivity determines how accurately the RPM values will be maintained.

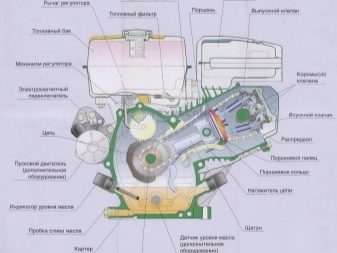

The role of the gas distribution mechanism is to supply a mixture of fuel and air to the cylinder. But the same device also provides exhaust gas removal. A decompressor is used to influence the compression ratio. Gasoline engines are necessarily equipped with carburetors responsible for preparing the fuel-air mixture. Regardless of the type of fuel, the starting device plays an important role.

Necessary components

To assemble or disassemble the engine of the walk-behind tractor, a flat, well-lit area is required, where nothing will interfere with the work. They are looking for the same place for repairs. The installation kit for both imported and domestic walk-behind tractor includes:

- nozzles;

- block heads;

- radiators;

- carburetors.

Troubleshoot startup problems

Often, repair of the walk-behind tractor engine is needed due to the fact that this engine does not start. If this problem occurs after winter storage, you might suspect:

- clogging of fuel or oil with water;

- oxidation of electrical contacts;

- insulation damage;

- solid debris in the carburetor.

To prevent these violations, it is required to carefully inspect any connections before each launch. Noticing the slightest clamp of the cable, especially its twisting, cannot start the engine.

Even before the very first start-up, it is necessary to assess whether there is enough oil in the crankcase. With a lack of it, rapid destruction of the piston group is likely. In less than a second, the cylinders will be covered with burrs.

In this case, very serious repairs will be required, and sometimes even replacement of damaged parts. Sometimes instability in the functioning of the apparatus is provoked by leaving the lubricant composition for the winter. If this is the reason, for the first few moments after starting, clouds of white smoke will pour out of the exhaust pipe.Immediately after this, the power plant will stall.

Diesel walk-behind tractors may also not start due to lack of oil. Only a few models are equipped with systems that prevent the lubricant level from falling. Most people will have to monitor the health of the walk-behind tractor on their own. It is also worth considering that failures occur due to the systematic use of unsuitable fuel. If the usual recommendations do not give much effect, you need to remove the candle and see if there are any oil stains.

Oil, especially carbon deposits, should be carefully cleaned. Then the candle must be dried. The cylinder is also required to dry. A very simple technique is used as "drying": repeated sharp pulling out of the starter cable. The question often arises: what to do if the walk-behind tractor does not start, while it smokes with black smoke.

This usually indicates that the engine is overfilled with gasoline. It is also worth fearing damage to the piston group. If both assumptions turned out to be incorrect, you should contact the service center. Further attempts to fix the problem yourself may lead to an aggravation of the breakdown.

When violations are related to the lack of fuel in the working chamber, the candle will be dry.

You can deal with such a problem if:

- pour out the old fuel;

- thoroughly wash the gasoline or diesel tank;

- clean the air filter;

- clean the fuel hose and jets with a jet of compressed air;

- add fresh fuel;

- after opening the fuel line, blow out the channel located in the fuel tank cap.

In some cases, the failure is due to the fact that gasoline has entered the oil sump. It is necessary to check if this problem exists after any adjustment, carburetor adjustment.

If the lubricant is clogged with fuel constantly, you need to look at the carburetor needle. It is likely that this particular node has become a weak point. It is worth noting that sometimes the motor of the walk-behind tractor also shoots at the muffler, and, perhaps, even with a flame.

The most likely reason is incomplete fuel combustion. She is provoked by:

- gaps in the ignition system;

- excessively saturated fuel mixture;

- unjustified heating of this mixture.

When the walk-behind tractor also does not want to act, interruptions in the ignition system must be looked for thoughtfully and consistently. Magneto, caps, candles and high-voltage wires are examined.

Searching for even minor contaminants is of paramount importance. If everything is clean, it is required to inspect the contacts of the ignition wires. Next, the stability of the electrodes is checked, the distances between them are measured using a special probe.

Functional failures

Quite often, among the engine malfunctions of the walk-behind tractor, its unstable action appears. If the engine runs jerky at idle speed, and when you try to add gas, it stops altogether, the reason is rooted in a lack of fuel. Clean the screens of the fuel tank, carburetor and pipeline valve. And when problems arise even at idle speed, it is advisable to check the centrifugal regulator. Traction often sticks there.

Suppose the walk-behind tractor simply decelerates without jerking. In many cases, this is due to the use of improperly tuned, unsuitable or simply badly worn motors. But replacing the power plant is not always wise. Installing a better quality spark plug can help. It is also worth assuming the appearance of malfunctions in the operation of the carburetor float in the high-voltage wire.

If the engine of the walk-behind tractor knocks, it is required to inspect the camshafts and crankshafts. It is there that the sources of extraneous sounds are mainly located.

In all these situations, there is no particular need to carry out major repairs. High-quality troubleshooting is very important. It is pointless to try to increase the compression in all modern engines, anyway the decompressor will not allow you to do this.

Replacement and adjustment

Quite often, unfortunately, it becomes necessary to completely change the motor on the walk-behind tractor. When choosing a replacement device, it is recommended to give preference to products from well-known companies. Traditional prejudices about the products of Chinese factories have long since become irrelevant. To avoid overpaying funds, you need to carefully analyze how productive the power plant should be. Buying a unit that is too powerful is simply irrational.

Even if there is no talk of a complete replacement, it is important to know how to adjust the engine of agricultural machinery. It is advisable to start disassembly only after flushing the engine and removing oil from it. The lubricant is poured out only when the engine is warmed up after a short operation. Then it's time to remove the fuel tank. Sequentially remove:

- fuel supply hose;

- air filter;

- screen covering the cylinder.

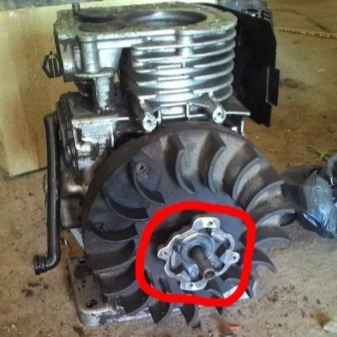

Then remove the crankshaft pulley. Following the pulley, it is required to remove the fan, reflectors, insulating flywheel casings. Unscrew the cover, removing the rings and coupling housings. With the washer removed, you can press out the flywheel with a piece of wood.

Now, having dealt with the flywheel, remove the cylinder cover, camshaft and pusher. Once access to the connecting rod is obtained, remove the oil spray and locknut. Having repaired and changed the damaged parts, the engine is assembled in the reverse order. You should familiarize yourself with the diagram in advance, then there will be no errors.

Damaged valves for a gasoline walk-behind tractor are replaced after removing:

- gasoline tank;

- the head of the cylinder block;

- carburetor;

- muffler;

- boxes.

It is often necessary to replace the rings. But this should be done only in the process of more serious repairs. An isolated change of rings is in itself irrational both economically and technically. In addition, a high quality ring group usually has the same service life as the cylinder. Change them at the same time.

Installation on an elastic band is advisable if a Chinese motor is installed on domestic walk-behind tractors. Rubber cushions are often used as a platform. Parts of the front shock absorber from a classic car are suitable as them. Along with the need to rearrange individual parts of the walk-behind tractor, many people have a need to put the electric starter on their own. This starter will have to be correctly connected to the battery.

The crown is attached only to the removed flywheels. Pre-remove all interfering parts of the motor. To remove the flywheel, in many cases, you cannot do without a special key. A generator and its magnets are placed in the flywheel assembly. When the terminals and contacts of the battery are aligned, a test run of the walk-behind tractor should be carried out.

Advice

To repair and adjust the walk-behind tractor less often, it is required to protect the motor from falling. This is especially true for products with four-stroke motors. Their maximum slope during operation cannot exceed 25 degrees. For a long time, the unit cannot be tilted by more than 15 degrees. Otherwise, you can fear that part of the engine will be deprived of lubrication. She will soon be out of order.

For the same reason, long-term operation of the walk-behind tractor in idle mode is not recommended. Always check that there is sufficient fuel and lubricating oil before starting work. It is only necessary to change these fluids and even add them when the motor is off.

Do not start the walk-behind tractor when the levers associated with the wheel drive are locked. A cold engine is started only after setting the air dampers of the carburetors to the closed position; Always use the strictly recommended fuel.

The valves are adjusted using:

- universal wrenches;

- probes of various sizes;

- flat-blade screwdrivers.

About the intricacies of repairing the Subaru ex21 engine for the "Neva" walk-behind tractor, see below.

I bought a walk-behind tractor with a Chinese 173F engine. I worked for a year, broke down. Opened it - it turned out that the engine is 170F, the piston is not 72, but 70, there are no valve stem seals at all. Here is the Chinese quality.

The comment was sent successfully.