All about carburetors of motoblocks

Without the carburetor inside the construction of the walk-behind tractor, there would be no normal control of hot and cold air, the fuel would not ignite, and the equipment would not work efficiently.

For this element to work properly, it needs to be carefully monitored and tweaked.

How does it work?

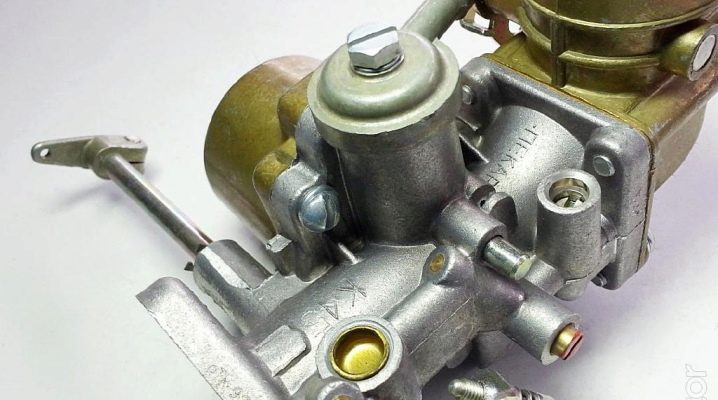

If we consider the carburetor from a constructive point of view, then it is arranged quite simply.

It contains the following nodes:

- throttle valve;

- float;

- the valve, the role of which is to lock the chamber, it is installed of the needle type;

- diffuser;

- a mechanism for spraying fuel;

- a chamber for mixing gasoline and air;

- fuel and air valves.

In the chamber, the role of the regulator responsible for the amount of incoming fuel is played by the float. When the level reaches the minimum allowable, the needle valve opens, and the required amount of fuel penetrates inside again.

There is a spray gun between the mixing chamber and the float chamber. The fuel subsequently turns into a single mixture with air. The air flow is transferred inward through the nozzle.

Views

The operation of the walk-behind tractor is provided by the engine, inside of which no ignition can occur without the required amount of oxygen, which is why it is required to properly adjust the operation of the carburetor.

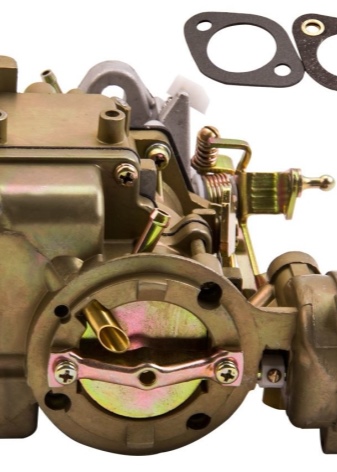

In the design of such equipment, units of two types are used:

- rotary;

- plunger.

Each of them has its own advantages and disadvantages, the use of one or another carburetor is due to the type of work performed and other characteristics of the equipment.

Rotary carburetors are most often used in motoblock designs. They are designed for 12-15 cubic meters. m. This design has gained popularity due to its simplicity.

For the first time, carburetors of this type were used in aircraft construction and the automotive industry. Over time, the design has undergone some changes and has become more perfect.

In the center of such a carburetor, there is a cylinder in which there is a transverse hole. As it rotates, this hole opens and closes, so that air flows through the unit.

The cylinder not only makes a rotational action, but also gradually approaches one side, it is similar to unscrewing a screw. When operating at low speed, this carburetor is less sensitive, the hole opens only slightly, turbulence is created, as a result of which fuel does not flow in the required amount.

Even if you run it to the maximum, there are many elements in the design of such a unit that will impede the development of high power, since the air flow remains strictly limited.

In walk-behind tractors, this is used as an advantage, since instant acceleration is not required when the engine is running. Plunger carburetors have many similar elements that are installed on the rotary model. The only difference is that they cost differently here, hence the ability to increase engine power faster.

There is no hole in the central section, so the cylinder is almost solid. To allow air to pass through, the cylinder moves, and at low speed it is pushed into the carburetor, so most of the air flow is blocked, thereby reducing the number of revolutions.

When the user presses on the gas, the cylinder moves, the space opens, and air freely enters the chamber where the fuel is located.

Adjustment

Each user was faced with the problem of unstable operation of the carburetor, since over time, any technique can fail. This is one of the first reasons why it becomes necessary to independently adjust the operation of the unit.

Experts advise to follow the sequence of actions if the setting is done independently:

- at the first stage, the user is required to turn the throttle screws to the end, and then half a turn;

- activate the ignition and let the engine warm up a little;

- without muffling the unit, set the speed lever to the minimum permissible mode;

- start idling to the maximum possible;

- turn on idle running again to a minimum;

- these last few steps will need to be repeated several times until the motor begins to demonstrate stable operation;

- at the end, the control lever is set to gas.

Repair and maintenance

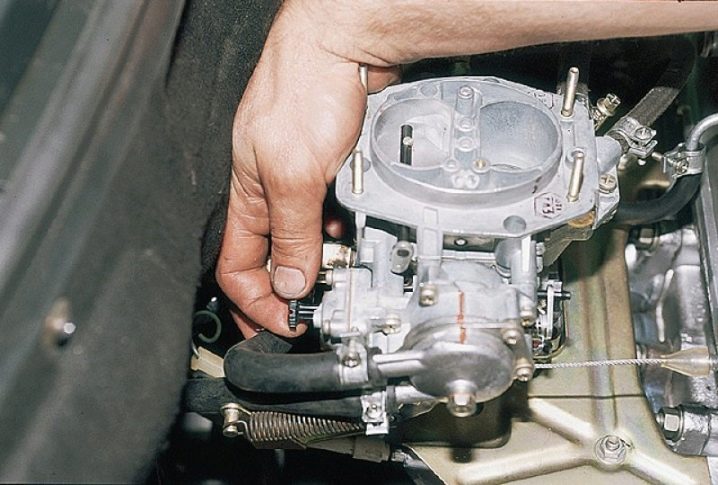

Sometimes it is not enough to adjust the operation of the carburetor and one of its parts needs to be replaced.

The most common cause of the problem is the air damper, which stops closing completely. In this case, you will first need to check how the drive works.

If a jam is found, it must be removed.

Serious breakdowns can be avoided only if you constantly monitor and control the operation of the unit. In addition to adjustment, cleaning or simply replacing worn parts is necessary.

The cause of contamination may lie in poor quality fuel or dirty air. Filters, additionally installed in the carburetor design, make it possible to correct the situation.

It is necessary to select high-quality fuel, because it significantly affects the resource of use of all elements in the unit design. You can learn how to disassemble the carburetor yourself or hand it over to specialists. The first way is chosen by those who want to save money. During the operation of the walk-behind tractor, dust and combustion products are collected inside its device, then the efficiency of the element is reduced.

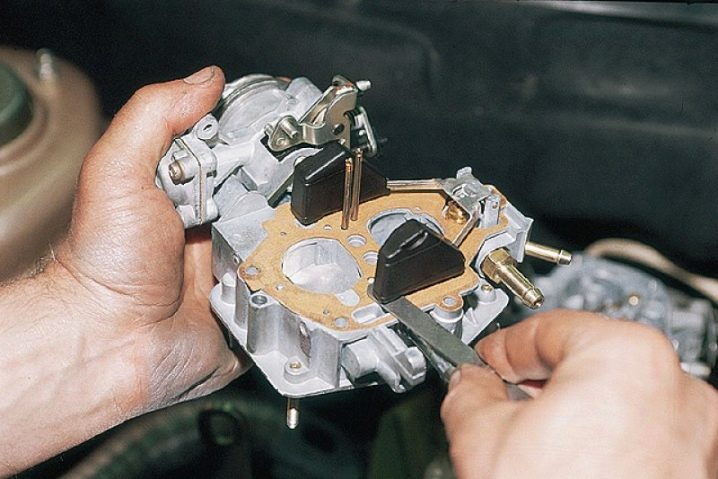

In this case, cleaning can help, which is performed in the following sequence.

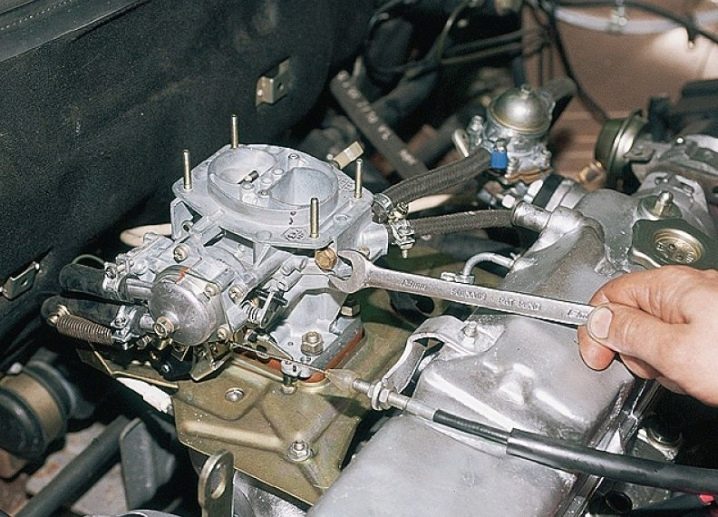

- Remove the carburetor from the walk-behind tractor.

- Drain the fuel completely.

- An inspection of the nozzle is carried out, in the case when the fuel is removed from it poorly, then it must be purged. A compressed air cylinder is used. After that, it is turned 180 degrees, if the fuel no longer flows, then it works normally.

- The next step is to check the jets. To do this, you need to remove the screws that are responsible for the gas and remove the carburetor body. The jets are flushed together with the fuel cock. The best remedy in this case is gasoline, then blown with air.

- Next, you need to decompose the washed elements, and then assemble the carburetor in the same sequence.

When assembling, it is important to pay attention to the location of the spray tube, which should be opposite the hole present at the top. Only after that, the carburetor is again installed on the walk-behind tractor.

All described methods are suitable for motor-blocks "K-496", "KMB-5", "K-45", "DM-1", "UMP-341", "Neva", "Pchelka", "Cascade", Mikuni, Oleo-Mac, "Veterok-8" and others.

Cleaning a Japanese carburetor and adjusting it is as easy as any other manufacturer's unit. There is no difference, since the design is almost the same for everyone, the main thing is to know the technology.

You will learn how to disassemble and clean the carburetor of an air-cooled walk-behind tractor from the video below.

The comment was sent successfully.